Die for manufacturing glass container

A technology for glass containers and moulds, applied in glass blowing moulds, etc., can solve the problems of difficult heat dissipation, deformation, elongation and deformation of the neck and shoulders of the bottle, and achieve the effect of accelerating the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail below in conjunction with the accompanying drawings in the form of embodiments, but none of the descriptions of the embodiments is a description of the present invention. Restriction of the inventive solution, any equivalent transformation made according to the concept of the present invention which is merely formal but not substantive shall be regarded as the scope of the technical solution of the present invention.

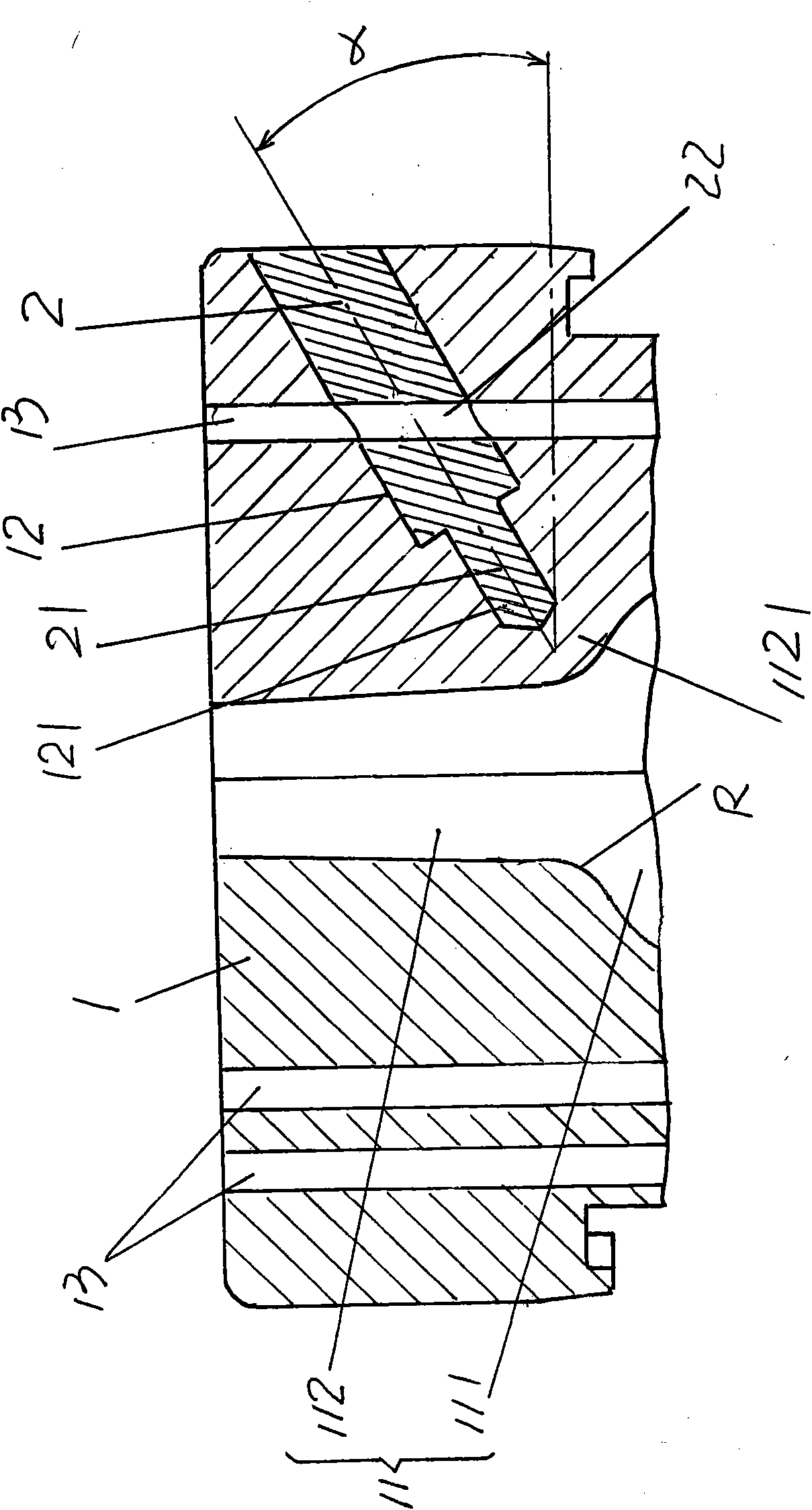

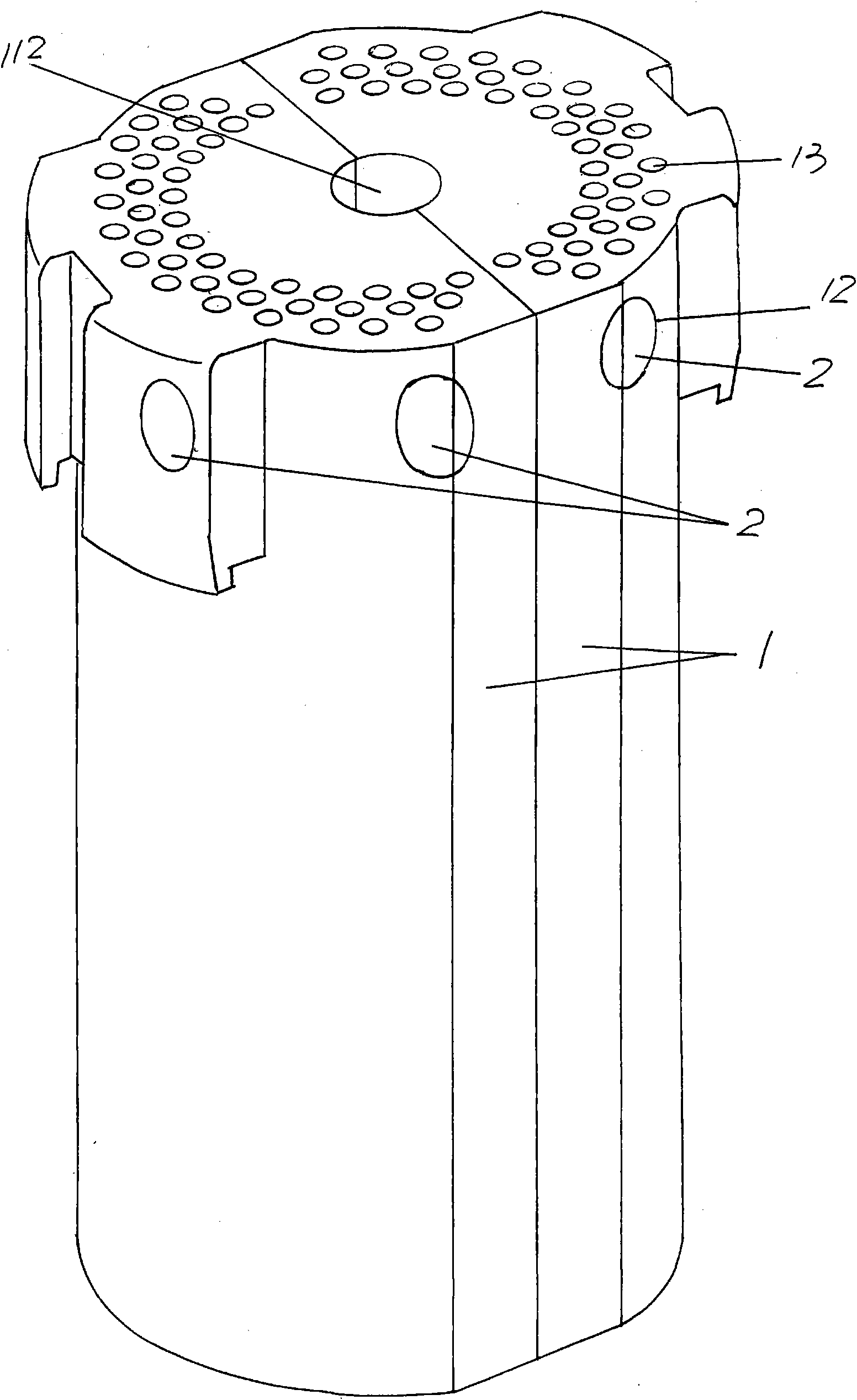

