Alignment assembly machine and alignment assembly process for manufacturing pipe truss steel structure

A technology for assembling machinery and steel structures, applied in manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of low productivity of steel structure pipe trusses, cumbersome positioning and fixing process of horizontal connecting pipes, etc., to save manpower and material resources and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

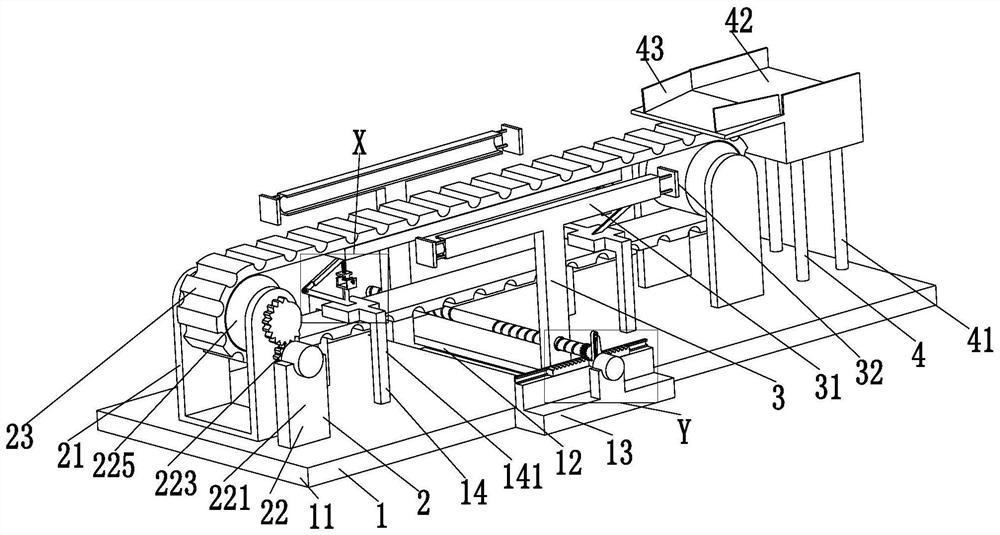

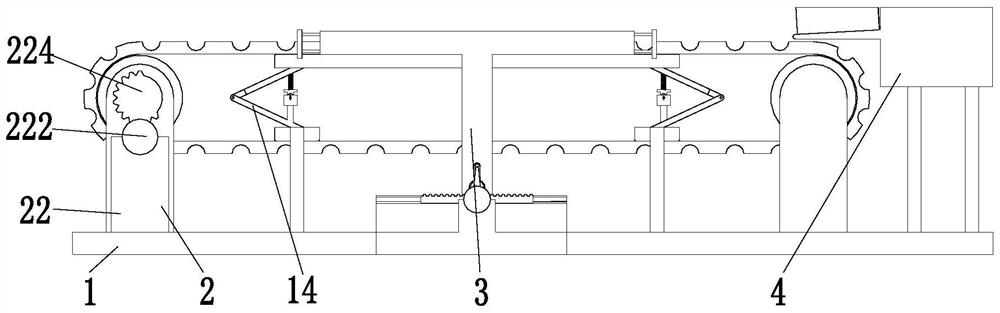

[0036] Such as Figure 1 to Figure 5 As shown, a pipe fitting truss steel structure production alignment assembly machine, including a fixed base 1, a transmission device 2, a propulsion frame 3, and a feeding device 4, the upper middle of the fixed base 1 is provided with a transmission device 2, and the fixed base The front and rear ends of 1 are symmetrically installed with a propulsion frame 3 by means of sliding fit, and the right end of the fixed base 1 is provided with a feeding device 4 .

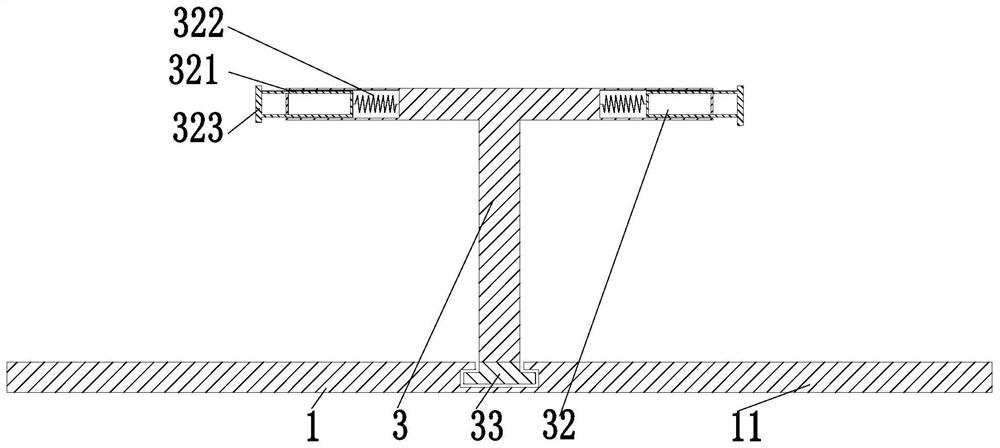

[0037] The fixed base 1 includes a fixed base plate 11, a sliding groove 12, a propulsion mechanism 13, and a support mechanism 14. The middle part of the fixed base plate 11 is provided with a sliding groove 12, and the middle part of the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com