Hybrid coupling and assembling method thereof

A coupling and coaxial technology, applied in electric brakes/clutches, permanent magnetic clutches/brakes, asynchronous induction clutches/brakes, etc., can solve problems such as excessive magnetic leakage and difficult assembly of couplings, and achieve reduction Effects of magnetic leakage, simple assembly, and precise speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

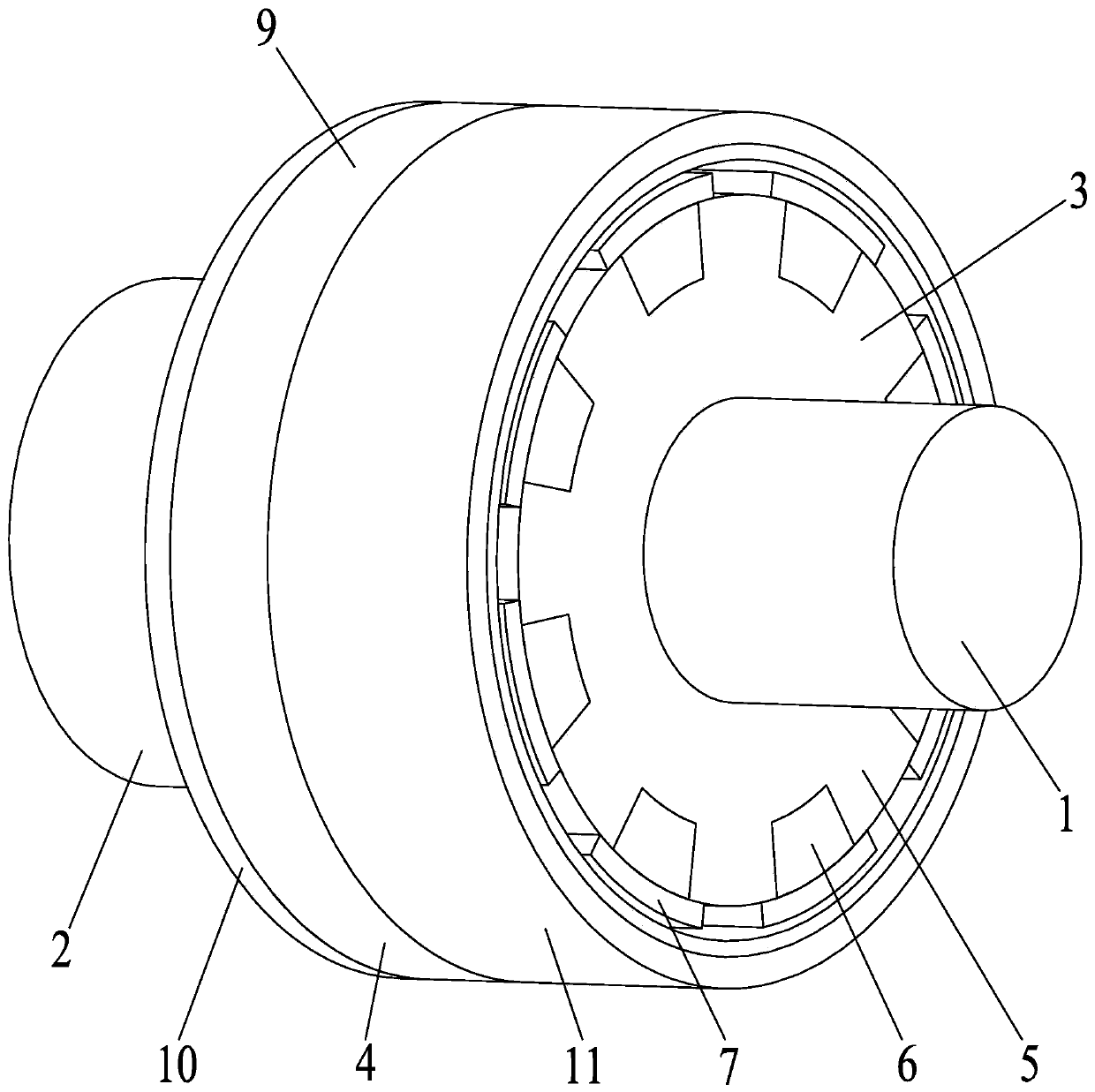

[0049] see figure 1 , this embodiment provides a hybrid coupling for coupling the driving shaft 1 and the driven shaft 2 . Wherein, the hybrid coupling includes a driving disc 3 and a driven disc 4 . In this embodiment, the driving shaft 1 and the driven shaft 2 are not part of the hybrid coupling, but in some other embodiments, the driving shaft 1 and the driven shaft 2 can be used as parts of the hybrid coupling, and can Connect with driving disk 3 and driven disk 4 respectively.

