Constant-temperature phase change energy storage material

A phase change energy storage and normal temperature technology, which is applied in the field of building wall materials, can solve the problems of phase change materials losing application value, difficulty in achieving expected results, and high degree of supercooling, and achieve low cost, large latent heat, and high degree of supercooling. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

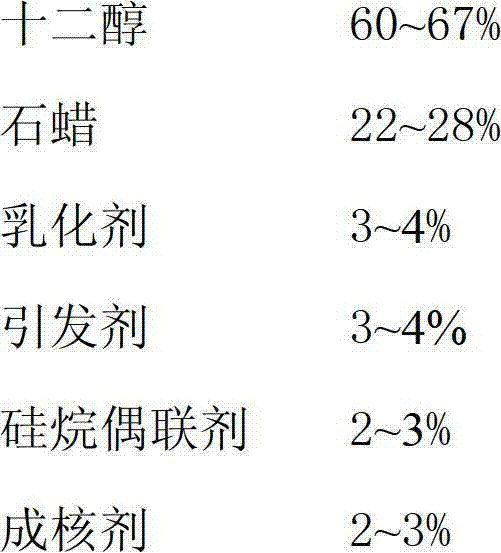

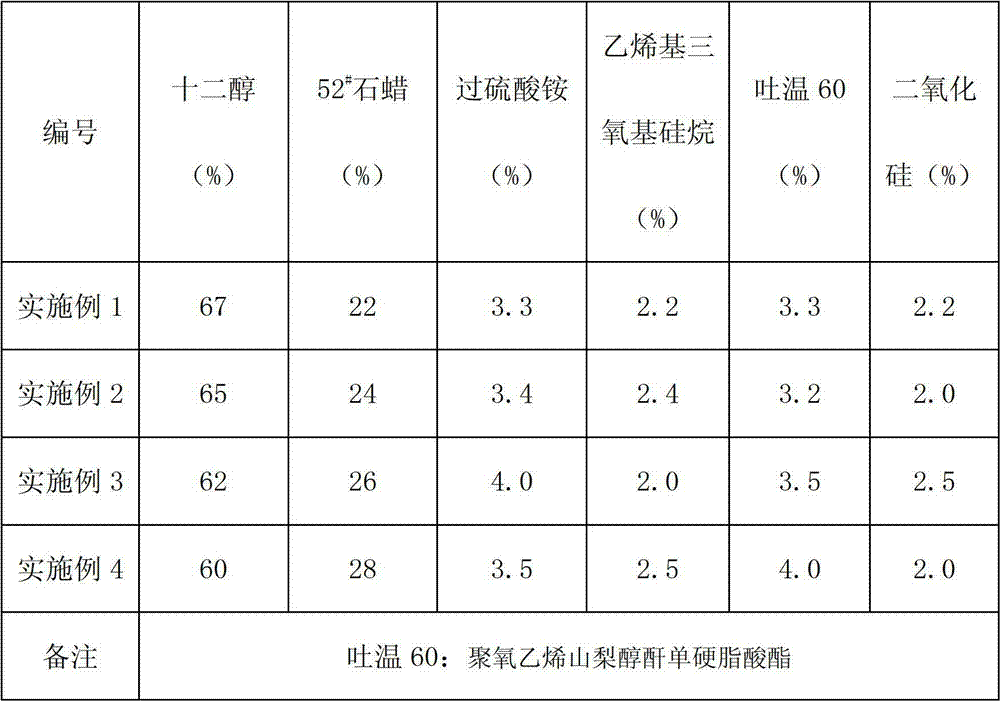

Method used

Image

Examples

Embodiment 1

[0017] The proportion and dosage of ingredients are: lauryl alcohol, 60kg; paraffin, 20kg; Tween 60, 3kg; 30kg of 10% ammonium persulfate solution by mass percentage (prepared before use, and the preparation time should not exceed 5h); Silane (151), 2kg; Silica 2kg

[0018] 1. Add lauryl alcohol, paraffin, Tween 60, and vinyltrioxysilane (151) into the reaction kettle, start the stirrer, adjust the speed to 250r / min, raise the temperature to 70°C, and continue stirring for 30 minutes. Vinyltrioxysilane (151) can also be replaced by vinyltrimethoxysilane (171).

[0019] 2. Add ammonium persulfate solution dropwise while stirring, and stop heating after 3 hours.

[0020] 3. Add silicon dioxide, continue stirring for 1 hour, and discharge.

[0021] The technical properties of the phase change energy storage material prepared by this method are as follows:

[0022] Phase transition point: 28°C

[0023] Latent heat of phase change: 156J / g

[0024] PH value: 6.5

[0025] Densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com