Patents

Literature

179results about "Sensitive elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

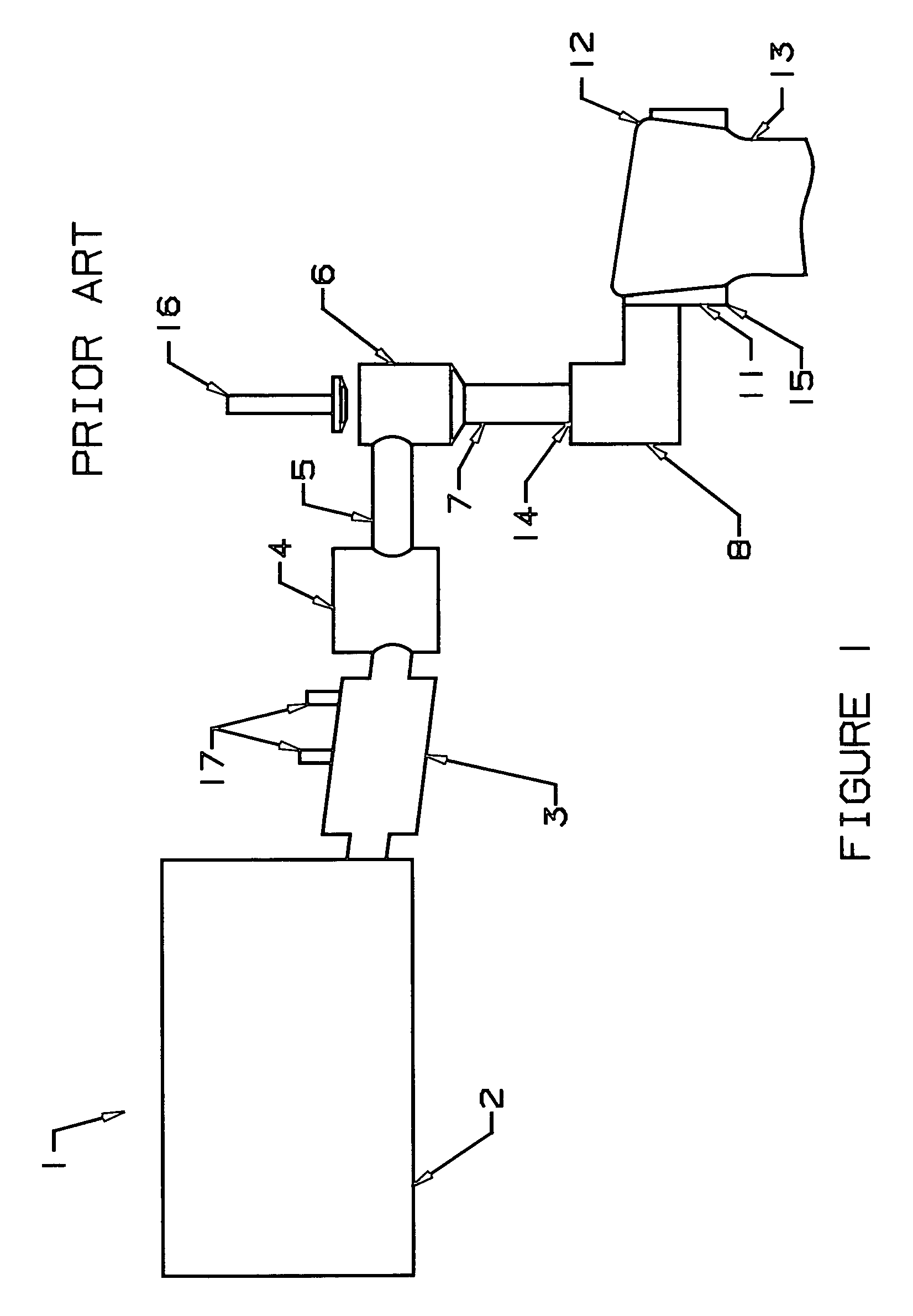

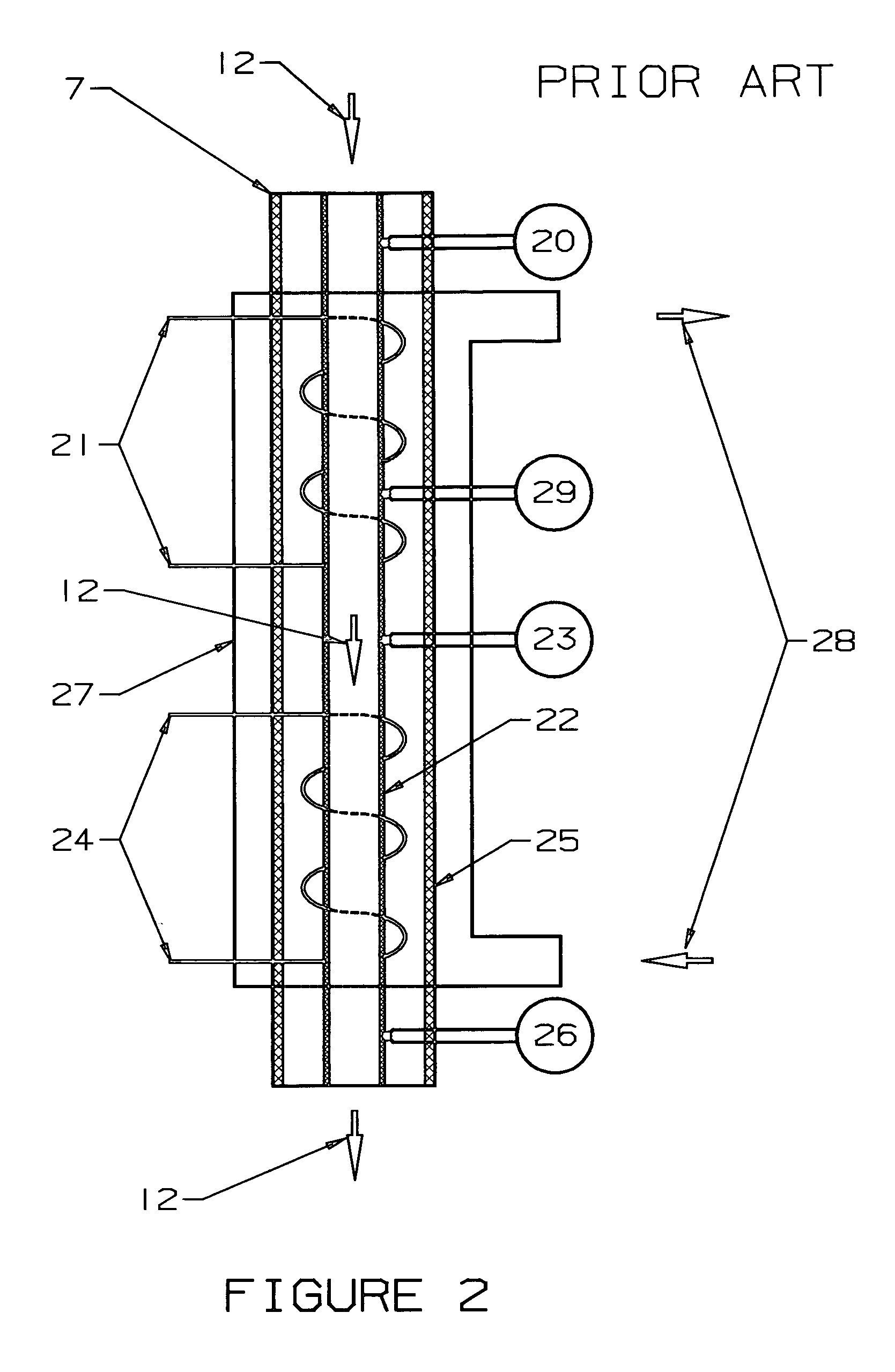

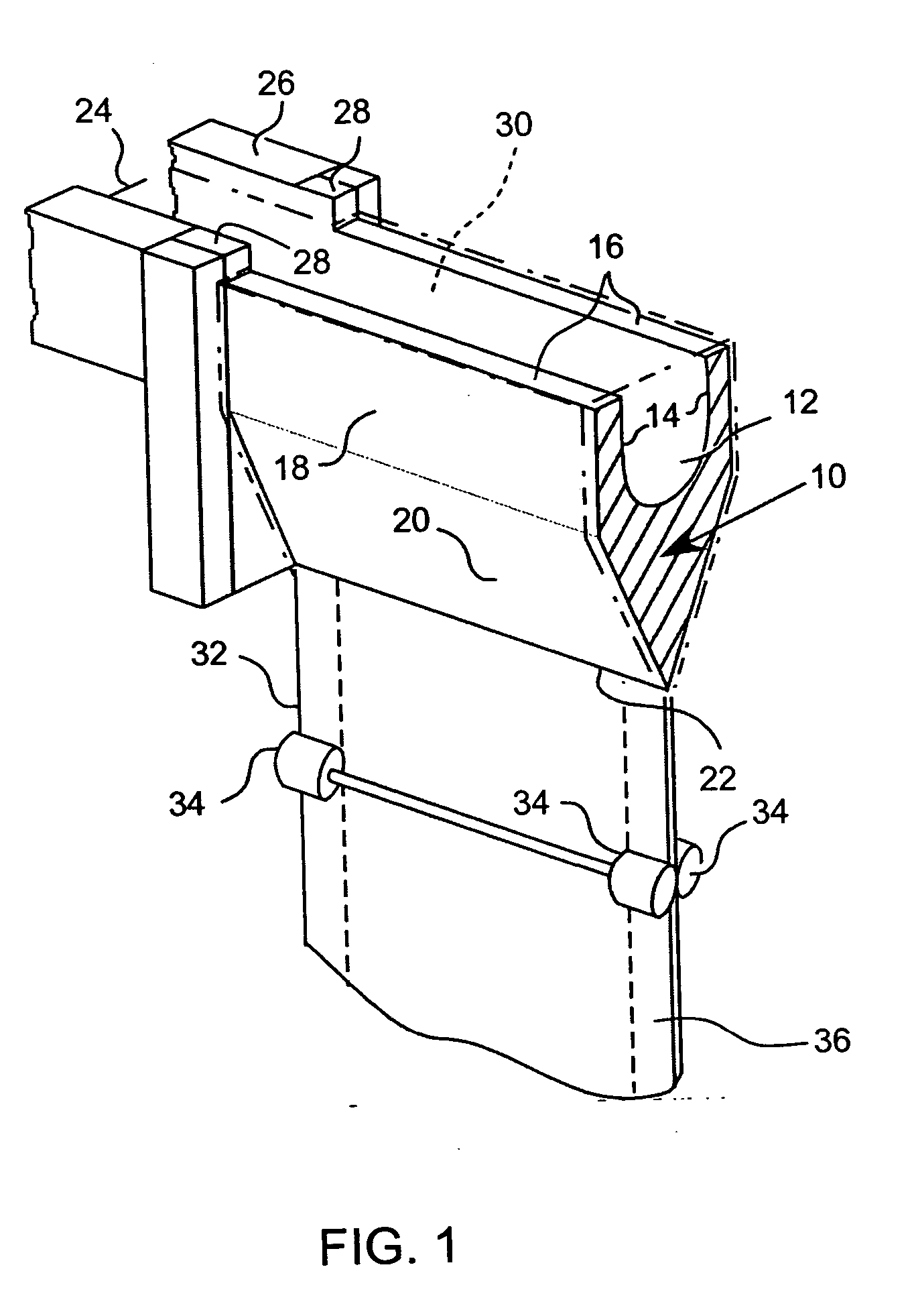

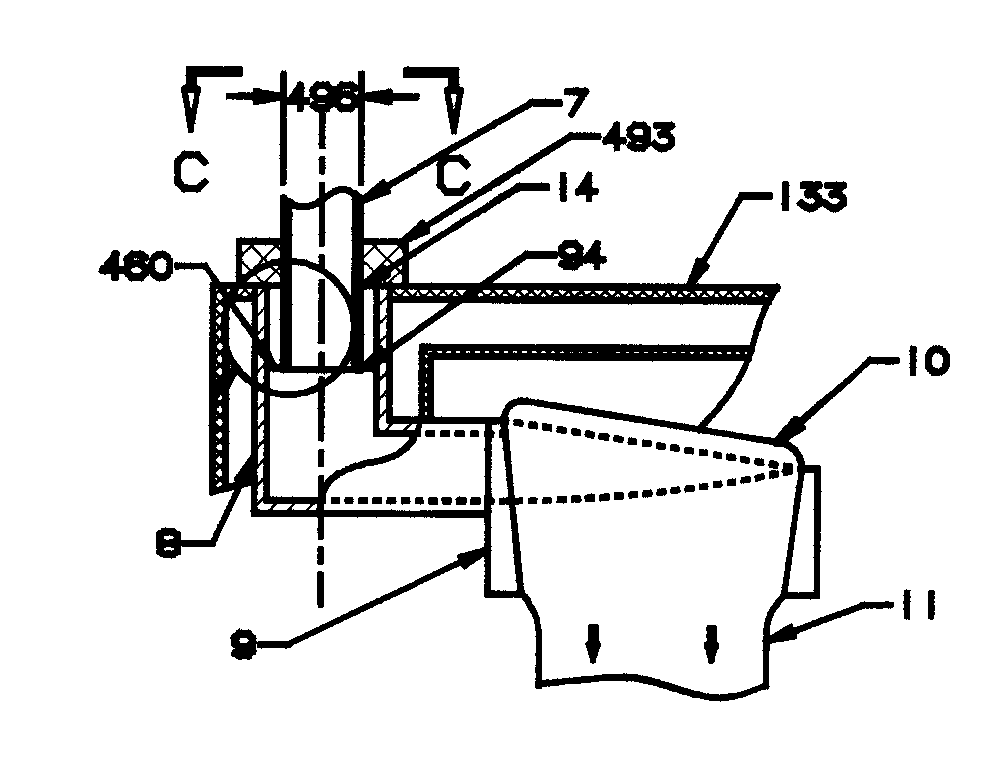

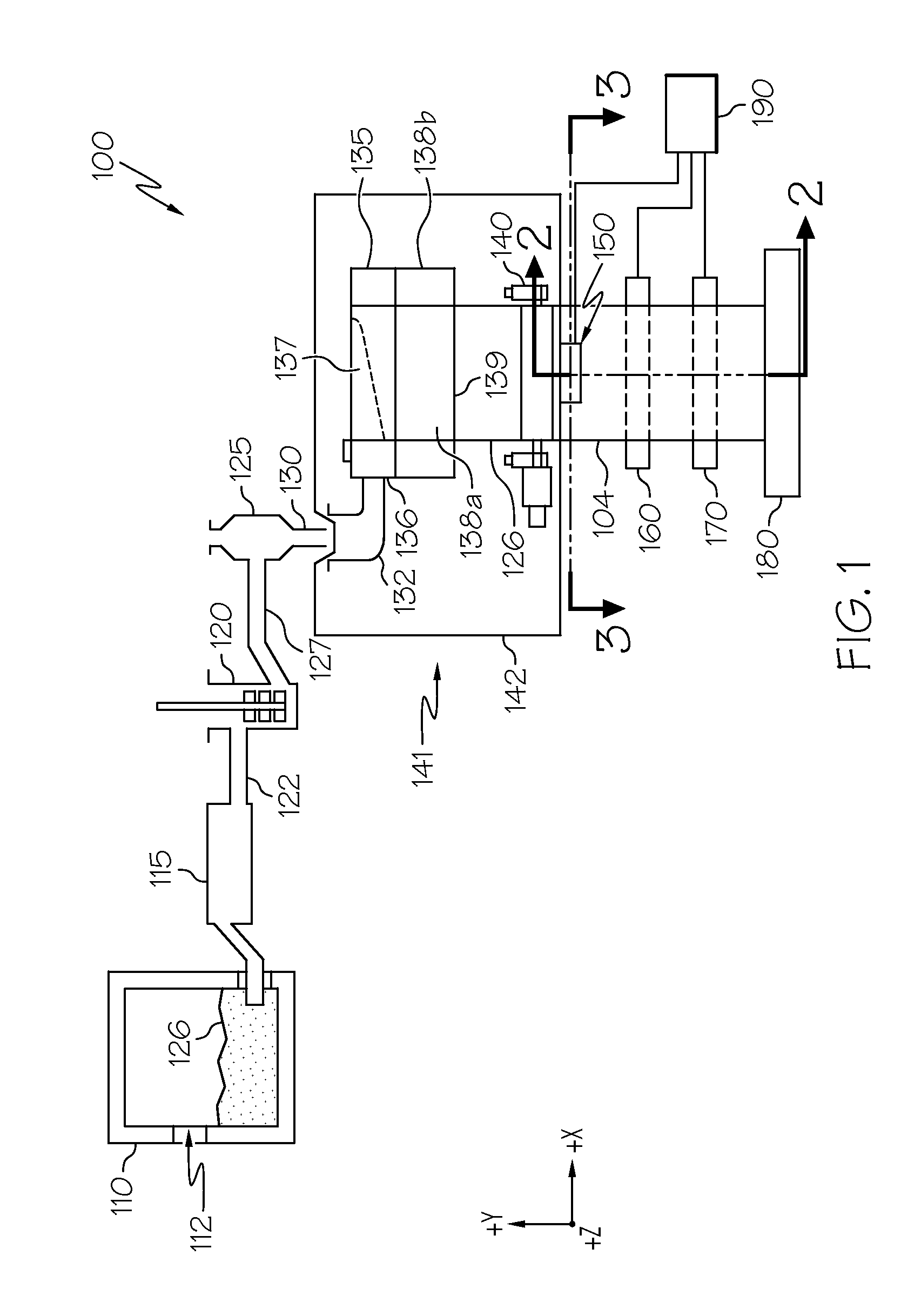