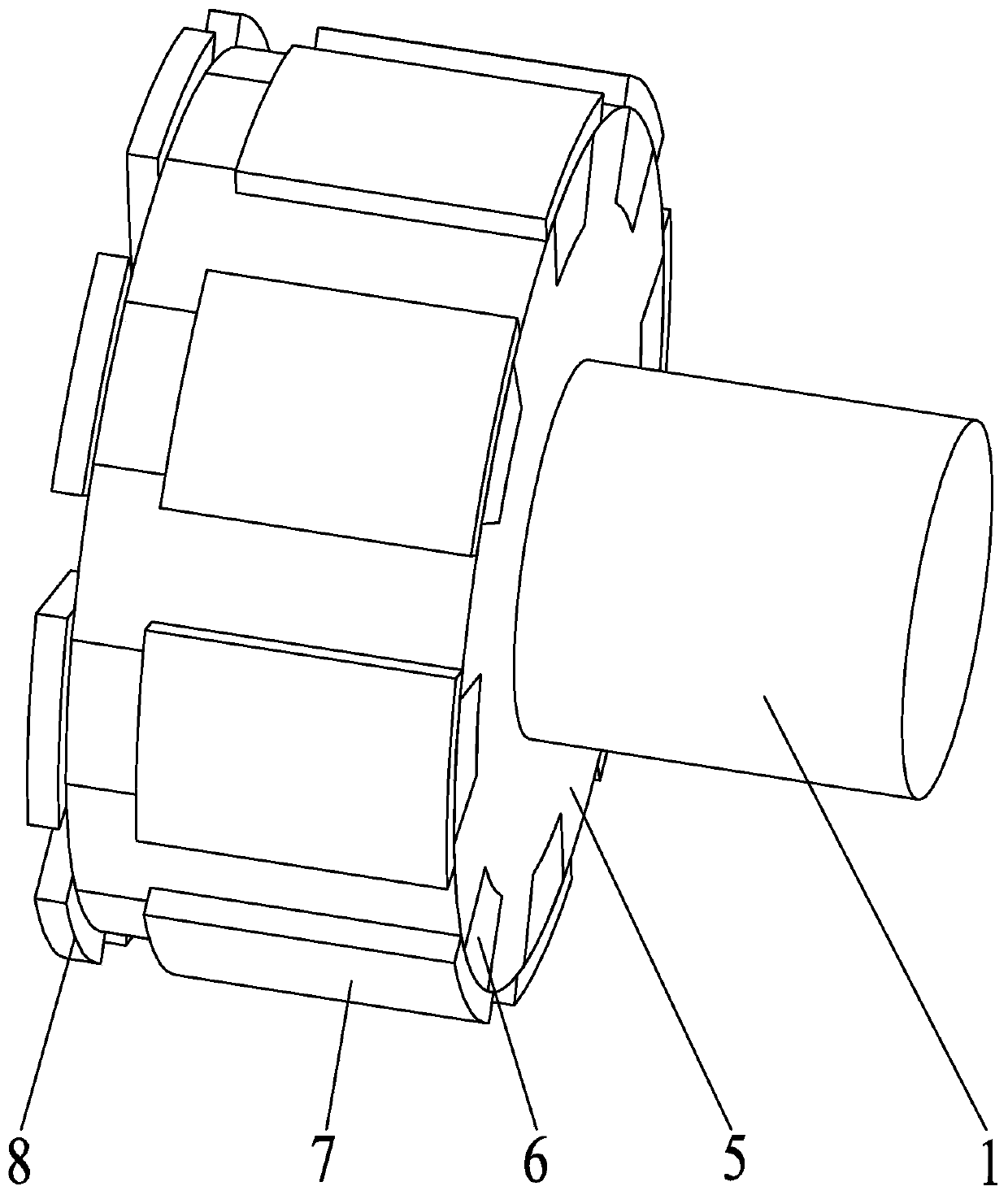

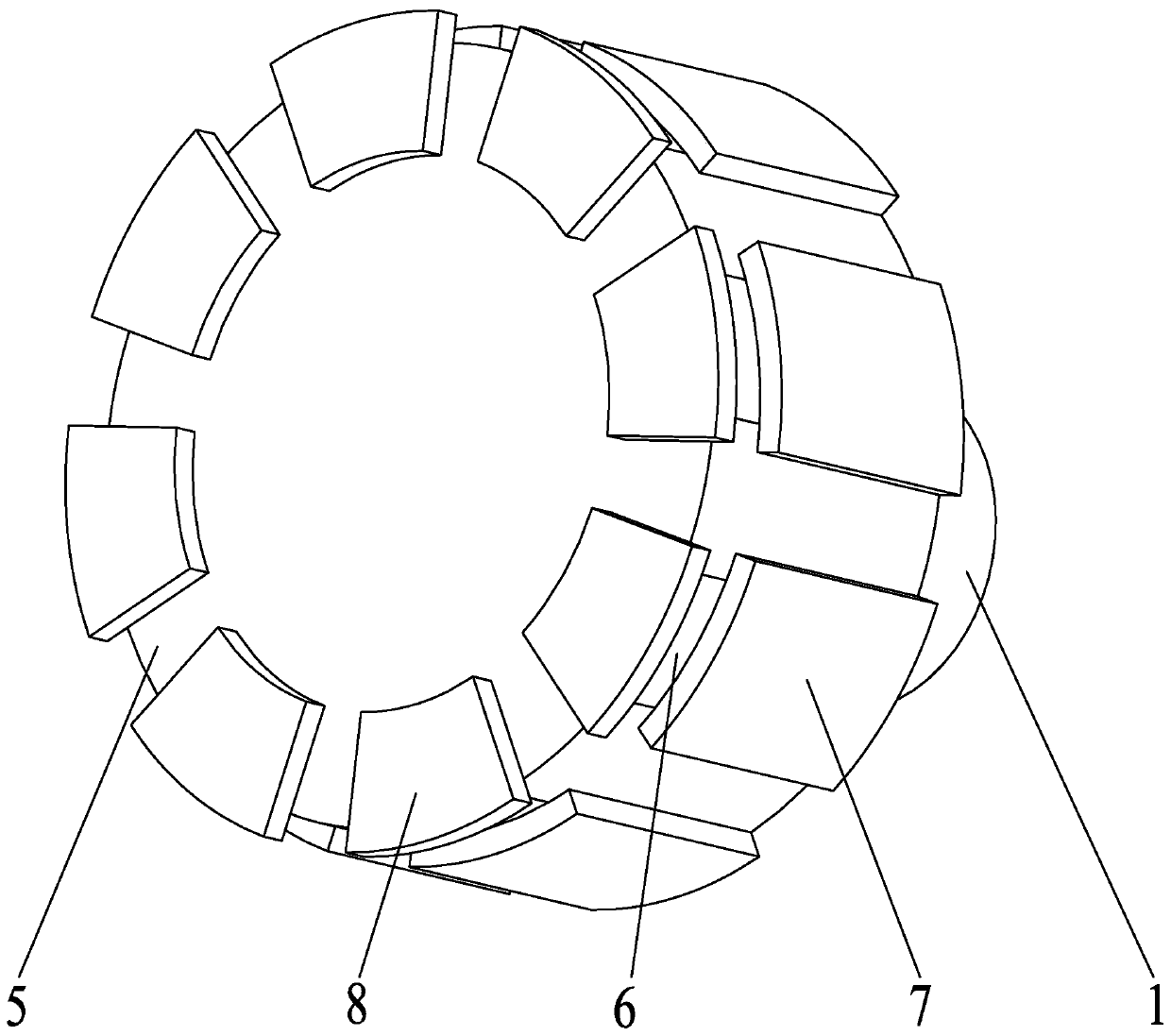

[0050] see figure 2 as well as image 3 , the driving disk 3 is connected to the driving shaft 1 , and in some other embodiments, the driving shaft 1 can be formed directly on the driving disk 3 . The driving disk 3 is used as the connecting structure of the driving shaft 1 , and includes a connecting cylinder 5 , a back iron block 6 , a magnetic coil 1 7 and a magnetic coil 2 8 . The connecting cylinder 5 is arranged coaxially with the driving shaft 1 and is fixedly connected. The driving ...

Embodiment 2

[0069] This embodiment provides a hybrid coupling whose structure is refined on the basis of Embodiment 1. Wherein, the preset distance between each magnetic coil three 12 and the corresponding magnetic coil two 8 is d, and the value range of d is 2-4mm. Of course, what needs to be explained here is that the smaller the value of the distance d, the better, but when the value of the distance d is too low, especially when the value of the distance d is lower than 2mm, the manufacturing of the hybrid coupling at this time The cost will be greatly increased, this is because the second magnetic ring 8 and the corresponding third magnetic ring 12 are attracted together because the distance is too low.

[0070] In some embodiments, the preset distance d between each magnetic coil 3 12 and the corresponding magnetic coil 2 8 is 3 mm, and the distance d can be around 3 mm, and the optimal effect can be achieved at this time.

[0071] In some other embodiments, the distance d between e...

Embodiment 3

[0073] This embodiment provides a hybrid coupling whose structure is refined on the basis of Embodiment 1. Specifically, the total projected area of all magnetic coils-7 on the outer wall of the connecting cylinder 5 accounts for 70%-90% of the area of the cylinder where the projected plane is located. The projection planes of all magnetic coils 2 8 on the end face of the connecting cylinder 5 are located on the same sector 1, and the total projected area accounts for 70%-90% of the area of sector 1; all magnetic coils 3 12 are on the end face of the connecting sleeve 9 The projection planes are located on the same second sector, and the total projected area accounts for 70%-90% of the area of the second sector. What needs to be explained here is that the larger the value of these area ratios in this embodiment, the better the performance of the hybrid coupling. However, when the area ratio is greater than 90%, the gap will be too small, which is not conducive to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com