Shield segment splicing machine with six-freedom degree

A shield segment and assembling machine technology, which is applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve the problems of damaging the parallelism of the left and right two lifting cylinders 505, dislocation of segment assembly, and poor rigidity, so as to overcome adverse effects , the effect of improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

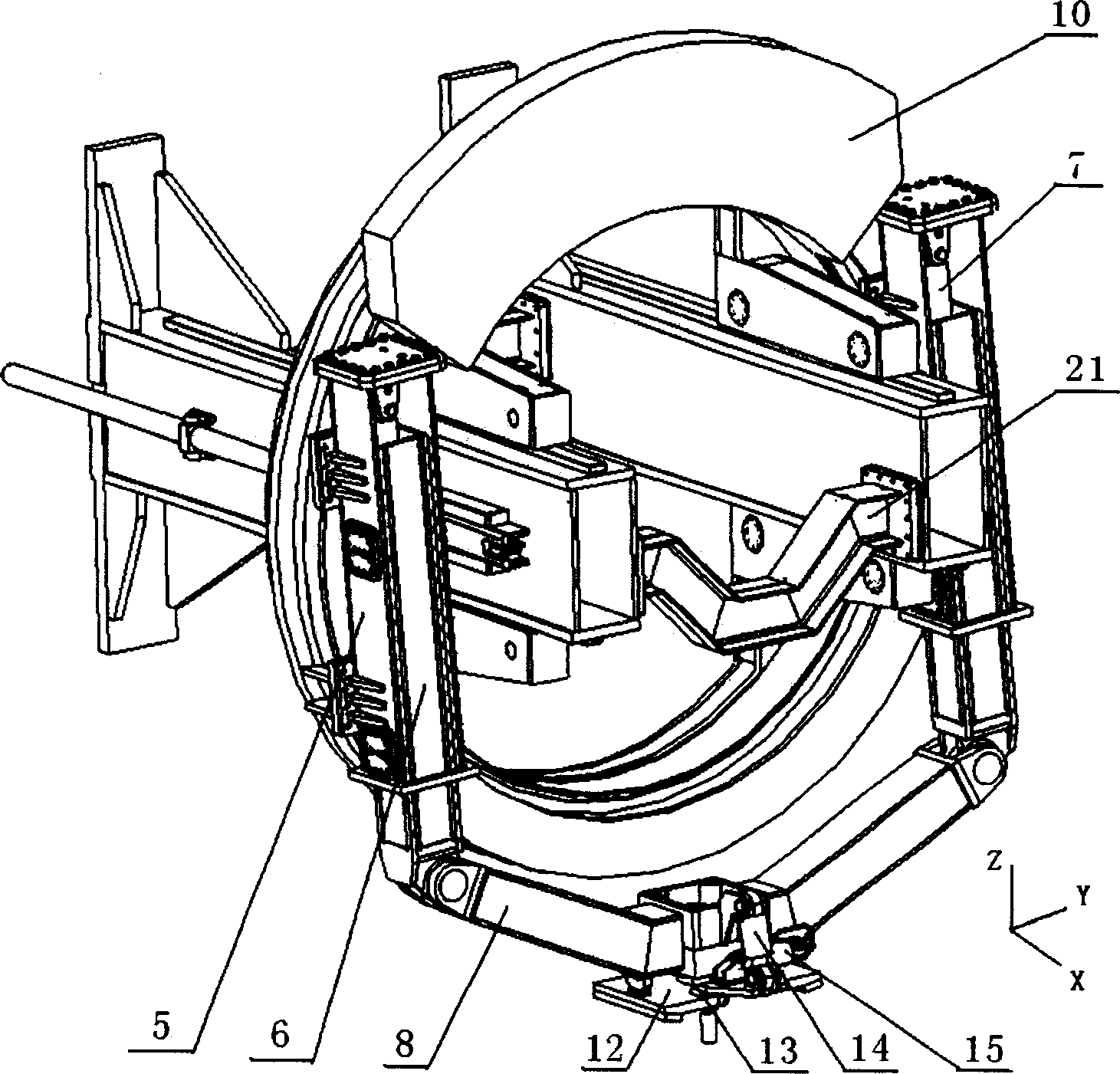

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

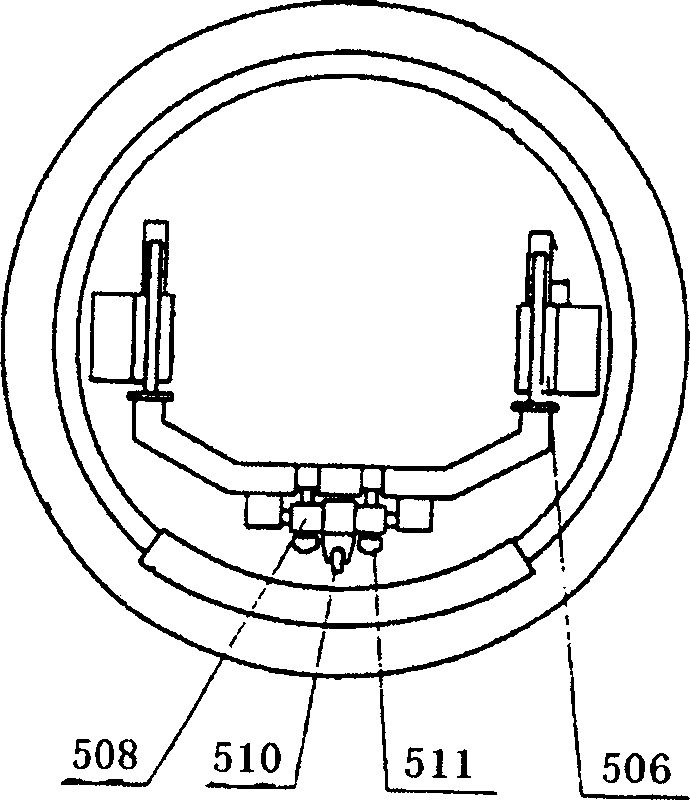

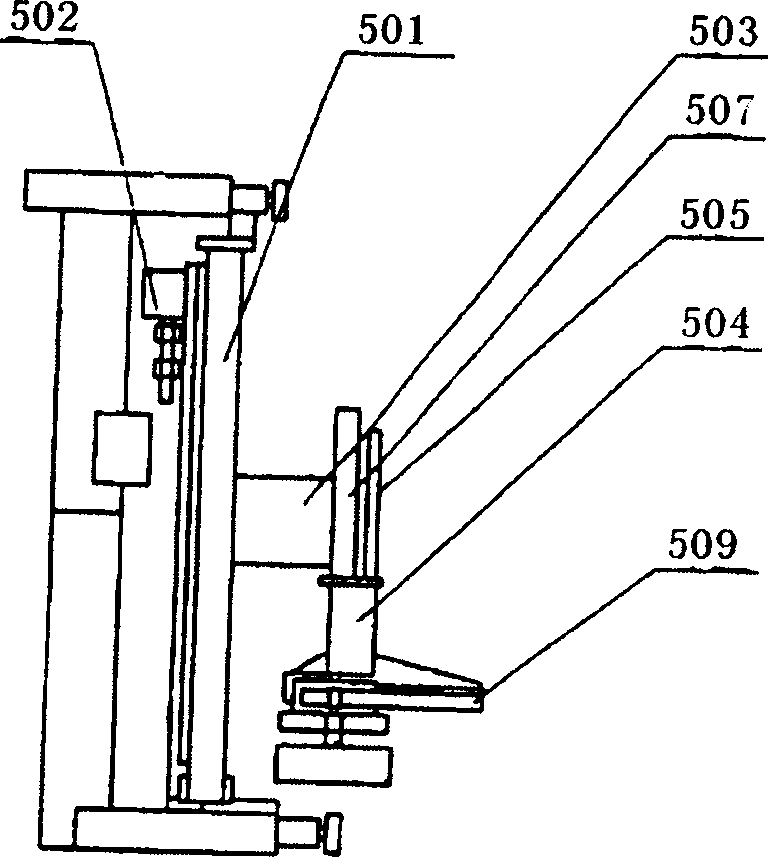

[0020] like image 3 and Figure 4 As shown, the shield segment assembly machine with six degrees of freedom described in the present invention includes a rotating disk body 1, a driving device 2, two cantilever beams 3, two translation cylinders 4, two guide outer sleeves 5, and two guide inner sleeves 6. Second lifting cylinder 7, lifting beam 8, segment clamp head device 9, segment counterweight 10, rotating platform 12, center ball joint bearing 13, segment tilting cylinder 14, segment rotating cylinder 15, fixed disc body 16 And roller device 17.

[0021] The two cantilever beams 3 are fixed on the inner casing of the shield machine along the axial direction of the shield and parallel to the left and right, and an intermediate beam 21 is installed between the two cantilever beams 3, and the two ends of the intermediate beam 21 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com