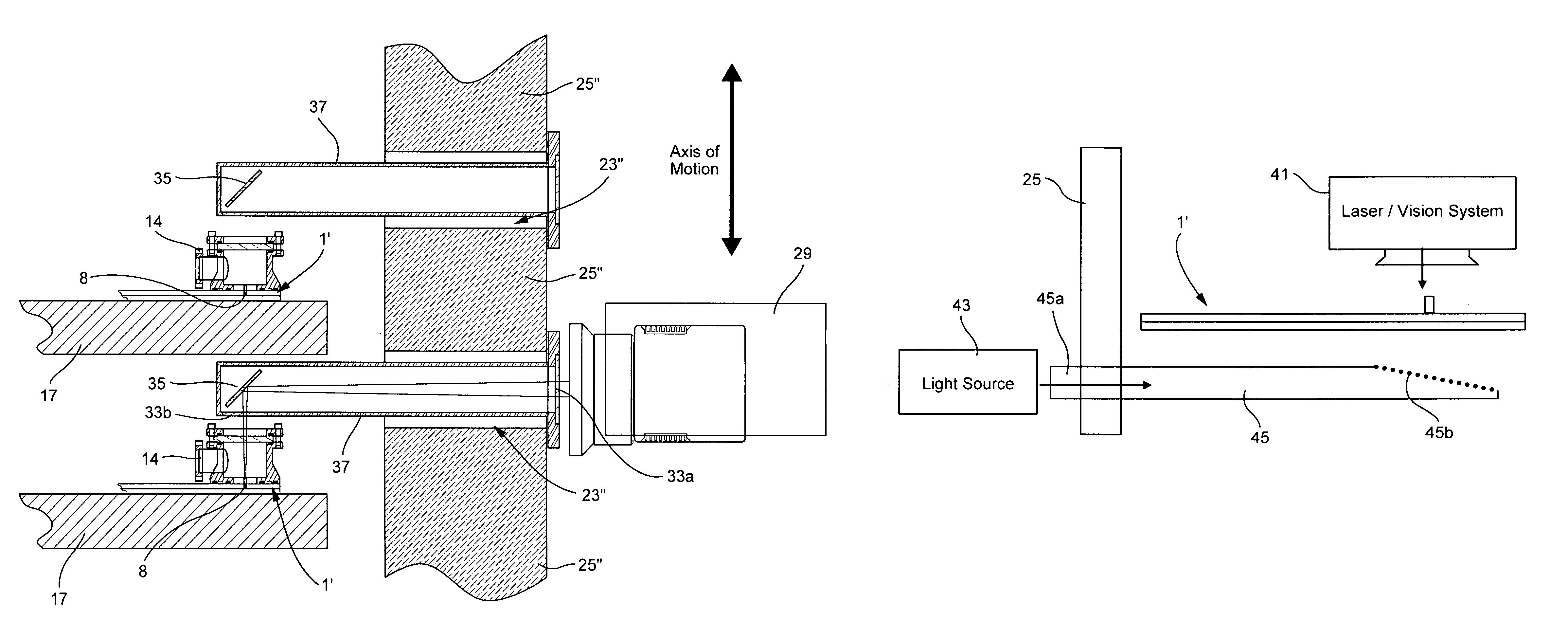

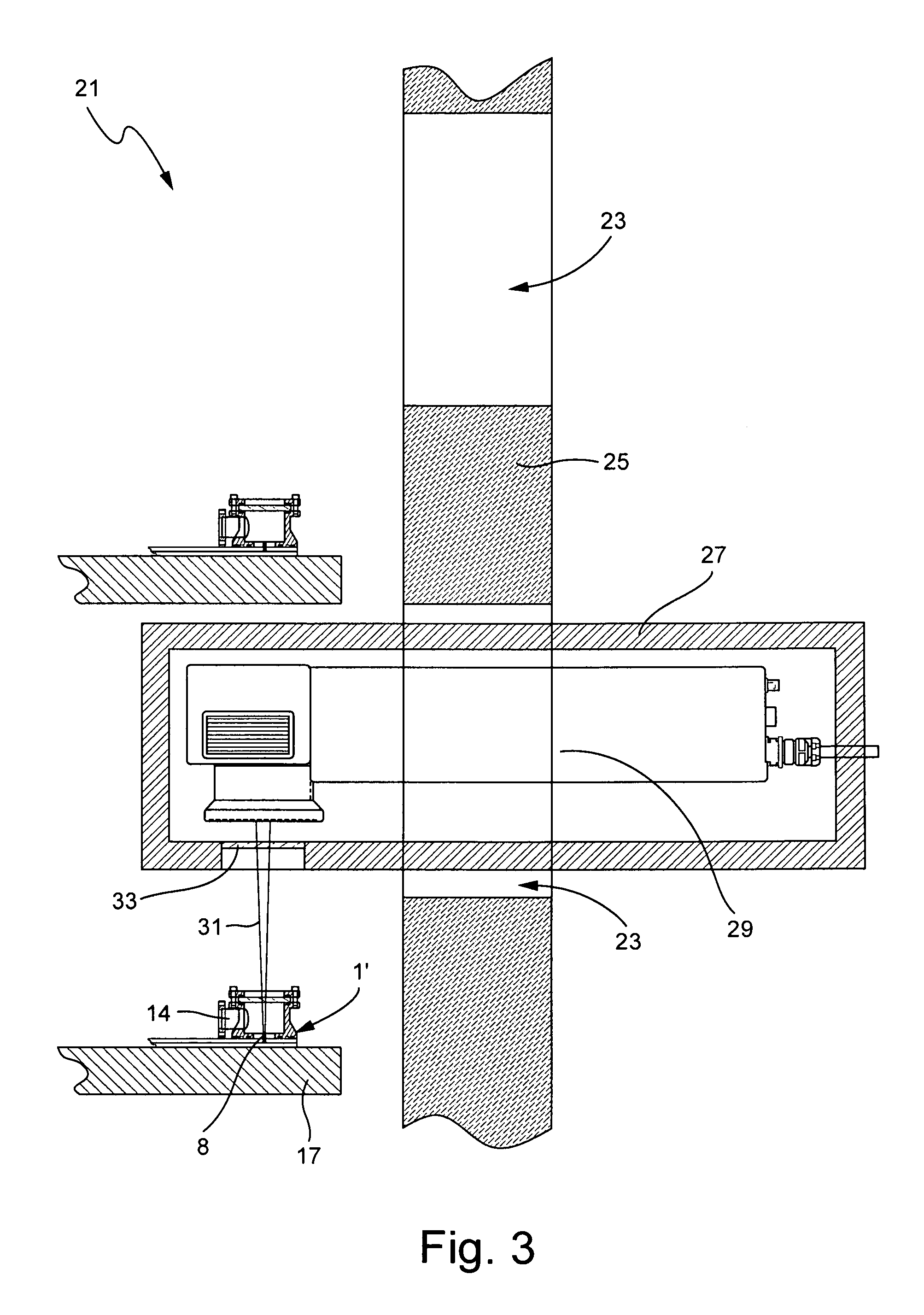

Overflow downdraw glass forming method and apparatus

ActiveUS20060016219A1Process can be modifiedMinimizing thickness variationGlass furnace apparatusVolume/mass flow measurementThermal creepEngineering