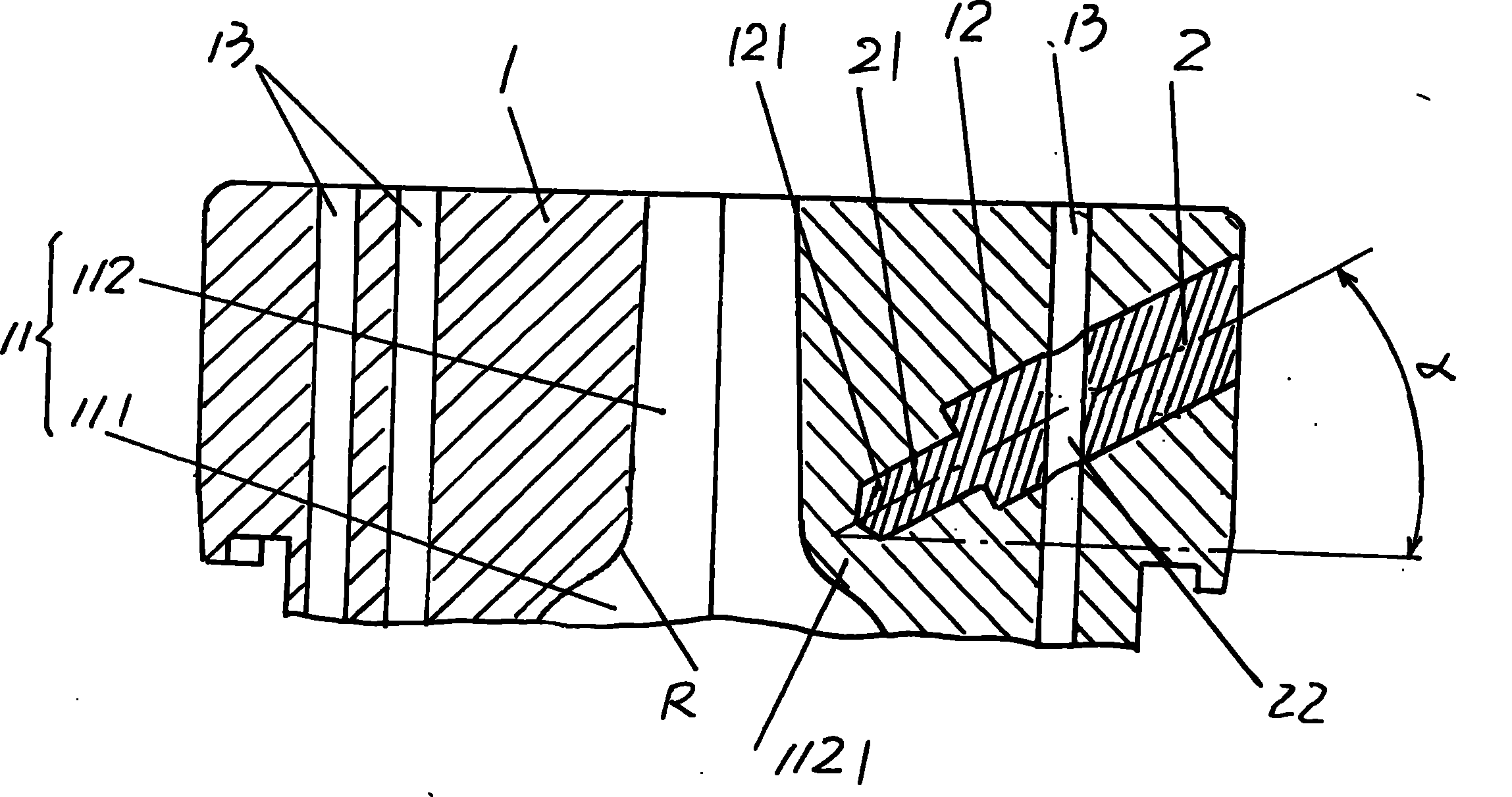

[0018] Please see figure 1 with figure 2 , a pair of bottle half-molds 1 opposite to each other in the use state with the same shape each have a bottle mold cavity 11. According to known common sense, each bottle mold cavity 11 is composed of a bottle body cavity 111 and a bottleneck cavity 112. The bottle body cavity 11 and the bottle neck ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com