Machine head device capable of adjusting wall thickness of extrusion pipe

An extruded pipe, adjustable technology, applied in the field of extruded pipe wall thickness adjustable head device, can solve the waste of time and manpower, time-consuming (disassembly, installation, cooling, heating time, heat consumption and other problems, to achieve Save the energy consumed by cooling and heating, save adjustment time and manpower, and the preparation process is reliable and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

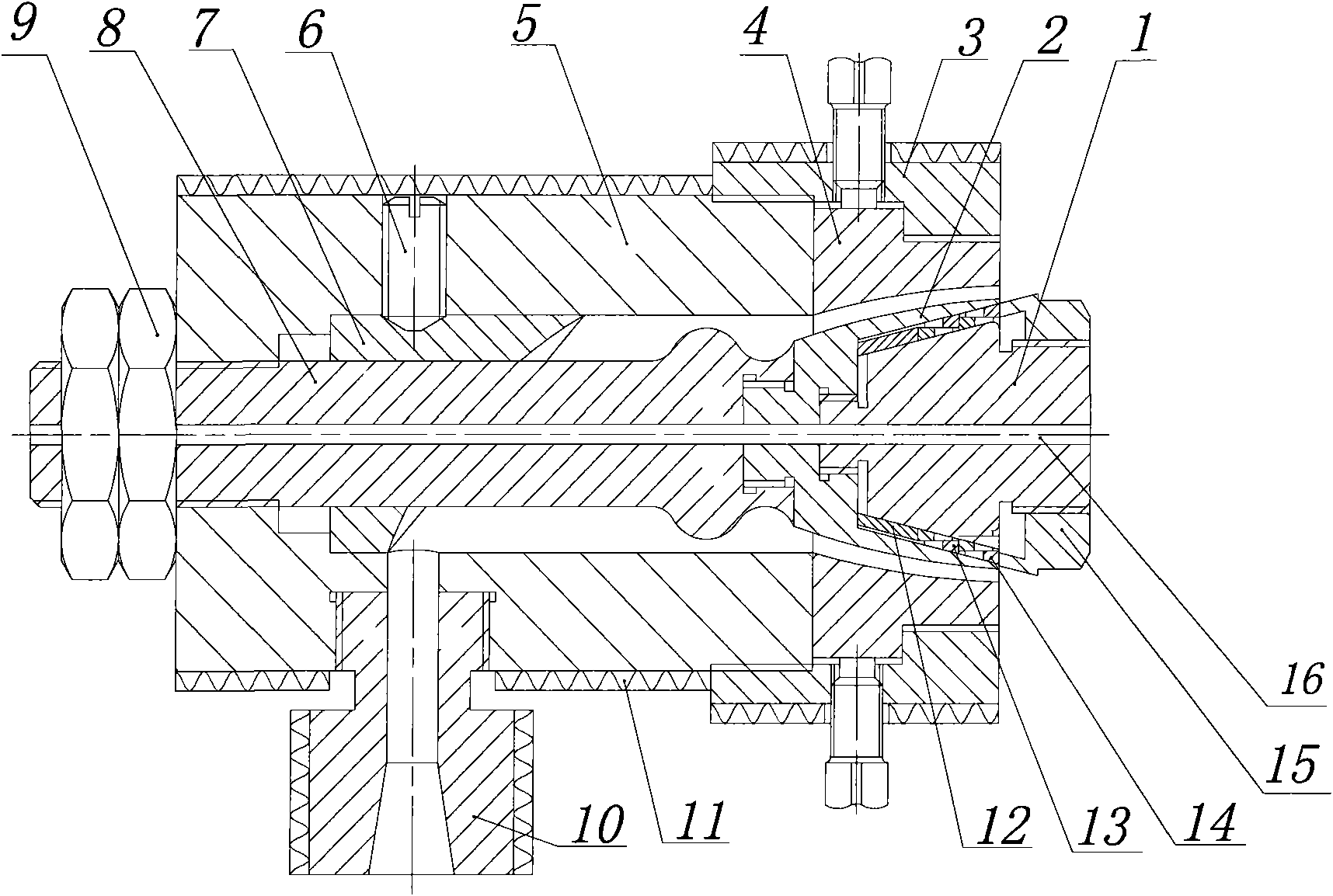

[0010] The main structure of the speed-adjustable extrusion pipe wall thickness head involved in this embodiment includes a core die inner shaft 1, a core die body 2, a press sleeve 3, a die 4, a main die body 5, a set screw 6, and a transition block. 7. Mandrel 8, nut 9, machine diameter 10, heating ring 11, inner spacer block 12, upper expansion sleeve 13, lower expansion sleeve 14, adjusting nut 15 and vent hole 16; The lower expansion sleeve 14, the upper expansion sleeve 13 and the inner spacer block 12 of the core mould are sleeved, and the outer thread of the left end is screwed into the inner thread of the right end of the core mould body 2 to form an inner wall thickness adjustment mechanism; the right end thread of the adjusting nut 15 is screwed into the core Inside the nut on the right end of the shaft 1 in the mold; the diameter 10 is used to connect the screw head of the extruder, and a wavy line heating ring 11 is made around it to supply enough heat to the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com