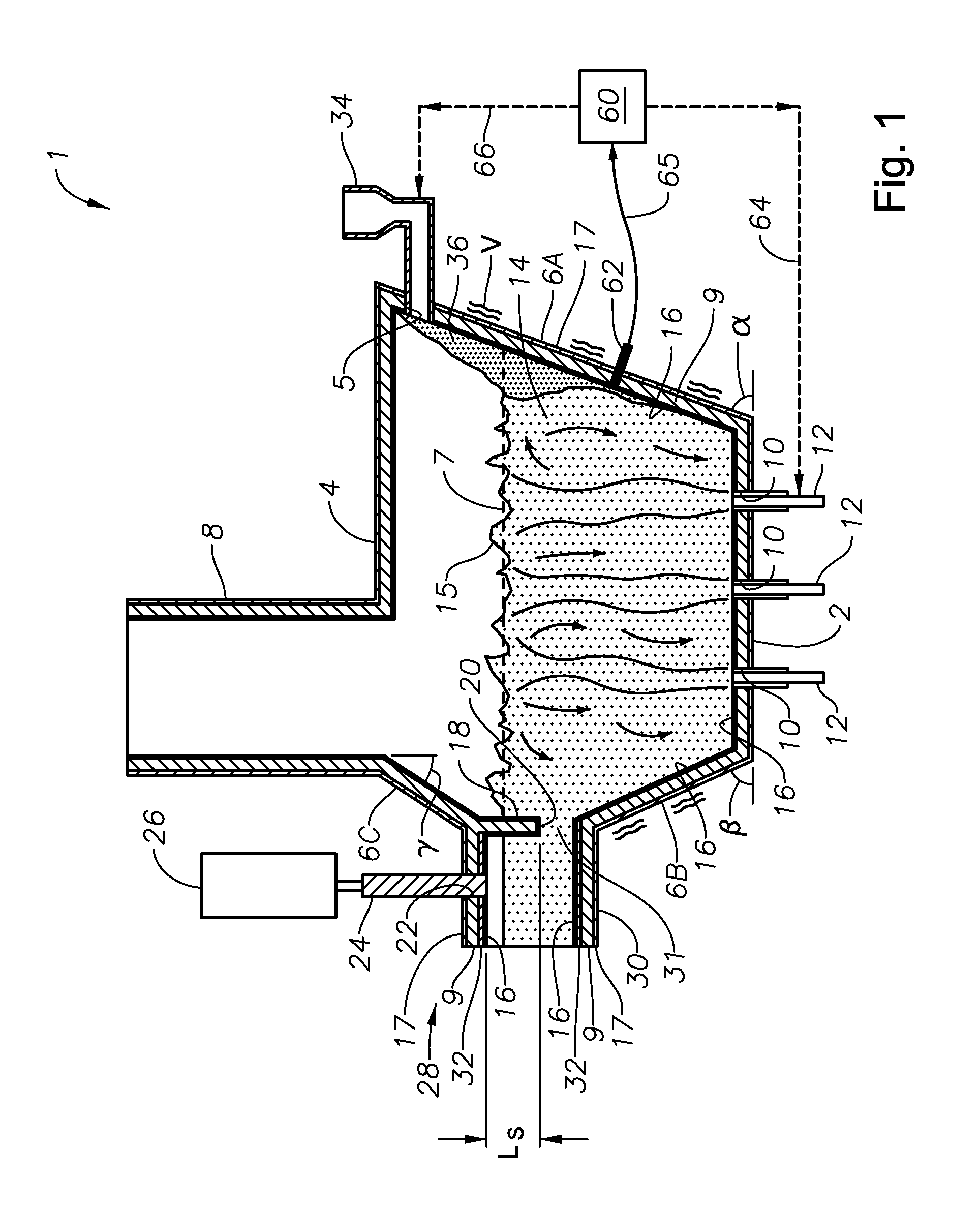

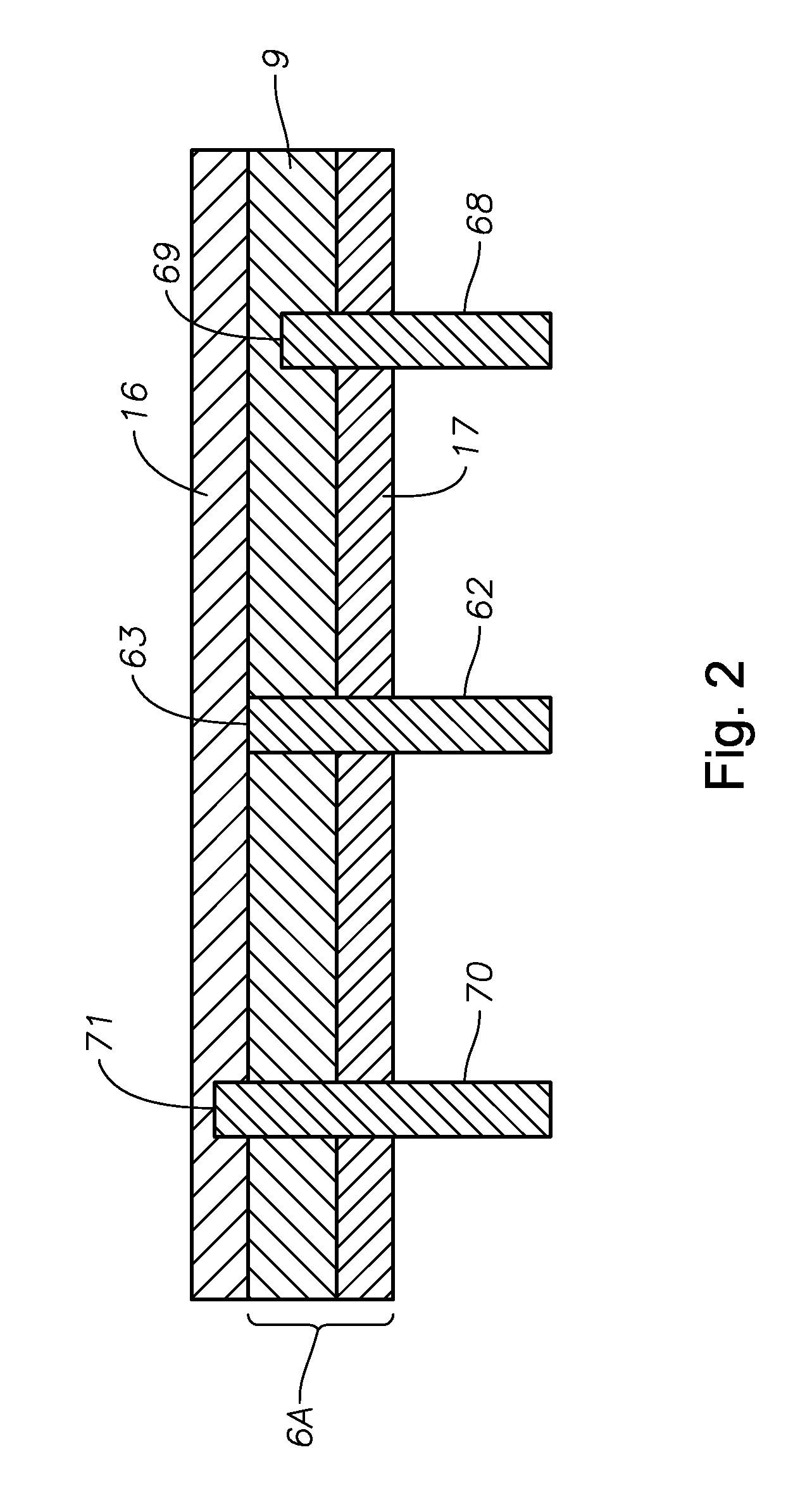

The present invention significantly modifies “The Overflow Process”. It includes a method and apparatus for measuring glass flow rate and maintaining a constant glass flow rate. It also embodies design features and methods that support and stress the forming apparatus in a manner such that the deformation that results from thermal creep is corrected, thus minimizing the effect of the thermal creep on the thickness variation of the glass sheet. The present invention also embodies design features that change the process from a single step (combined flow distribution and cooling) to a two step process; step one being flow distribution and step two being cooling.

