Rubber band core rod processing device without stub bars

A processing device with no material head technology, which is applied in the field of clamping devices for processing rubber hoses for automobiles, can solve the problems of wasting raw materials and increasing costs, and achieve the effects of saving man-hours, facilitating maintenance, and avoiding difficult assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention will be described below in conjunction with the drawings.

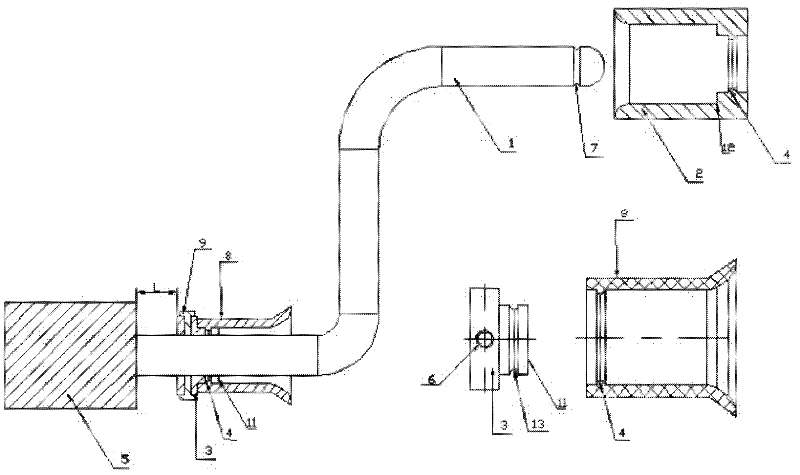

[0012] Such as figure 1 As shown, the processing device includes a mandrel 1, a rubber hoop lower hoop 8, a rubber hoop upper hoop 2, a spherical stopper 4, a positioning plate 3, a stabilizing body 5, and a screw 9.

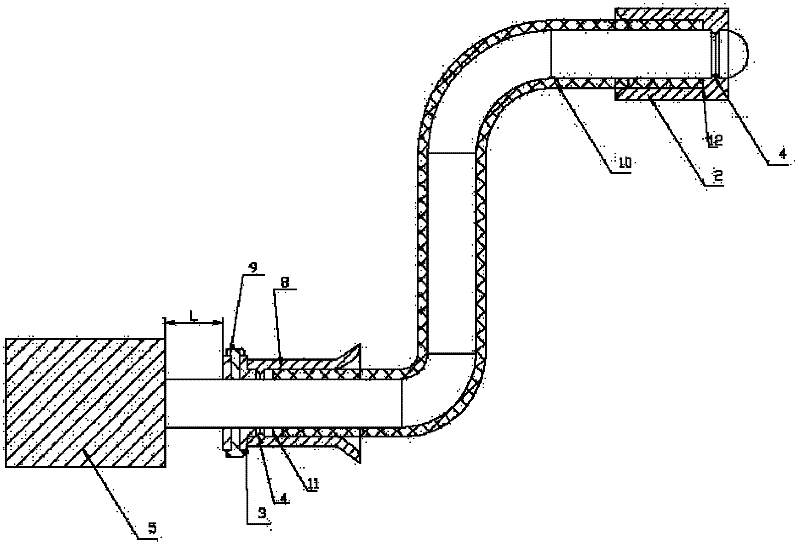

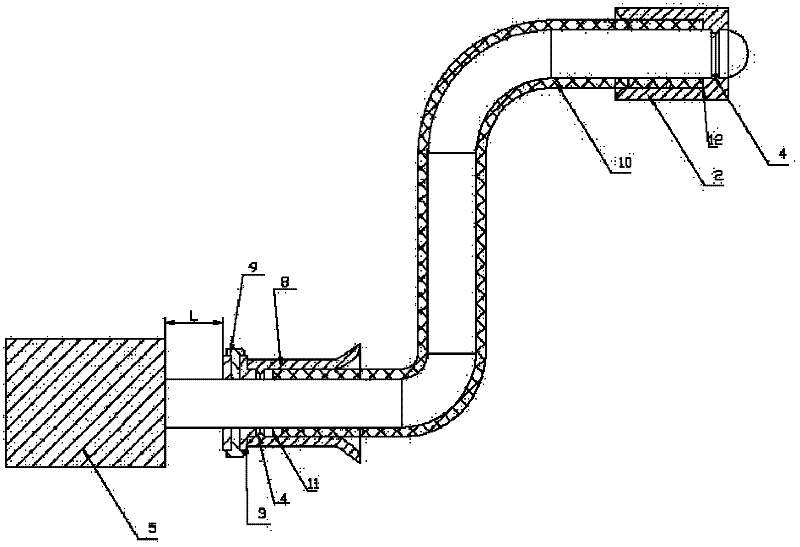

[0013] Such as figure 2 As shown, install the positioning disc 3 at one end of the mandrel 1, and install the lower hoop 8 of the rubber hoop onto the positioning disc 3, so that the spherical stopper 4 inside the lower hoop 8 of the rubber hoop is closely aligned with the groove 13 on the positioning disc 3. Cooperate well, and the screw 9 is screwed in the positioning hole 6, and the stabilizing body 5 is welded on the lower end of the mandrel. When vulcanizing, put the rubber tube 10 into the mandrel 1, make one end of the rubber tube 10 fit closely with the positioning boundary 11, and then install the rubber hoop 2 on the other end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com