Patents

Literature

177results about How to "Solve assembly difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

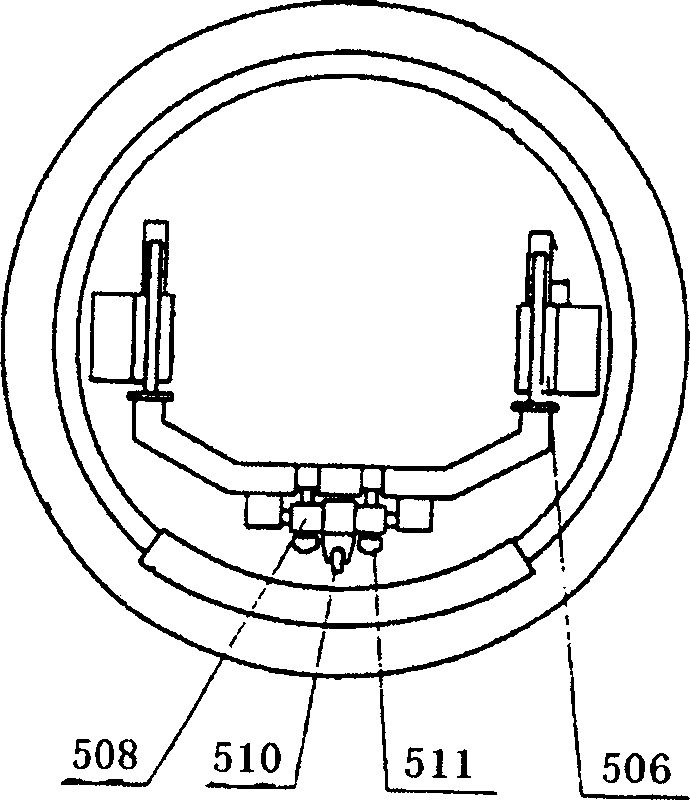

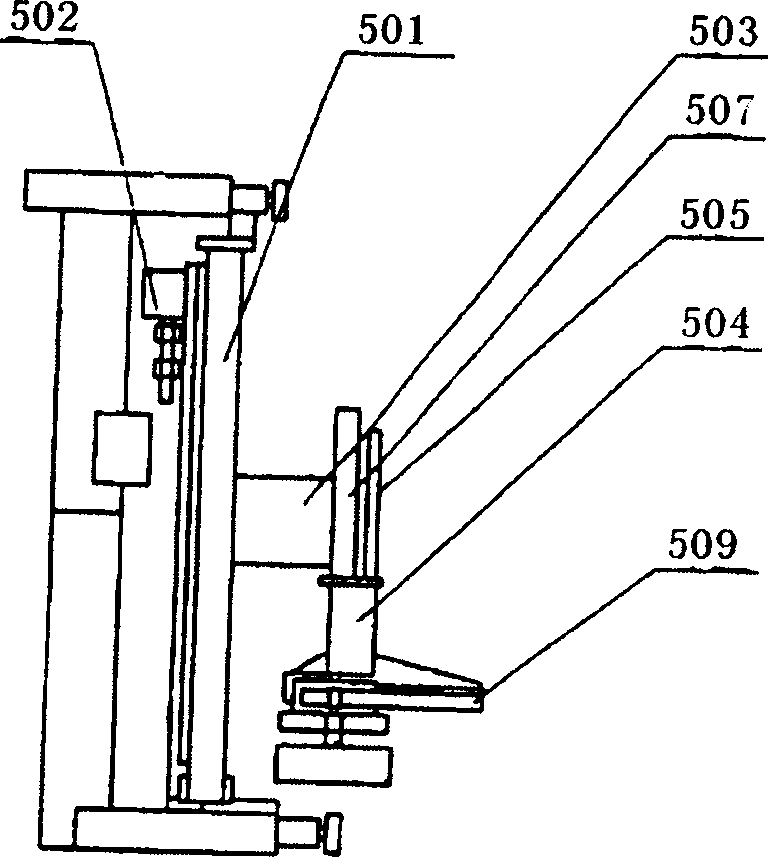

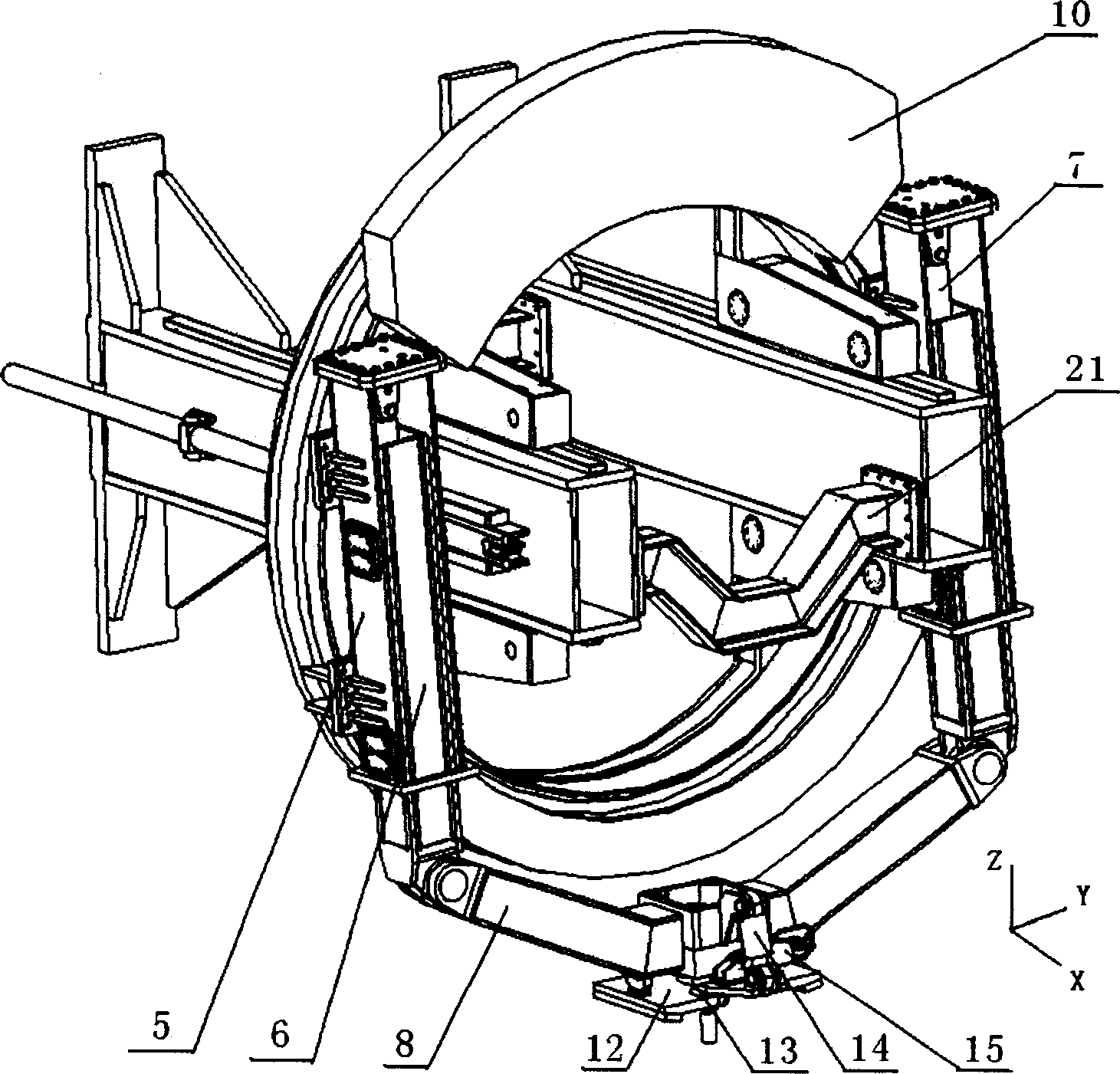

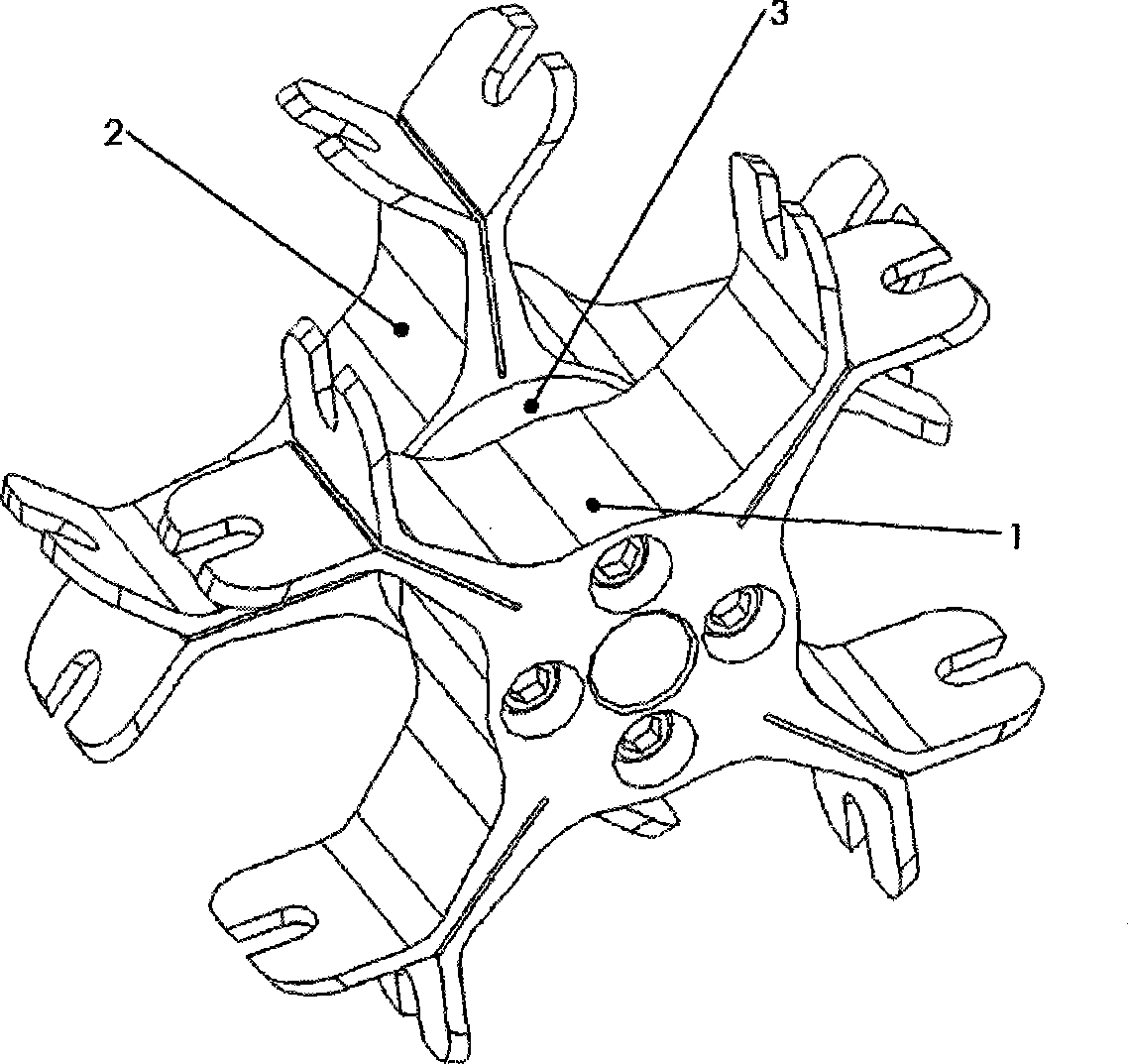

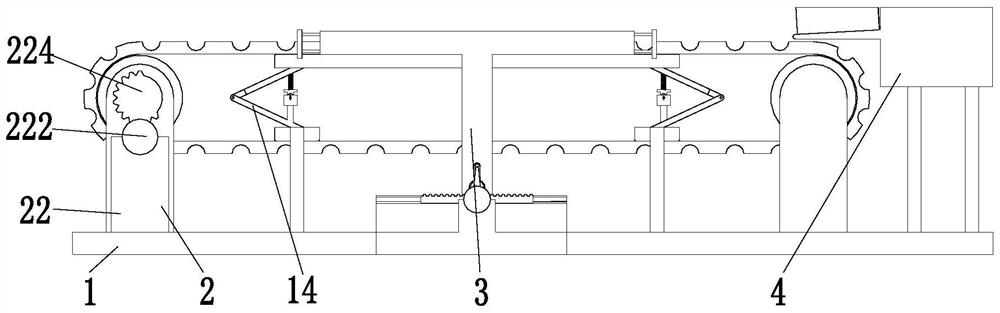

Shield segment splicing machine with six-freedom degree

InactiveCN1837578AIncrease loadReduce adverse effectsUnderground chambersTunnel liningEngineeringSystem stability

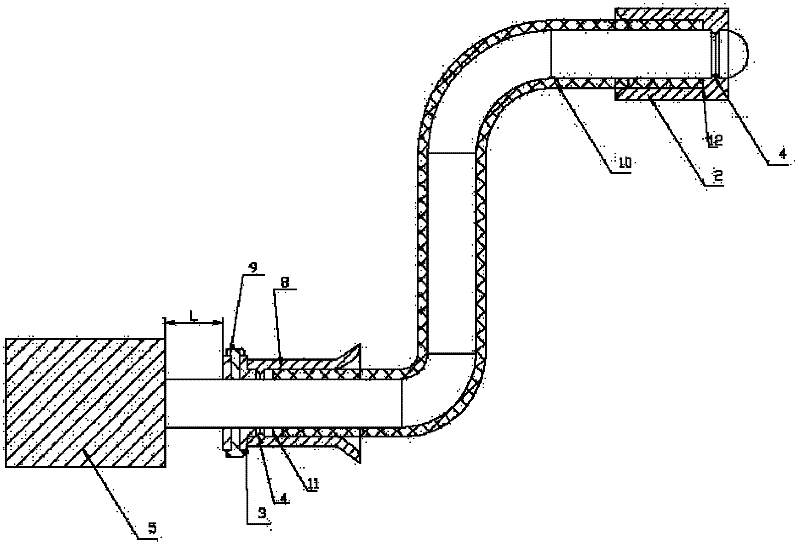

The invention relates to a shield construction tube assembler with six freedoms, which comprises a rotational disc, a driving device, two suspending beams, two translation cylinders, two guide sheathes, two guide inner sheathes, two lifting cylinders, a lifting beam, a tube clamper, a tube weight, a rotational platform, a central ball joint bearing, a tube incline cylinder, a tube rotational cylinder, a fixed disc and a rolling wheel. The invention has six freedoms to meet the demand of assemble different spatial positions; and a middle beam and a tube clamper, etc, are arranged between two suspending beams to improve the system stability.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

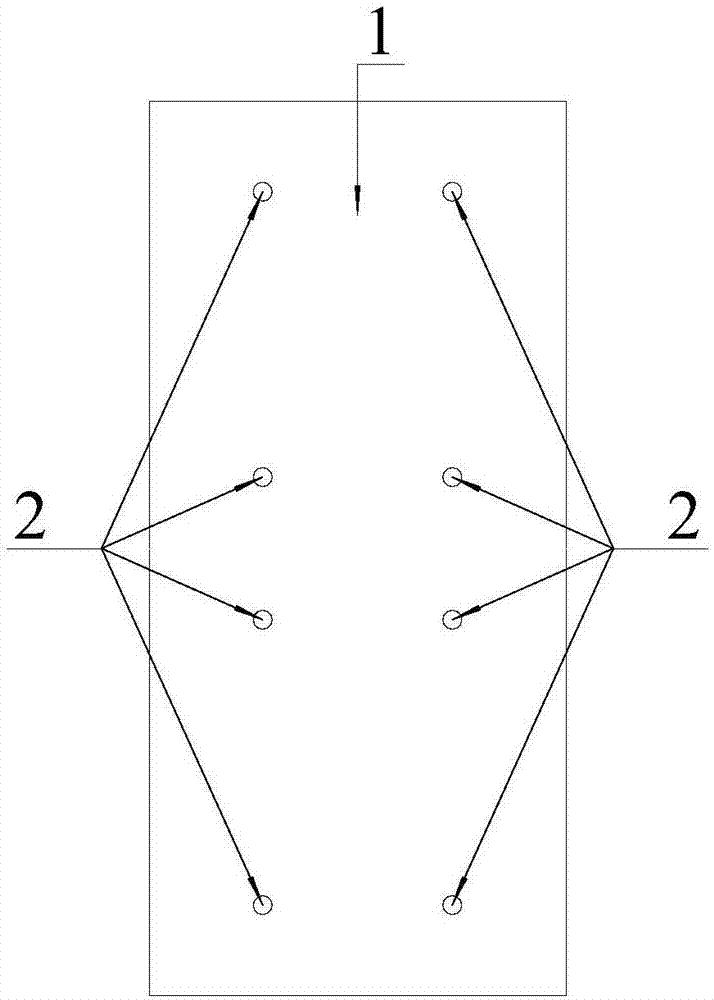

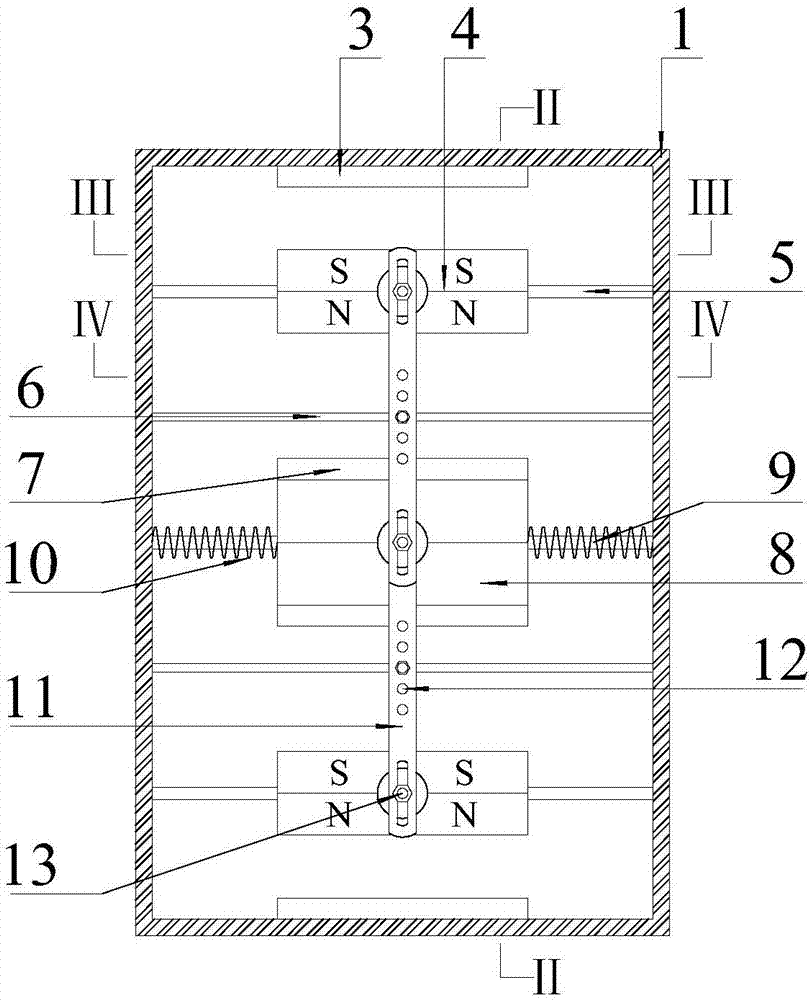

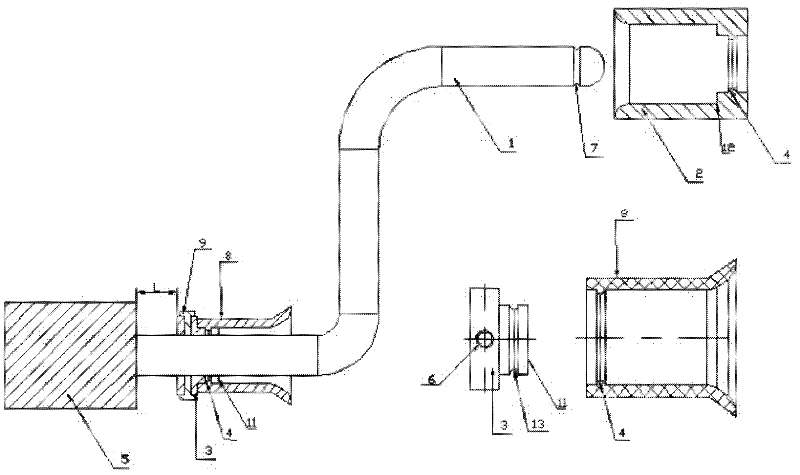

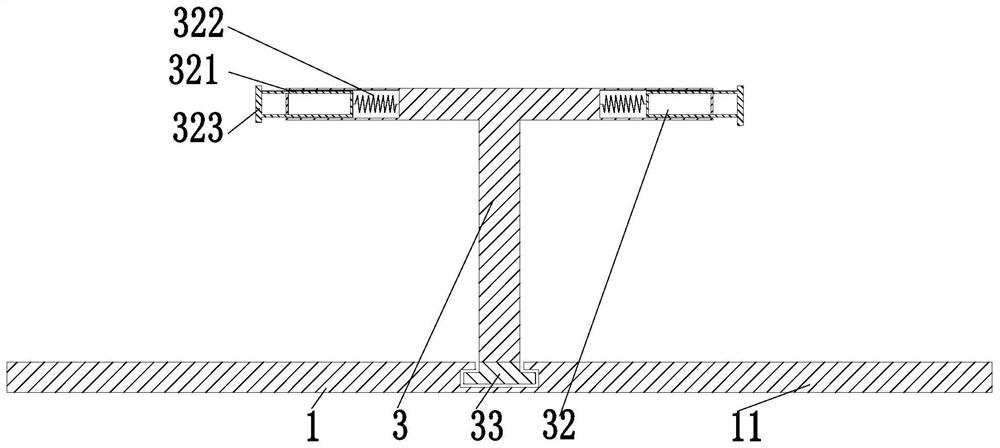

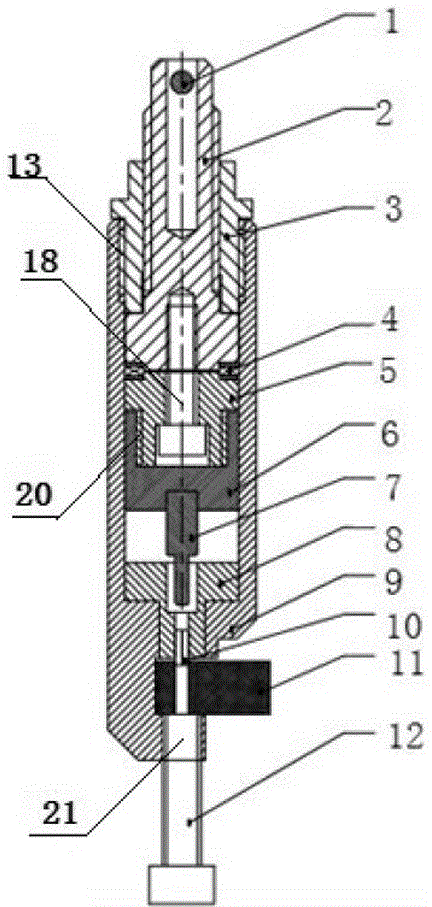

Eddy-current damping device utilizing lever principle

ActiveCN107355509AImprove energy consumptionImprove work efficiencyNon-rotating vibration suppressionMagnetEngineering

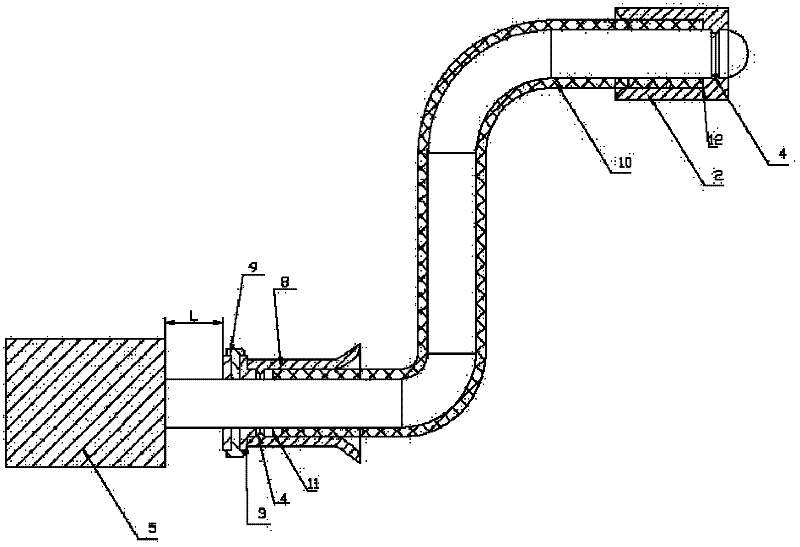

The invention provides an eddy-current damping device utilizing the lever principle. The eddy-current damping device comprises a box body (1), a connecting screw hole (2), a fixed copper plate (3), a permanent magnet (4), a permanent magnet guide rail (5), a supporting rod (6), a movable copper plate (7), a mass block (8), a mass block guide rail (9), a spring (10), a connecting rod (11), a hinged screw hole (12) and a drive pin roll (13); when the structure vibrates, a TMD damper is firstly used to perform energy transfer, so that vibrations of the structure are reduced; then, the mass block drives the permanent magnet to generate motion reverse to that of the mass block through a lever system, so that relative motion velocity of the copper plate and the permanent magnet is increased, and non-contact type energy dissipation is performed through an eddy-current damp. The lever principle is utilized to effectively increase the relative motion velocity of the copper plate and the permanent magnet, so that energy-dissipating capacity of the damp is improved; the position of a central fulcrum of the connecting rod and length of a force arm of the lever are regulated, so that parameters of the TMD damp can be regulated, and therefore, applicable frequency range of the device is wider.

