Wire harness support for mounting automobile wire harness

A technology of wire harness bracket and automobile wire harness, which is applied in the direction of vehicle parts, transportation and packaging, electrical components, etc., can solve the problems of difficult assembly and assembly of wire harnesses, achieve the effect of reducing the risk of serious accidents and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

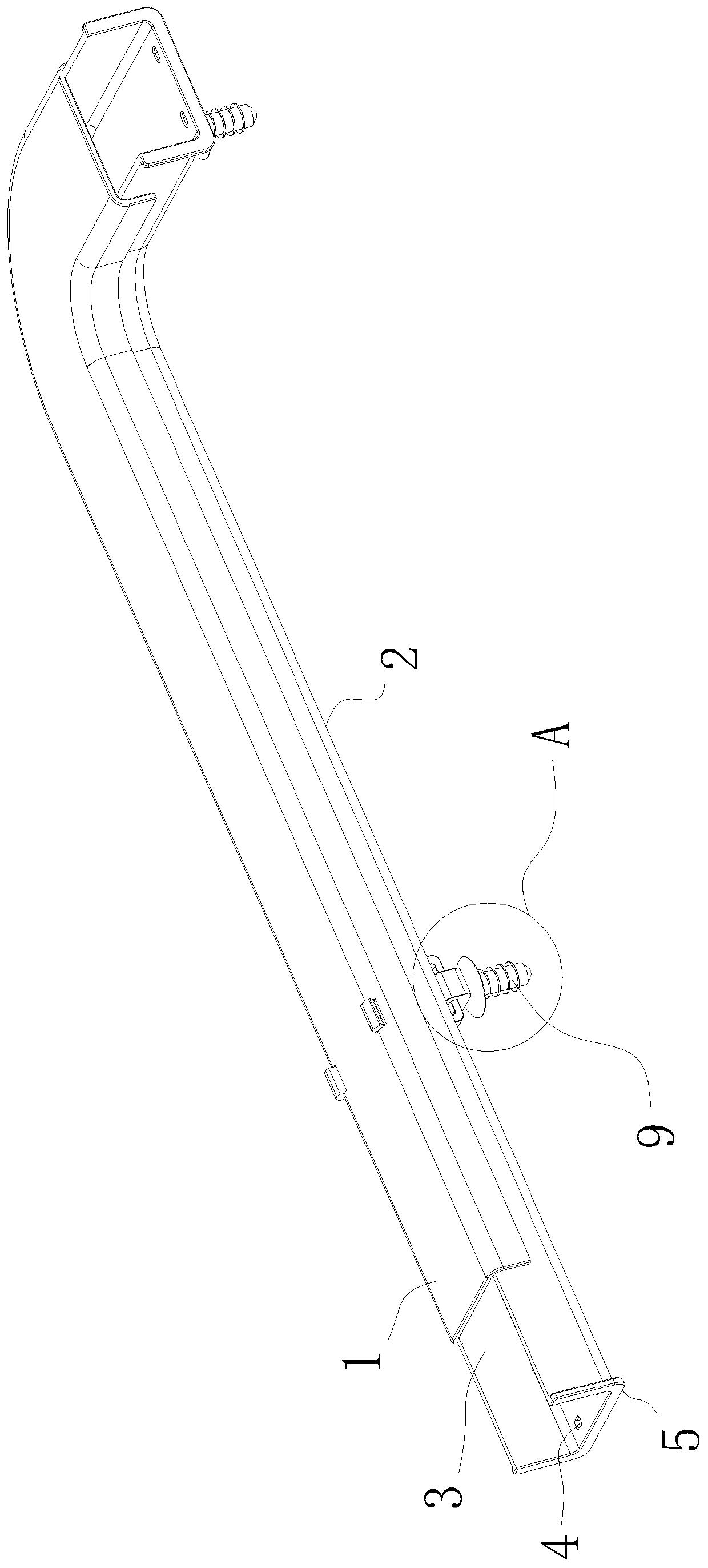

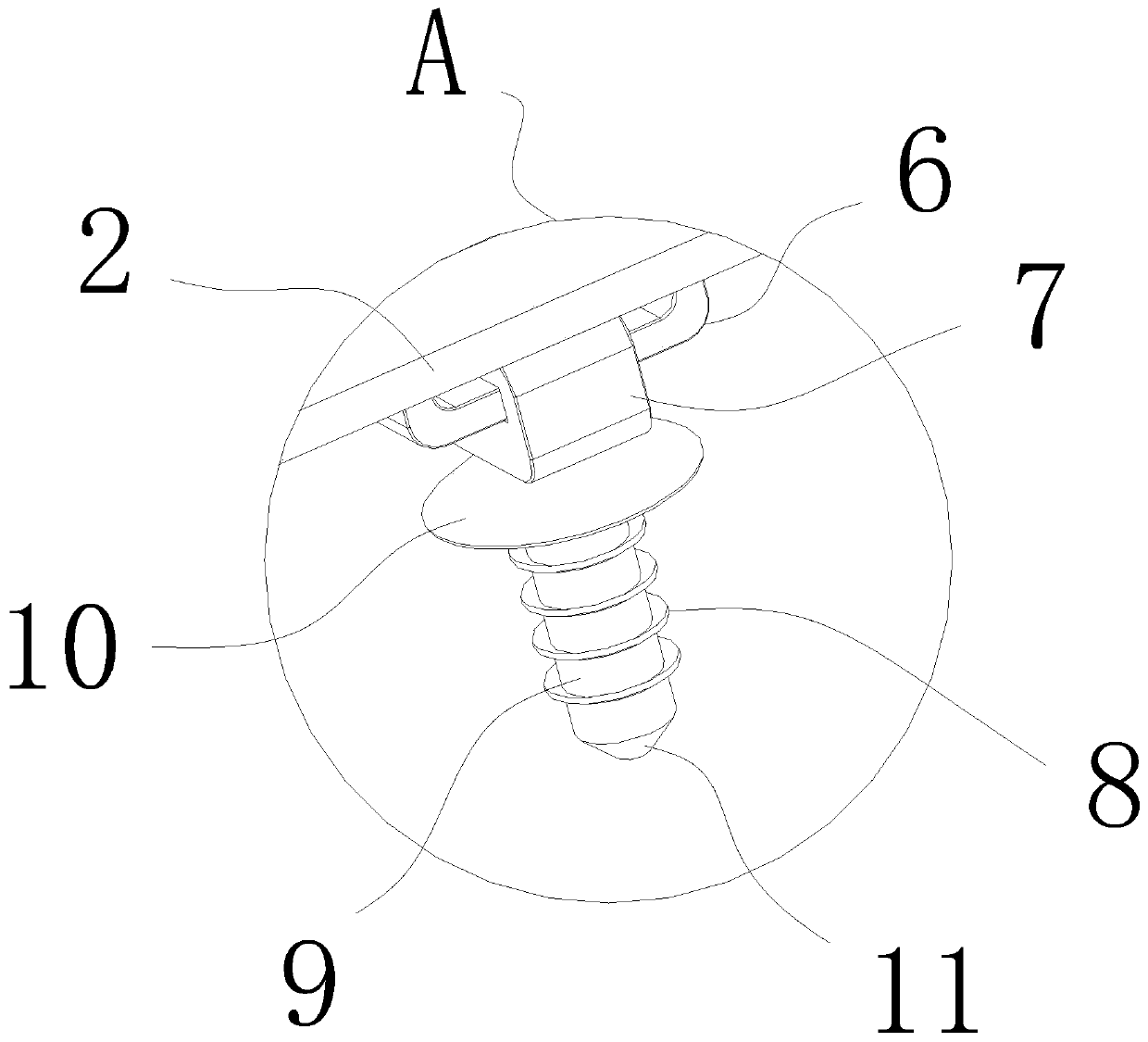

[0017] like Figure 1-2 The shown wiring harness bracket for automobile wiring harness installation includes an upper cover 1 and a lower cover 2 made of high-temperature-resistant materials. For installation, the upper cover 1 and the lower cover 2 are snapped together and form a threading slot 3 between the two for the passage of the wire harness. The outer contours of the upper cover 1 and the lower cover 2 are generally L-shaped for avoiding Most of the components on the car, the two ends of the lower cover 2 are vertically provided with a number of threading holes 4, and the threading holes 4 are used to pass through the external car wiring harness connection buckle to bind the car wiring harness. The two ends of the lower cover 2 There is a protruding part 5 that is turned outwards to prevent the wire harness from being worn out by the edge of the lower cover 2. Further, in order to improve the stability of the wire harness being bundled by the external automobile wire h...

Embodiment 2

[0019] The elastic member is an annular piece made of soft plastic material, and the rest is the same as that of embodiment 1. The soft plastic material has certain elasticity, and also has the strength to increase the connection between the connecting rod and the upper parts of the external vehicle.

[0020] When the present invention is in use: firstly, the connecting piece is clamped on the lower cover through the prior art. At this time, the two connecting columns can slide along the vertical direction on the horizontal plane respectively, and the connecting column is inserted into the automobile panel through the guidance of the guide cone. In the hole of the metal part (by sliding the sliding part on the bracket, the position of the two connecting columns corresponds to the position of the hole on the automobile sheet metal part, and the installation of the connecting column and the hole on the automobile sheet metal part is completed), the connecting column After being i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com