Assembly technology of adjustable supporting columns and eight type modularized steel floor slab moulds

An assembly technology and support column technology, which is applied to the preparation of pillars, formwork/formwork/work frames, and building components on site, can solve the problems of high cost, environmental protection, leaking floor strength, and low overall strength, and achieve savings Working hours, guaranteed construction quality, strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

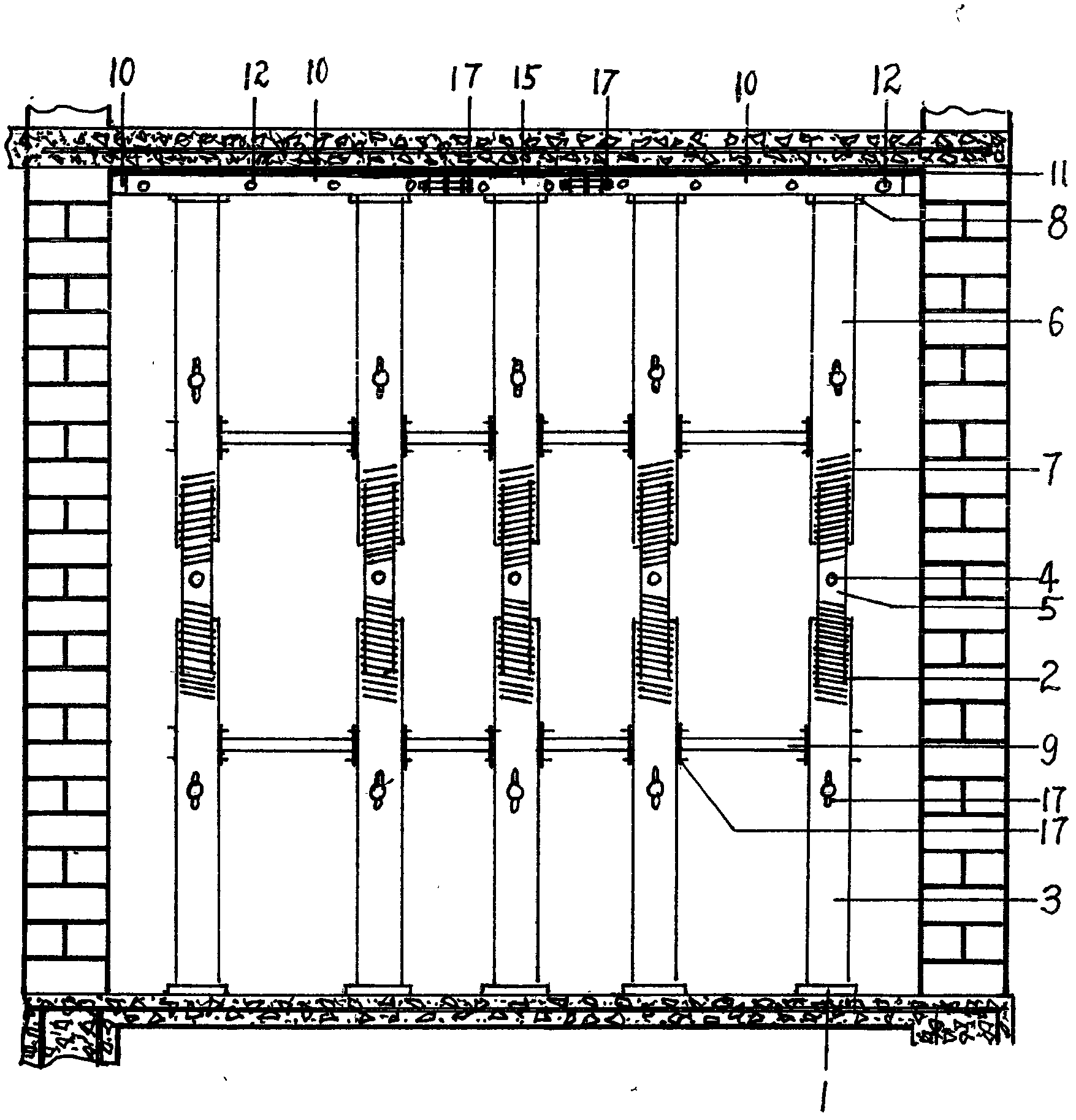

