Omnidirectional wheel structure

An omnidirectional wheel and hub technology, which is applied in the directions of wheels, transportation and packaging, and vehicle parts, can solve the problems of robot movement direction deviation, large carrying capacity, and spatial layout effects, and achieve the effect of increasing overlap and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

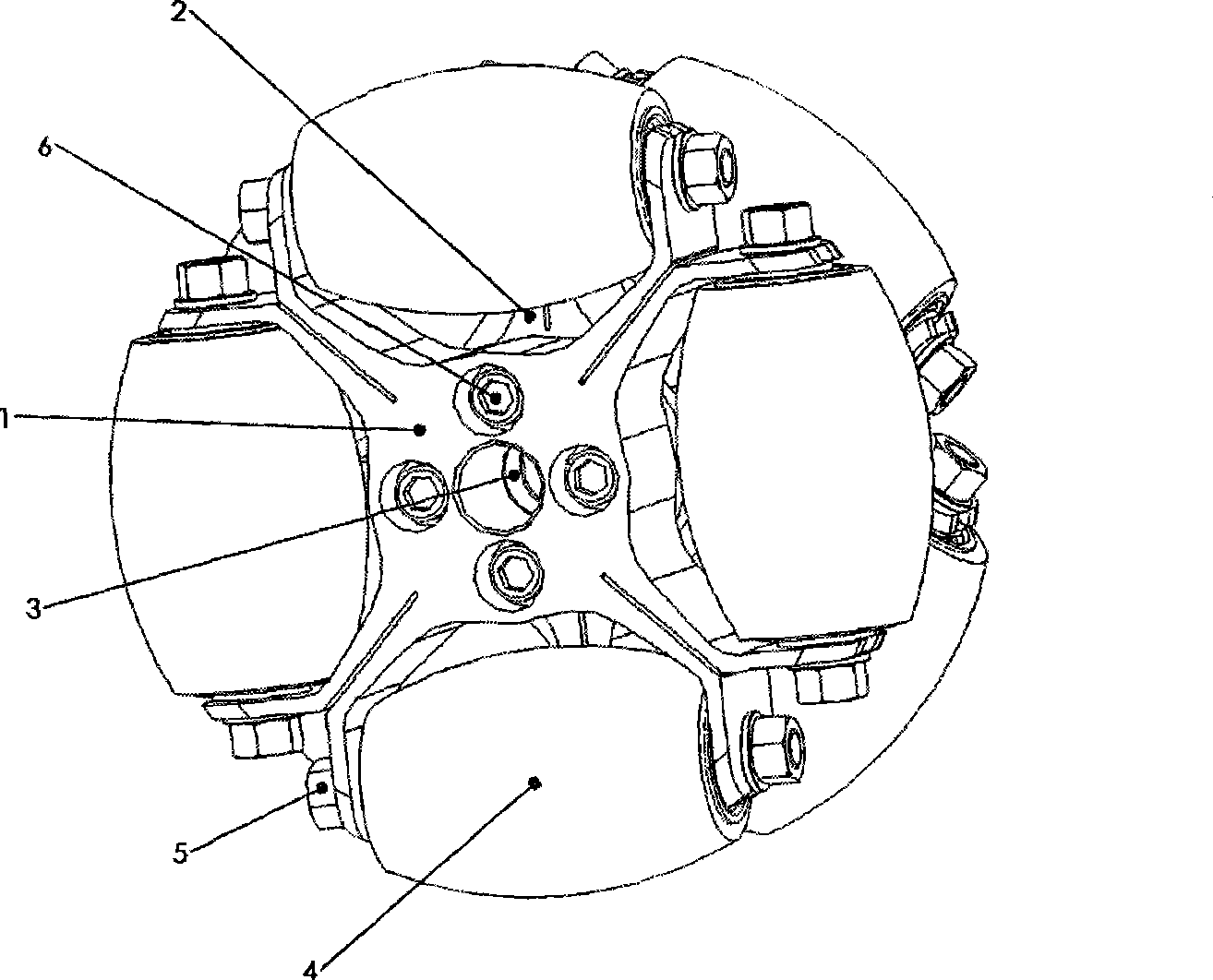

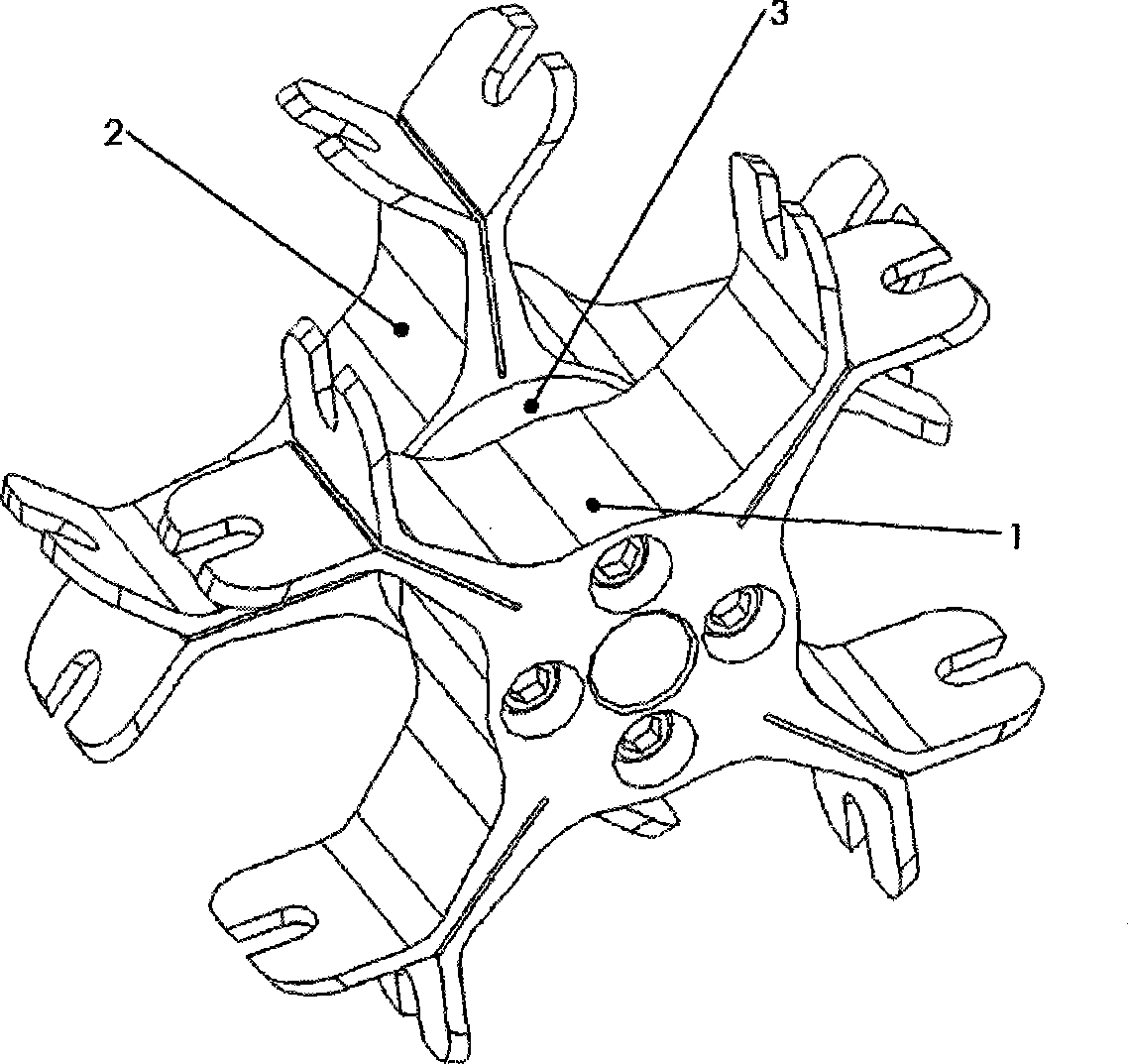

[0020] Shown in Fig. 1 with reference to, omnidirectional wheel is by outer hub support 1, inner hub support 2, spacer 3, spindle small wheel 4, nut 5 five major parts form. The outer hub bracket 1 and the inner hub bracket 2 are staggered at an angle of 45 degrees, with spacers 3 sandwiched between