Owner:SOUTHEAST UNIV

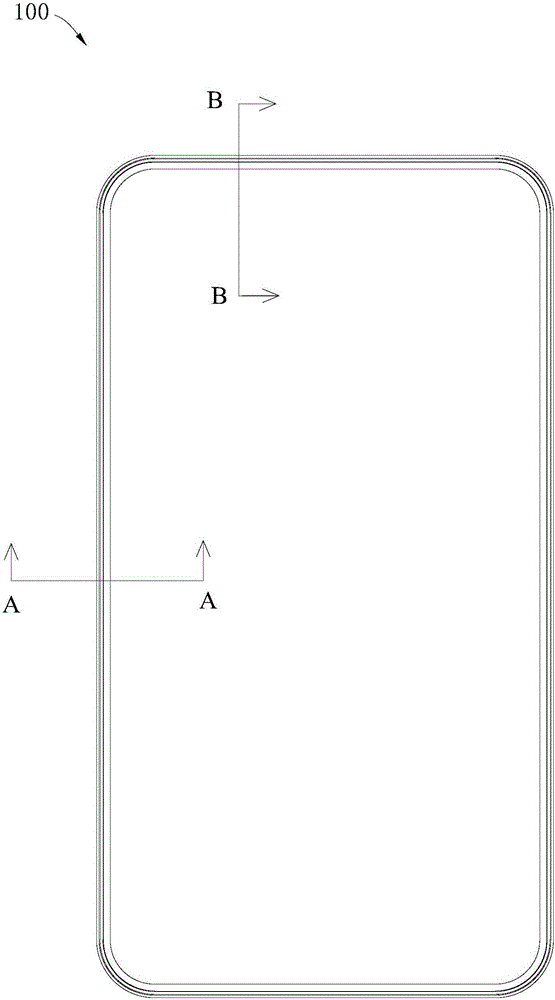

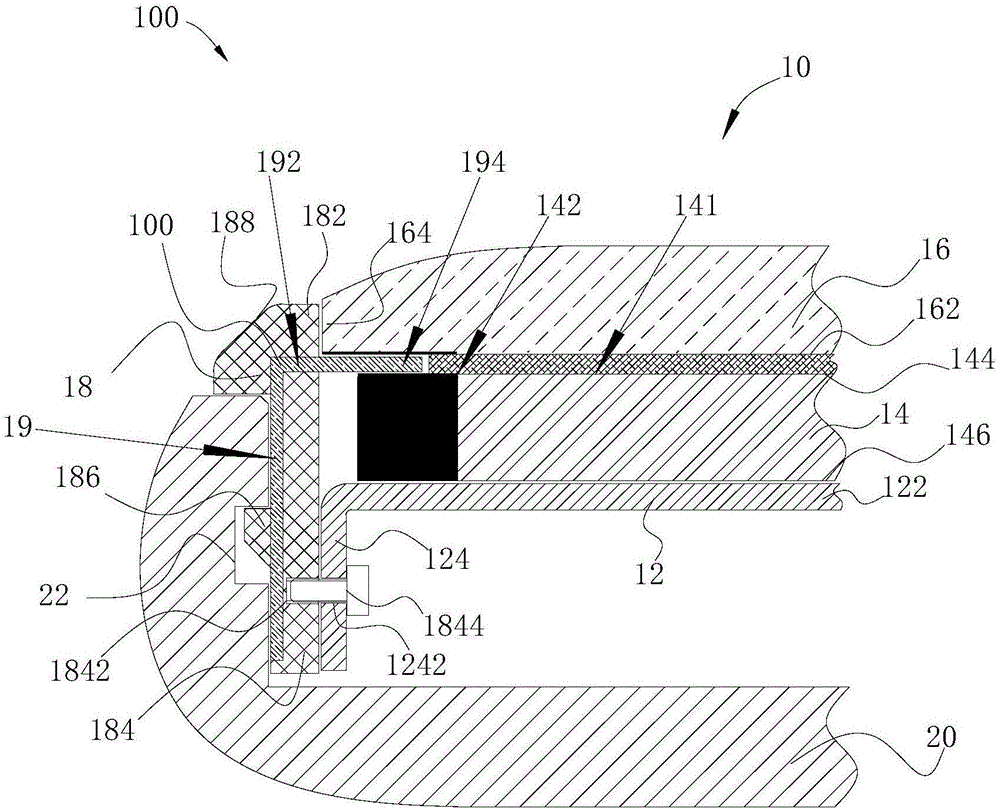

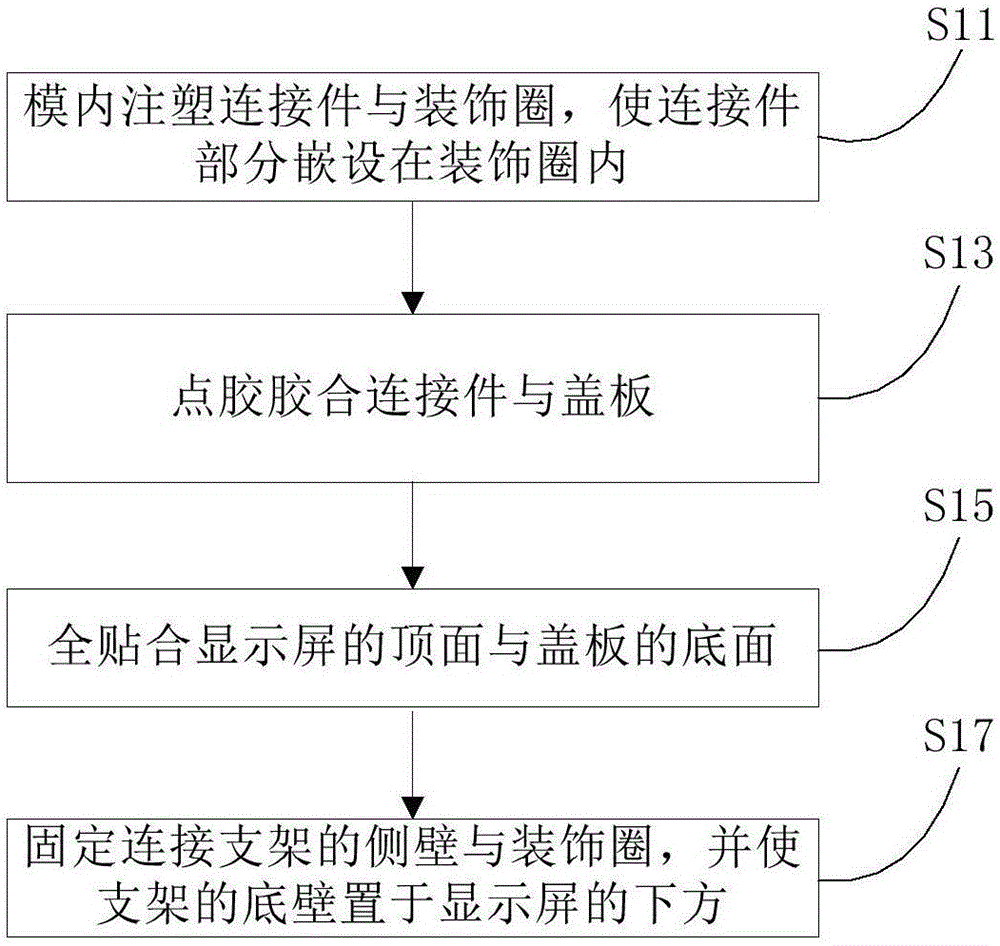

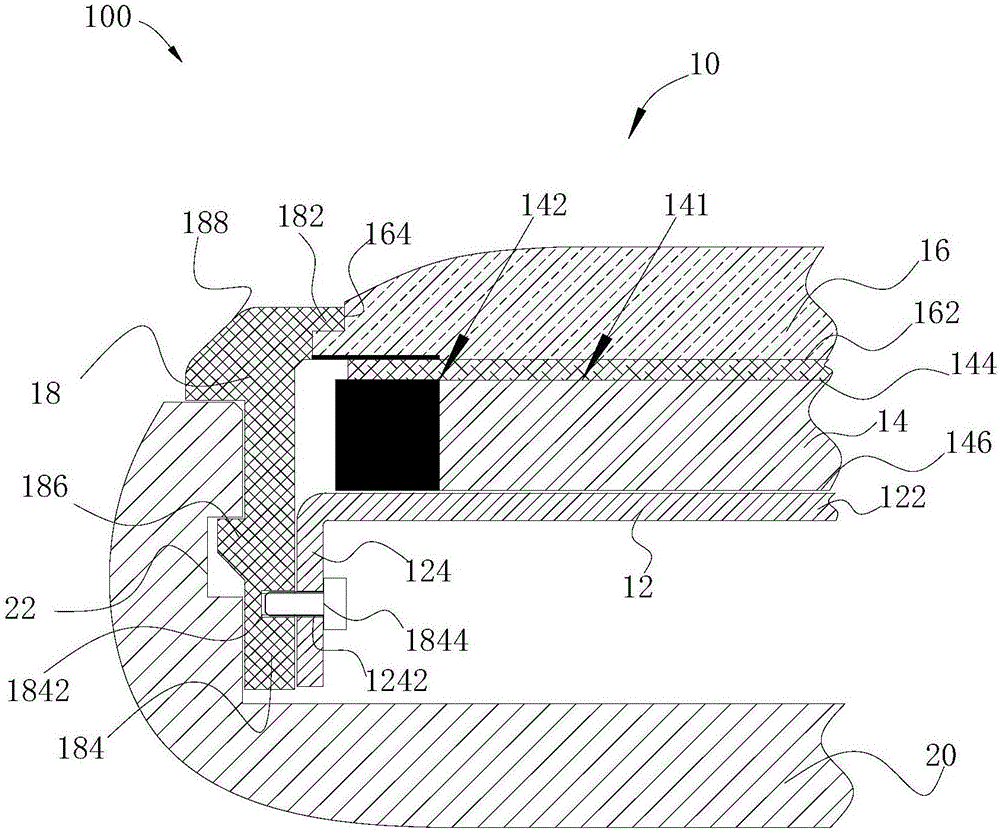

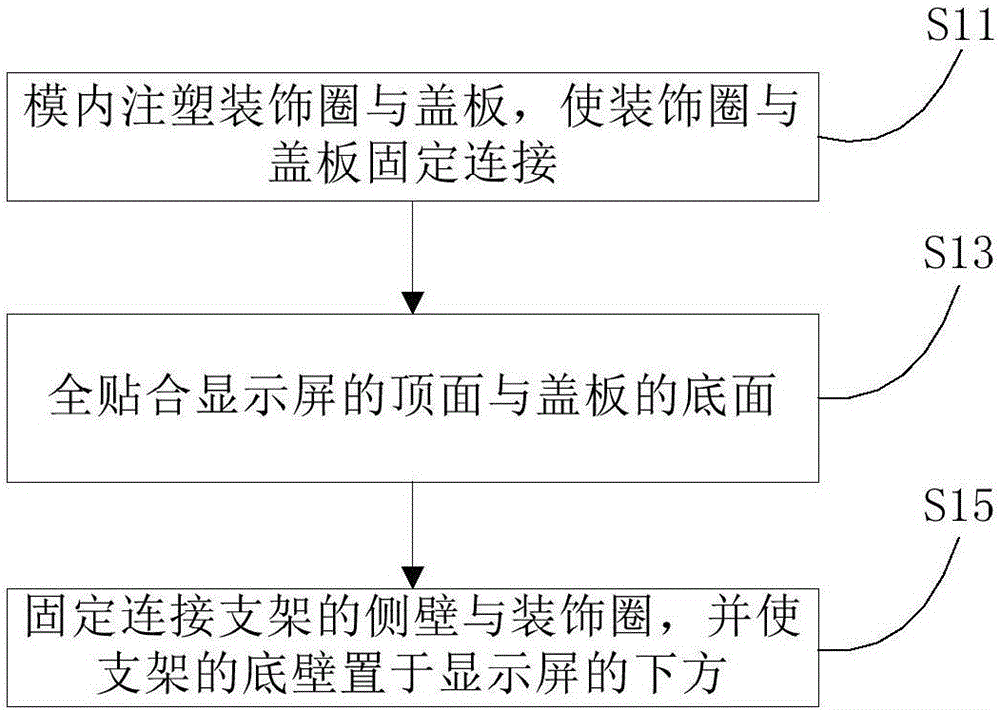

Display screen module, a making method thereof and electronic device

ActiveCN106843574AIncrease the proportionSolve assembly difficultiesInput/output processes for data processingEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

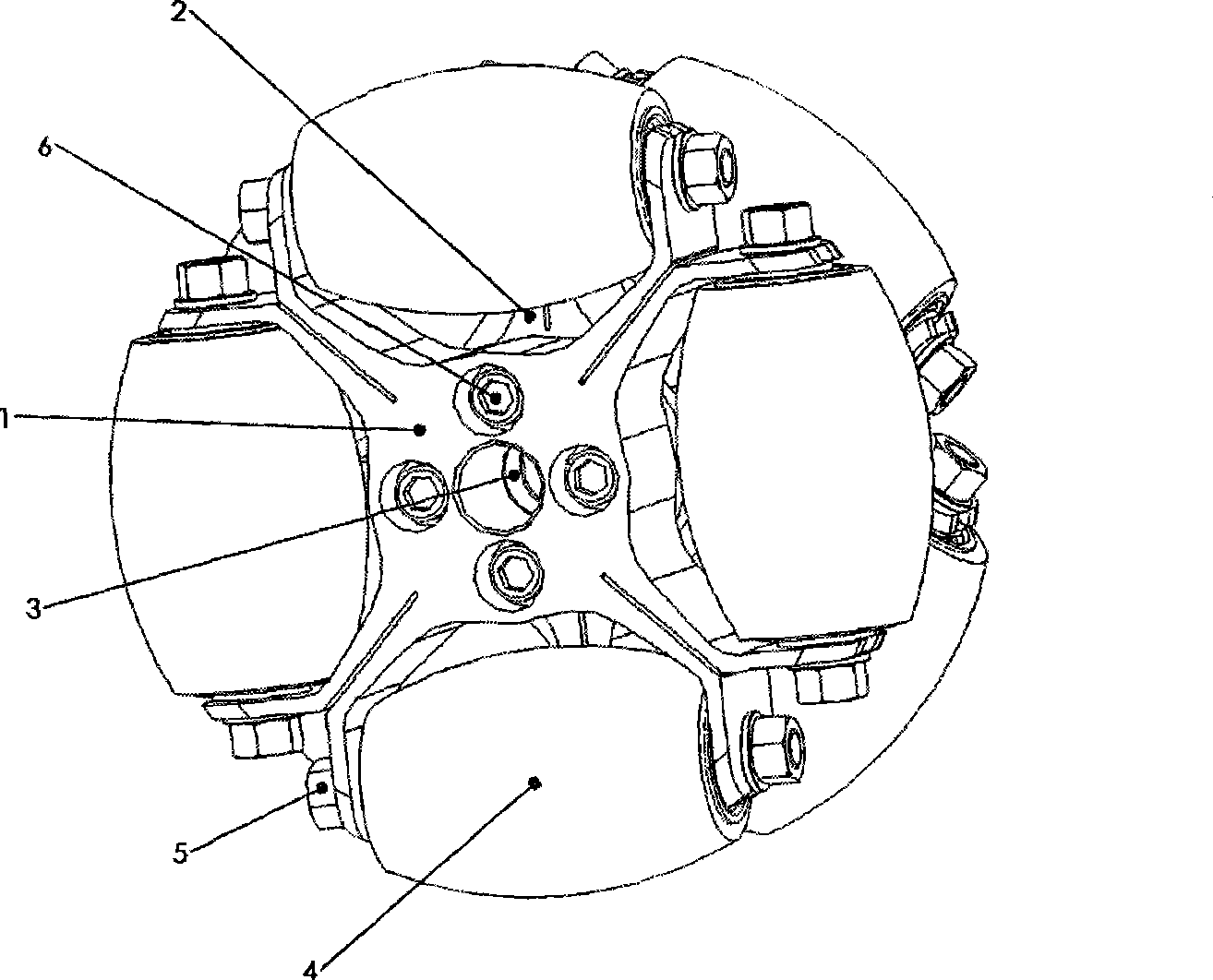

Blade hoisting device and blade hoisting system

ActiveCN108147267ASimplify the assembly processReduce assembly difficulty and assembly costLoad-engaging elementsImpellerEngineering

The invention provides a blade hoisting device and a blade hoisting system. The blade hoisting device comprises a bearing main body and a blade sucking device. The blade sucking device comprises a keeping component and a sucking connecting piece. The keeping component is connected with the bearing main body, the sucking connecting piece is arranged on the side, away from the bearing main body, ofthe keeping component, and the blade sucking device can suck blades to be assembled through sucking force produced by the sucking connecting piece. The impeller assembling process can be simplified, the assembling difficulty and cost can be reduced, and meanwhile impeller assembling efficiency is improved.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

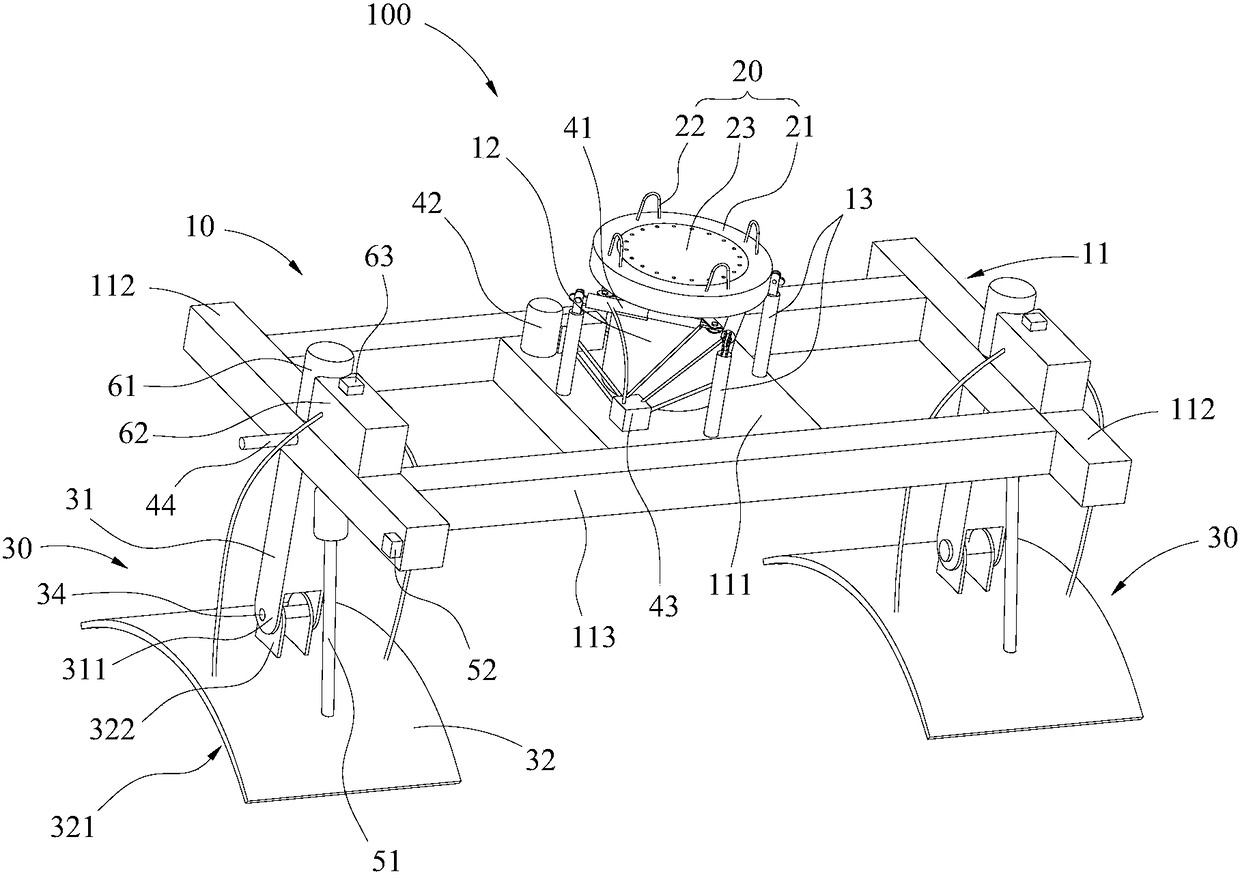

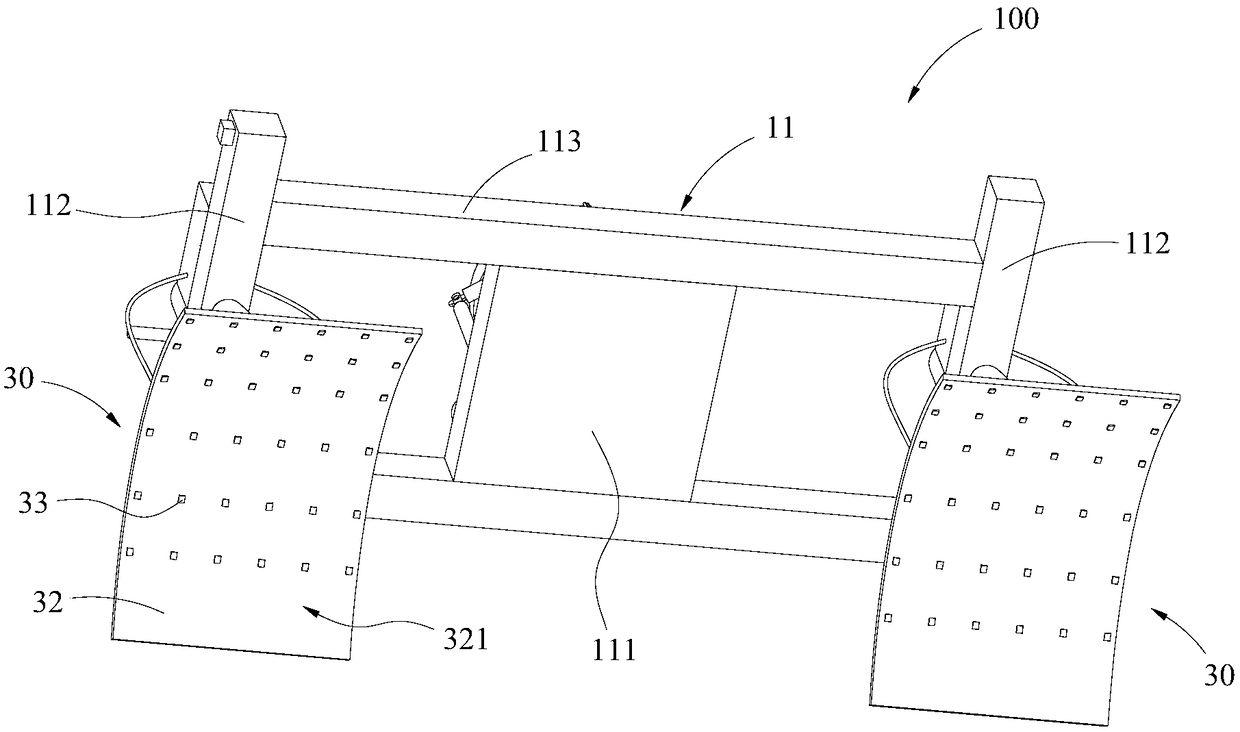

Display screen module, making method thereof and electronic device

ActiveCN106847091AIncrease the proportionSolve assembly difficultiesTelephone set constructionsIdentification meansEngineering

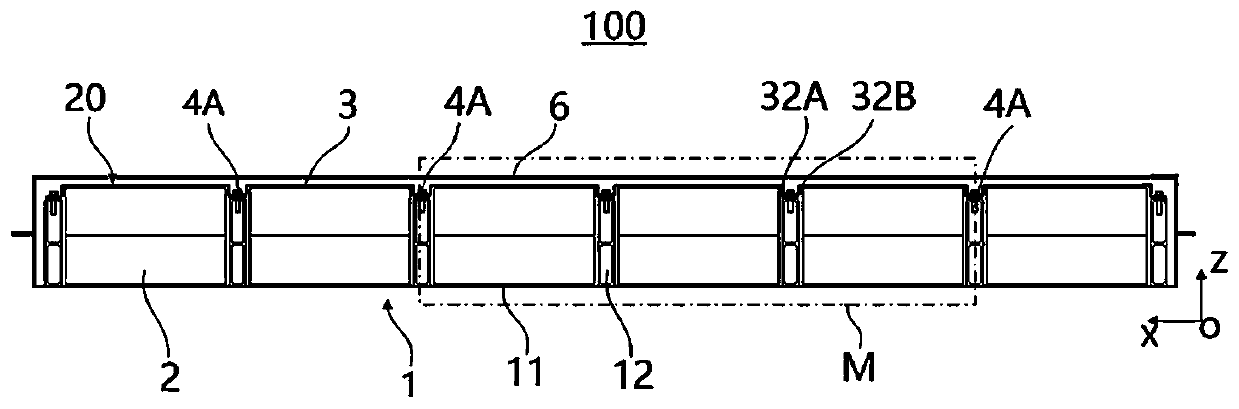

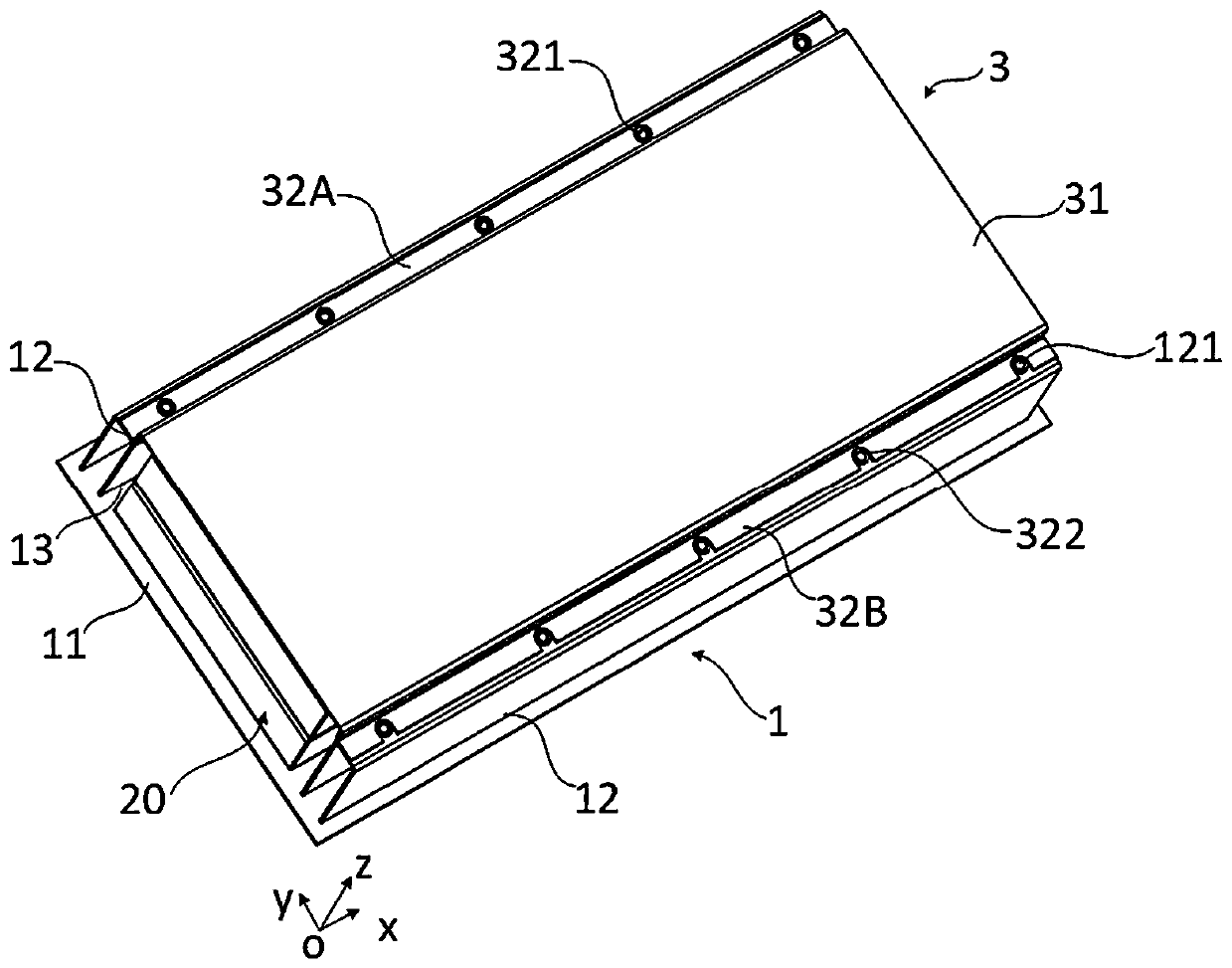

The embodiment of the invention discloses a display screen module, an electronic device and a making method of the display screen module. The display screen module comprises a support, a display screen, a cover plate and decorative rings. The support comprises a bottom wall and side walls extending from the bottom wall in a bent mode. The display screen comprises a top face and a bottom face, the bottom face of the display screen is arranged on the bottom wall, and the display screen and the side walls are located on the two reverse sides of the bottom respectively. The bottom face of the cover plate is combined with the top face of the display screen, and a clamping groove is formed in each side wall of the cover plate. The decorative rings comprise first combination parts and second combination parts connected with the first combination parts, the first combination parts are clamped into the clamping grooves, and the second combination parts are combined with the side walls. By reasonably designing the structures of the support, the display screen, a touch screen and the decorative rings, when the borders of the four sides of the electronic device are quite narrow, the display screen and the cover plate are assembled into the electronic device, the problem that when the borders of the electronic device are quite narrow, assembly is difficult is solved, and the screen-to-body ratio is increased because of the quite narrow borders are obtained.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

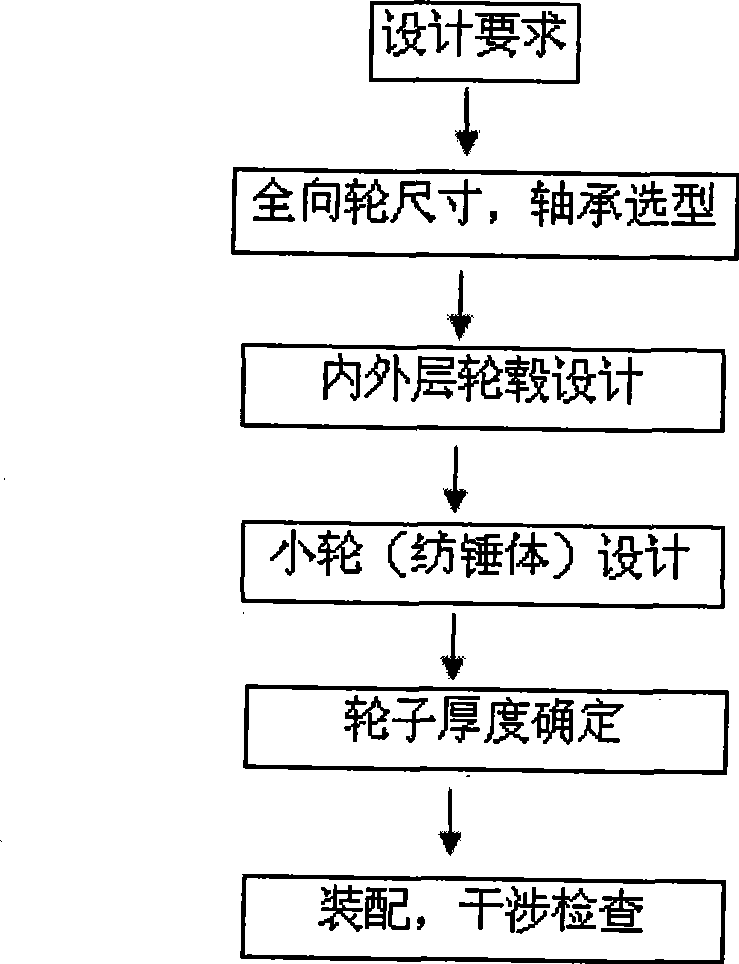

Omnidirectional wheel structure

The invention discloses a structural design method for an omni wheel and belongs to the mobile robot control field. As a hub of the omni wheel adopts an arrangement structure with two layers of an inner layer and an outer layer which are alternatively staggered at 45 degree angle, so the installation difficulty brought by the hub integration is avoided. A cushion block is clamped between an outer hub support and an inner hub support which are respectively connected with a spindle annulet. The invention causes the whole hub support to have better flexibility and easy installation. As a driven wheel uses an integrated structure of a support sleeve and the rubber vulcanization, the movement precision of the omni wheel is ensured. The invented omni wheel moves smoothly and has the advantages of compact structure and strong environmental adaptability.

