Assembly device and application method for disk type motor

A technology for assembling devices and disc motors, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as assembly difficulties and disc motor assembly difficulties, reduce manual operations, solve assembly difficulties, and overcome axis The effect of magnetic pull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

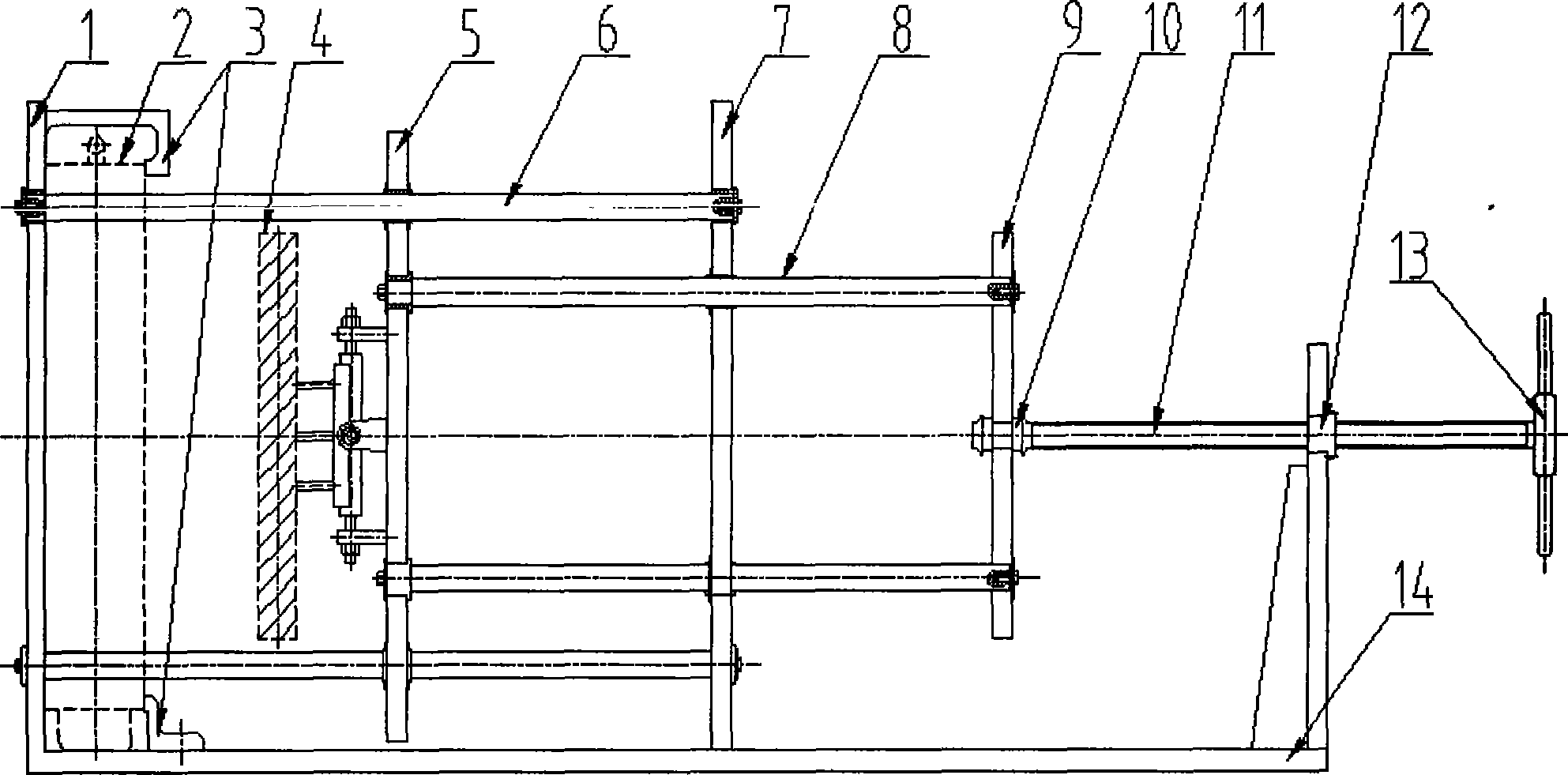

[0014] Further describe content of the present invention below in conjunction with accompanying drawing:

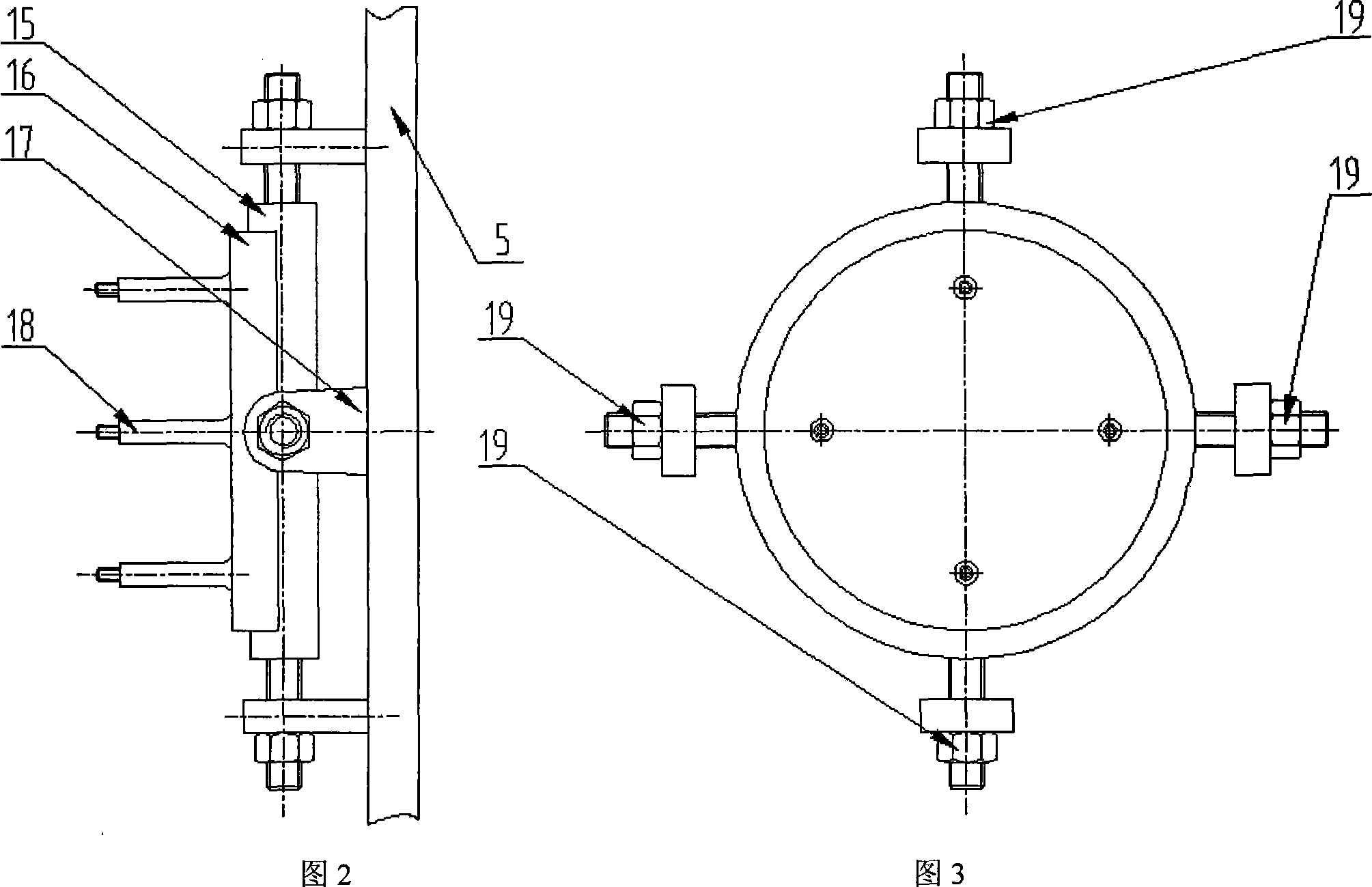

[0015] The assembly device of the disc motor of the present invention is as figure 1 , shown in 2, consists of a fixed part and a feed part, one side of the side plate 1 in the fixed part and the other side where the side plate 1 is connected with the bottom plate 14 are respectively provided with a base pressing device 3, a base 2 The same side plate 1 and the bottom plate 14 are fixed by the base pressing device 3 . A guide rail 6 is arranged between the side plate 1 and the support plate 7, the guide rail 6 is cylindrical, and a slide plate 5 is arranged on it, and the slide plate 5 is connected with the thrust plate 9 through a slide bar 8, and the thrust plate 9 is provided with a thrust bearing 10. The thrust bearing 10 can withstand the axial load generated by the motor. The right side of the thrust bearing 10 is connected with a lead screw 11. The lead screw 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com