Automatic assembly mechanism for steel ball

An automatic assembly and steel ball technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to adapt to sliding balance, product flow of leaking balls, and inability to meet the increase in bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

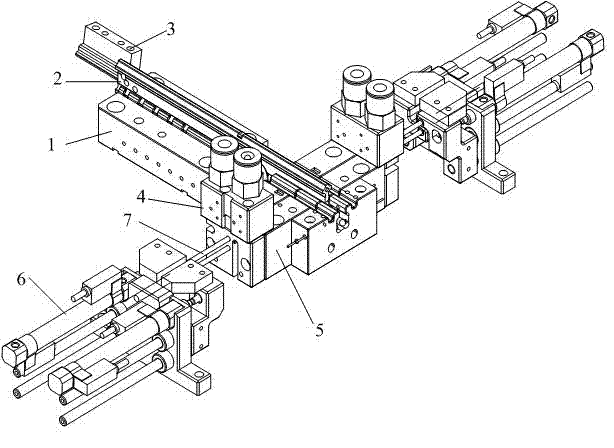

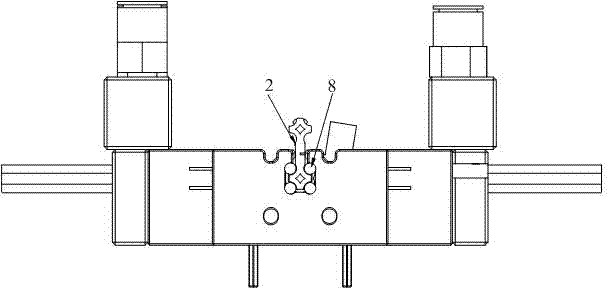

[0017] Such as figure 1 As shown, the steel ball automatic assembly mechanism includes a steel ball cage 2, a scoring mechanism, a ball pushing mechanism, a channel fixture 1 and a ballway fixture 5. The steel ball cage 2 has four corners distributed in a square shape, and each Each corner is provided with a notch groove for accommodating steel balls, the steel ball cage 2 is placed in the chute of the channel fixture 1, and the rear end of the steel ball cage 2 is provided with a pusher block 3, which is connected with the pusher mechanism Connected, the front end of the channel jig 1 is docked with the fairway jig 5, and the fairway jig 5 is provided with a chute for the steel ball cage to slide, and the left and right sides of the fairway jig chute are respectively arranged on the two fairway , the four lanes coincide with the notch grooves of the steel ball cage, and the left and right parts of the lane jig 5 are respectively equipped with a goal mechanism, and an optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com