Owner:XI AN JIAOTONG UNIV

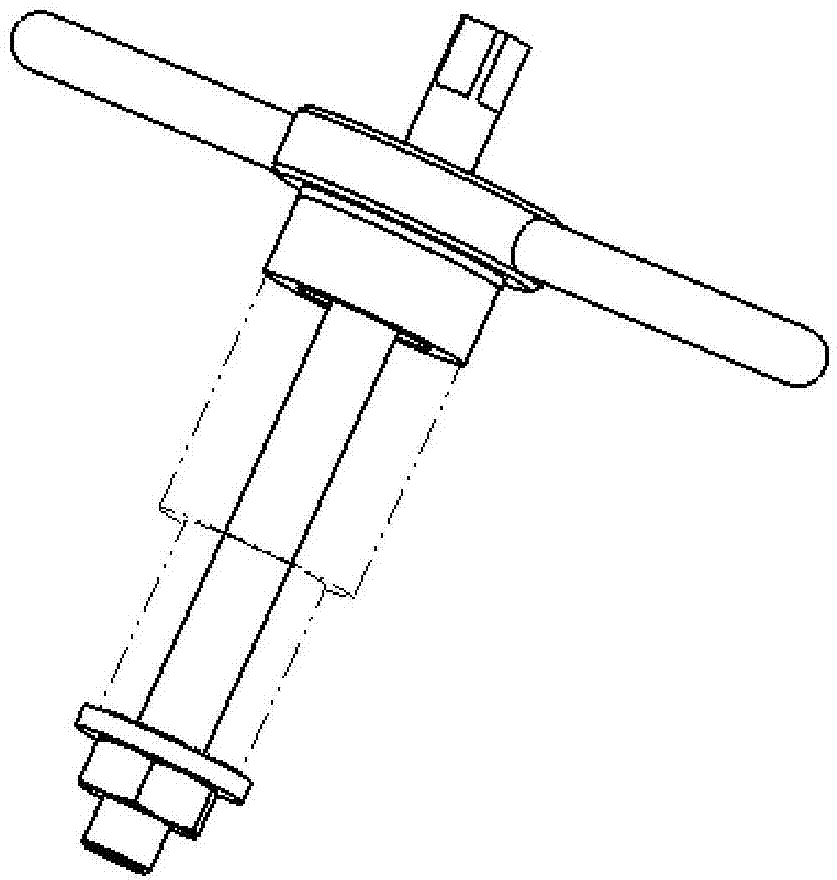

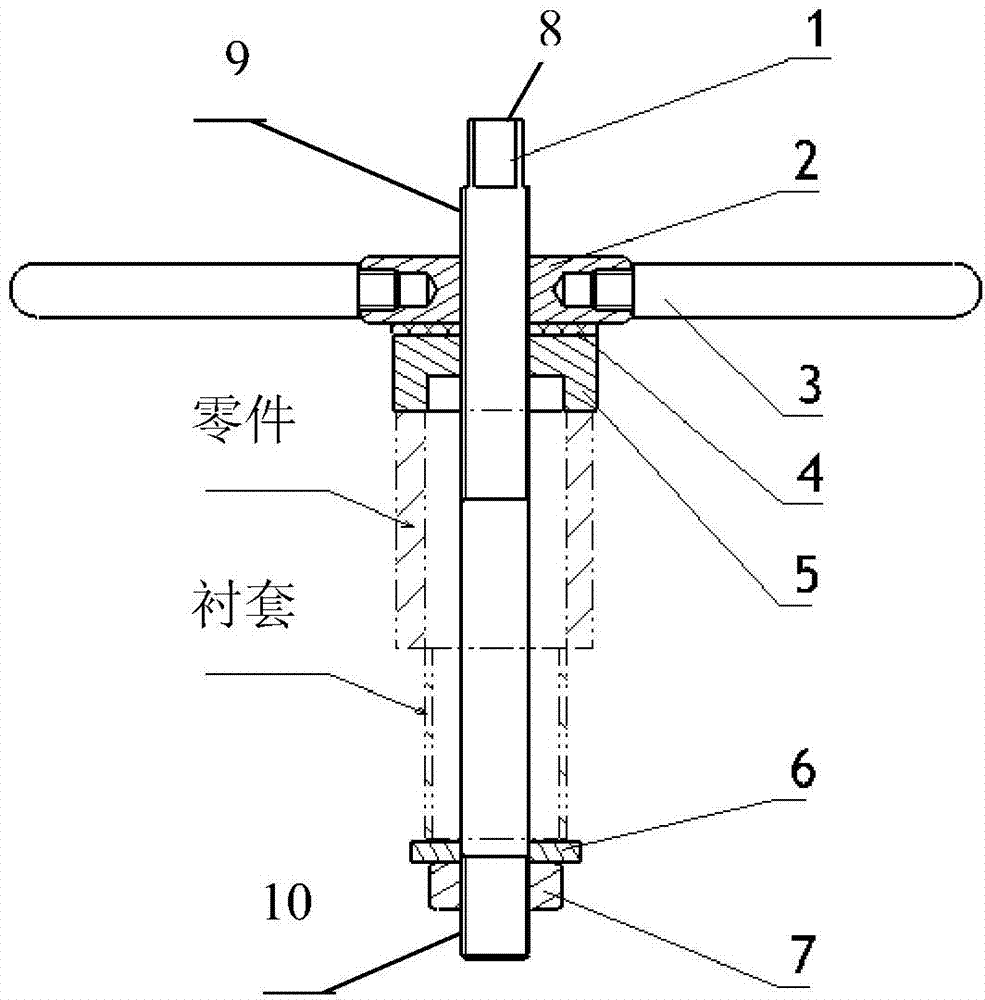

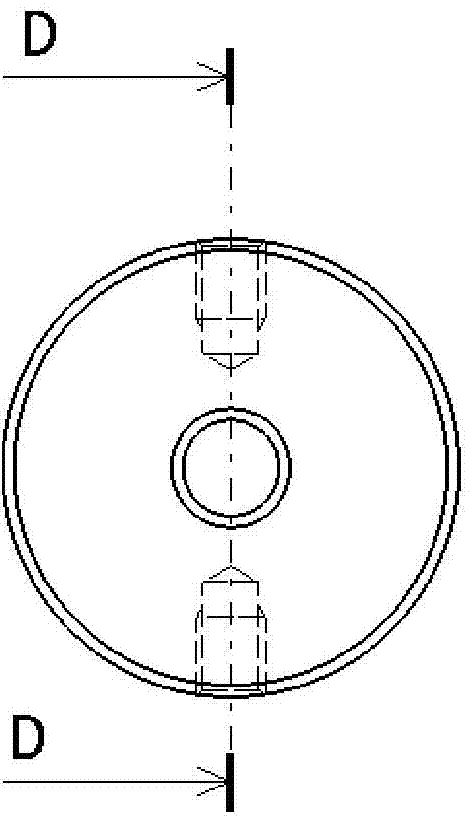

Bushing installation tool

InactiveCN104723271AEasy to installImprove work efficiencyMetal-working hand toolsEngineeringMechanical engineering

The invention relates to the tooling field, and provides a bushing installation tool. The bushing installation tool comprises a drive screw, a transmission nut, a handle, a press sleeve, a tray plate and a nut, wherein the press sleeve penetrates into the drive screw from a space above the drive screw, is pressed against the upper surface of a part, the passing nut is screwed on the drive screw, and pressed against the upper surface of the press sleeve, the handle is connected with the transmission nut, the drive screw sequentially passes through the part where a bushing is to be inlaid and the bushing, enables the tray plate to penetrate into the drive screw from a space below the drive screw, and is pressed against the lower surface of the bushing, and the nut is screwed on the drive screw, and pressed against the lower surface of the tray plate. The bushing installation tool is not restricted by a small space. By using the bushing installation tool, the bushing can be smoothly installed in a hole where the bushing is to be inlaid, and therefore work efficiency is improved, and assembly difficulty is avoided.

Owner:HARBIN

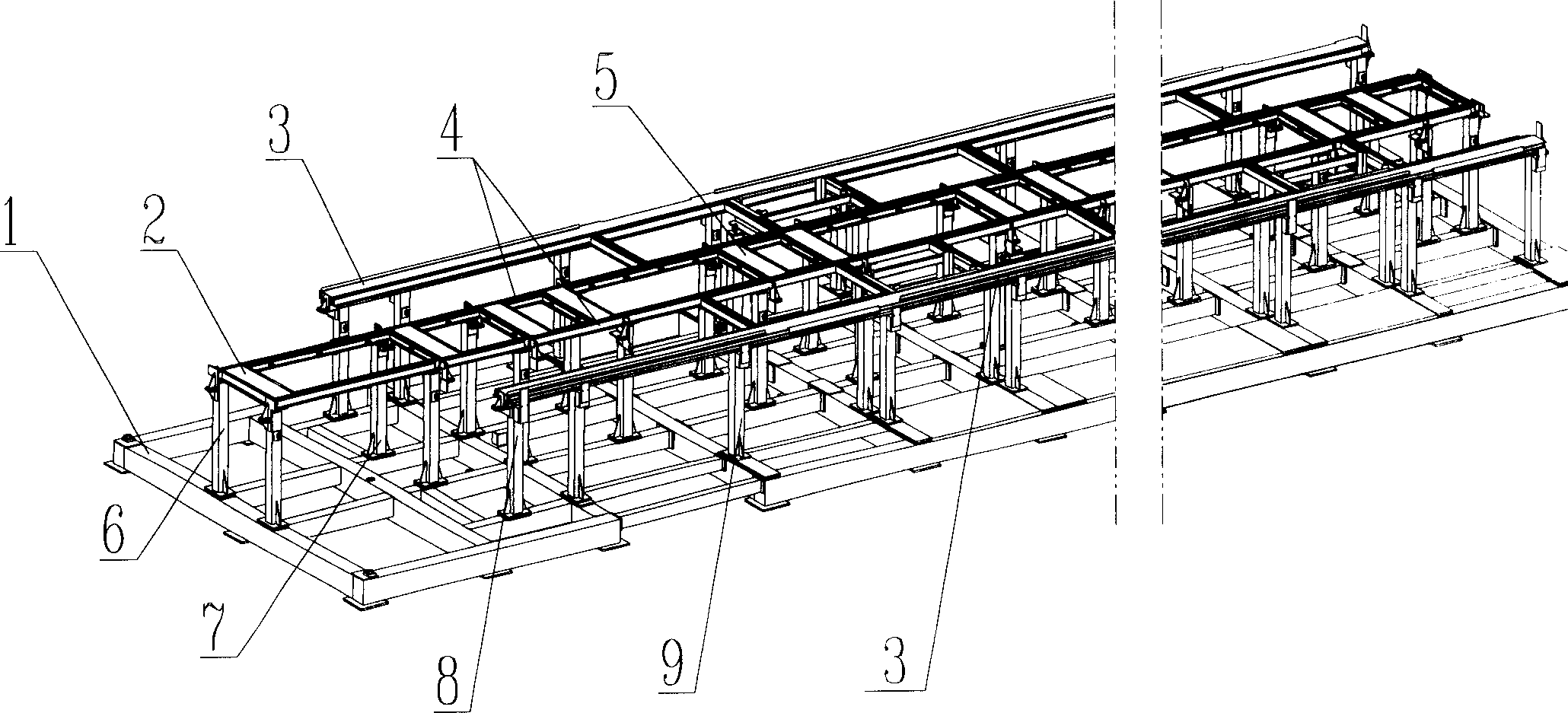

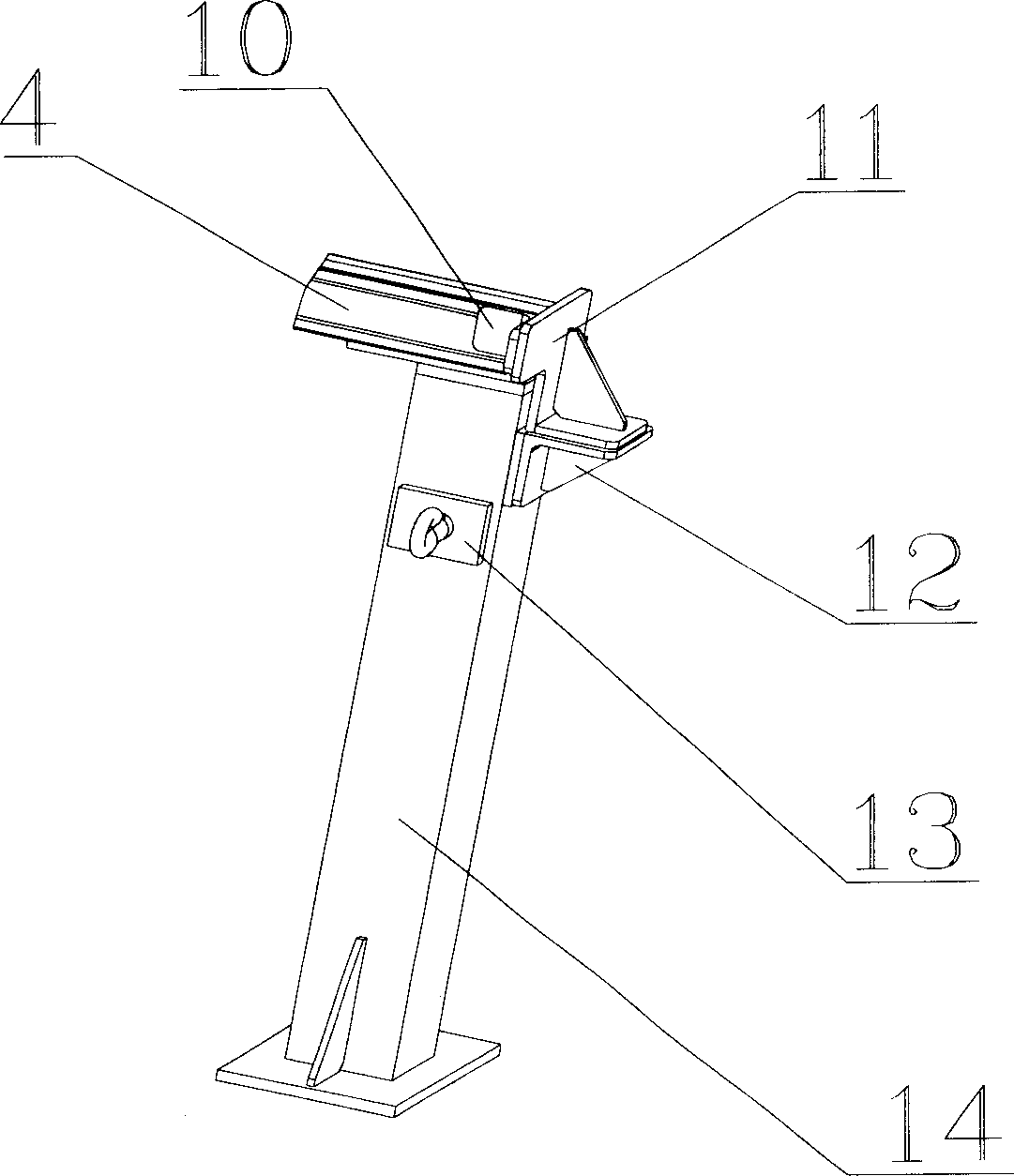

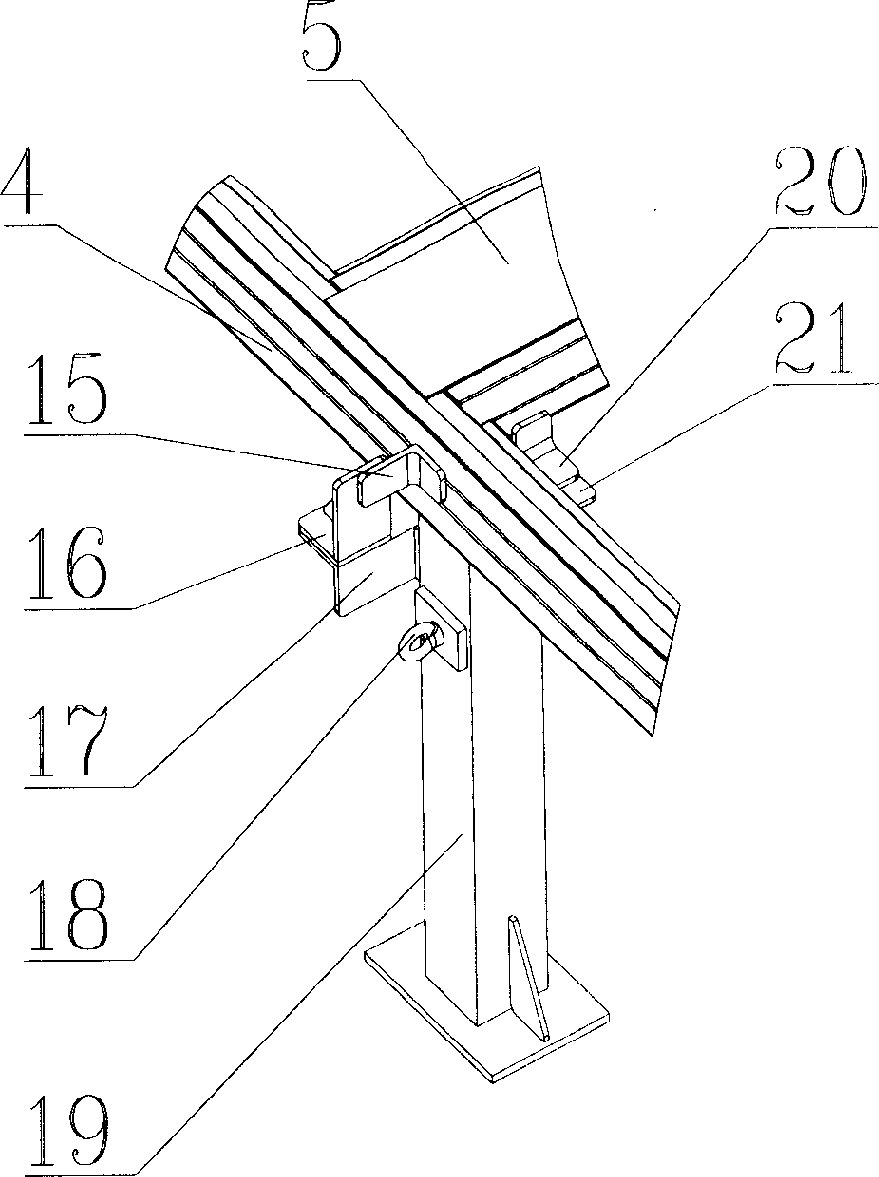

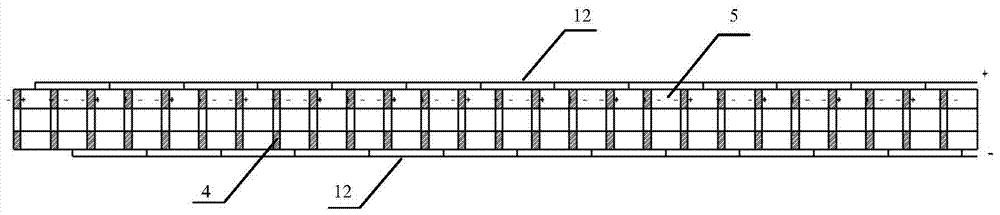

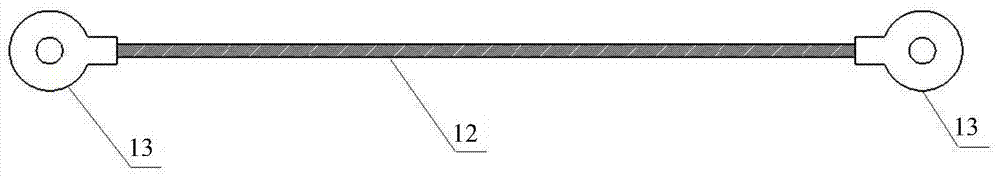

Multi-status combined frame for installing large-length vehicle container

ActiveCN1843686ASolve assembly difficultiesSave tooling manufacturing cycleMetal working apparatusLongitudeEngineering

The invention discloses a multi-condition composite support, which is used to assemble long compartment of vehicle, especially used to assemble the compartment of magnetic floating vehicle. The invention comprises upright positioning devices for supping beam supports, while said positioning devices are arranged along the ground latitude-longitude frame; and the positioning devices that arranged upwards are distanced 100mm from the surface of frame. The invention, via said multi-condition composite support, can solve the problems o present technique, which can not realize the assembly of floor, compartment, side walls and head on one support. And the invention can reduce the producing time and cost, with simple operation.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

