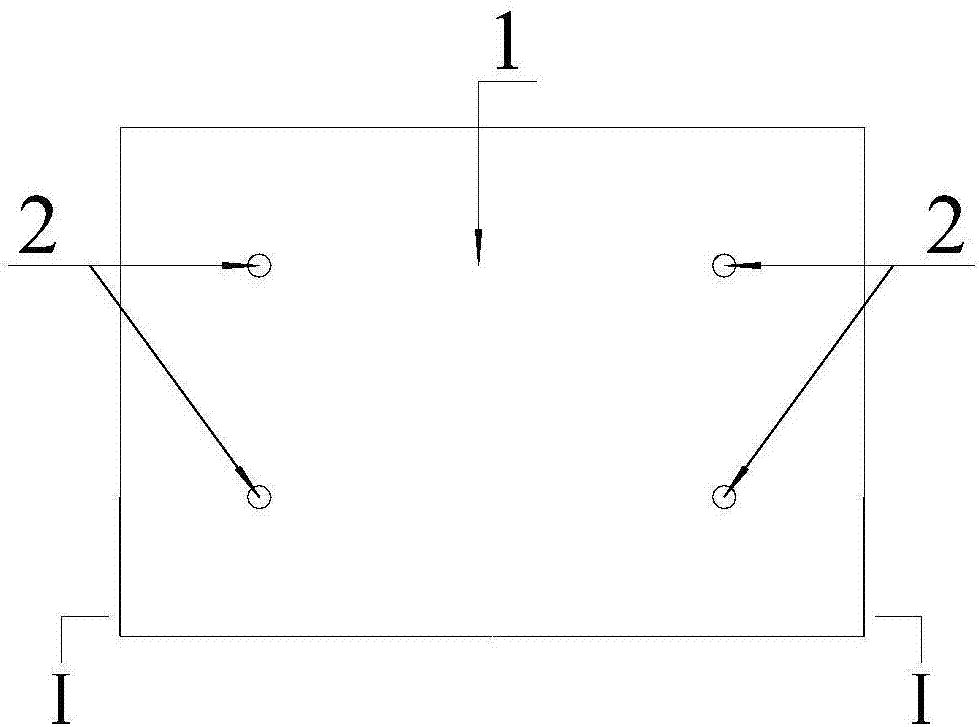

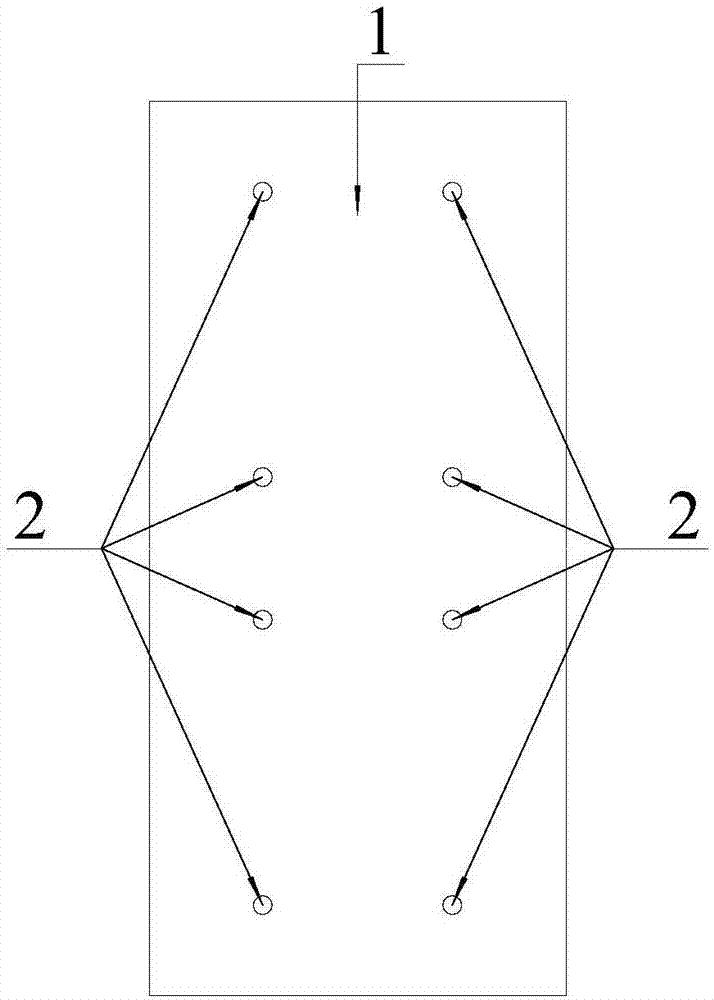

Eddy-current damping device utilizing lever principle

A vibration damping device, lever principle technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotation vibration suppression, etc., can solve problems such as large structural vibration, achieve large adjustability, prolong service life, and avoid assembly difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

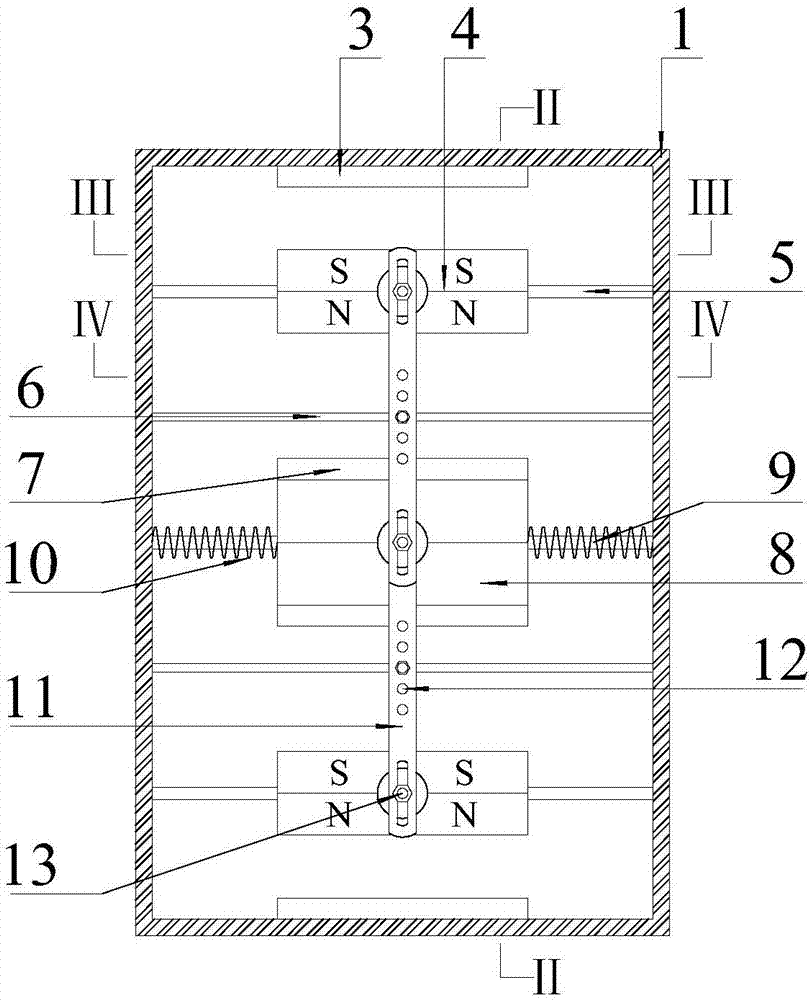

[0031] For the convenience of those skilled in the art to understand accurately, the present invention will be further described in detail below in conjunction with the accompanying drawings, and the content mentioned in the embodiments does not limit the present invention.

[0032] The eddy current damper is an energy dissipation vibration reduction device made of the damping effect of the eddy current. It has the advantages of simple structure and good durability. At present, it is mainly used as the damping element of the tuned mass damper in the vibration of civil engineering structures. control field. In addition, the lever device is simple and easy to operate. By adjusting the length of the force arm at both ends of the lever, the TMD parameters can be adjusted by borrowing the mass of the permanent magnet; and the two sides of the lever have obvious relative motion, which can increase the relative motion between the permanent magnet and the copper plate. speed, effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com