Owner:CORNING INC

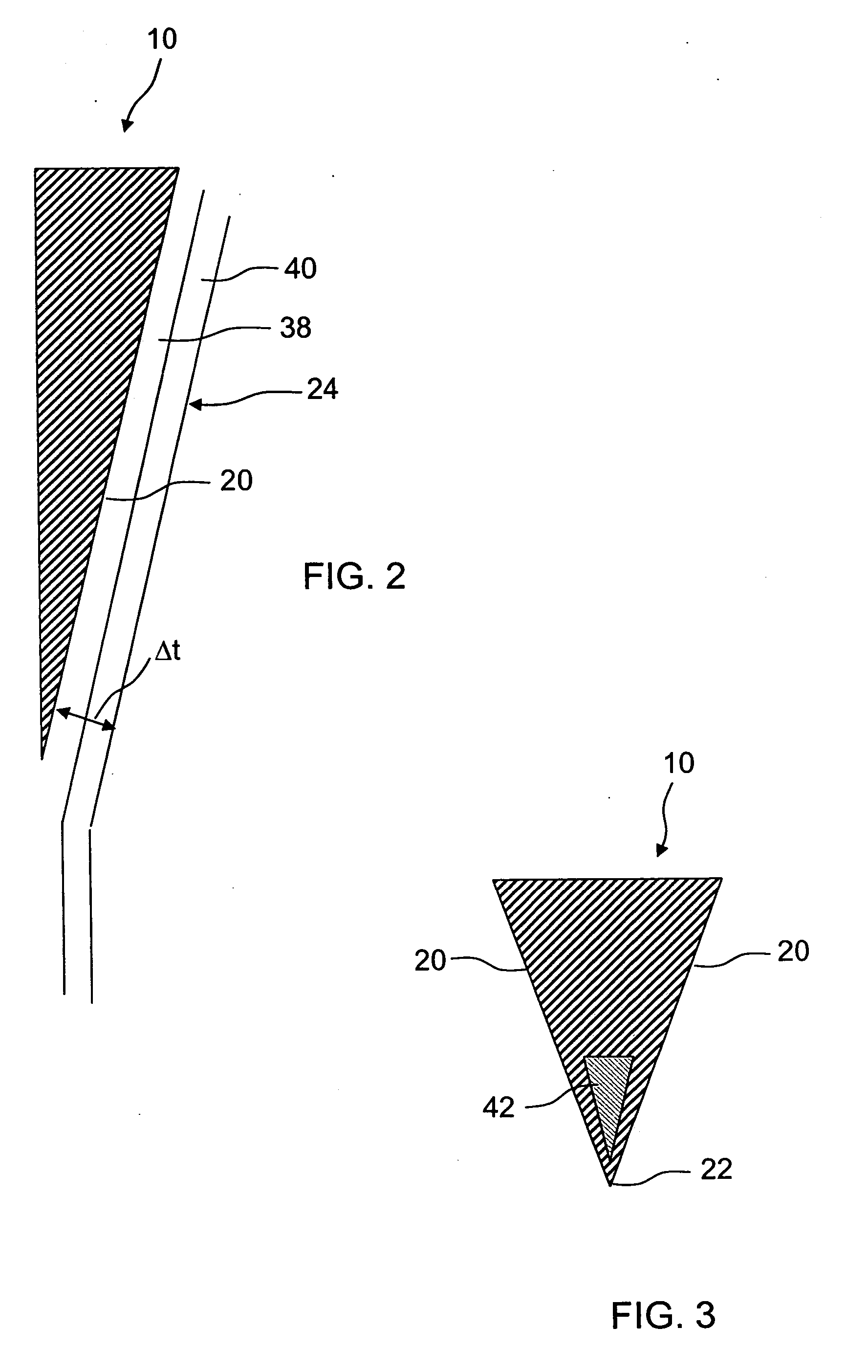

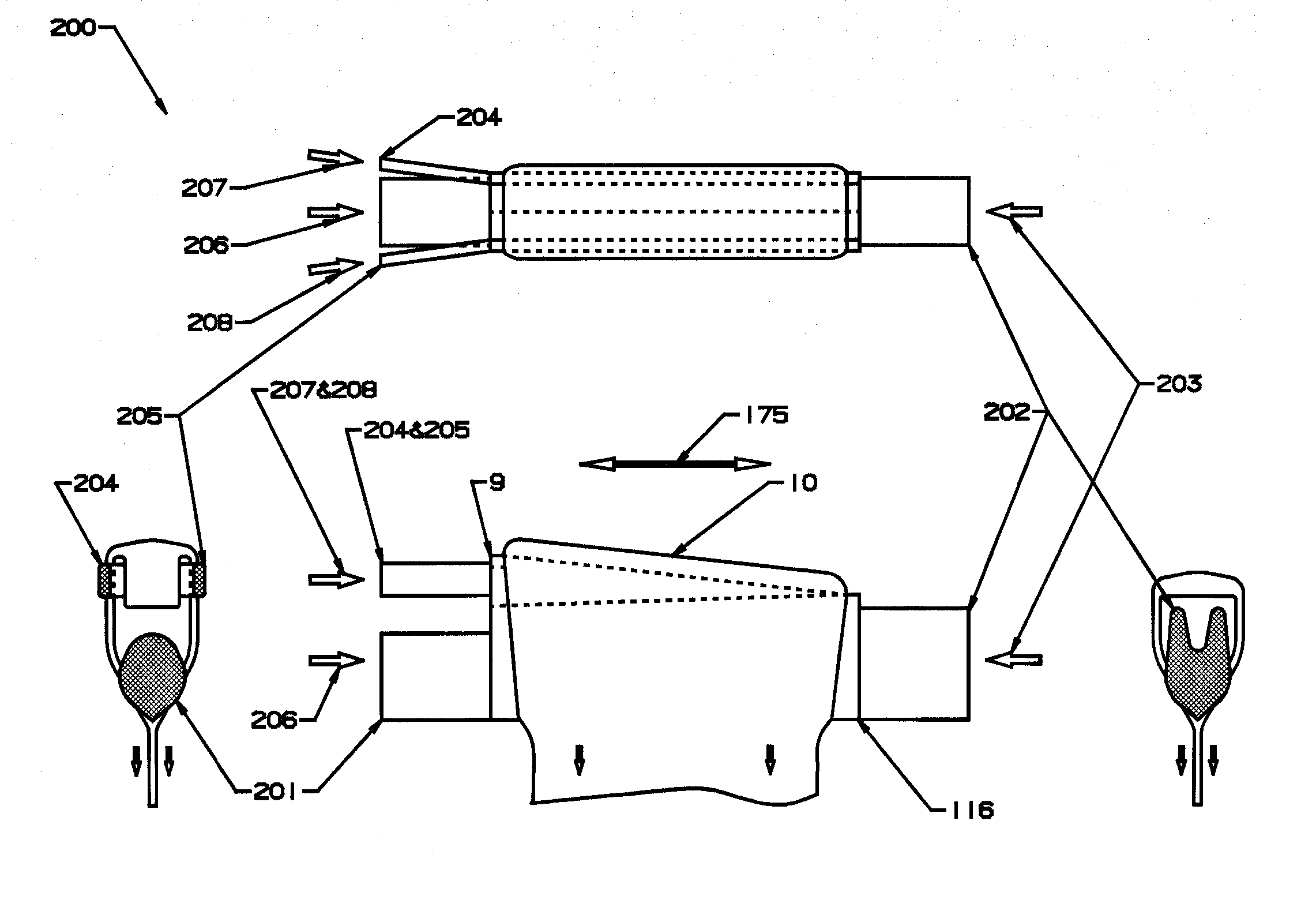

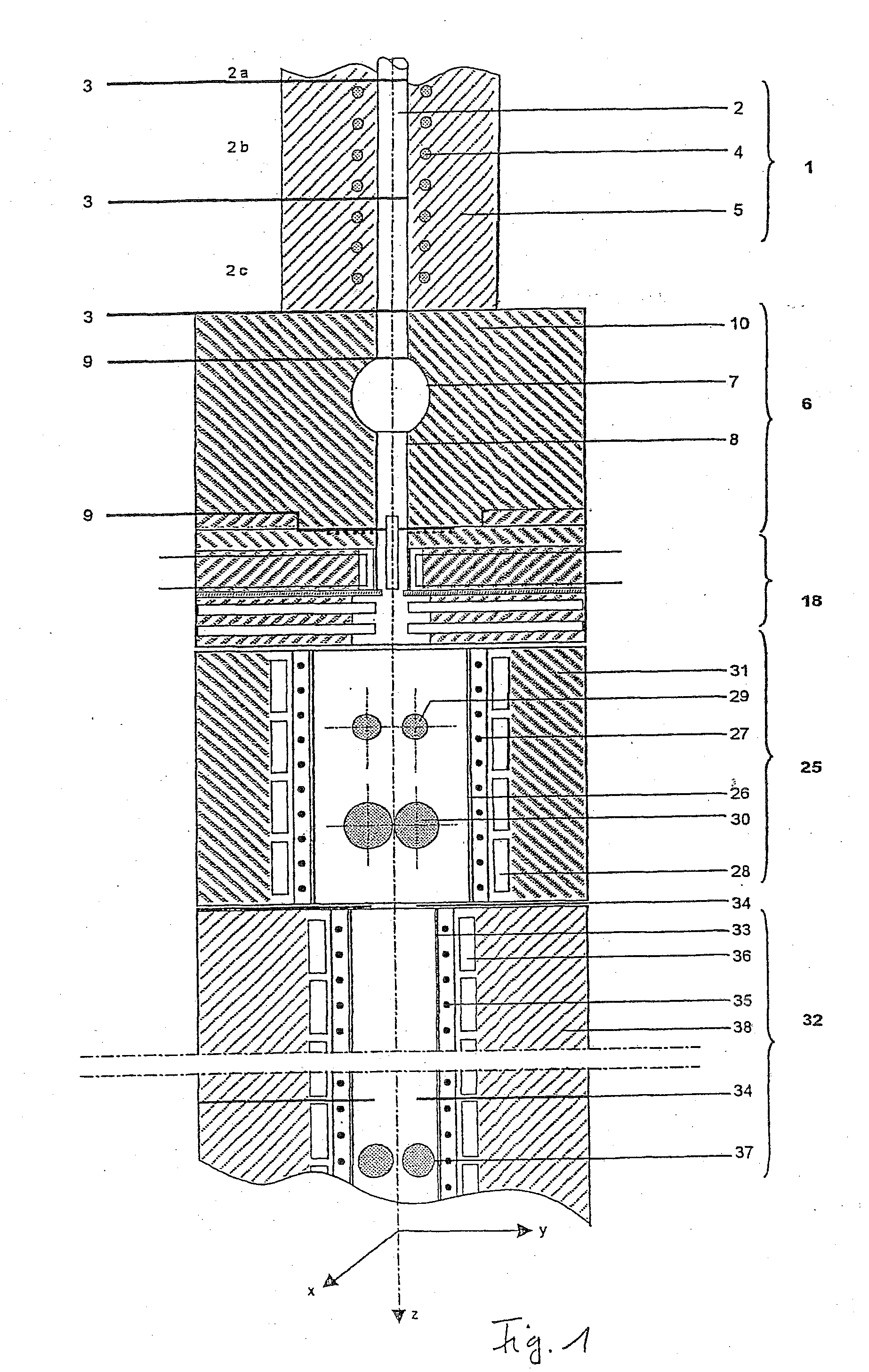

Method and apparatus for drawing a low liquidus viscosity glass

InactiveUS20070130994A1Easy to understandGlass furnace apparatusGlass drawing apparatusViscosityGlass sheet

A method of a drawing a glass ribbon from molten glass sheet via a downdraw process by creating a temperature drop across a thickness of the molten glass flowing over forming surfaces of a forming wedge. The forming wedge includes an electrically conductive material for heating the glass above the root.

Owner:CORNING INC

High Speed Laser Processing of Transparent Materials

ActiveUS20150299018A1Avoid focusHigh precision laserBlowing machine gearingsGlass furnace apparatusLaser processingAtomic physics

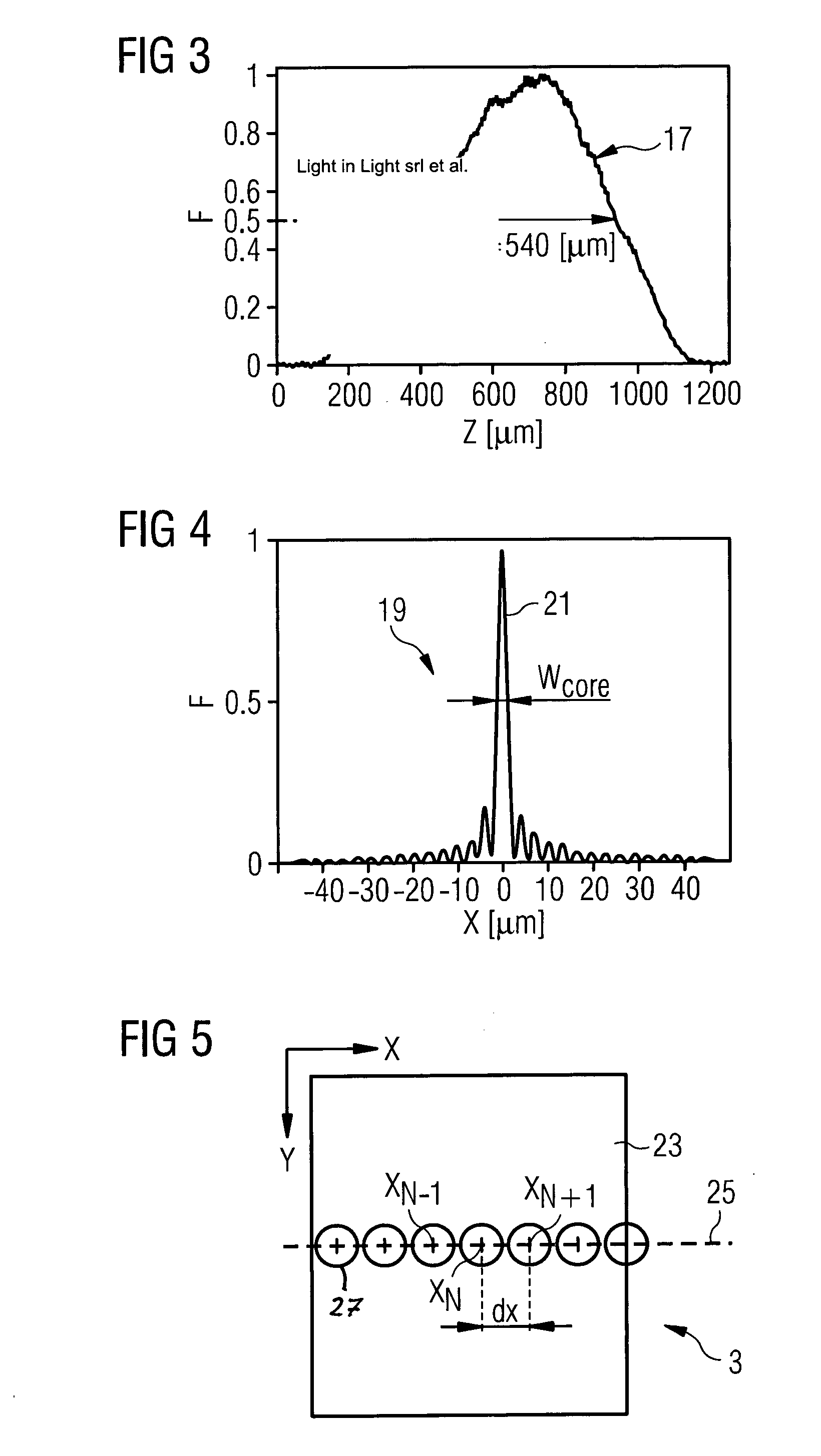

A method and system for laser pre-cutting a layered material (31) with a laser beam (14) is disclosed. The layered material (31) comprises at least one tensile stress layer (TSL), at least one compression stress layer (CSL1, CSL2), and at least one interface region (IR1, IR2) between the at least one tensile stress layer (TSL) and the at least one compression stress layer (CSL1, CSL2) and is transparent to allow propagation of the laser beam (14) through the layered material (31). The method may comprise setting an optical beam path (8) and a laser characteristic of the laser beam (14) such that an interaction of the laser beam (14) with the layered material (31) generates an elongate damage region (57) in the layered material (31), and, for each of a series of pre-cut positions (XN−1, XN, XN+1) of the layered material (31), pre-cutting the layered material (31) by positioning the layered material (31) and the laser beam (14) with respect to each other and irradiating the laser beam (14) such that the respective elongate damage regions (57) extend across the at least one interface region (IR1, IR2).