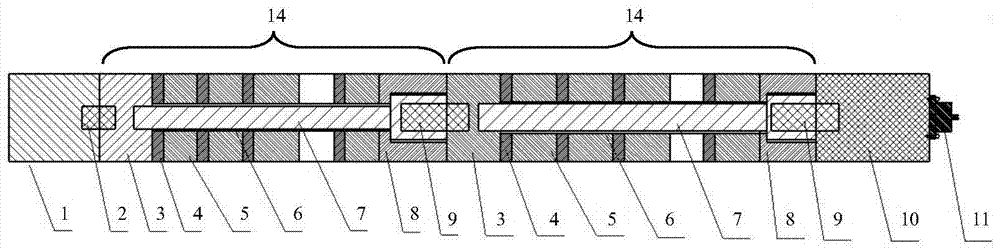

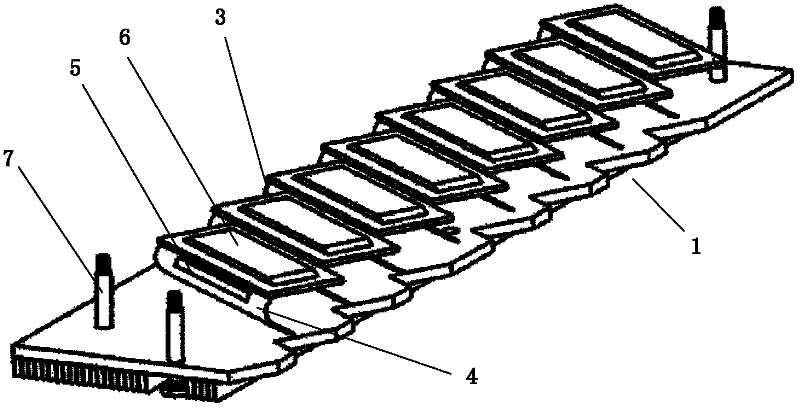

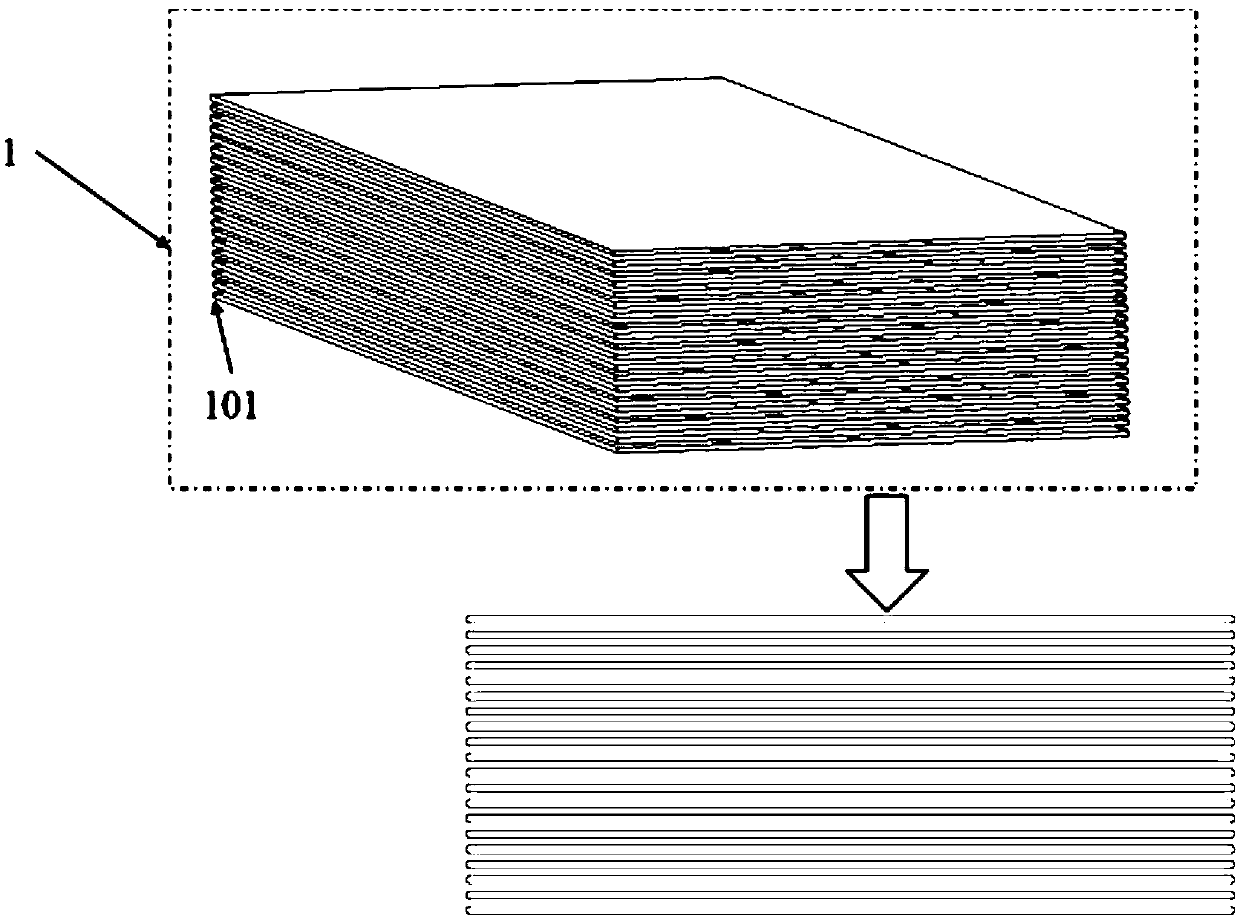

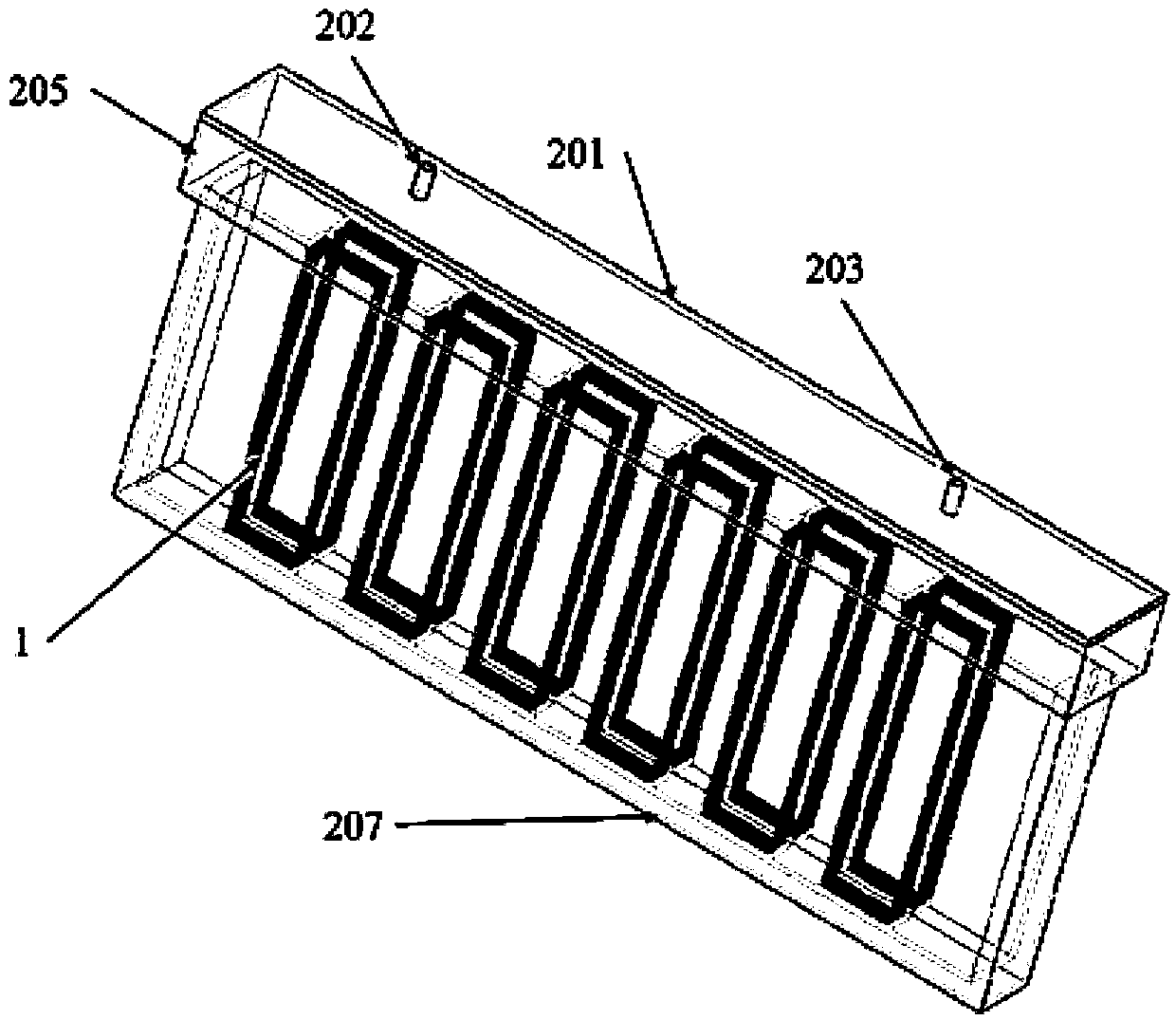

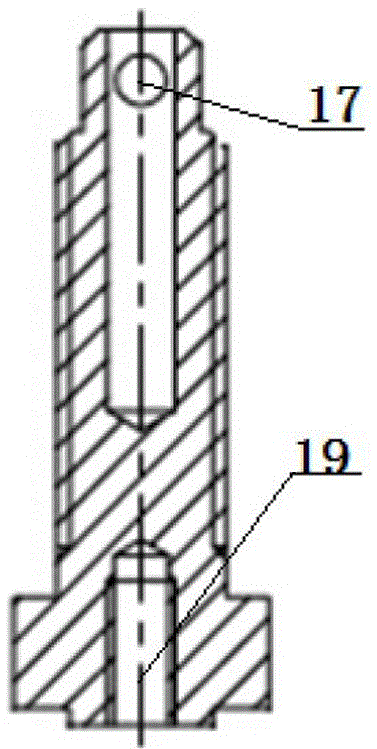

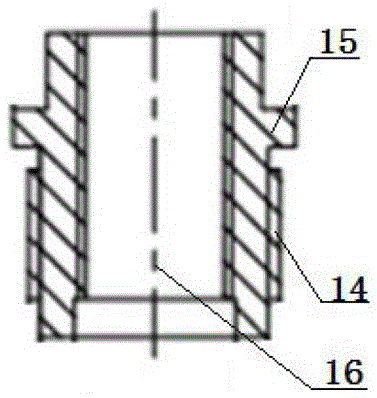

Low-frequency longitudinal vibration transducer used for oil well sound wave communication and manufacturing method thereof

The invention provides a low-frequency longitudinal vibration transducer used for oil well sound wave communication and a manufacturing method thereof. The low-frequency longitudinal vibration transducer comprises a radiation head (1) and at least two crystal stack modules (14). Each crystal stack module is formed by piling piezoelectric crystal plates and metals alternately. Every two adjacent crystal stack modules (14) are connected end to end and generate longitudinal vibration low-frequency sound waves after being connected with the positive pole and the negative pole of a power source. The radiation head (1) is fixed to the front end of the longitudinal vibration transducer and used for outputting the low-frequency sound waves generated through the crystal stack modules (14). According to the low-frequency longitudinal vibration transducer, the piezoelectric crystal plates and the metals are piled alternately, and thus radiating can be conducted effectively; and meanwhile, through the modular design, the operation simplicity and convenience and assembling reliability are greatly improved, and the problems of difficult machining and assembling and liable fracture during application caused by simplex long and thin prestressed screws are effectively solved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

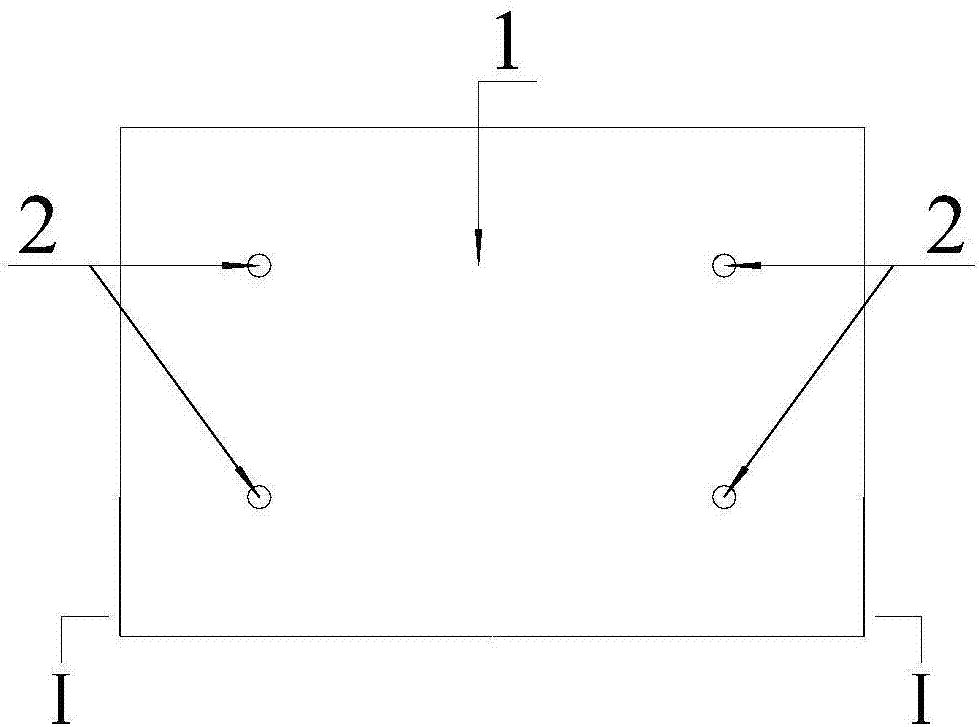

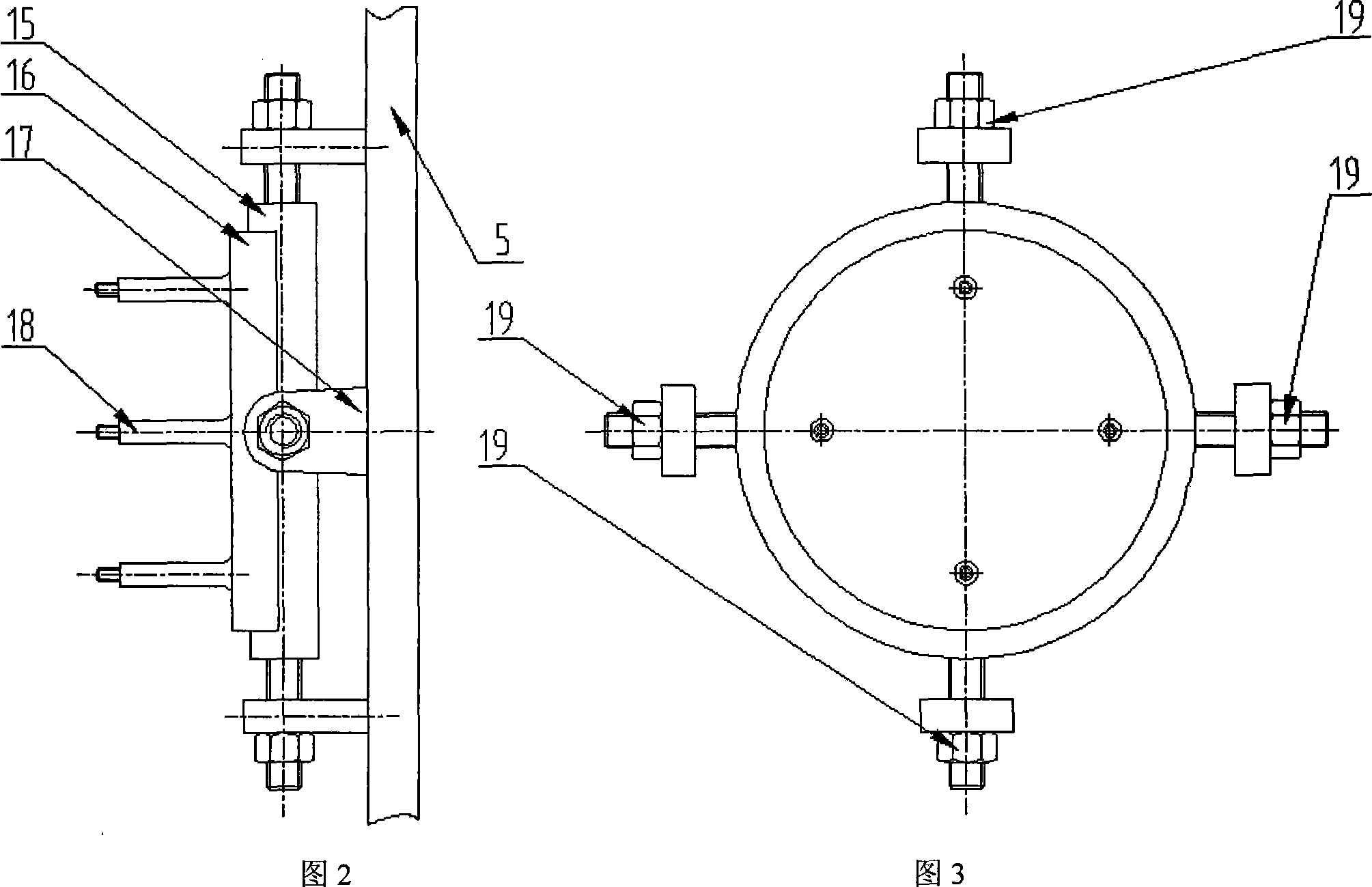

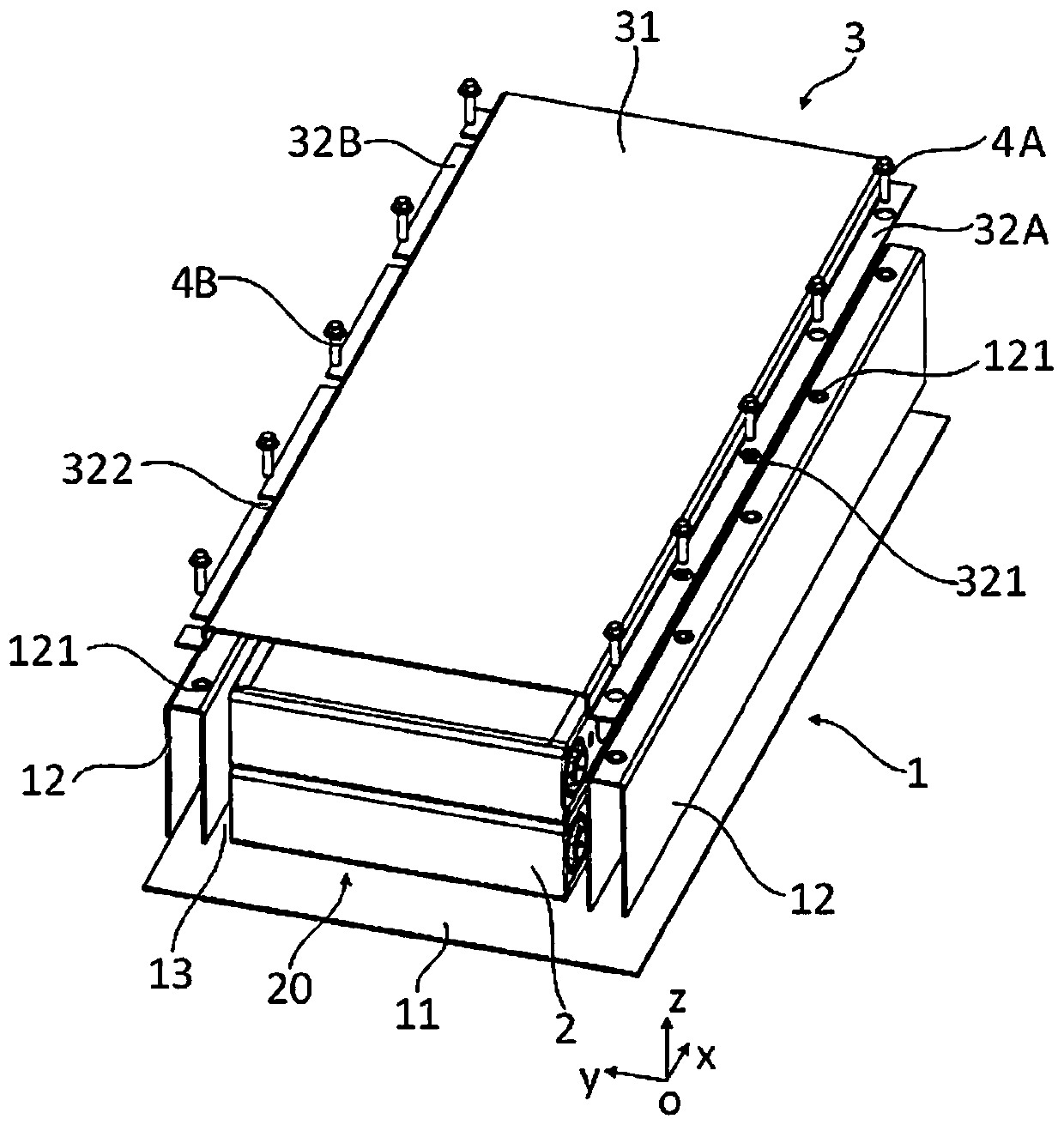

Assembly device and application method for disk type motor

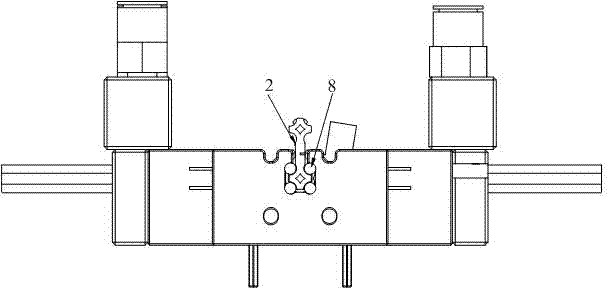

InactiveCN101369759AOvercoming axial magnetic pullSolve assembly difficultiesManufacturing stator/rotor bodiesCentering/balancing rotorsThrust bearingSlide plate

An apparatus and a method for assembling a disc type motor, and application method thereof, belong to motor technology field. The apparatus is composed of a fixed part and a feeding part, wherein the fixed part including a side board, a bottom board, bedplate compressing devices, a supporting board and a guide rail. The side board is connected with the bottom board on the square; the bedplate compressing devices locate on one end of the side board and on the other end connected with the bottom board; the stand is fixed with the side board and the bottom board by the bedplate compressing device; the guide rail is arranged between the side board and the supporting board. The feeding part includes a slide board, a rotor fixed component, a slide bar, a thrust bar and a screw rod, wherein the slide board locating on the top of the guide rail, the rotor fixed component being connected to the left side of the slide board; the rotor fixed component including a fixed parent matrix, a rotary body, a support frame and a rotor connection bar; the slide board being connected to the thrust plate through the slide bar, the thrust plate being equipped with a thrust bearing, and the screw rod being connected to the right side of the thrust bearing. The invention reduces excess manual operation, improves assembly efficiency, overcomes axial magnetic pull in the motor, and resolves the problem of being difficult to assembling the disc type motor.

Owner:SHENYANG POLYTECHNIC UNIV

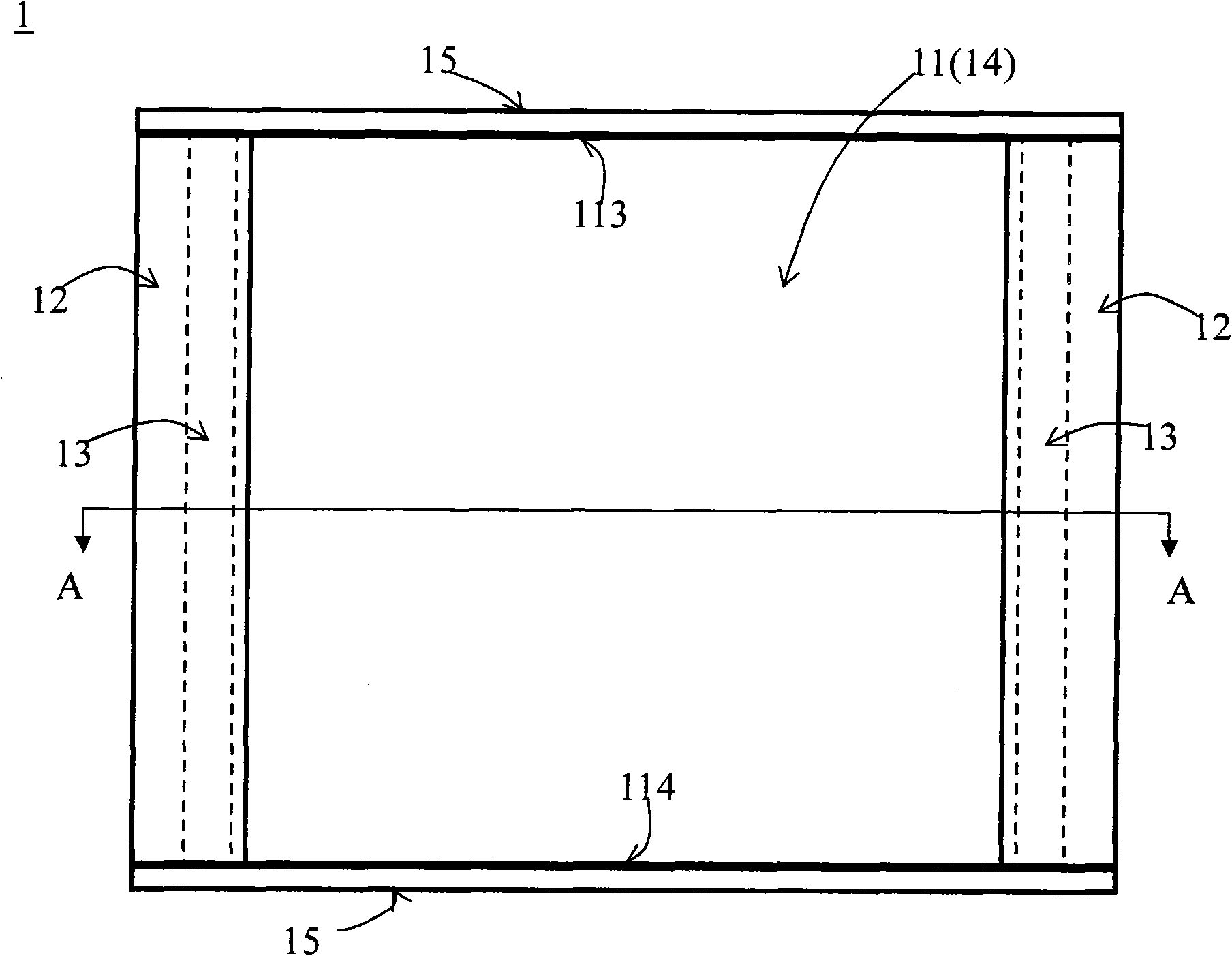

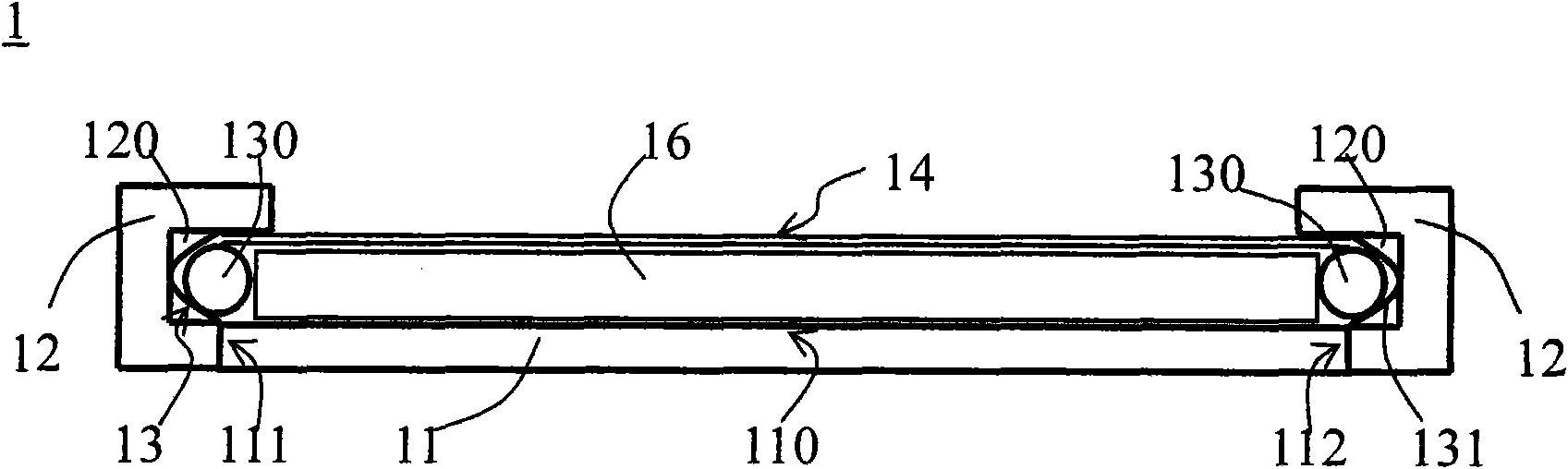

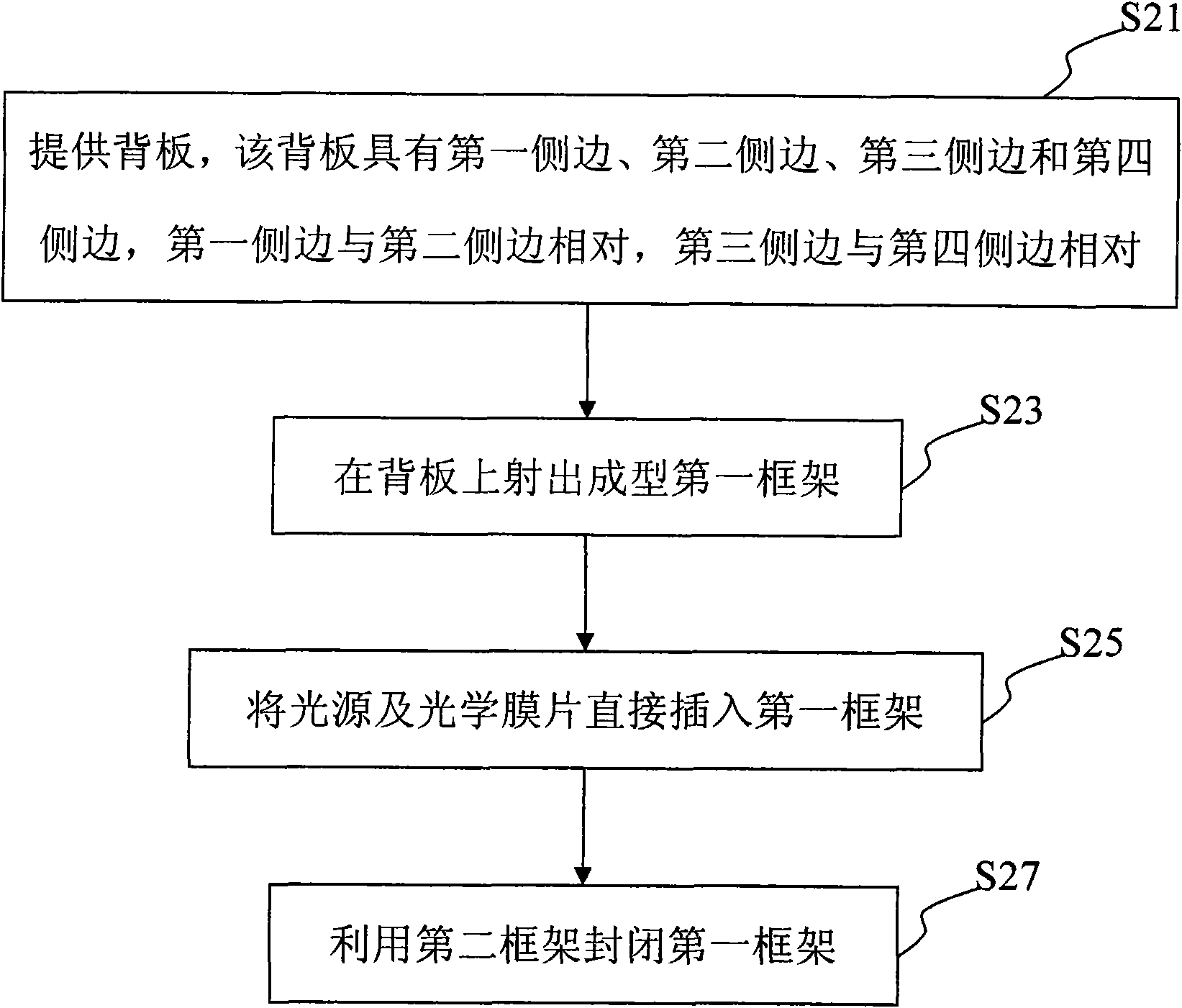

Back light module and manufacture method thereof

InactiveCN101634415AEasy to assembleOvercoming fit problemsNon-linear opticsLight fasteningsEngineeringOptical membrane

The invention relates to a back light module and a manufacture method thereof. The manufacture method of the back light module comprises the following steps: providing a back plate which is provided with a first side edge, a second side edge, a third side edge and a fourth side edge, wherein the first side edge is opposite to the second side edge and the third side edge is opposite to the fourth side edge; performing injection molding on a first frame on the back plate; inserting a light source and an optical membrane into the first frame; and enclosing the first frame by the a second frame. The invention can effectively reduce the complexity of the back light module and the assembly working time, solve a matching problem which may occur in assembly and also ensure that the reprocessing of the back light module is more convenient.

