Back light module and manufacture method thereof

A technology for a backlight module and a manufacturing method is applied to the backlight module and its manufacturing field where assembly and rework are more convenient. Difficulty, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

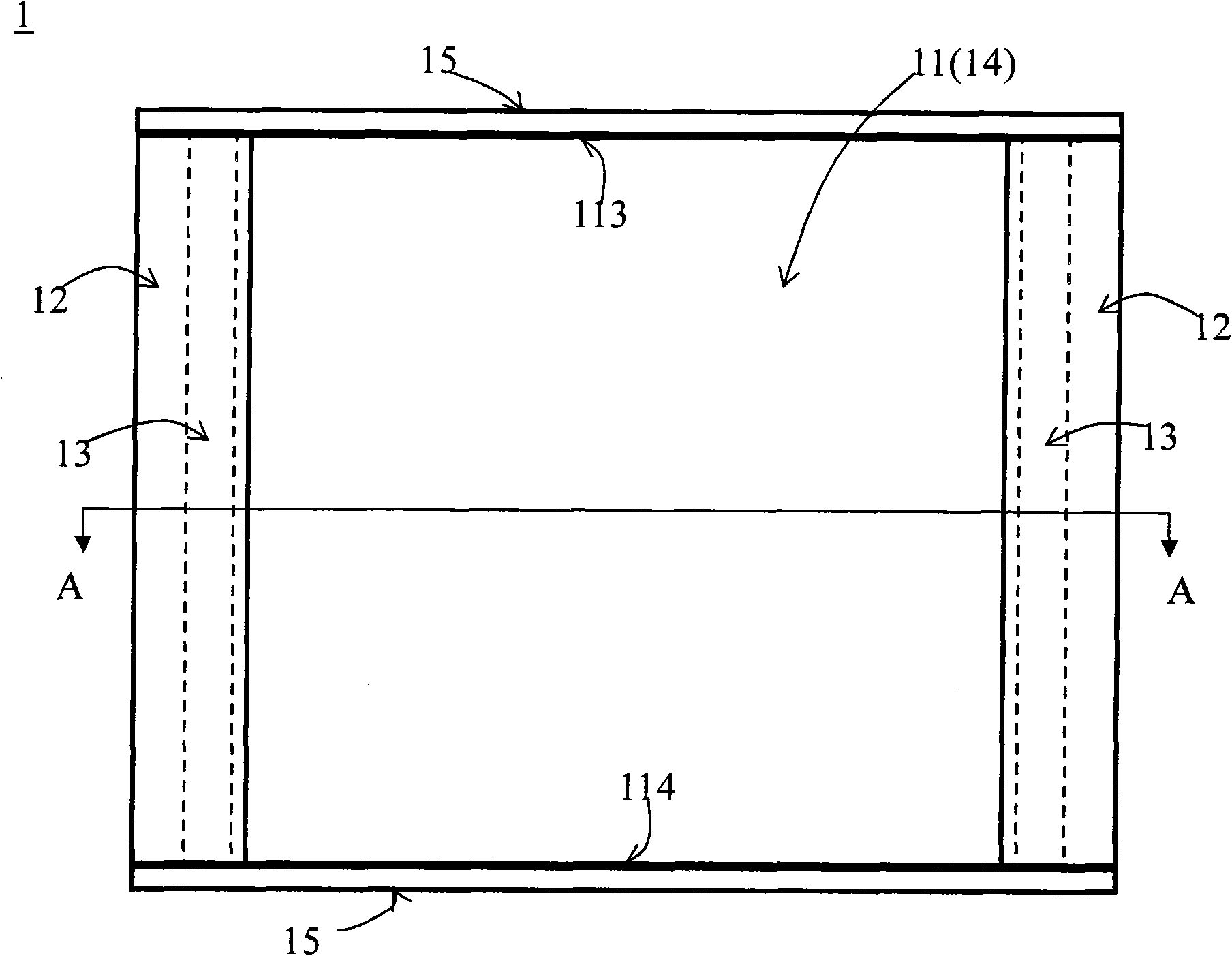

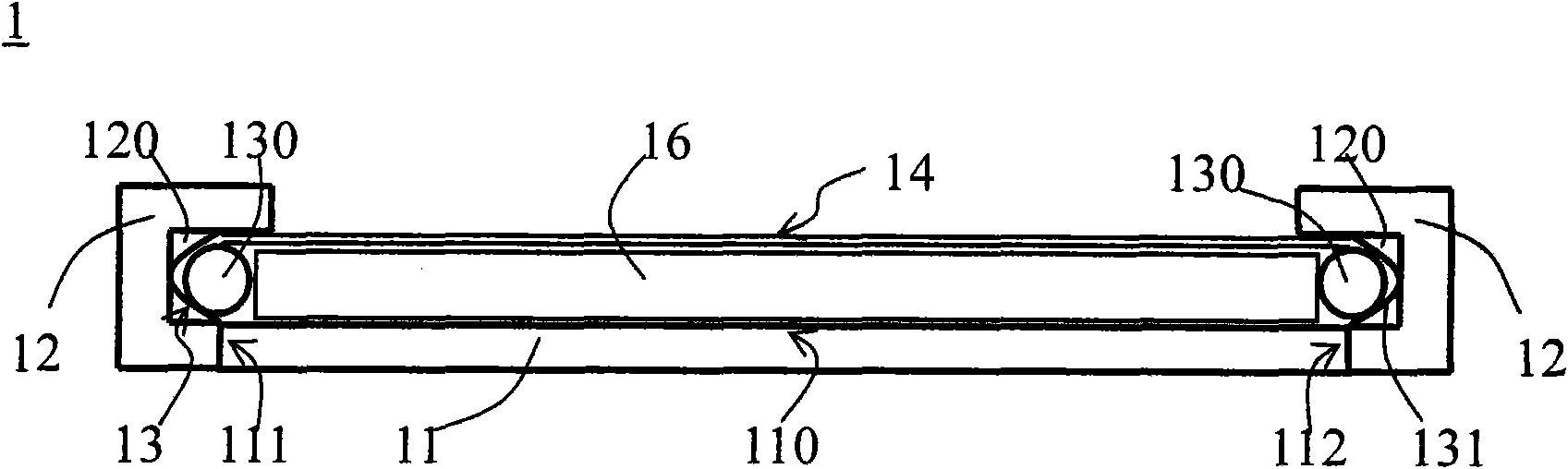

[0024] See Figure 1A with Figure 1B , Figure 1A It is a schematic diagram of a backlight module 1 according to an embodiment of the present invention, Figure 1B for Figure 1A Schematic diagram of the A-A cross-section. The backlight module 1 includes a backplane 11 , a first frame 12 , a light source 13 , an optical film 14 and a second frame 15 . The backboard 11 has a first side 111, a second side 112, a third side 113, a fourth side 114 and a first surface 110, the first side 111 is opposite to the second side 112, and the third side 113 is opposite to the fourth side 114 , and the first surface 110 is located between the first side 111 , the second side 112 , the third side 113 and the fourth side 114 . In one embodiment, the back plate 11 is a metal plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com