Owner:UAB ALTECHNA R&D

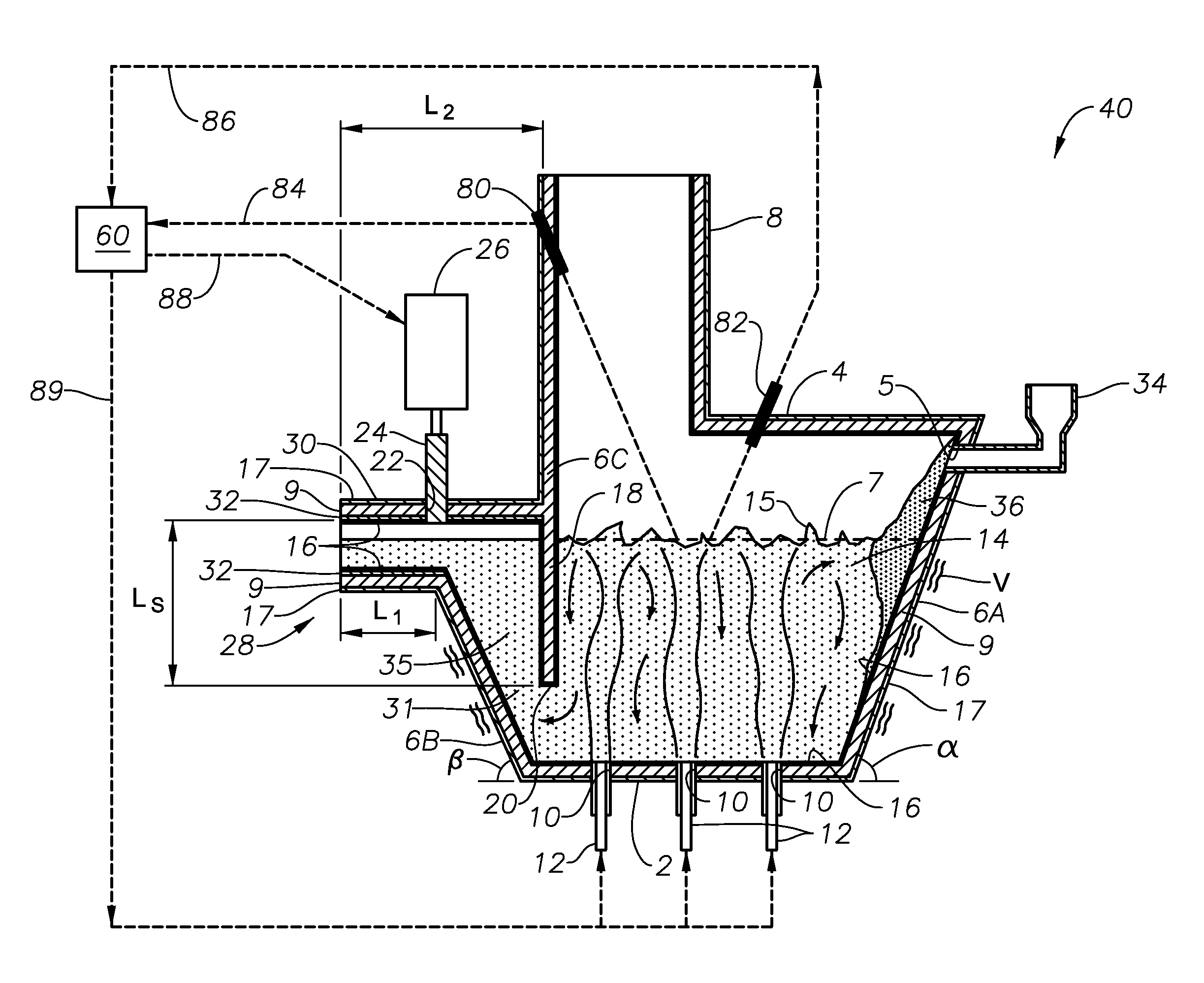

Submerged combustion melting processes for producing glass and similar materials, and systems for carrying out such processes