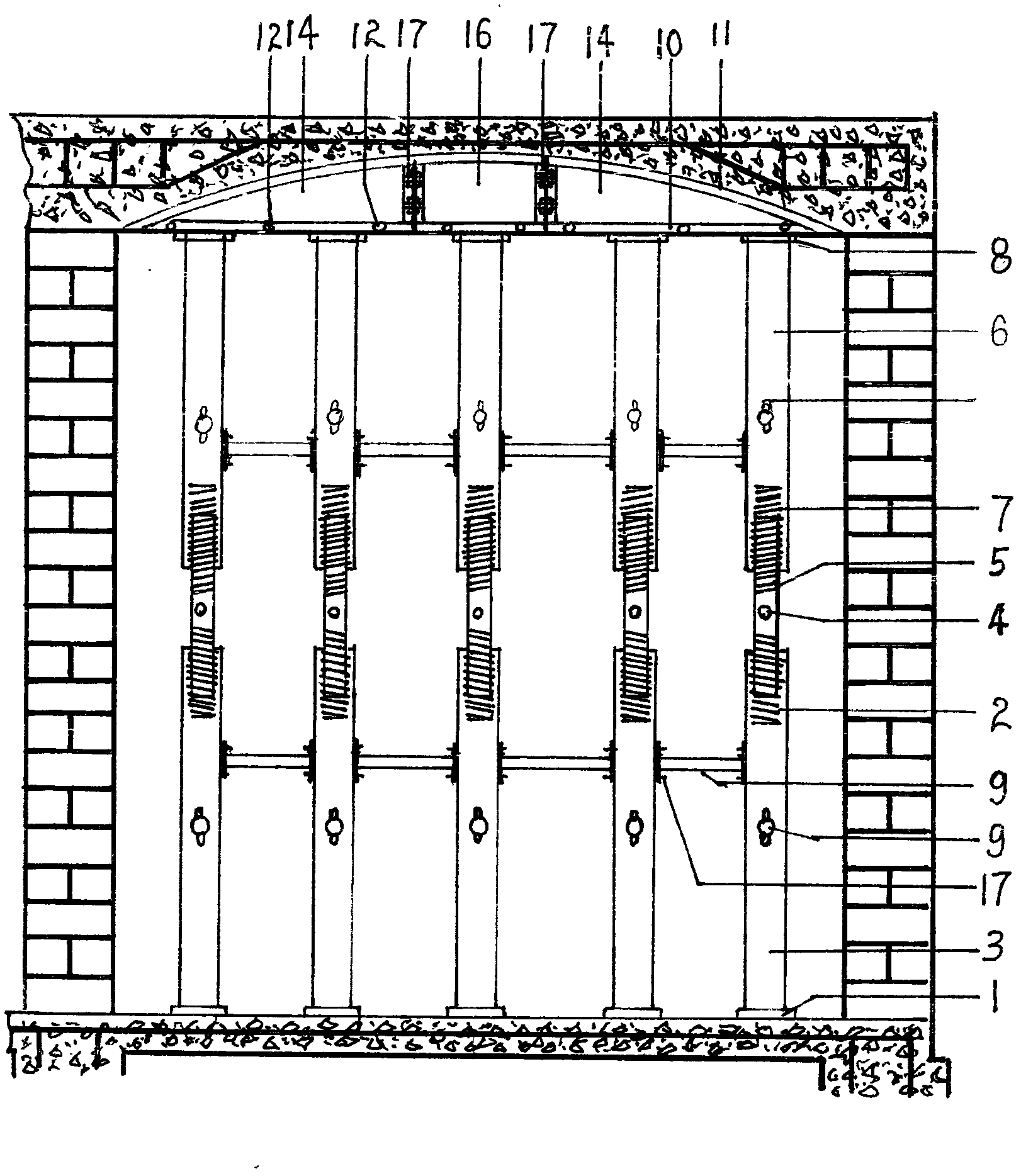

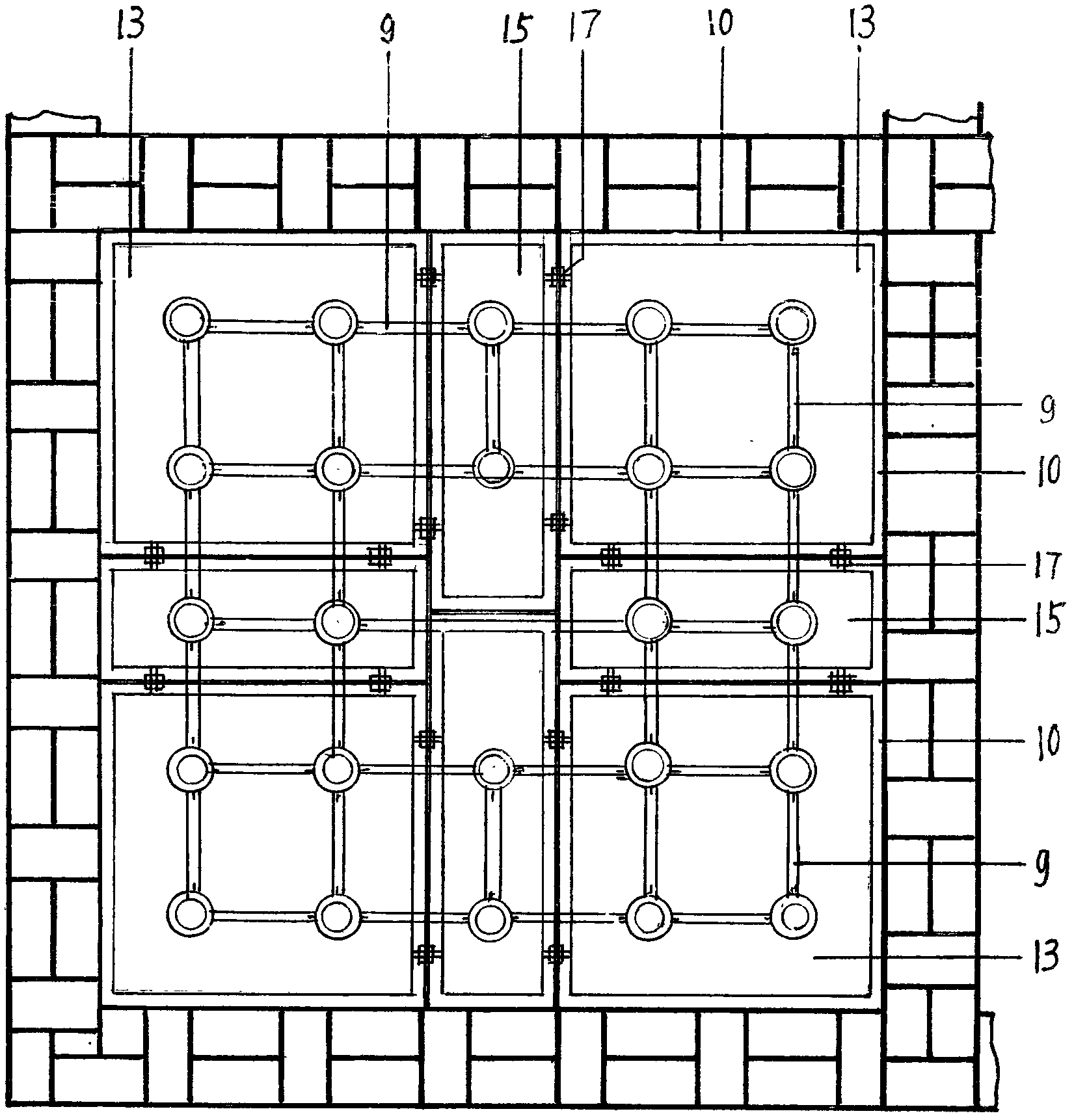

[0013] Below in conjunction with accompanying drawing the embodiment of the technical solution of the present invention is described in detail

[0014] Aiming at the defects existing in the technology of assembling and pouring reinforced concrete floor slab formwork with wood and small steel formwork, the present invention proposes an assembly technology of adjustable support columns and eight modular steel floor formworks, which is different from the existing wood and steel formwork assembly technology. The common necessary technical features of small piece steel formwork assembly pouring reinforced cement floor formwork technology: all are made up of floor slabs of each room, when the whole building layer is pouring reinforced cement concrete, the following formwork assembly technology plays a supporting role, and the technical characteristics of the present invention are: The technical scheme of pouring reinforced concrete floor formwork for each room is assembled by height-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com