Tool for mounting ejector-body

A technology of cylinders and tools, which is applied in the field of tools for installing tappets, and can solve problems such as difficulty in installing tappets into the installation holes of cylinder blocks, easy slipping of tappets and tappets, troubles in installing tappets, etc. Achieve the effects of eliminating hidden dangers in production safety, solving assembly difficulties, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

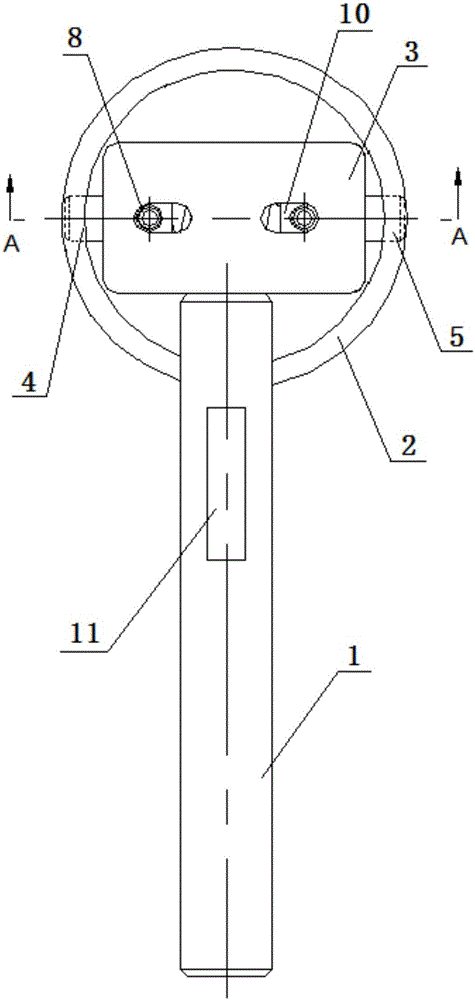

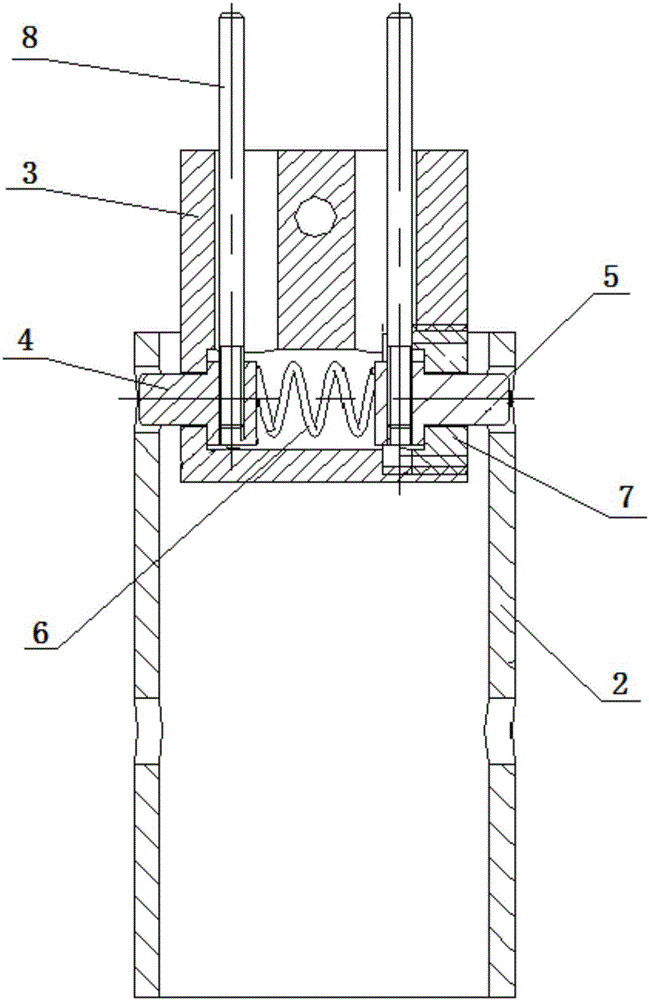

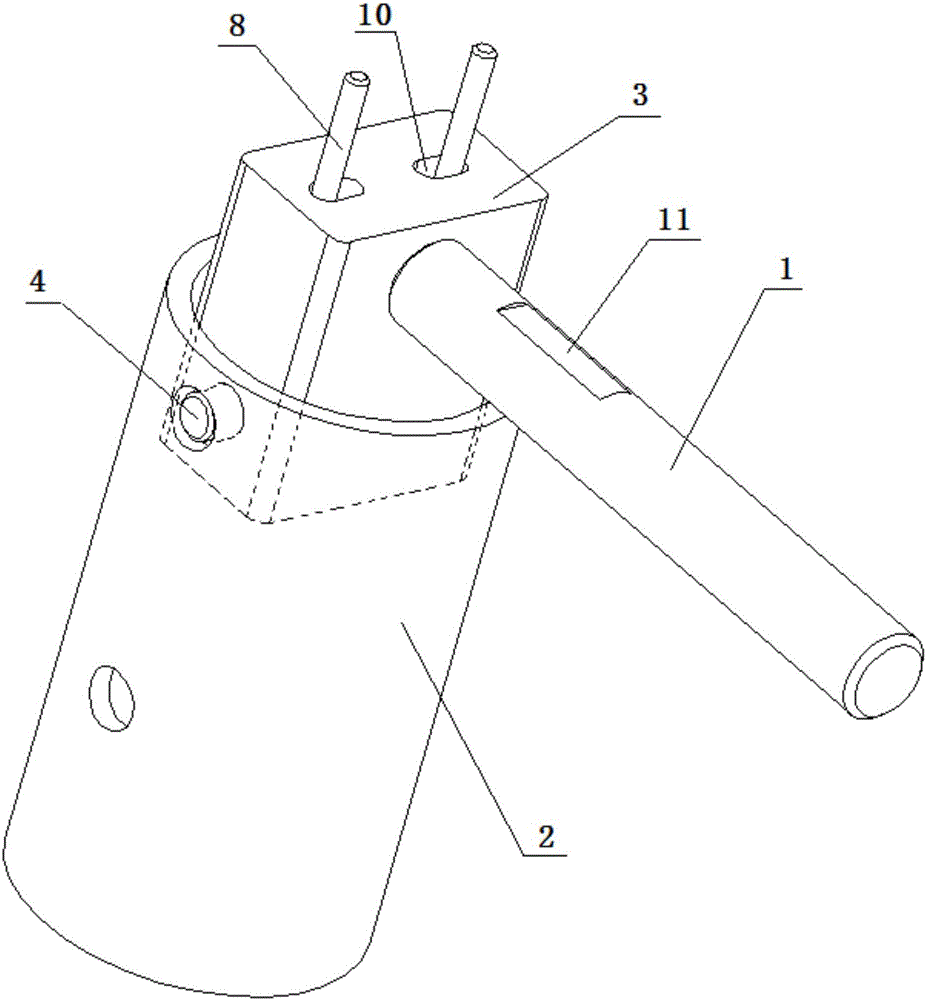

[0020] refer to Figure 1-5 , a tool for installing a tappet body of the present invention includes a handle 1, and one end of the handle 1 is provided with a push rod seat 3 that can be movably inserted into the inner cavity of the tappet body 2, and the handle 1 is perpendicular to the push rod seat 3 , the end of the handle 1 connected with the push rod base 3 is provided with an external thread, and at the same time, a screw hole matching the external thread on the handle 1 is provided on the push rod base 3, and the handle 1 can be fixed by threaded connection On the push rod base 3, it is convenient to assemble the handle 1 and the push rod base 3, and a groove 11 for taking the handle 1 is provided on the side of the handle 1 close to the push rod base 3, which is convenient for workers to operate; Both sides of the push rod seat 3 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com