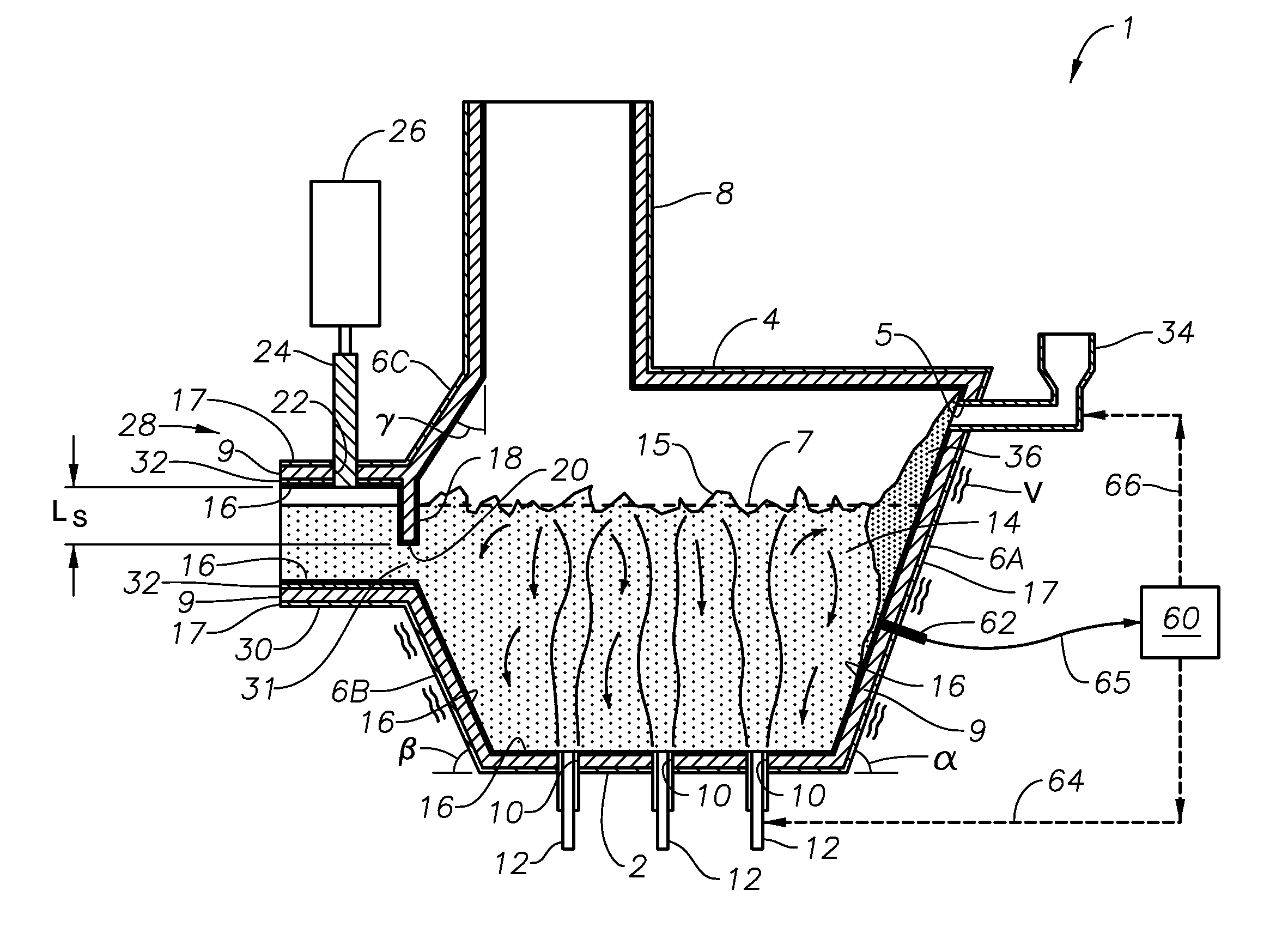

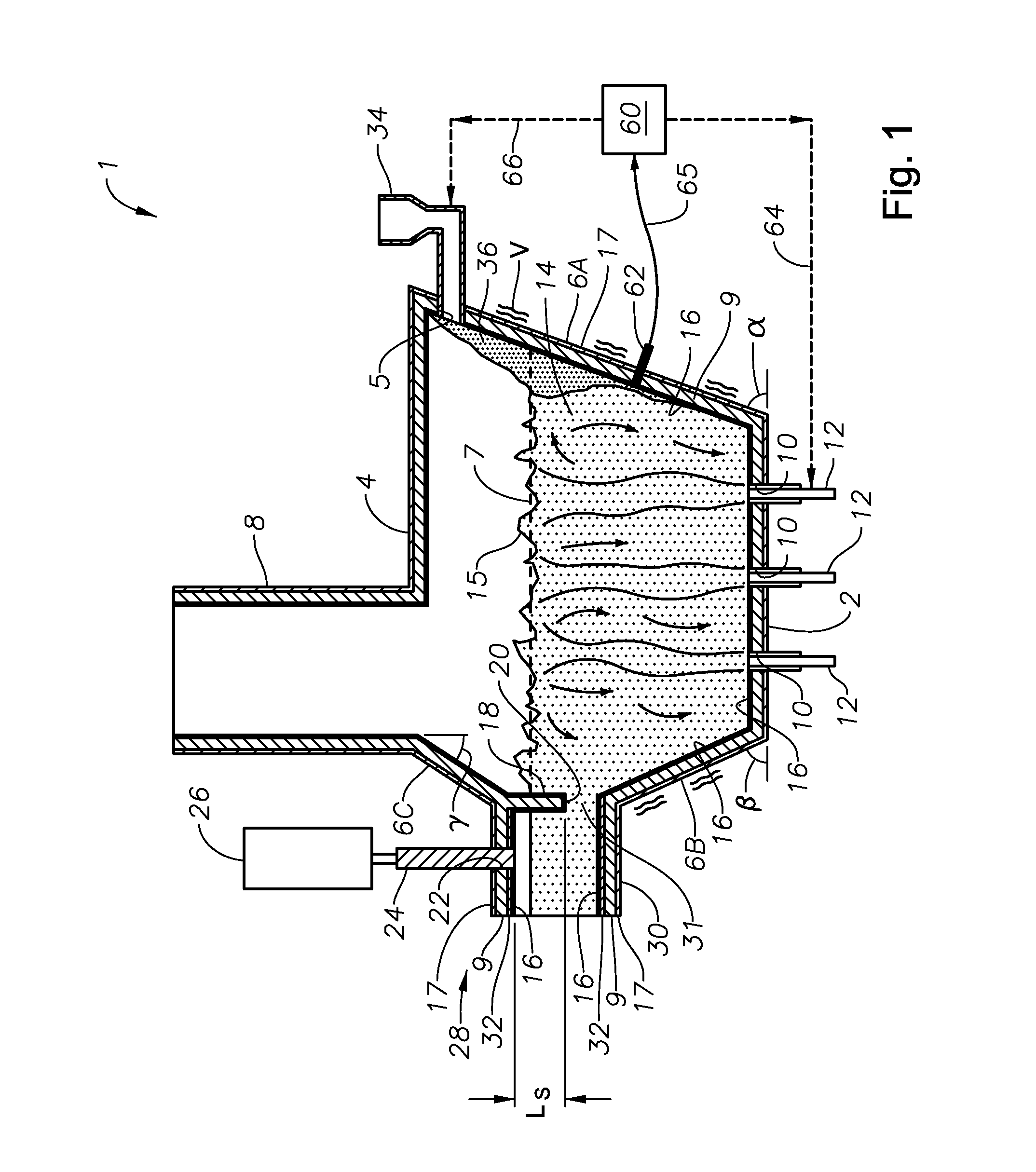

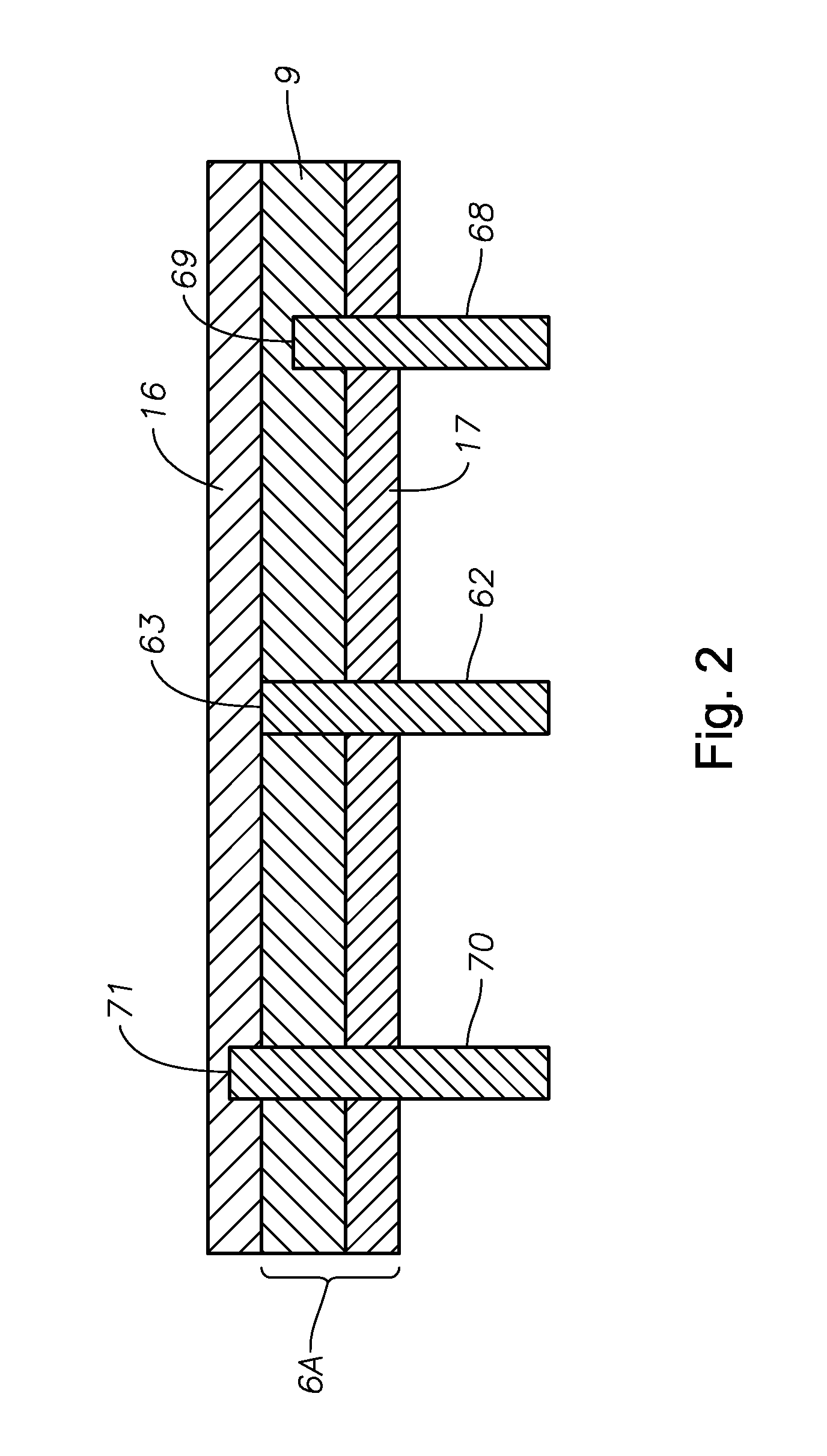

Processes of controlling submerged combustion melters, and systems for carrying out the methods. One process includes feeding vitrifiable material into a melter vessel, the melter vessel including a fluid-cooled refractory panel in its floor, ceiling, and / or sidewall, and heating the vitrifiable material with a burner directing combustion products into the melting zone under a level of the molten material in the zone. Burners impart turbulence to the molten material in the melting zone. The fluid-cooled refractory panel is cooled, forming a modified panel having a frozen or highly viscous material layer on a surface of the panel facing the molten material, and a sensor senses temperature of the modified panel using a protected thermocouple positioned in the modified panel shielded from direct contact with turbulent molten material. Processes include controlling the melter using the temperature of the modified panel. Other processes and systems are presented.