Owner:AU OPTRONICS (XIAMEN) CORP +1

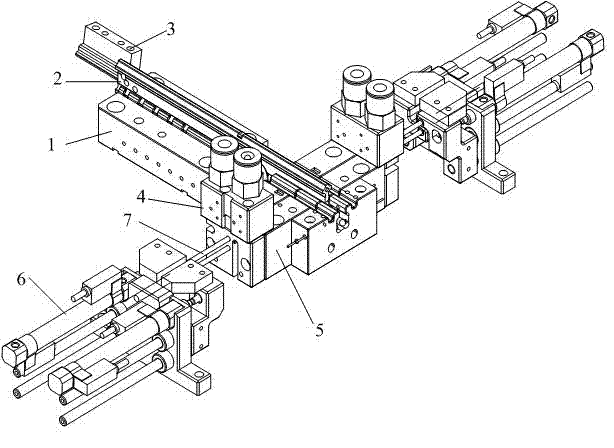

Automatic assembly mechanism for steel ball

ActiveCN103084837ASolve assembly difficultiesResolve detectionAssembly machinesButt jointEngineering

The invention relates to an automatic assembly mechanism for a steel ball. The automatic assembly mechanism for the steel ball comprises a steel ball retainer, ball feeding mechanisms and ball pushing mechanisms. Notch grooves for containing the steel balls are arranged at four corners of the steel ball retainer. The steel ball retainer is placed in a sliding groove of a channel jig. A material pushing block is arranged at the back end of the steel ball retainer. The material pushing block is connected with a material pushing mechanism. The front end of the channel jig is in a butt joint with a ball channel jig, wherein a sliding groove which the steel ball retainer can slide in is arranged in the ball channel jig. Two ball channels are arranged at the left side and the right side of the sliding groove of the ball channel jig, wherein the four ball channels are respectively matched with the notch grooves of the steel ball retainer. The ball feeding mechanisms are respectively installed on the left portion and the right portion of the ball channel jig. Two ball feeding channels of the left ball feeding mechanism are communicated with the left ball channels of the ball channel jig, and the two ball feeding channels of the right ball feeding mechanism are communicated with the right ball channels of the ball channel jig. The ball pushing mechanisms are respectively arranged on the left side and the right side of the ball channel jig. Pushing rods of the ball pushing mechanisms stretch into the ball channels of the ball channel jig. The problems that the four rows of ball sliding rails are difficult to assemble and the ball loss can not be detected are resolved.

Owner:KERUI AUTOMATION TECH SUZHOU

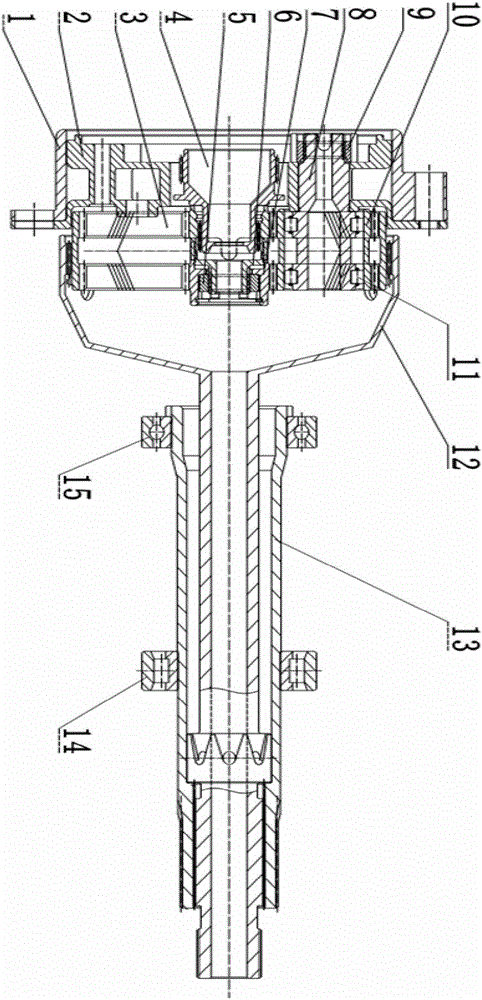

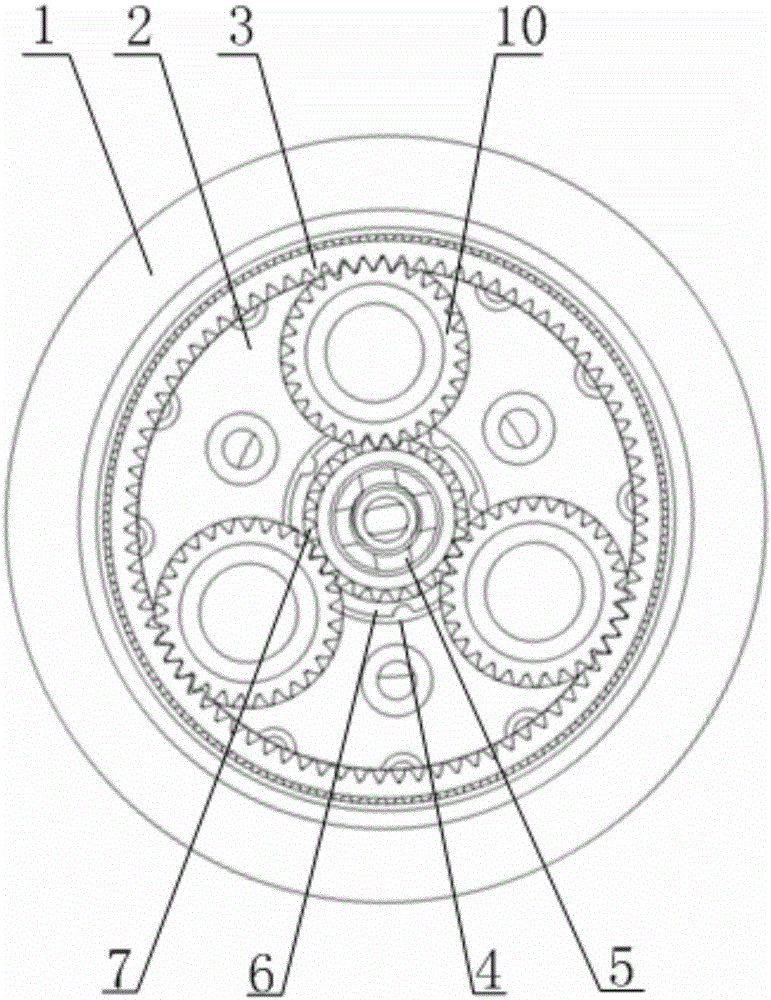

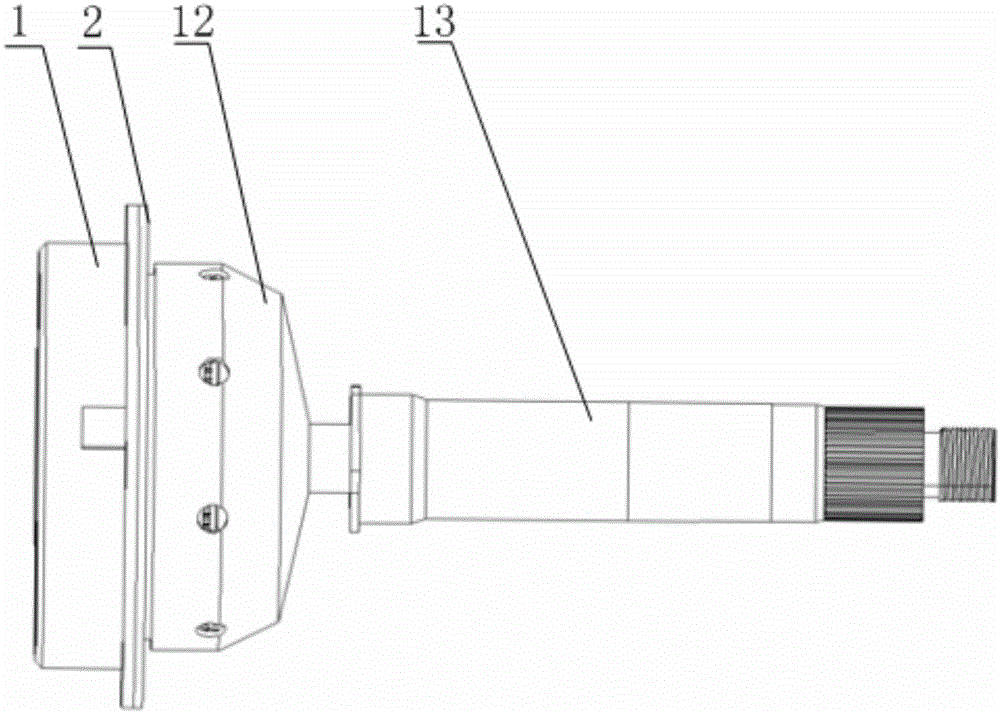

Gear transmission device of GTF engine

ActiveCN106195136ASolve assembly difficultiesSolve the accuracy problemToothed gearingsGearing detailsDrive shaftBypass ratio

The invention relates to a gear transmission device of a GTF engine. The gear transmission device comprises a fan sleeve, an inverted-V-shaped inner gear ring, inverted-V-shaped planet gears, a planet carrier, an input spline sleeve, two sun gears, a transmission shaft and the like. The sun gears conduct input, the planet gears only conduct self-rotation, and the inverted-V-shaped inner gear ring conducts output. The inverted-V-shaped inner gear ring is connected with the transmission shaft, the transmission shaft is connected with the fan sleeve through a spline, and the fan sleeve serves as the output end to be connected with the fan so as to achieve the deceleration and torque increasing movement. The rotation speed ratio of the fan sleeve to the input spline sleeve is equal to the gear ratio of the sun gears to the inverted-V-shaped inner gear ring. According to the gear transmission device, the rotation speed of a fan rotor is reduced, the fan and a low-pressure turbine do not need to work at the same rotating speed, the fan works at the low rotating speed when pneumatic losses and noise are low, and therefore the bypass ratio of the engine is increased. Meanwhile, a low-pressure rotor can work at the high rotation speed with high efficiency, so that the high rotation speed of the low-pressure rotor is matched with the optimal rotation speed of a high-pressure rotor, and the engine has the beneficial effects of being low in noise, emission and oil consumption rate and the like.

Owner:CHONGQING UNIV +1

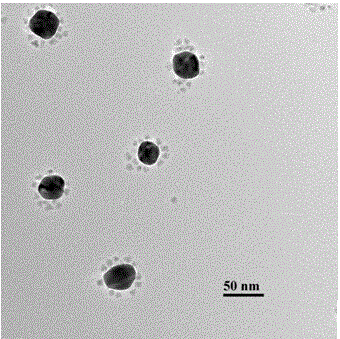

Preparation method of gold nucleus-quantum dot satellite structure assembly

ActiveCN105036073ASolve assembly difficultiesSolve yieldNanostructure manufactureMicrobiological testing/measurementQuantum dotBiology

The invention discloses a preparation method of a gold nucleus-quantum dot satellite structure assembly, belonging to the technical field of analytical chemistry. A high-yield assembly method of a gold nucleus-quantum dot satellite structure comprises the following steps of synthesis of gold nano particles with the particle size of 35nm, preparation of quantum dots with the particle size of 7nm, DNA-1 modification on the gold nano particles, complementary sequence DNA-2 modification on the quantum dots, assembling of the gold nucleus-quantum dot satellite structure, and purification of the gold nucleus-quantum dot satellite structure. By adopting the preparation method, the problems that quantum dot assembling is difficult and the yield is low are solved, and a way is paved for developing a fluorescence sensor based on quantum dot assembling.

Owner:JIANGNAN UNIV

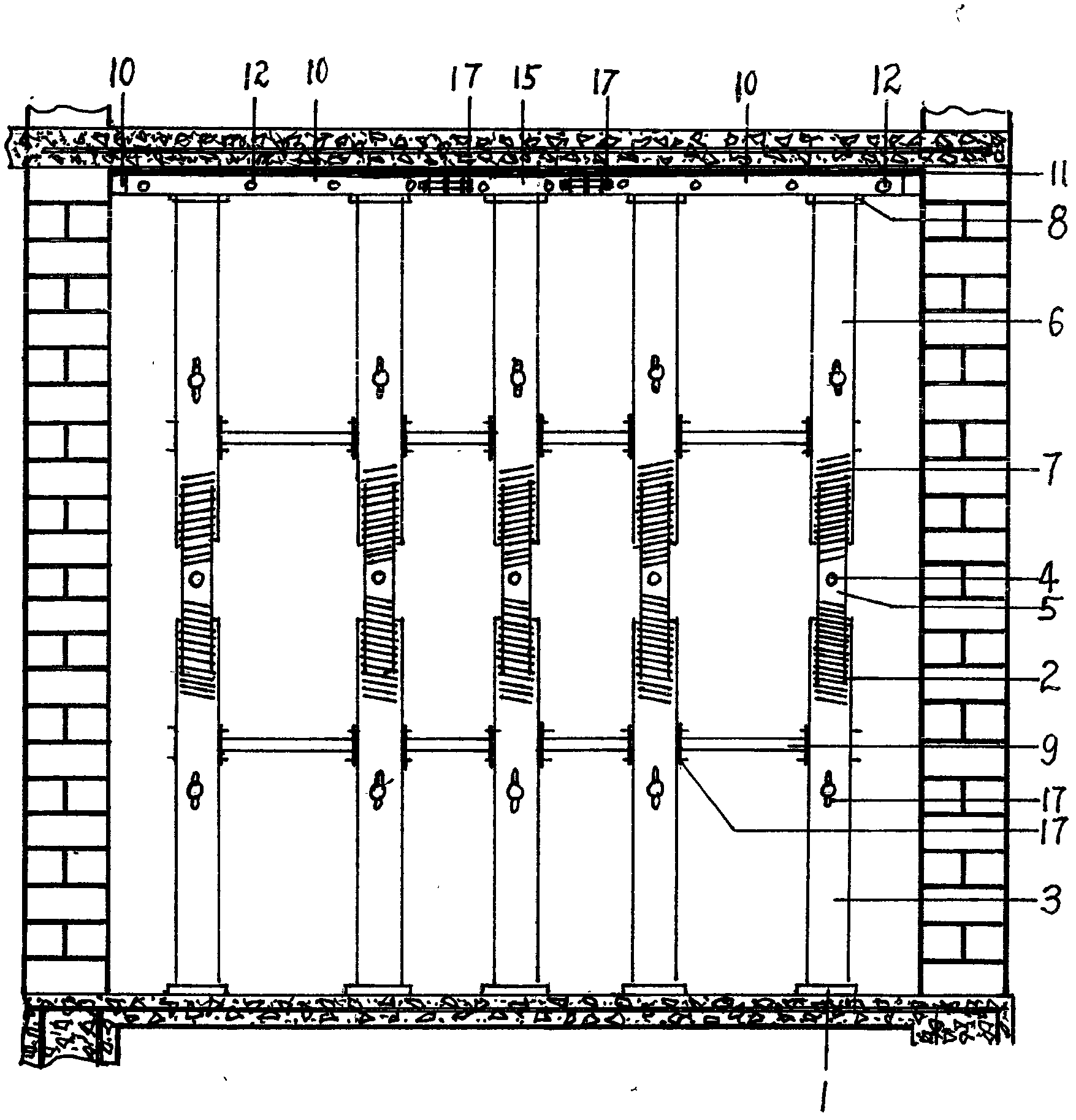

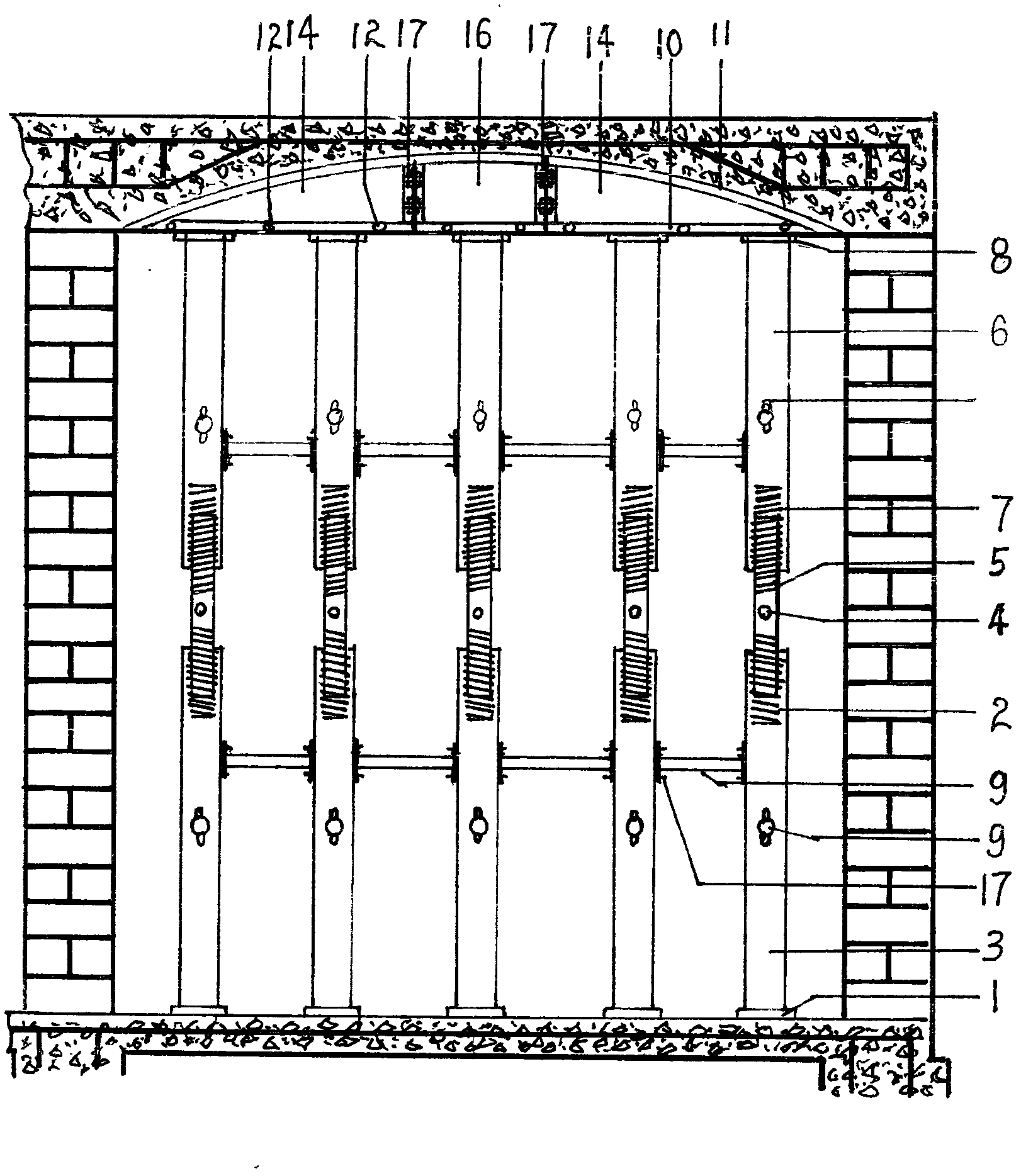

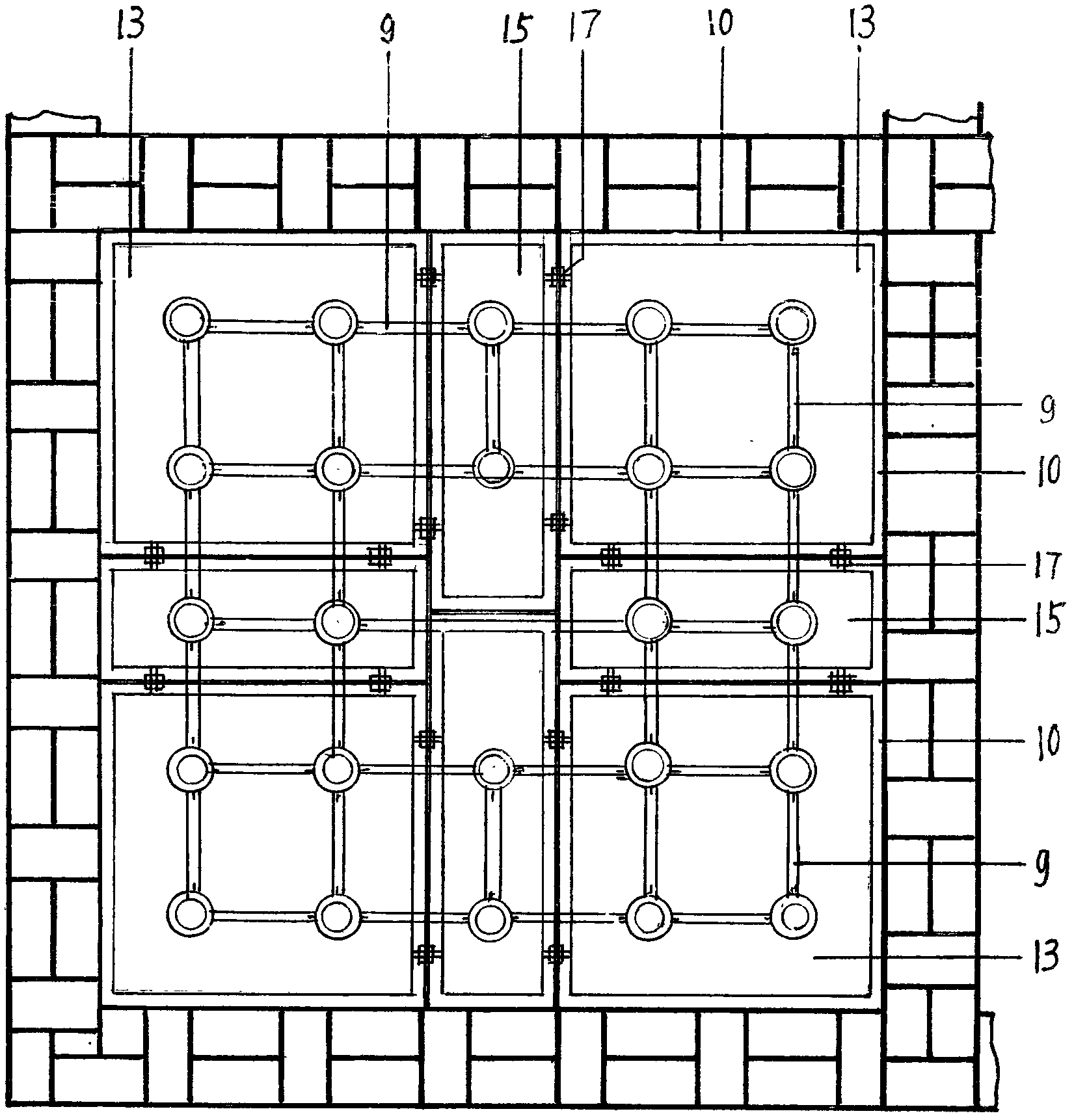

Assembly technology of adjustable supporting columns and eight type modularized steel floor slab moulds

InactiveCN103255929AImprove integrityHigh strengthForms/shuttering/falseworksShoresReinforced concreteFloor slab

Disclosed is an assembly technology of adjustable supporting columns and eight type modularized steel floor slab moulds. According to the technical scheme, the supporting columns with adjustable heights and the eight type modularized steel floor slab moulds are assembled into reinforced concrete cast floor slab templates of rooms. The assembled templates are high in wholeness and strength, few in joints and capable of preventing leakage and loss of cement paste during concrete casting and vibrating, and the construction quality can be effectively guaranteed. The assembly technology has the advantages that the disassembly speed is fast during construction, the process is simple, working hours are saved, the engineering progress and the generality are improved, the reusability is high, the problem that non-planar cast templates are assembled difficultly is well solved particularly, valuable wood resources are saved simultaneously, the environment is protected, and economic benefits are large.

