Wave finned heat exchanger and manufacturing method thereof

A manufacturing method and heat exchanger technology, which are applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc. Problems such as low bonding strength and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

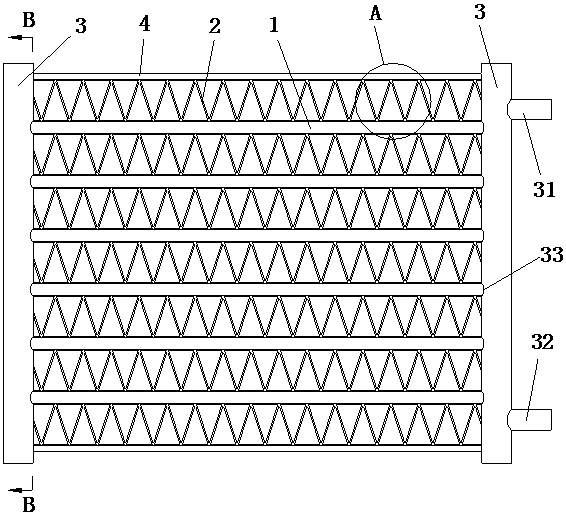

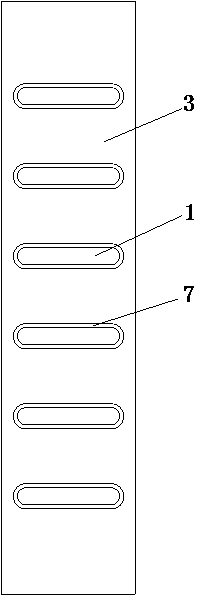

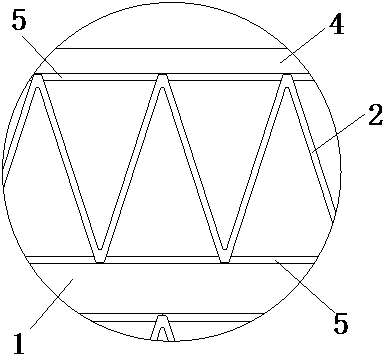

[0092] Such as figure 1 As shown, the flat tube-fin heat exchanger provided in this embodiment includes: several flat tubes 1, several fins 2 (or fin strips), two liquid collection chambers (or liquid collection pipes, or header) 3. Preferably, two outer side panels 4 are also included. Wherein, the flat tube 1, the fins 2, and the metal parts of the liquid collecting chamber 3 are all made of a single-layer aluminum alloy material. Abandoning the expensive aluminum alloy material of the solder composite layer in the prior art makes the manufacturing cost of the flat-tube-fin heat exchanger lower, for example, the cost of raw materials can be reduced by 30% to 40%.

[0093] Specifically, the flat tubes 1 and the fins 2 are sequentially arranged at intervals, and the flat tubes 1 and the fins 2 are bonded by a first adhesive layer 5 . The flat tube 1 includes a single-hole mouth-shaped tube, a B-shaped folded tube, an extruded porous harmonica-shaped tube, and the like. In ...

Embodiment 2

[0120] In this embodiment, the same reference numerals are assigned to the same parts as in the first embodiment, and the same text descriptions are omitted.

[0121] Such as Figure 1 to Figure 3 As shown, the first adhesive layer 5 is made of a mixture of an adhesive substrate and conductive and thermally conductive fillers, wherein the conductive and thermally conductive filler accounts for 20% to 30% by weight of the first adhesive layer 5 .

[0122] As a preferred technical solution, the conductive and thermally conductive filler is graphite powder or metal powder. Specifically, the conductive and thermally conductive fillers are formed by mixing graphite powders of different particle sizes. Of course, the conductive and thermally conductive fillers can also be formed by mixing metal powders of different particle sizes. Of course, the conductive and thermally conductive fillers are more likely to be formed by mixing graphite powder and Metal powders of different particle...

Embodiment 3

[0126] In this embodiment, the same reference numerals are assigned to the same parts as in the first embodiment, and the same text descriptions are omitted.

[0127] In this embodiment, the manufacturing method of the flat tube-fin heat exchanger is carried out in the following steps:

[0128] Step 1. Set a second adhesive layer on the outer surface of both ends of the flat tube or at the slot hole of the liquid collection chamber, insert the two ends of each flat tube into the corresponding slot hole, and apply the second adhesive The flat tube and the slot hole of the liquid collection chamber are bonded and solidified to form a flat pipe liquid collection chamber assembly;

[0129] Step 2, setting a first adhesive layer on the outer surface of the joint between the flat tube and the fin or at the crest of the fin;

[0130] Step 3. Fins are placed between two adjacent flat tubes, and the flat tubes and fins are bonded and solidified by the first adhesive layer to form a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com