Primary mold

An integrated, cavity technology, used in glass blowing molds, glass production, etc., can solve the problems of low production efficiency, reduced glass bottle production efficiency, long time consumption, etc., to improve production efficiency and reduce the movement and reset of the funnel. , the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

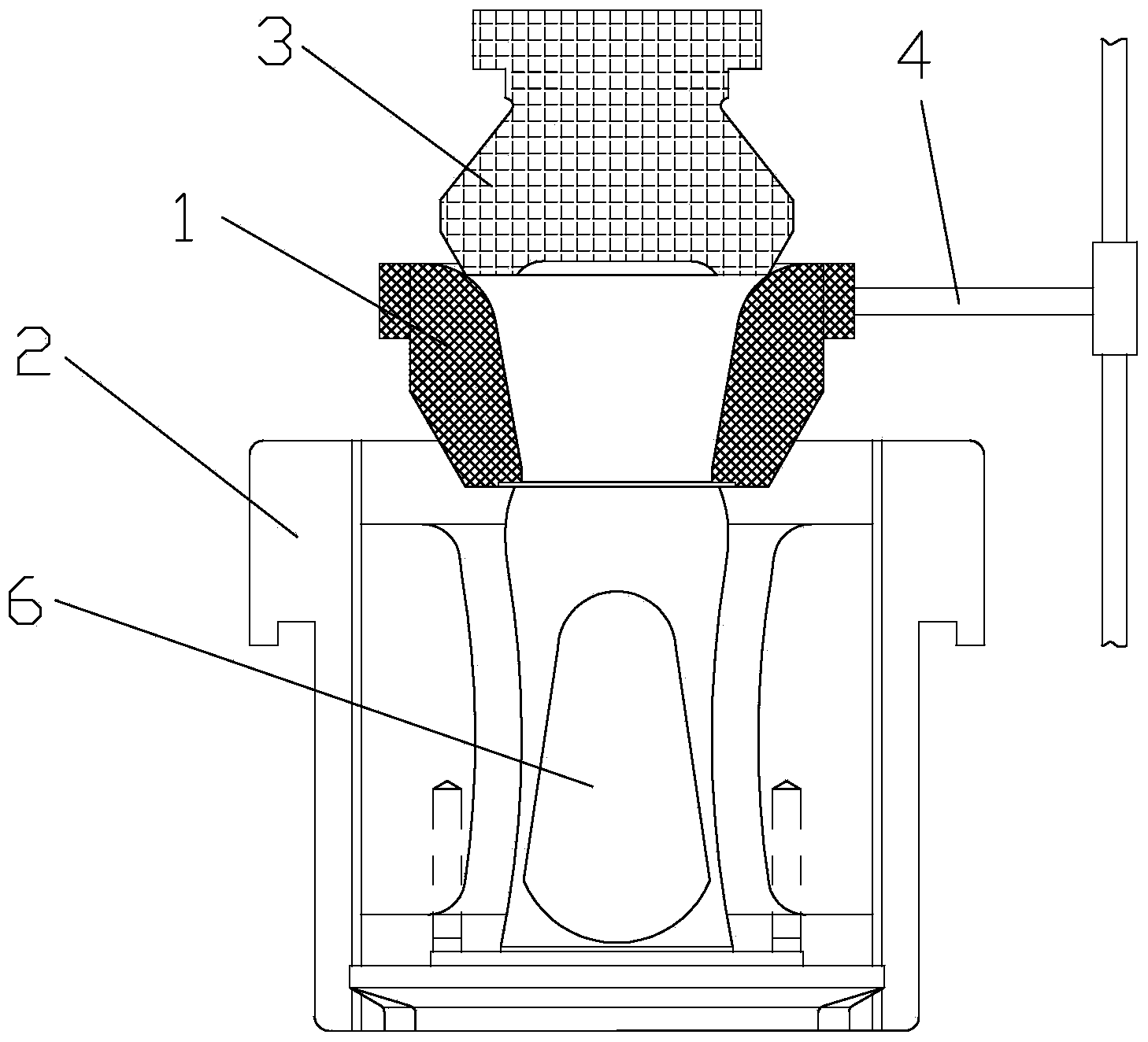

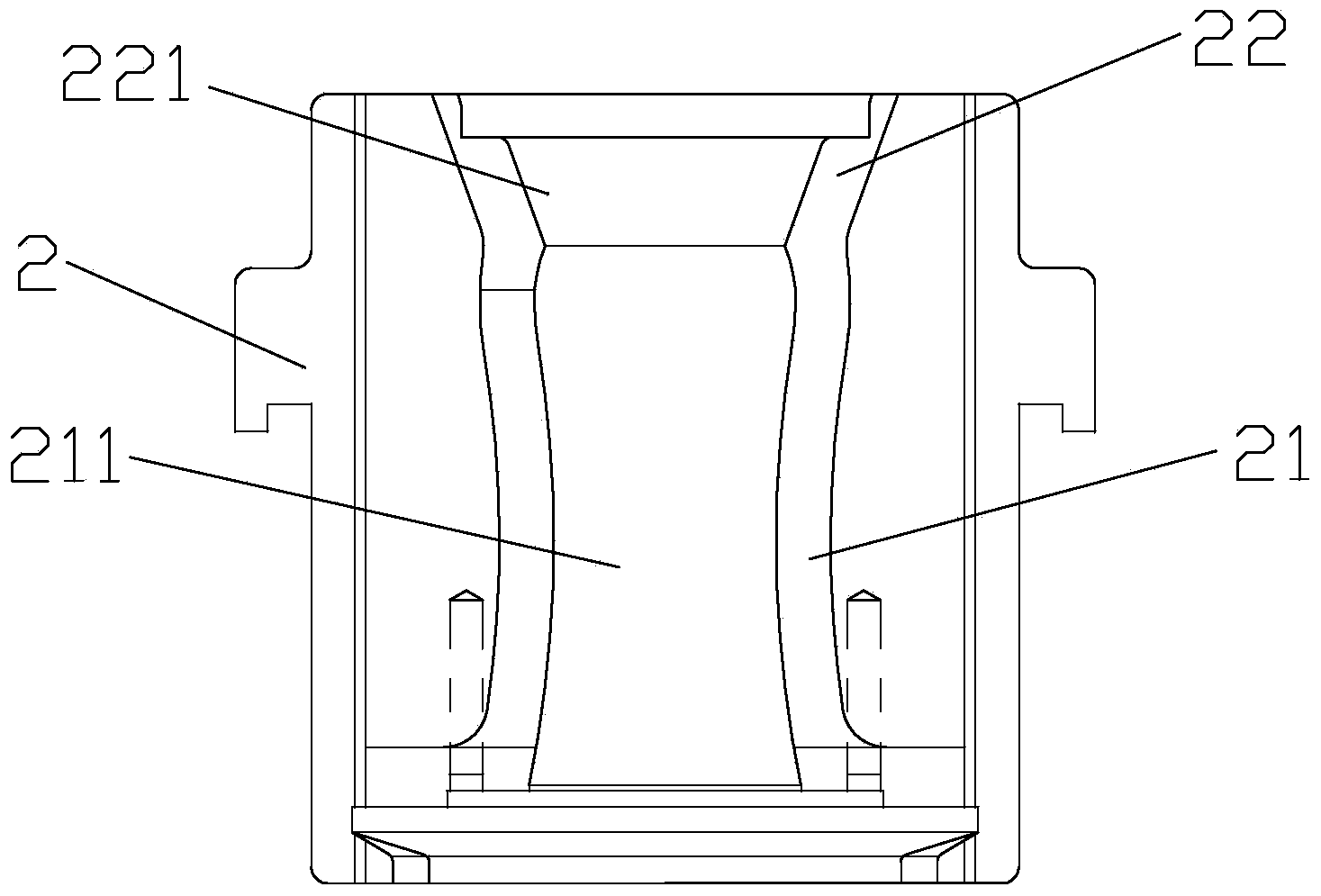

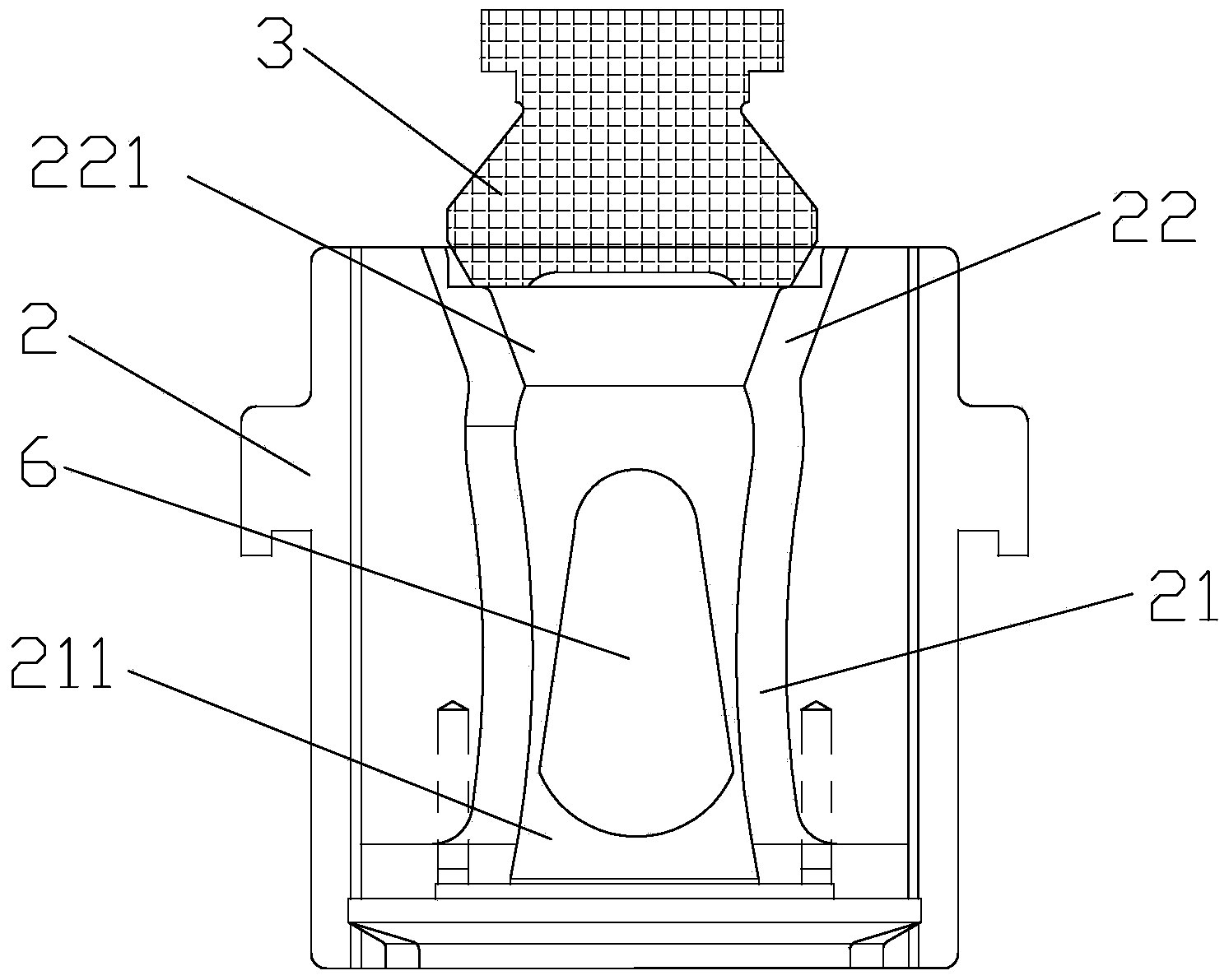

[0014] Embodiment: a kind of preliminary model, as figure 2 As shown, the primary mold 2 is provided with a cavity 211 , and a funnel-shaped feed cavity 221 is formed at the upper opening of the primary mold 2 , and the feed cavity 221 communicates with the cavity 211 .

[0015] Specifically, the bottom of the blank mold 2 is a bottle forming part 21, the cavity 211 is arranged in the bottle forming section 21, the top of the blank mold 2 is a feeding part 22, and the feeding chamber 221 is arranged in the feeding part 22, The bottle forming part 21 and the feeding part 22 are integrally formed, and the bottom of the feeding cavity 221 communicates with the top of the cavity 211 .

[0016] The specific working process is as follows: image 3 As shown, the distributing machine is opened so that the melted glass frit 6 falls from the distributing machine, and the glass frit directly enters the cavity 211 through the guide of the feeding chamber 221, and then the bulkhead 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com