Owner:TIANJIN SANCHUN TECH

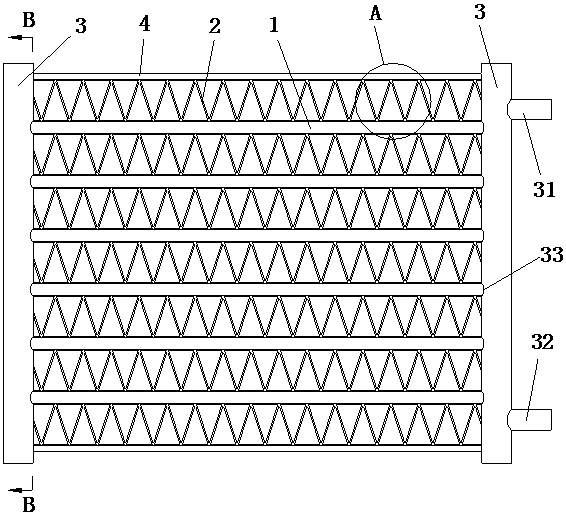

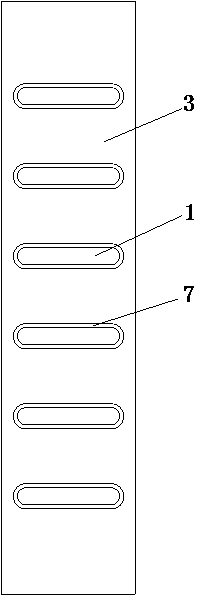

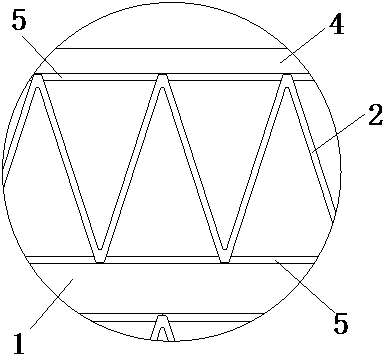

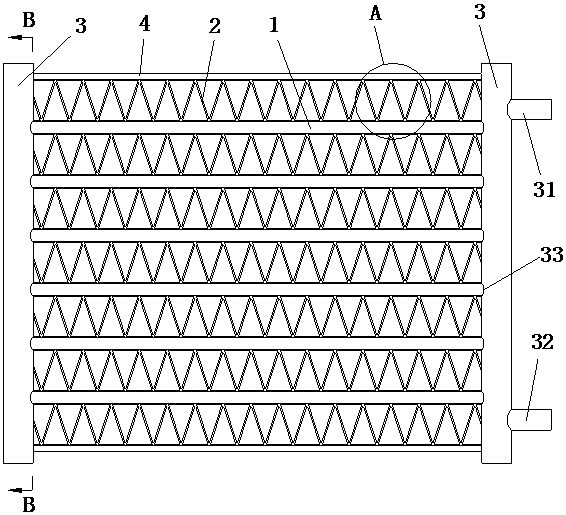

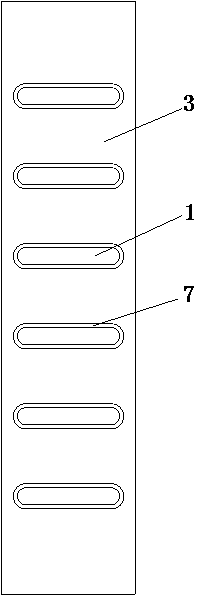

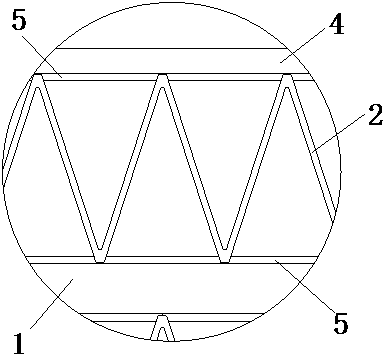

Wave finned heat exchanger and manufacturing method thereof

InactiveCN106524785AElimination of finless areasImprove heat transfer effectStationary conduit assembliesHeat exhanger sealing arrangementAdhesive cementEngineering

The invention discloses a heat exchanger and a manufacturing method thereof. The heat exchanger is characterized by comprising flat tubes, fins and liquid collection cavities, wherein the flat tubes and the fins are alternately arranged, and in addition, each flat tube is adhered to the corresponding fin through a first adhesive layer; the side wall of each liquid collection cavity is provided with a plurality of sequentially arranged slot holes; the two ends of each flat tube are inserted into the corresponding slot holes respectively; the end parts of each flat tube are adhered to the corresponding slot holes by second adhesive layers in a sealing manner respectively; or the liquid collection cavities are formed by stacking the ends of the flat tubes; and in addition, the ends of two adjacent flat tubes are adhered to each other by the corresponding second adhesive layer in the sealing manner. According to the heat exchanger, the adhesion effects between each flat tube and the corresponding fin as well as between each flat tube and the corresponding liquid collection cavity are both stable and firm, the sealing strength between each flat tube and the corresponding liquid collection cavity is fully guaranteed, and the heat exchange performance of the heat exchanger can also be greatly improved.

Owner:谢彦君

Rubber band core rod processing device without stub bars

The invention relates to a rubber band core rod processing device without stub bars. The device consists of a core rod, a lower rubber band, an upper rubber band, a spherical baffle block, a locating disk and a screw, wherein, a groove is arranged on one end of the core rod and is correspondingly assembled with and fixed to a boss of the upper rubber band, and an endpoint of a hose is located; and the locating disk is arranged on the other end of the core rod and is equipped with a locating hole, a locating groove and a hose locating interface, the other end of the hose and the locating disk are sequentially located according to the hose locating interface, the locating groove of the locating disk and a boss of the lower rubber band are assembled and fixed together correspondingly, and the locating hole on the locating disk is locked by the screw so that the locating disk is fixed on the core rod. Through the adoption of the rubber band core rod processing device, the stub bars on two ends of the original hose are not used any more; the operation procedure of cutting off the hose is not needed, thus saving precious cost of unit production time; and the outer diameter of two ends of the vulcanized finished hose can be controlled, thus greatly improving the dimensional precision and the qualification rate of the product and avoiding waste of raw materials.

Owner:TIANJIN PENGYI GRP CO LTD

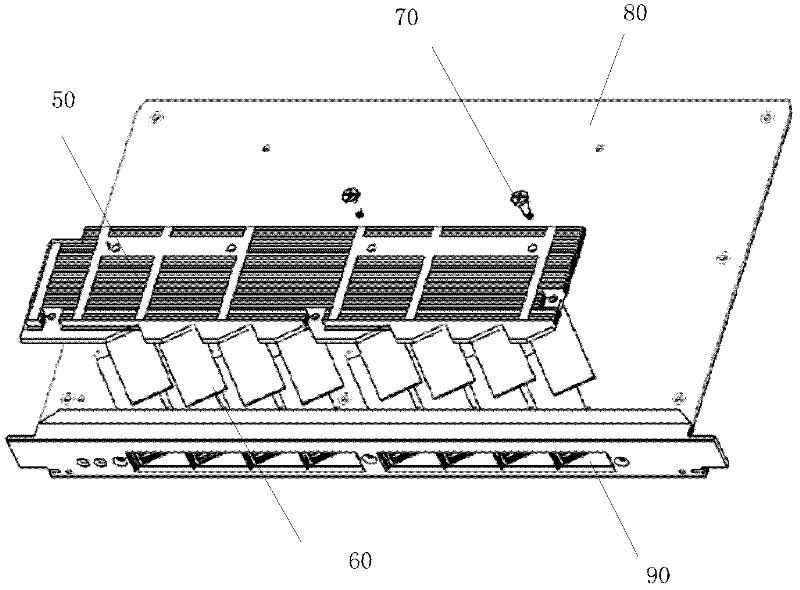

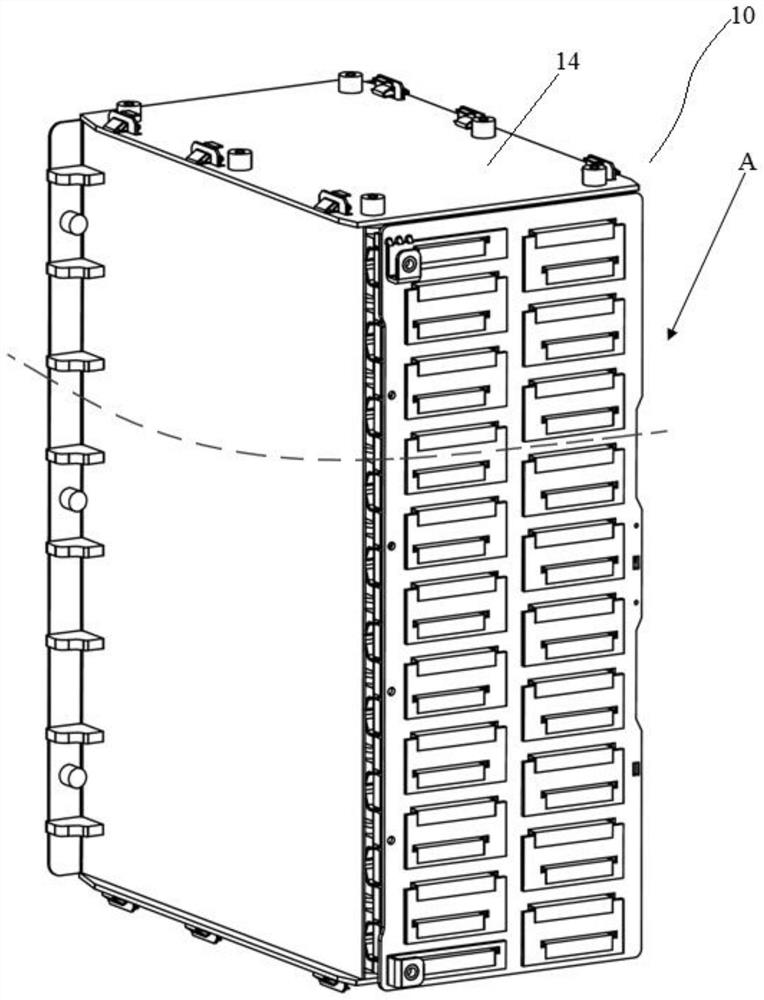

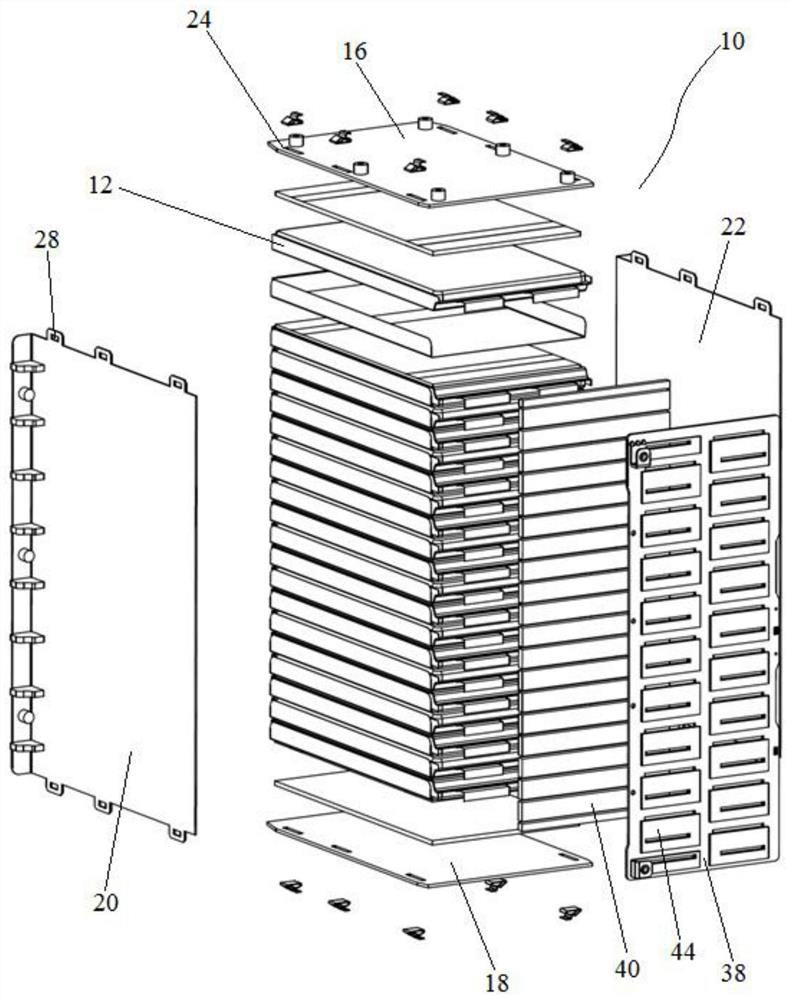

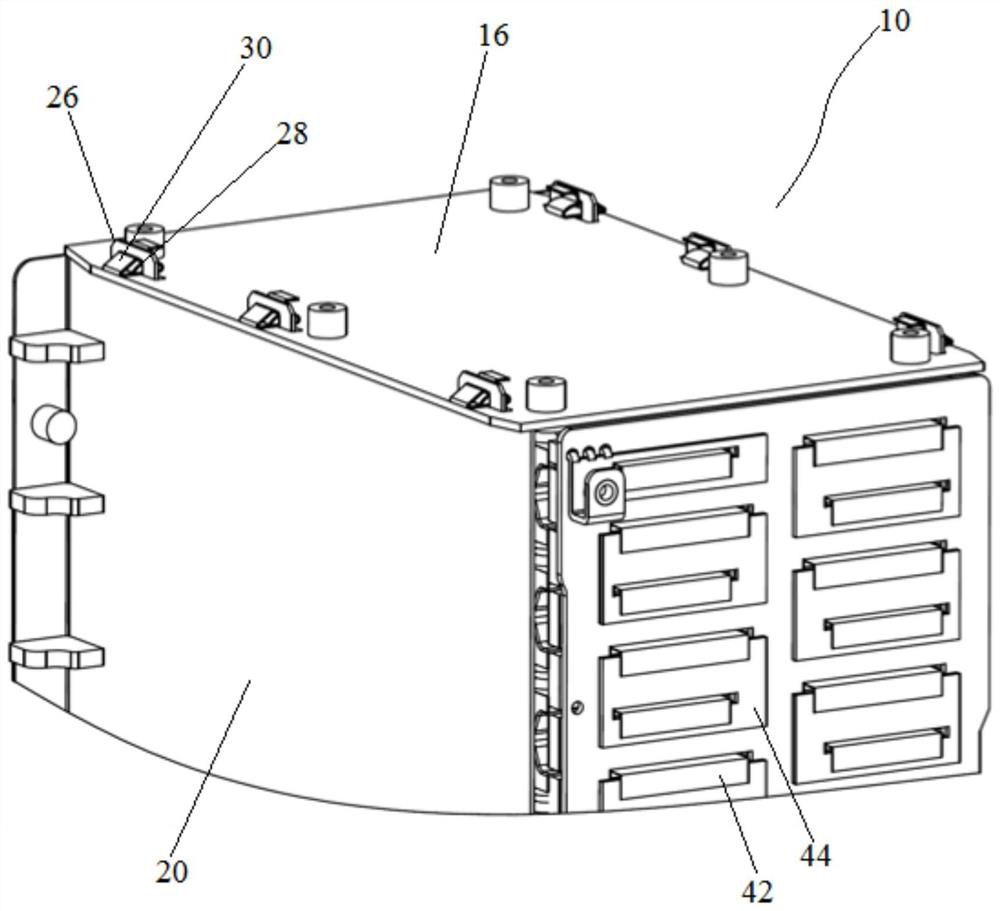

Battery pack

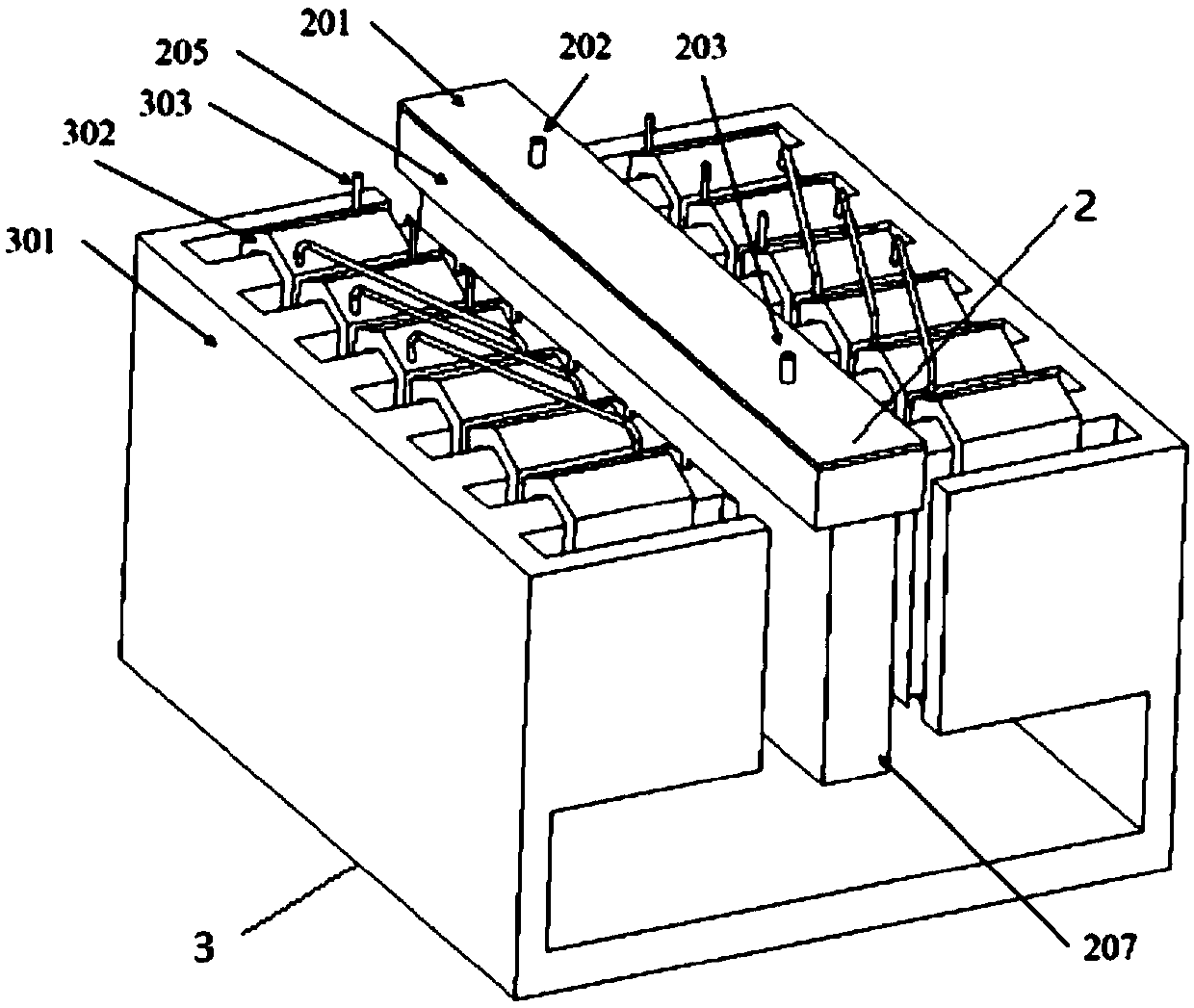

ActiveCN111106282AImprove assembly efficiencyStable and effective pressing forceFinal product manufactureSmall-sized cells cases/jacketsMechanical engineeringBattery cell

The invention relates to a battery pack, which comprises a box body assembly, which is divided into a plurality of accommodating cavities by a plurality of fixed beams; a plurality of battery modules,which are arranged in the accommodating cavities respectively; a plurality of restraining parts, wherein a limiting part of each restraining part covers the battery module, a first mounting part anda second mounting part are connected to the two sides of the limiting part and are fixed to the fixed beams at the two sides respectively, and first mounting part and the second mounting part are respectively provided with a plurality of first mounting holes and a plurality of second mounting holes at intervals along the length direction of the fixed beam; a plurality of first fasteners, which penetrate through the corresponding first mounting holes and are fixed to the fixed beams corresponding to the first mounting part; and a plurality of second fasteners, which penetrate through the corresponding second mounting holes and are fixed to the fixed beams corresponding to the second mounting part. According to the battery pack, the matching error between the restraining parts and the fixedbeams can be allowed, and the assembly efficiency is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

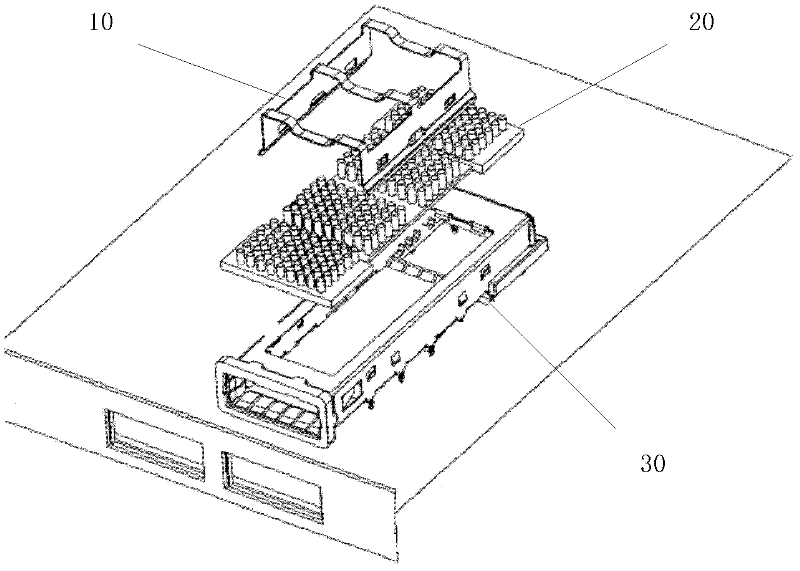

Heat radiation device of multiple XFP (10 Gigabit Small Form Factor Pluggable) optimal modules on single board of communication equipment

InactiveCN102448277AEfficient deliverySolve assembly difficultiesCoupling light guidesCooling/ventilation/heating modificationsOptical ModuleSmall form factor

The invention discloses a heat radiation device of multiple XFP (10 Gigabit Small Form Factor Pluggable) optimal modules on a single board of communication equipment. The heat radiation device comprises a heat radiator body and flaky heat radiation boards which are arranged in one-to-one correspondence to a plurality of shielding cages for plug-in mounting of the XFP optical modules, wherein the flaky heat radiation boards are arranged below the heat radiator body, and one side edge of each flaky heat radiation board is respectively connected with the heat radiator body respectively through arc-shaped flexible heat conduction fins. According to the invention, because the flaky heat radiation boards arranged in one-to-one correspondence to the plurality of XFP optical modules are respectively connected with the heat radiator body through the arc-shaped flexible heat conduction fins, structure design and assembly difficulties that the plurality of XFP optical modules share the heat radiator are effectively solved by utilizing high heat conduction performance and better flexibility and bendability of the arc-shaped flexible heat conduction fins, therefore the purpose that heat generated by each XFP optical module can be effectively transferred to the heat radiator from optical module shells and is then discharged to the environment under the action of cold air through the heat radiator is ensured.

Owner:FENGHUO COMM SCI & TECH CO LTD

Wavy fin type heat exchanger and manufacturing method thereof

InactiveCN106247821AElimination of finless areasImprove heat transfer effectStationary conduit assembliesHeat exhanger sealing arrangementPulp and paper industryUltimate tensile strength

The invention discloses a heat exchanger and a manufacturing method thereof. The heat exchanger comprises a plurality of flat tubes, a plurality of groups of fins, and at least two liquid collection cavities, wherein the flat tubes and the fins are sequentially arranged at intervals; the flat tubes and the fins are bonded through a first adhesive layer; a plurality of sequentially arranged slot holes are formed in the side walls of the liquid collection cavities; the two ends of the flat tubes are inserted into the corresponding slot holes; the end parts of the flat tubes and the slot holes are bonded and sealed through a second adhesive layer; or the liquid collection cavities are formed through stacking the ends of the flat tubes; and the ends of every two adjacent flat tubes are bonded and sealed through the second adhesive layer. According to the heat exchanger, a stable and firm bonding effect is achieved between the flat tubes and the fins, and between the flat tubes and the liquid collection cavities, the sealing strength between the flat tubes and the liquid collection cavities is fully guaranteed, and the heat exchange performance of the heat exchanger can be greatly improved.

