Narrow neck glass container with internal embossments and method of manufacture

a glass container and narrow neck technology, applied in the field of ##row neck glass containers, can solve the problem that the technique of narrow neck press-and-blow manufacturing operation is not feasibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

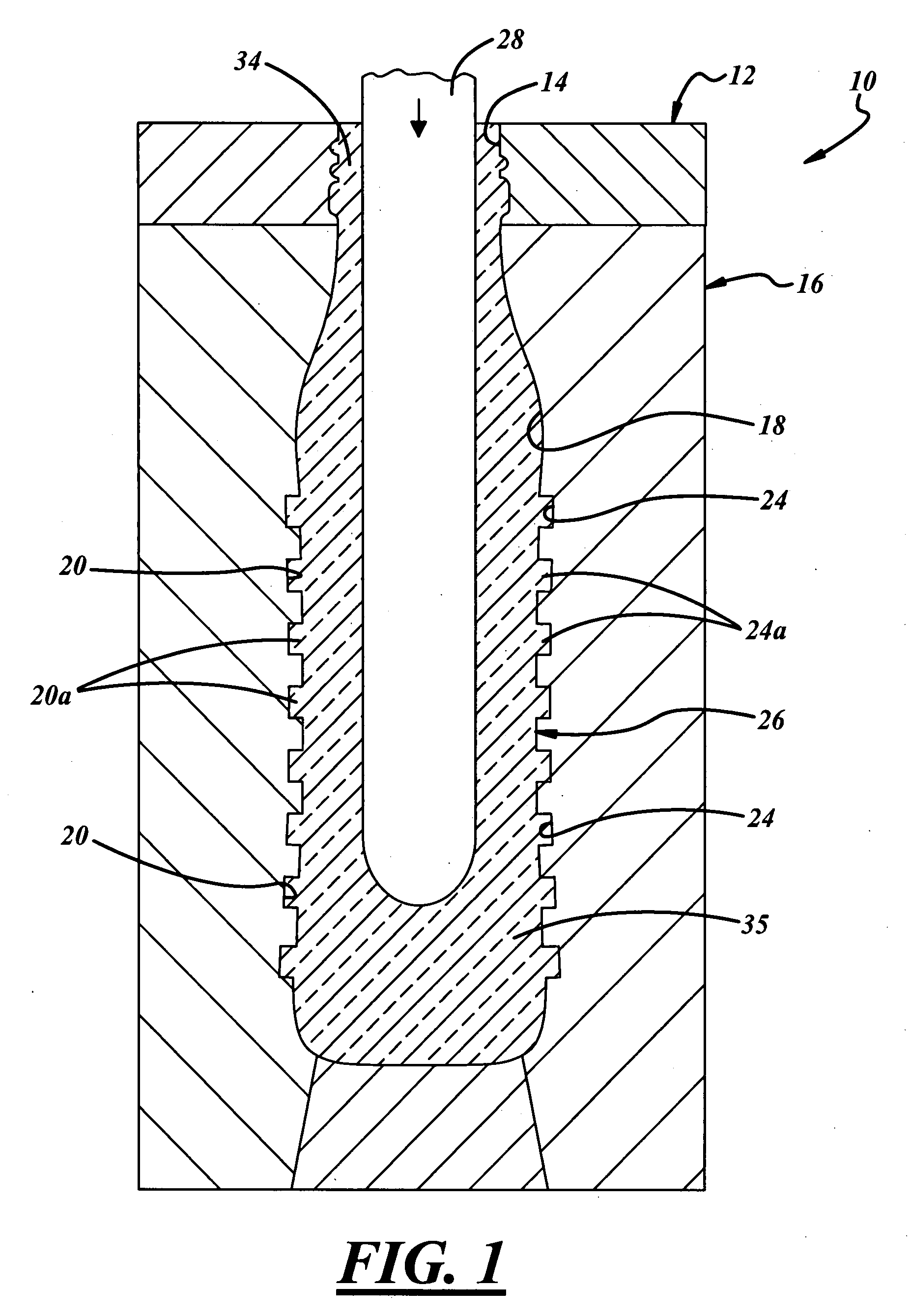

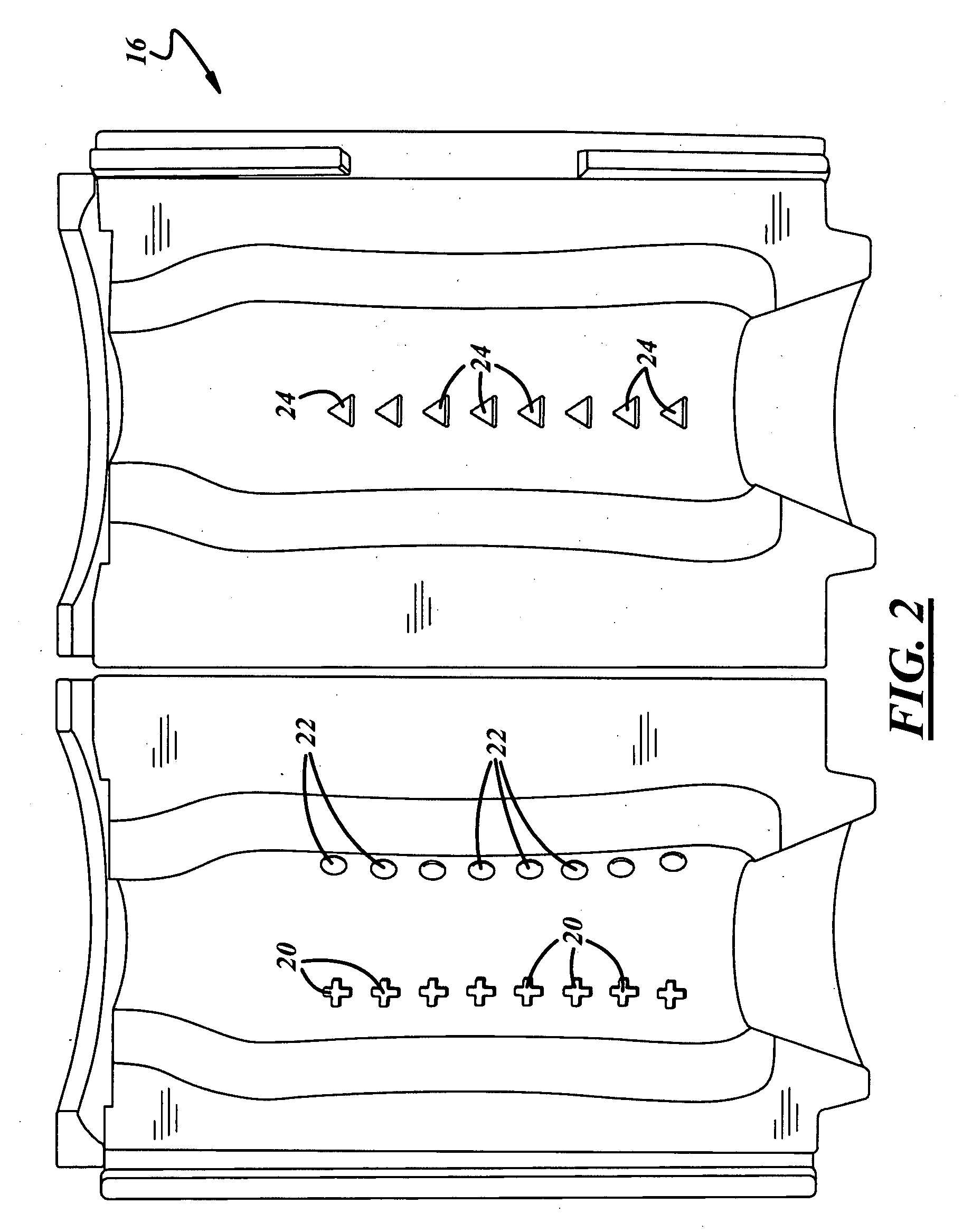

[0013]FIGS. 1 and 2 illustrate the blank mold stage of a glass container manufacturing operation in accordance with an exemplary embodiment of the present disclosure. A blank mold 10 includes a multi-section neck ring 12 having an internal surface 14 for forming the final container neck finish geometry at the blank mold stage of manufacture. A multi-section blank mold body 16 has an internal surface 18 with at least one internal pocket or debossment, and preferably a plurality of internal pockets or debossments of predetermined geometry and preferably in a predetermined geometric pattern. For example, FIG. 2 illustrates internal debossments 20 of cross-shaped geometry, internal debossments 22 of part-spherical geometry and internal debossments 24 of triangular geometry. The respective series of debossments 20,22,24 are in linear arrays parallel to the axis of blank mold body 16. These particular exemplary debossment geometries and placements are for purposes of illustration only.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com