them, and connected by hexagon socket screws 6 (4 in total). Outer hub bracket 1, inner hub bracket 2 edges have U-shaped small grooves, and spindle small wheel 4 (8 in total) is fixed on the inner and outer hub brackets by nuts 5 (16 in total). When the omnidirectional wheel rotates in the radial direction, the spindles of the small wheels touch the ground alternately; when moving axially, the spindles of the small wheels roll laterally, always keeping rolling friction with the ground.

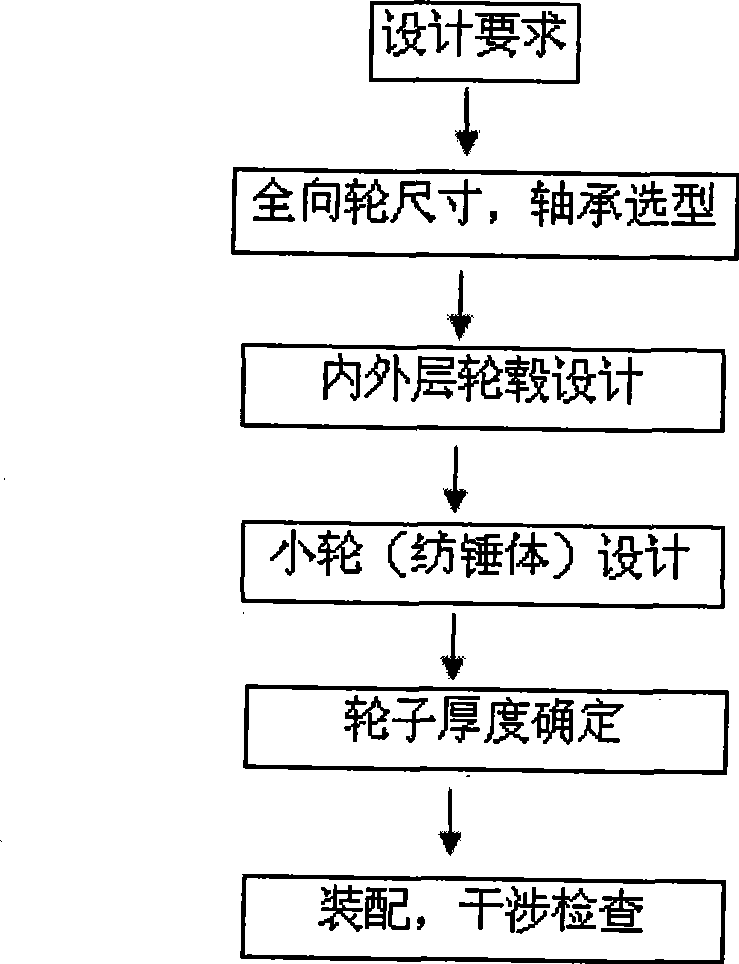

[0021] refer to figure 2 As shown, the flow chart of omnidirectional wheel structure design.

[0022] First determine the size of the omnidirectional wheel according to the design requirements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com