Owner:谢彦君

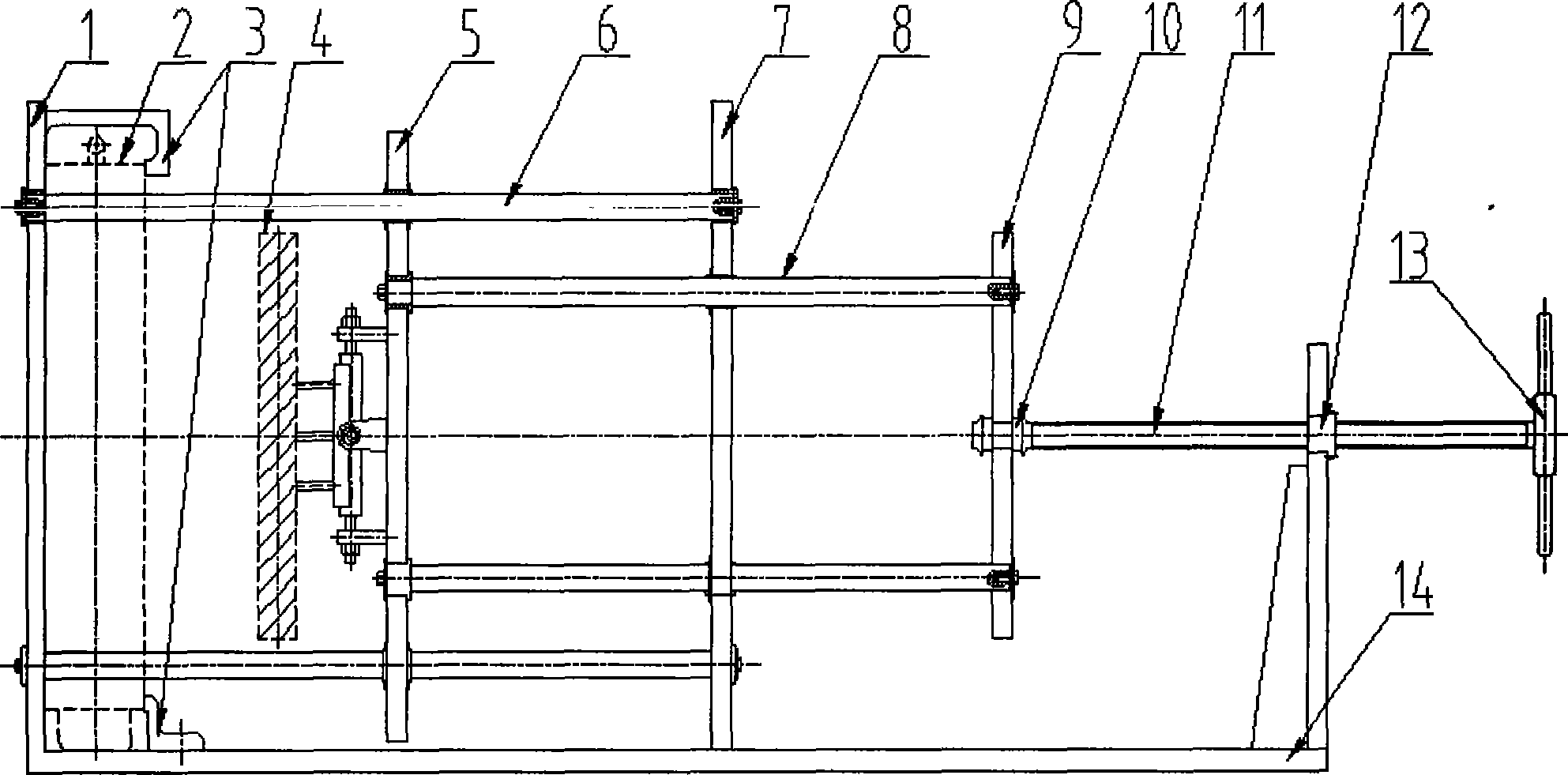

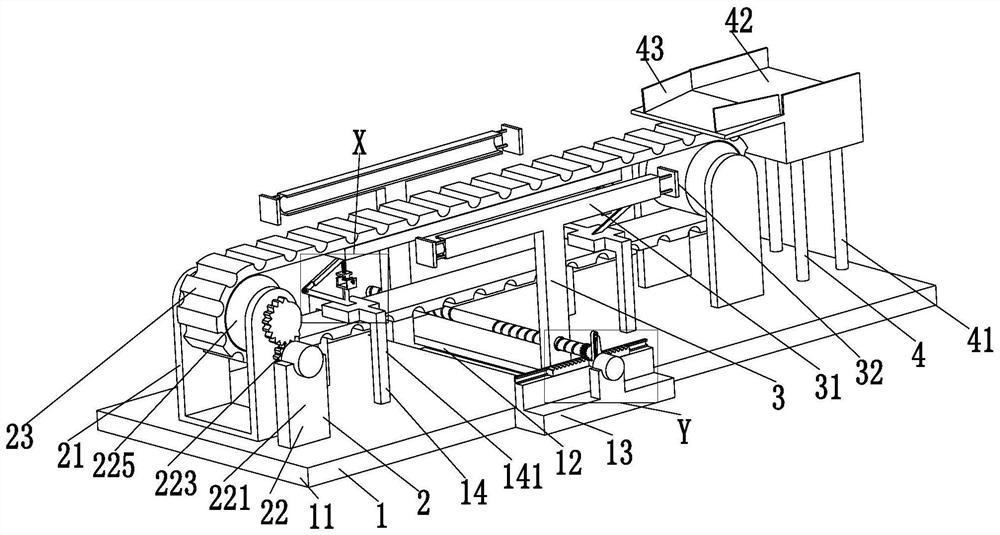

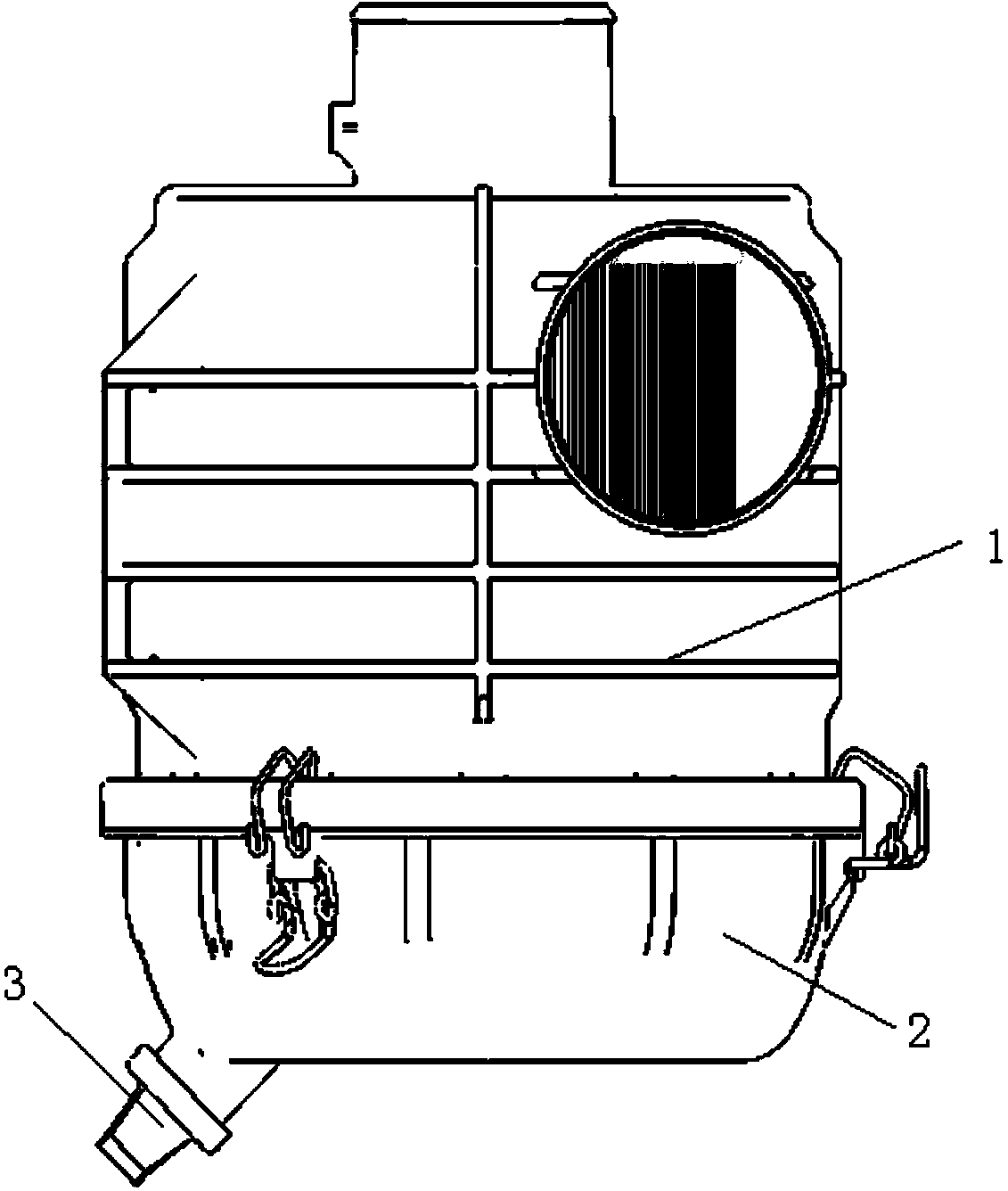

Alignment assembly machine and alignment assembly process for manufacturing pipe truss steel structure

InactiveCN111644783ASolve assembly difficultiesEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingIndustrial engineering

The invention relates to an alignment assembly machine and alignment assembly process for manufacturing pipe truss steel structure. The pipe truss steel structure manufacturing alignment assembly machine comprises a fixed base, a conveying device, pushing frames and a feeding device, the conveying device is arranged in the middle of the upper portion of the fixed base, the pushing frames are symmetrically installed at the front end and the rear end of the fixed base in a sliding fit mode, and the feeding device is arranged at the right end of the fixed base. The problems that when a traditional pipe truss steel structure is manufactured, a steel structure pipe truss is generally welded in a manual welding mode, generally, a longitudinal installation pipe is locked and fixed manually, thena transverse pipe is positioned and fixed to the longitudinal installation pipe, and therefore the longitudinal installation pipe and the transverse pipe are welded together; only one transverse connecting pipe can be manually welded at a time, the positioning and fixing process of the transverse connecting pipe is tedious during welding, equidistant synchronous fixing is needed, and therefore theproductivity of the steel structure pipe truss is low.

Owner:熊美俊

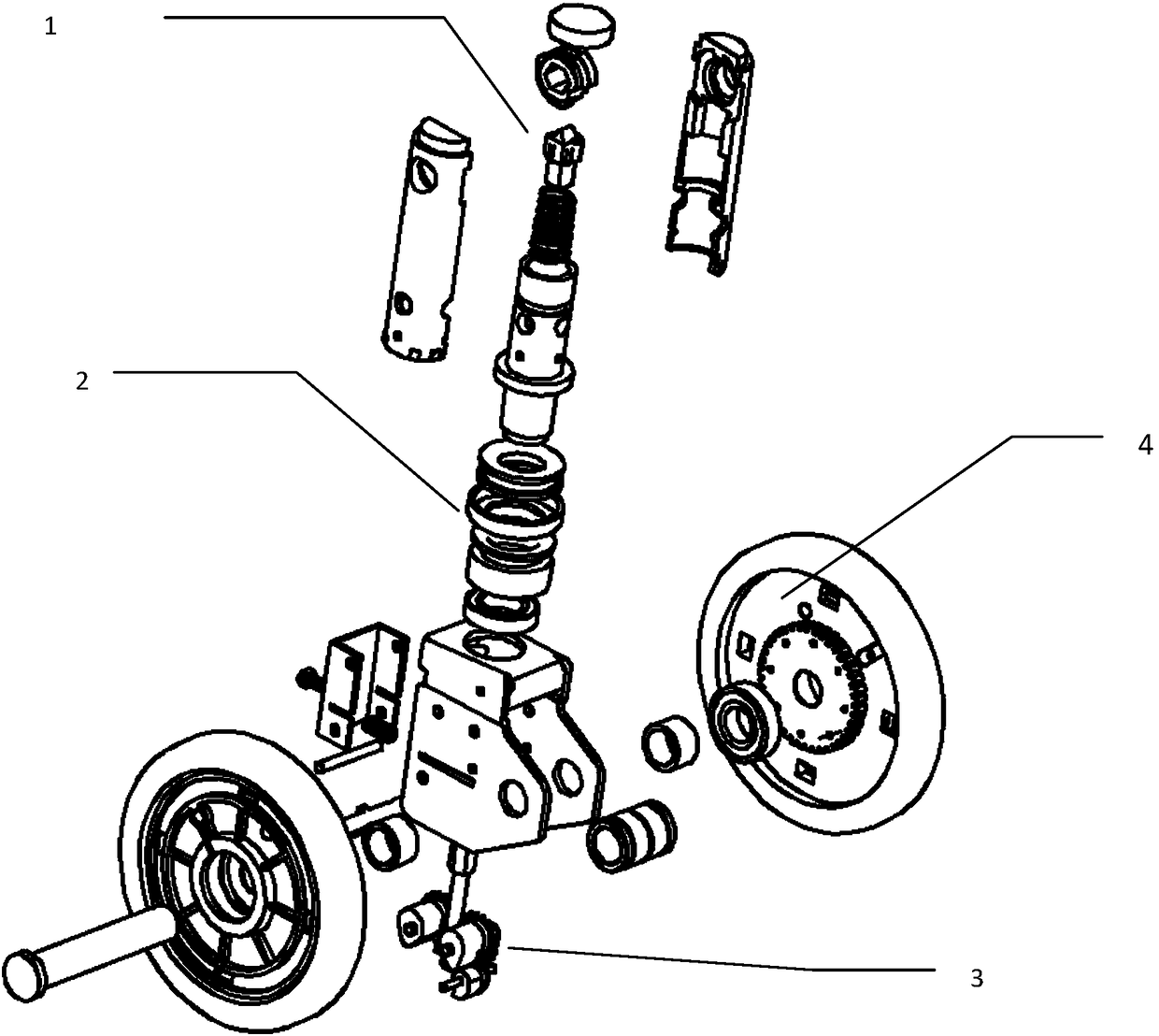

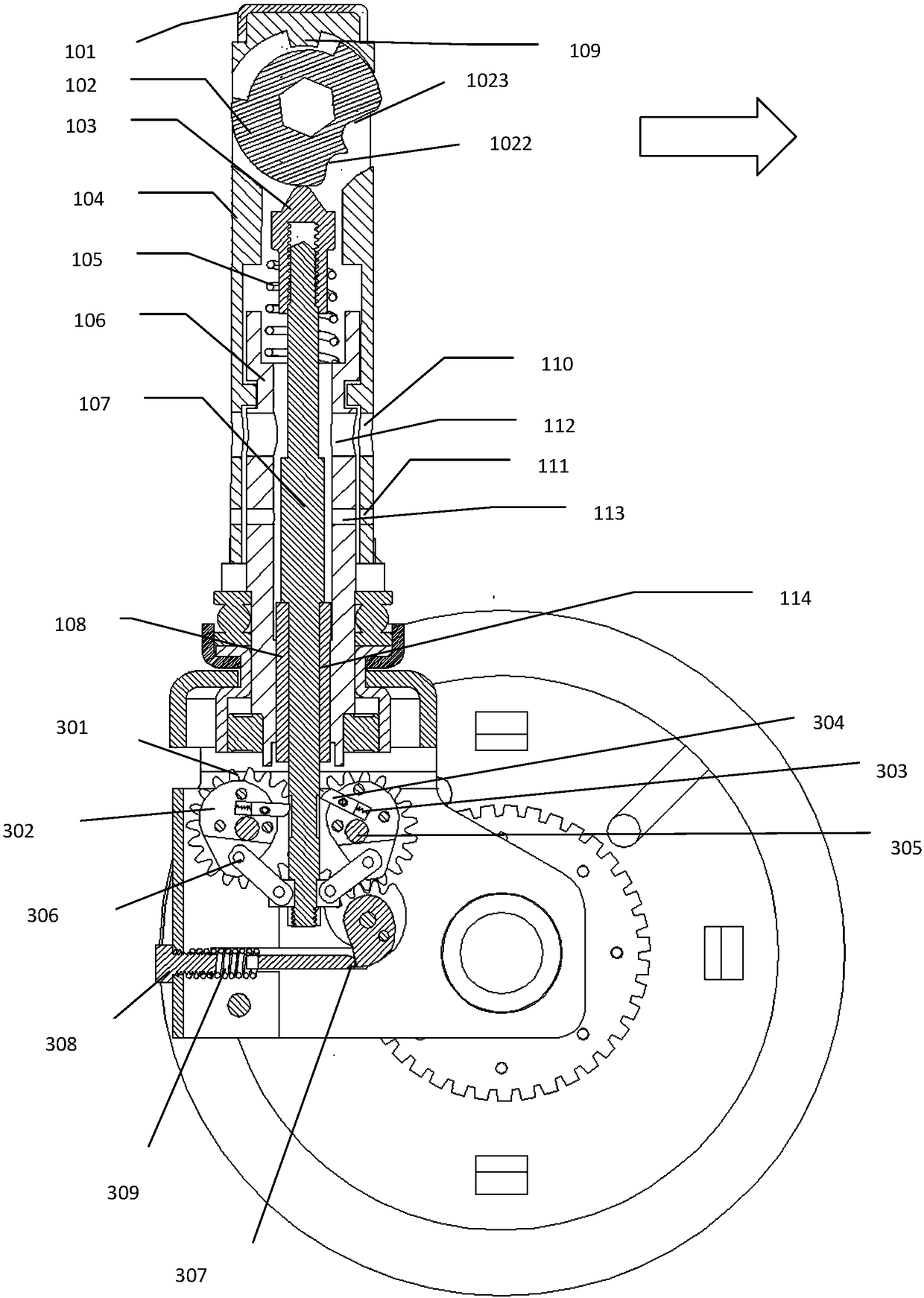

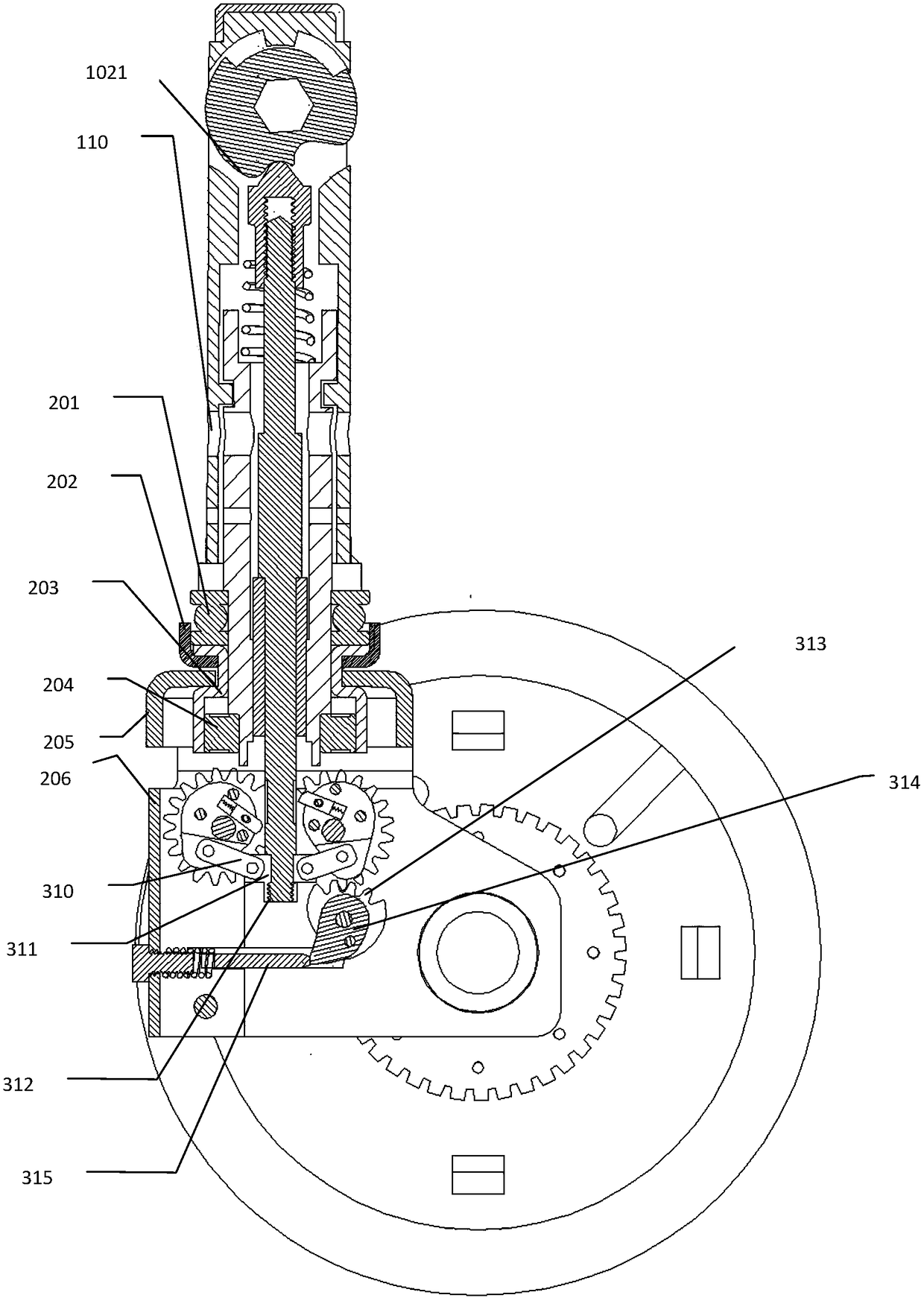

Connecting rod type central control caster control system

PendingCN108099497AEasy to turn and adjustAddressing Structural ComplexityCastorsNursing bedsBall bearingControl system

The invention provides a connecting rod type central control caster control system. The system comprises a linkage device, a rotating body, a clamping set and an execution set; the linkage device comprises a hexagonal head, a cam, a hexagonal rod, a hexagonal sleeve, a mounting shaft, a left bushing, a right bushing and a bushing cover. The rotating body comprises a ball bearing, a ball bearing sleeve, a main shaft bearing, a main shaft bearing sleeve and a support; the clamping set is of a symmetric structure and comprises a fluted disc, a rotating block, telescopic blocks, a spring, a connecting rod, a rotating sleeve half gear, a baffle and a brake block. When the left telescopic block is located in a symmetric groove, a caster is enabled to be in a straight advancing state; when the left telescopic block and the right telescopic block are separated from the symmetric groove, the cater is in a universal state; when the left telescopic block is located in the symmetric groove and thebrake block is clamped in the fluted disc in the caster, the caster is in a braking state. On the premise that it is guaranteed that the straight advancing state, the universal sate and the brake orientation state are quickly switched, the system is compact in structure, easy to assemble and convenient to assemble and maintain.

Owner:WUXI ZHONGGUAN LOGISTICS EQUIP +1

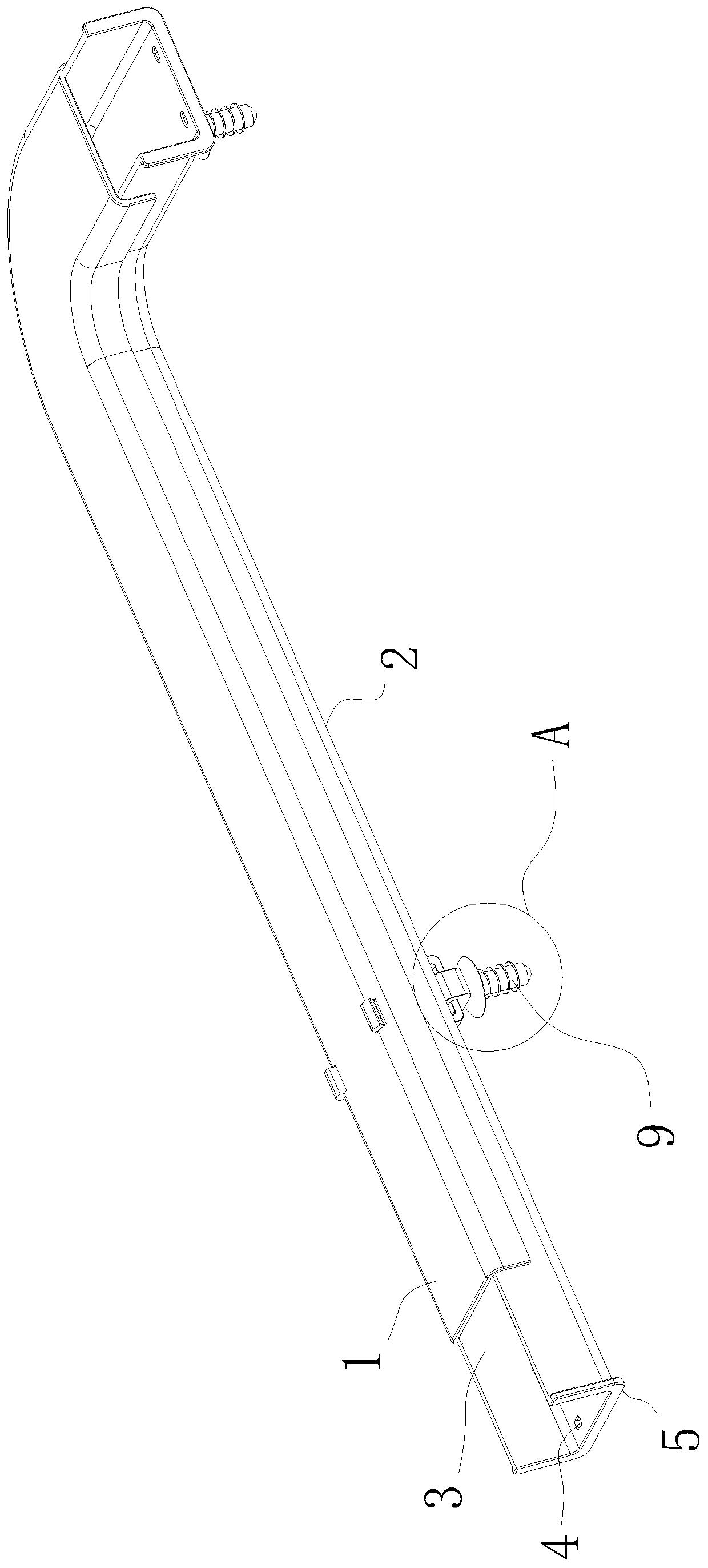

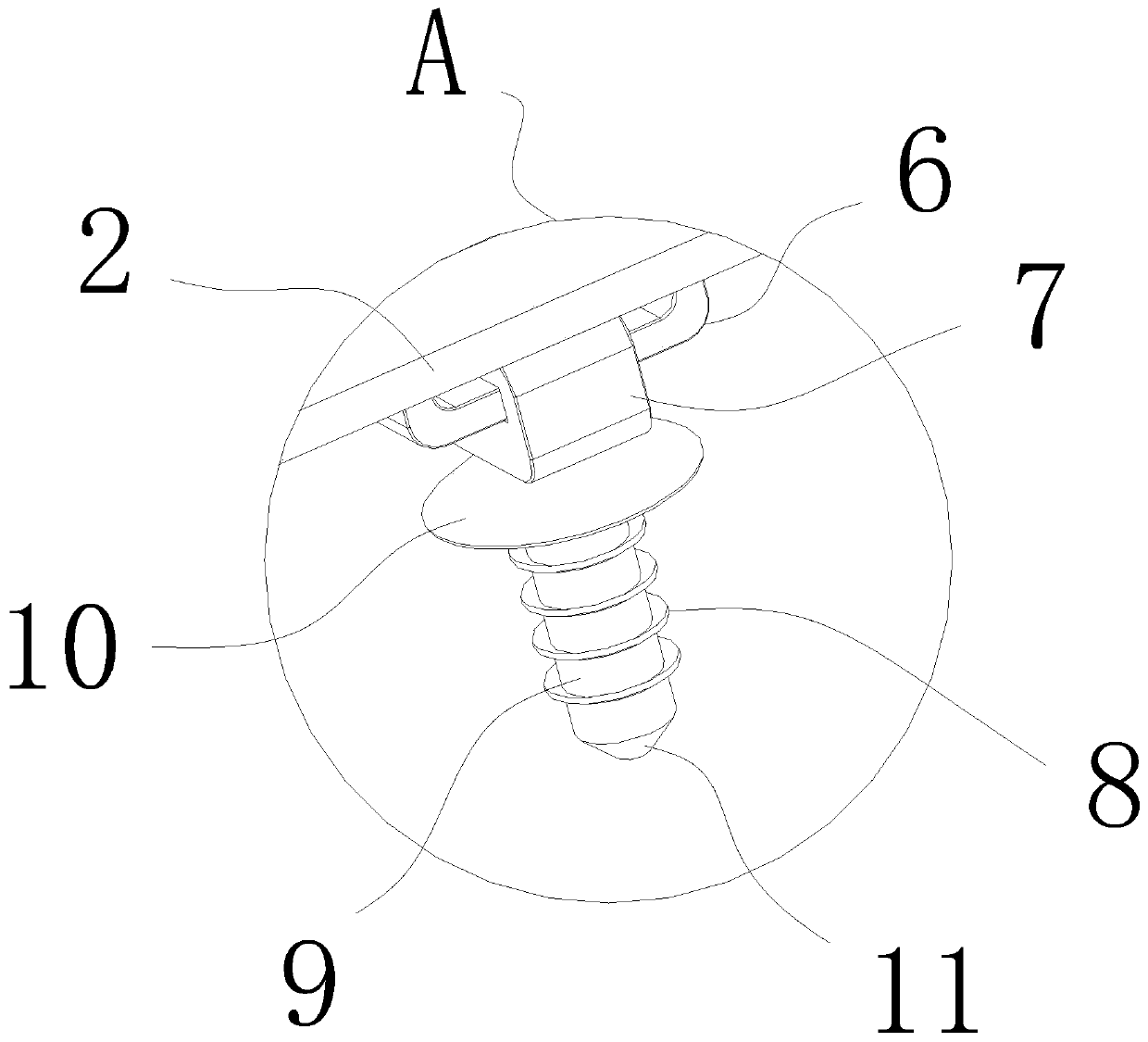

Wire harness support for mounting automobile wire harness

InactiveCN110450736ASolve assembly difficultiesReduce the risk of serious accidentsElectrical apparatusElectric/fluid circuitEngineeringMechanical engineering

The invention relates to the technical field of mounting devices for automobile wire harnesses, in particular to a wire harness support for mounting an automobile wire harness. The wire harness support comprises an upper cover, a lower cover, a threading groove, threading holes and a rapid connector. The rapid connector comprises connecting frames, a sliding portion, an elastic part, a connectingrod, spinal plates and a guide cone. The wire harness support has the beneficial effects that by means of the threading groove defined between the upper cover and the lower cover, the automobile wireharness can penetrate through the threading groove during assembly, the situation that the automobile wire harness intervenes with other parts on an automobile, so that assembly is difficult is avoided, meanwhile, the risk of serious accidents caused by the fact that the automobile wire harness is abraded by the other parts can be reduced, in addition, the rapid connector is arranged, the rapid connector is inserted into a hole in a metal plate part of the automobile through a connecting column, and the upper cover and the lower cover are rapidly mounted in the automobile.

Owner:合肥科维特电气科技有限公司

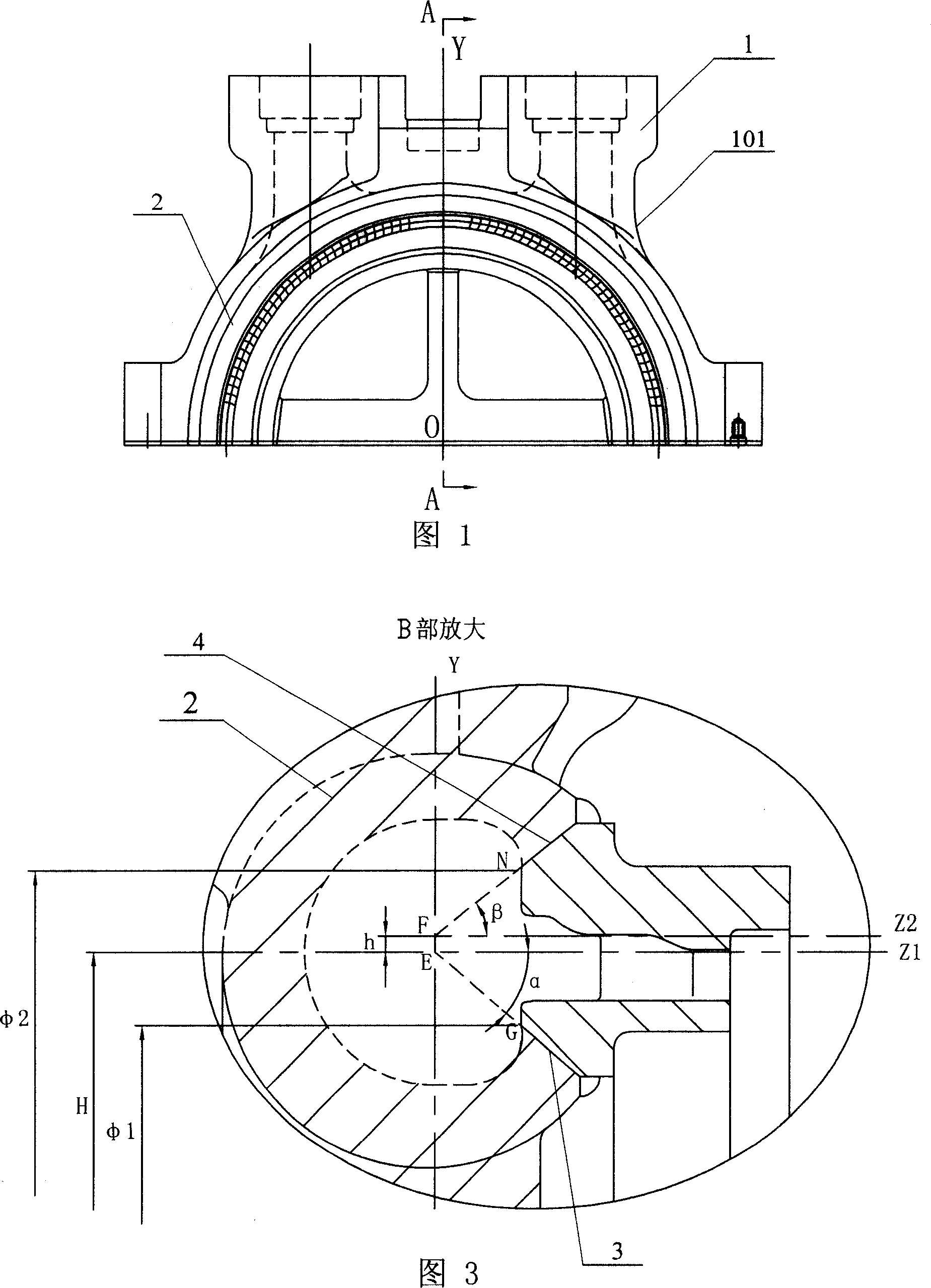

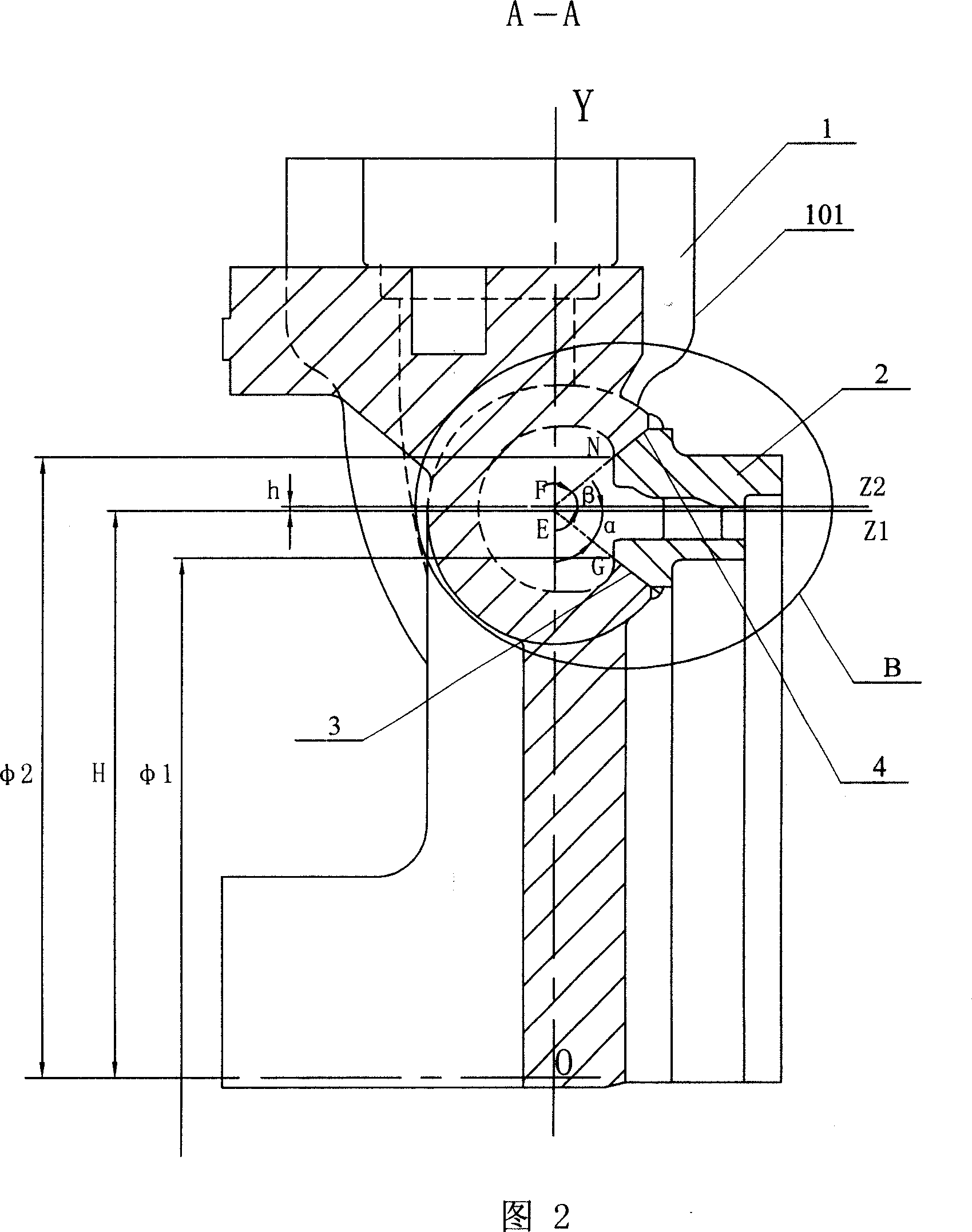

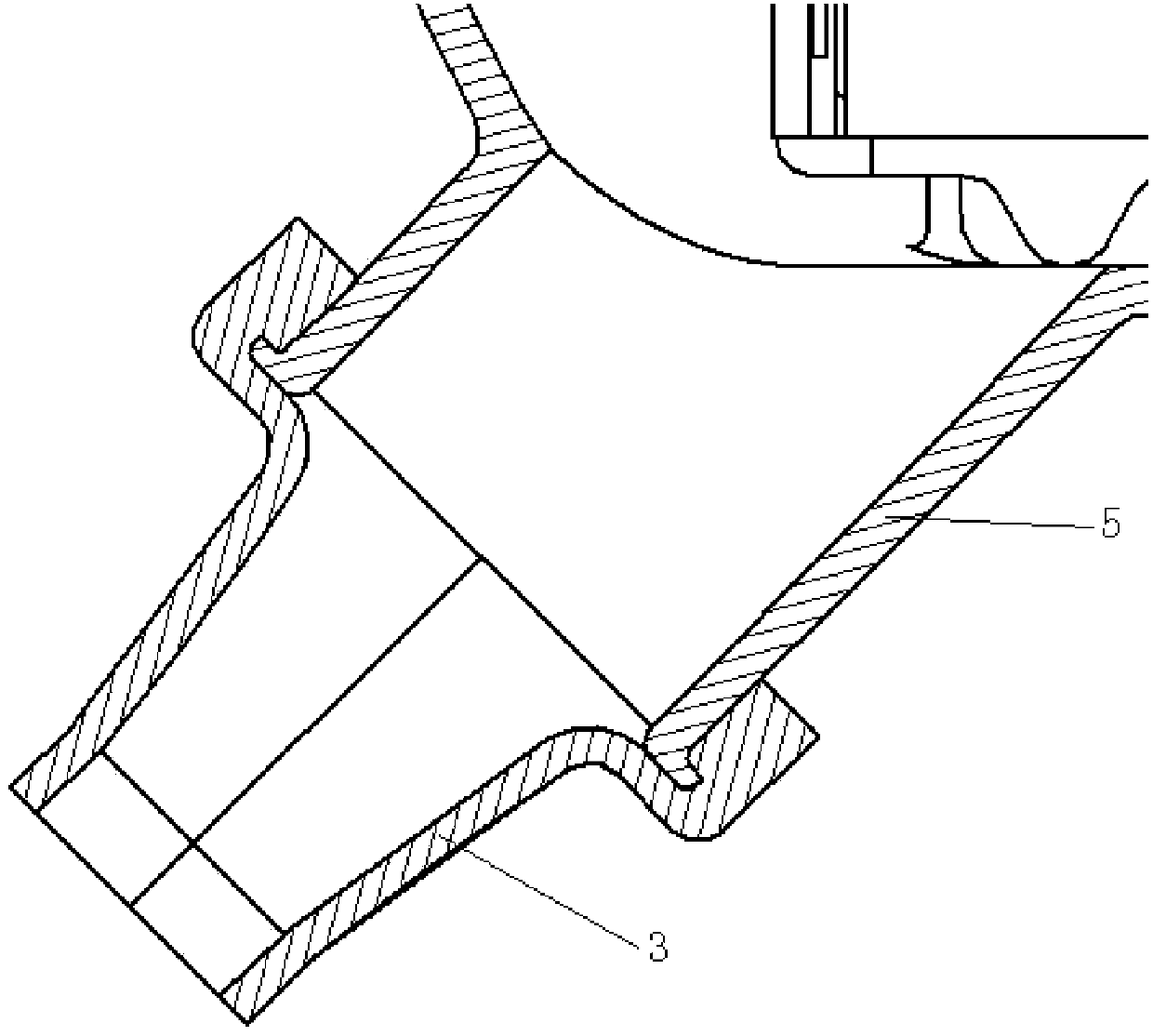

Nozzle of steam turbine with structure of groove face by using electron beam bonding

This invention relates to a seal structure of turbine nozzles, in which the prolonged lines of lower welding groove faces between a nozzle chamber and a nozzle set meet at point E of Y central axes of a nozzle and the distance H between point E to the central point O of the nozzle is 1100mm, and the included angle between the lower groove face and Z1 direction line over point E is 40deg., prolonged lines of the upper groove faces between the chamber and the set meet at point F of the Y-oriented central axes of the nozzle and F is above E, the distance between them is 5mm and the included angle between the upper groove face and the Z2 line over point F is 40deg., which finishes two seams of a nozzle at one run with electronic beams.

Owner:HARBIN TURBINE

Packaging shell and battery pack

ActiveCN111653697ASolve assembly difficultiesImprove assembly convenienceFinal product manufactureSecondary cells manufactureStructural engineeringMechanical engineering

The invention provides a packaging shell. The packaging shell comprises a first end plate and a second end plate opposite to the first end plate, and a first side palte and a second side plate arranged opposite to the first side plate. The first side plate and the second side plate are arranged between the first end plate and the second end plate. A first through hole is formed in the first end plate, and a convex body penetrating through the first through hole is arranged on the first side plate. The packaging shell further comprises a fixing piece, and the fixing piece detachably fixes the first end plate and the first side plate or the second side plate. The invention also provides a battery pack. The invention aims to at least solve the problem of difficult assembly of the soft packagelithium battery module under the condition of narrow assembly space so as to improve the assembly convenience of the soft package lithium battery module.

Owner:DONGGUAN POWERAMP TECH LTD

Novel double-side linear synchronous motor employing high-temperature superconducting stacked magnet

ActiveCN109639092ASimplify the magnetization processSolve assembly difficultiesPropulsion systemsSuperconductor elements usageSynchronous motorHigh temperature superconducting

The invention discloses a novel double-side linear synchronous motor employing a high-temperature superconducting stacked magnet. The motor comprises a plurality of high-temperature superconducting strip stacked structures serving as a secondary side, a cooling system and a double-side opposite primary unit. The high-temperature superconducting strip stacked structures are blocky structures formedby stacking, packaging or hot melting of a plurality of superconducting strip sheet bodies. The cooling system comprises a low-temperature container filled with cooling liquid, and a plurality of mounting grooves are formed in the left side wall and the right side wall of the low-temperature container. The high-temperature superconducting strip stacked structures are embedded in the mounting grooves. The bilateral opposed primary unit comprises a bilateral iron core and a copper winding. A plurality of stator teeth are arranged on the inner sides of the left side plate and the right side plate. The copper windings are wound on the stator teeth in an integral pitch arrangement manner. The cooling system is arranged in an air gap of the double-side iron core, and each high-temperature superconducting strip stacked structure is right opposite to the stator teeth at the same side. The motor is high in thrust density, low in electric energy loss, high in loading capacity, high in operationspeed and convenient to magnetize.

Owner:SOUTHWEST JIAOTONG UNIV

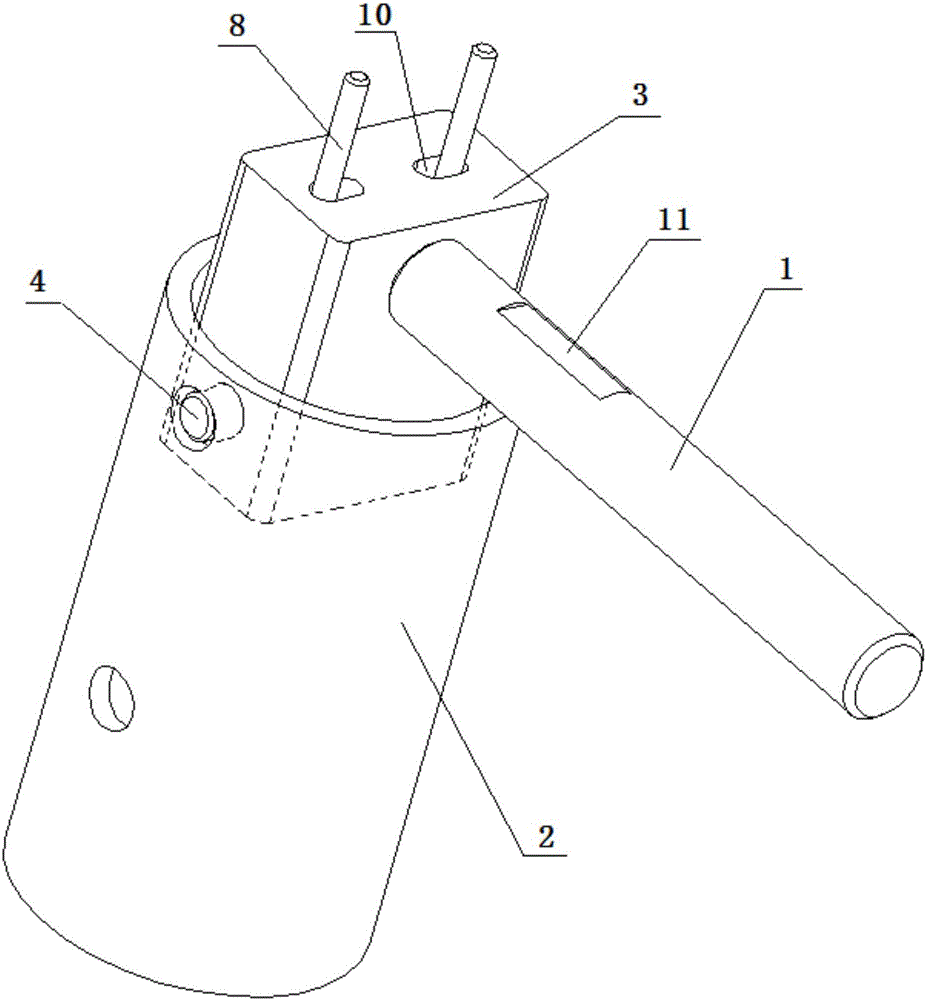

A positioning pin assembly tooling

The invention provides a locating pin assembly tool. The locating pin assembly tool comprises a tool body, a guide hole vertically extending from the upper end face towards the lower vertical face is formed in the tool body, a spiral jacking mechanism is assembled in the guide hole, the lower end of the spiral jacking mechanism is provided with an ejector pin used for jacking a locating pin, a guiding structure used for preventing the locating pin from deflecting and guiding the locating pin when the ejector pin jacks the locating pin is arranged at the lower end of the tool body, and a locating and supporting mechanism used for locating and supporting a workpiece is arranged at the lower end of the tool body. When the locating pin assembly tool is used, a locating hole in the workpiece is aligned to the locating pin, and the ejector pin can be driven to enable the locating pin to be pressed into the workpiece by simply rotating a screw. By the adoption of the locating pin assembly tool, the problem that assembly is difficult when the workpiece is suspended or the assembly space is narrow is solved, and the labor efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

Lubricating liquid for tire assembly

InactiveCN102911776ASolve the hardnessSolve assembly difficultiesLubricant compositionTubeless tirePolyethylene glycol

The invention relates to a type of lubricating liquid, in particular to a type of lubricating liquid for tire assembly, wherein the lubricating liquid for tire assembly is suitable for the assembly of tubeless tire. The lubricating liquid is characterized by comprising the following components according to weight percentage: 79-80% of a mixture consisting of linoleic acid, linoleic acid, polyethylene glycol, glycerol and palmitoleic acid, 0.5-3% of fatty glyceride, 1-3% of sodium laurylsulfate, 3-8% of thickener, 0.5-1.5% of bactericide and the balance of deionized water. The lubricating liquid provided by the invention has the characteristics of high efficiency, environment friendliness, freeness from pollution, good lubricating effect and capability of effectively solving the problems of higher hardness and difficulty for assembly in the process of assembling a tubeless radial tire.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

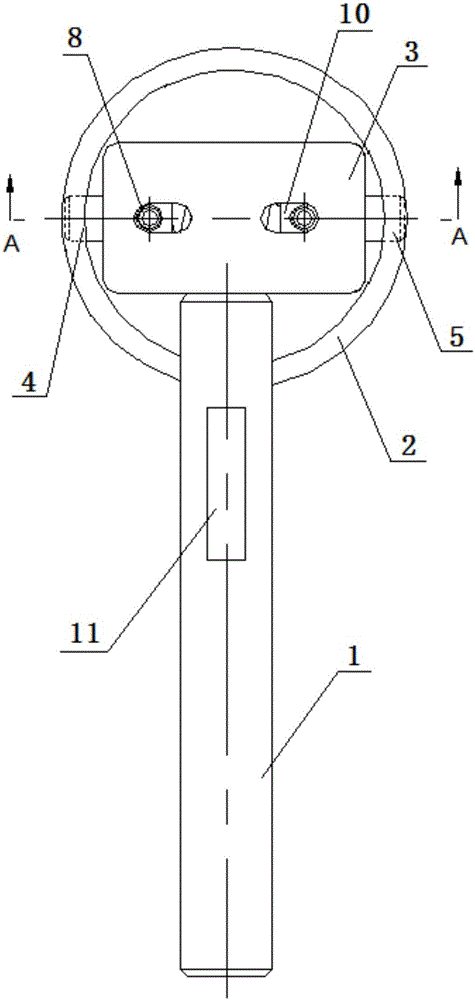

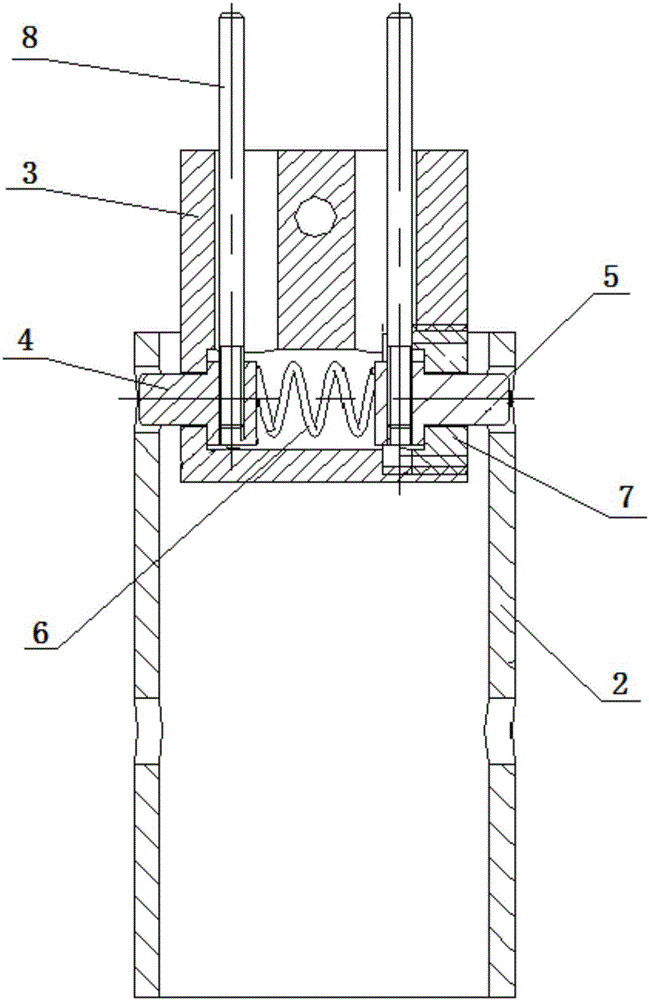

Tool for mounting ejector-body

ActiveCN106141984AEasy loadingPrecise positioningMetal-working hand toolsReciprocating motionEngineering

The invention discloses a tool for mounting an ejector-body. The tool comprises a handle, wherein a push rod seat which is movably inserted into an inner cavity of the ejector-body is arranged at one end of the handle; a first ejector block and a second ejector block which can move back and forth and are adaptive to the size of an inner hole on the side wall of the ejector-body are arranged on two sides of the push rod seat below the handle; a compression spring is arranged between the first ejector block and the second ejector block; a plug screw which jointly lock the first ejector block, the compression spring and the second ejector block is arranged on the push rod seat located on one side of the second ejector block; and push rods which are connected to the first ejector block and the second ejector block and perpendicularly protrude out of the top of the push rod seat for controlling the first ejector block and the second ejector block to move back and forth are arranged on the first ejector block and the second ejector block, respectively. The tool disclosed by the invention is simple in structure. By designing the push rod seat, which can be inserted into the inner cavity of the ejector-body, with stretchable ejector blocks, the ejector-body is quickly, simply and conveniently mounted by locating by virtue of the ejector blocks and the inner hole on the side of the ejector-body.

Owner:GUANGXI YUCHAI MASCH CO LTD

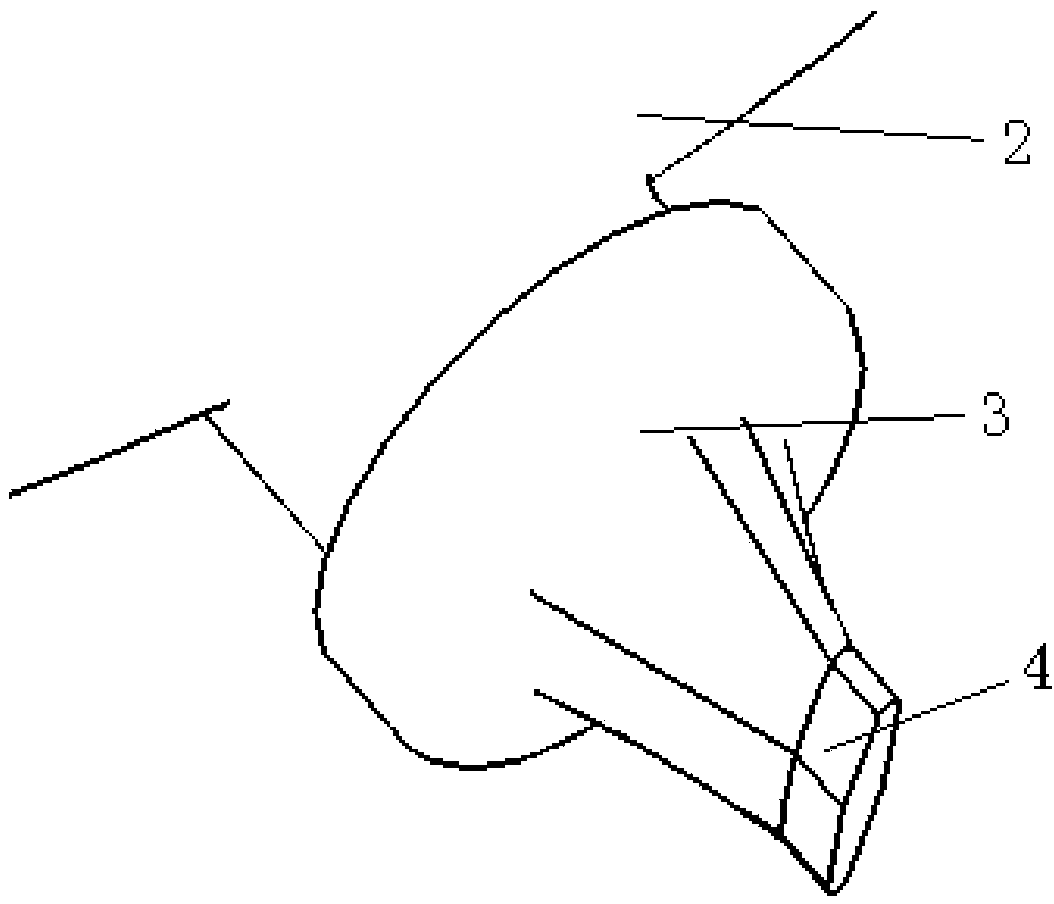

Automotive dust discharge valve

ActiveCN103775261AAvoid pitfalls in layoutAvoid interferenceAir cleaners for fuelEngineeringCircular disc

The invention relates to an automotive dust discharge valve. The automotive dust discharge valve comprises a valve core and a valve body, wherein the valve body is formed by a disk and a circle of bosses below the disk, the valve core is formed by a valve rod and a cambered surface structure connected with the valve rod, the valve rod is arranged at the center of the cambered surface structure, the valve rod is formed by an upper cylinder, a lower cylinder and a middle circular cone, the diameter of the upper cylinder is less than the diameter of the lower cylinder, and a circle of grooves are formed in the lower cylinder. The automotive dust discharge valve prevents defects generated when an air filter is arranged, and is prevented from protruding out of a housing of the air filter by forming a dust discharge valve interface in the lower end of the air filter, and therefore the problem that an interval between the dust discharge valve and each surrounding part is undersized or the dust discharge valve interferes with the surrounding parts is prevented.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com