Owner:JOHNS MANVILLE CORP

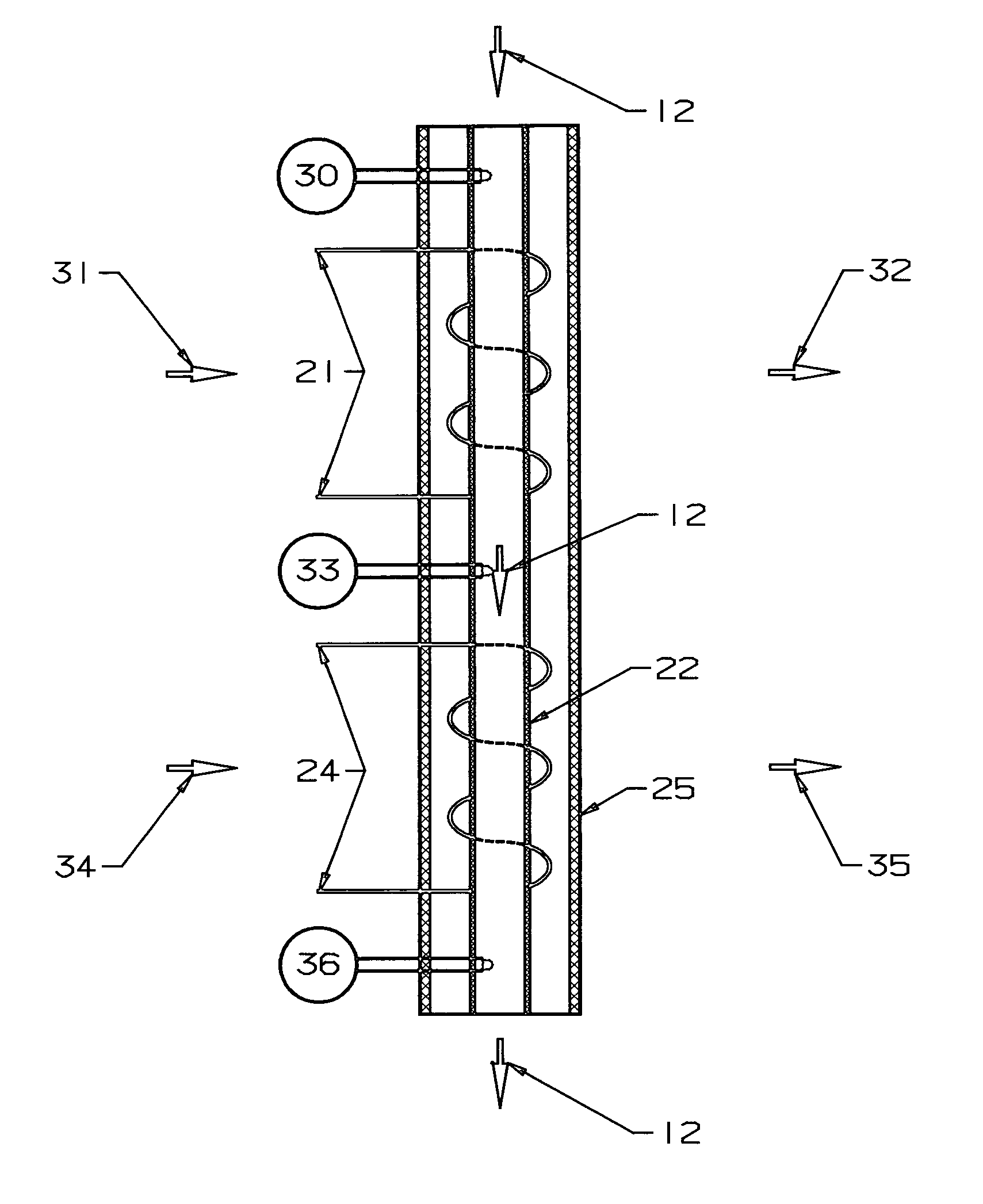

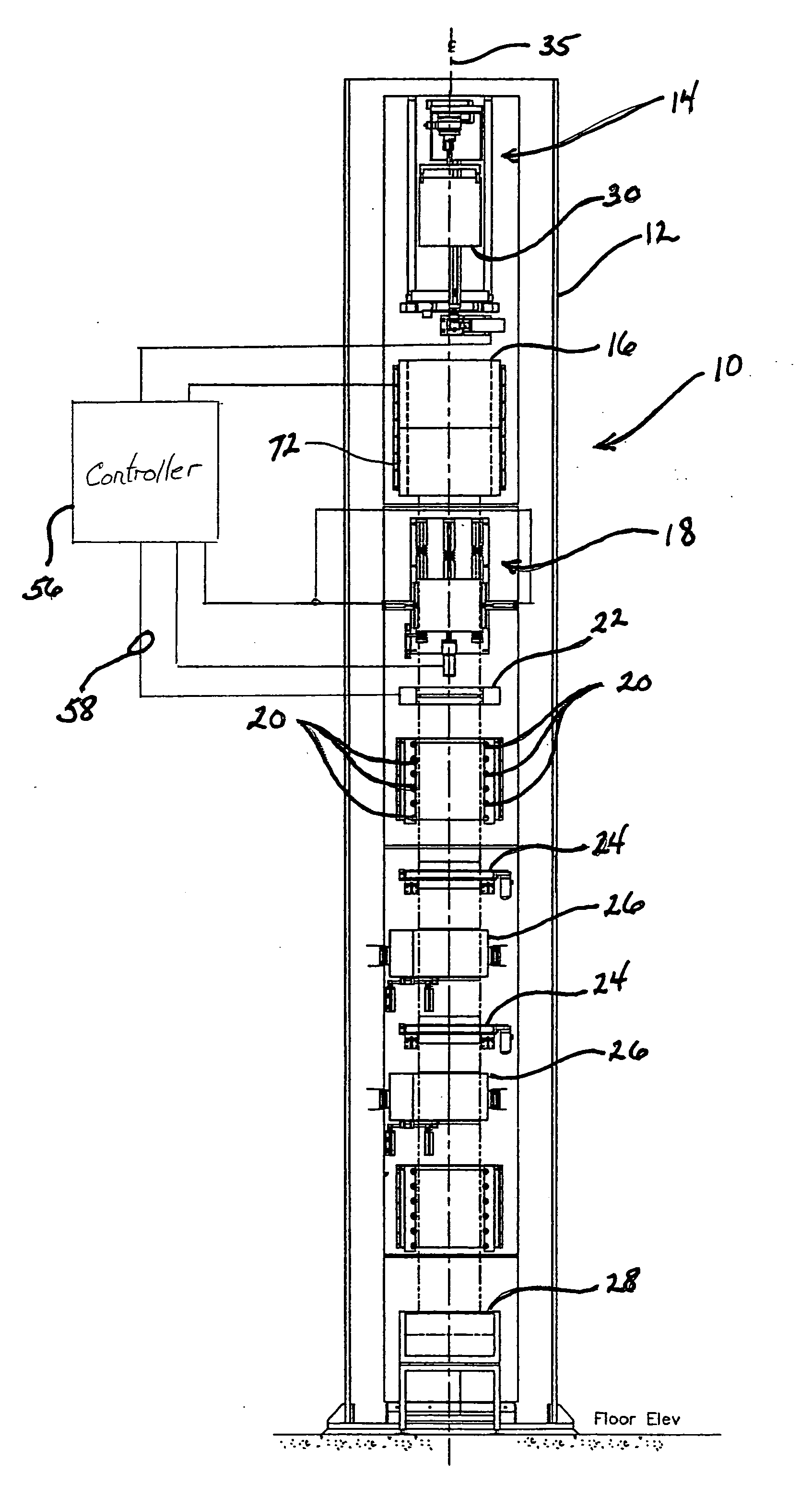

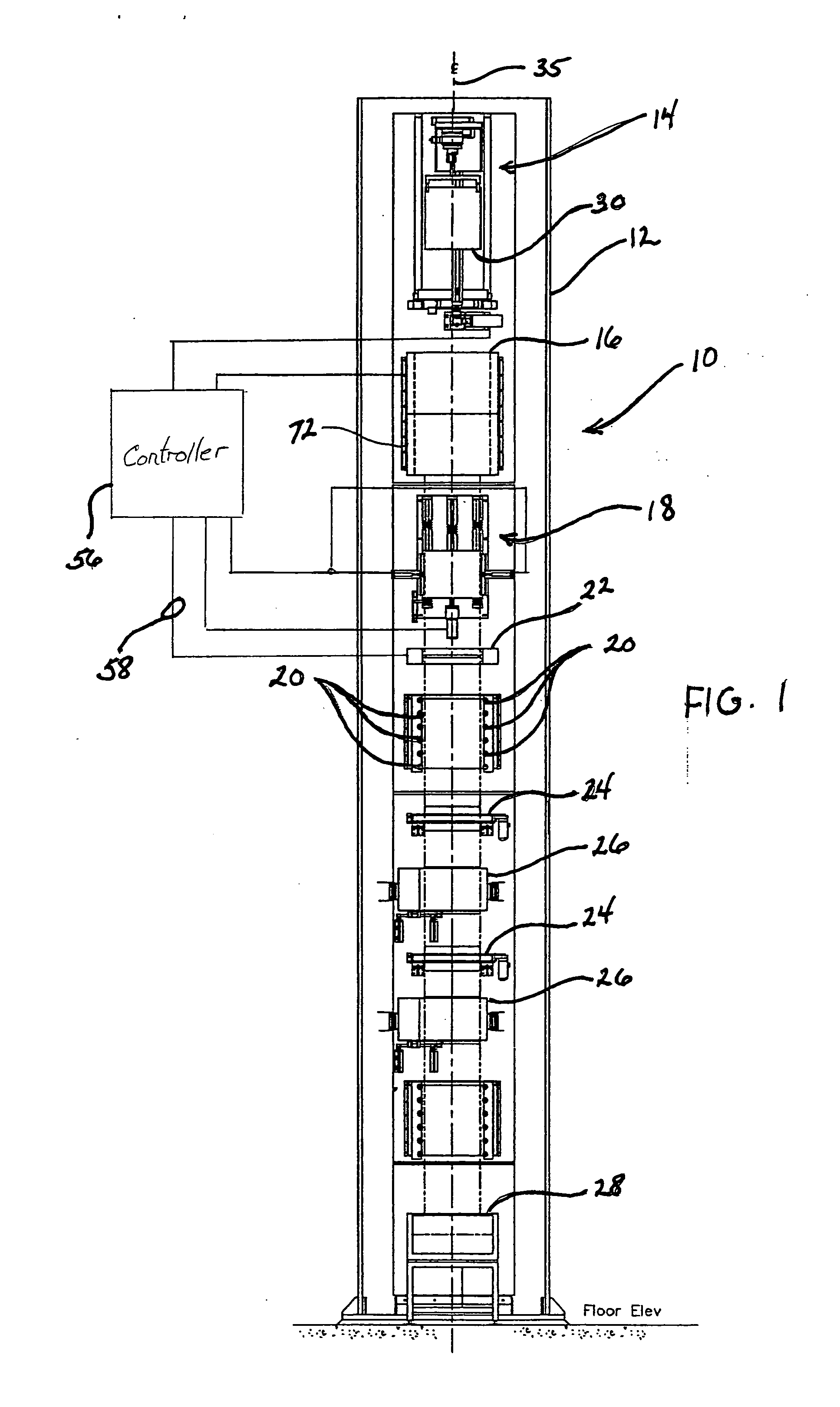

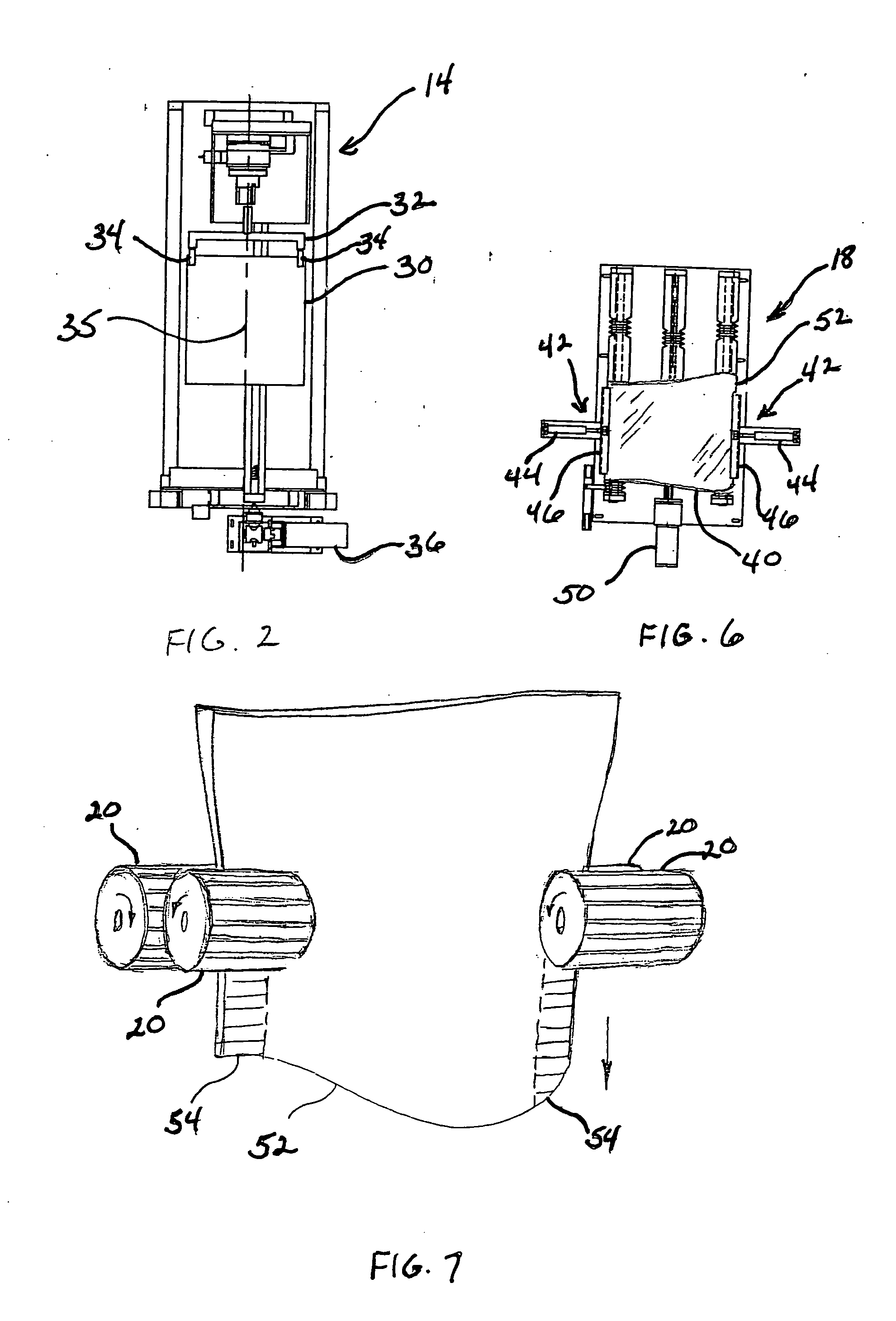

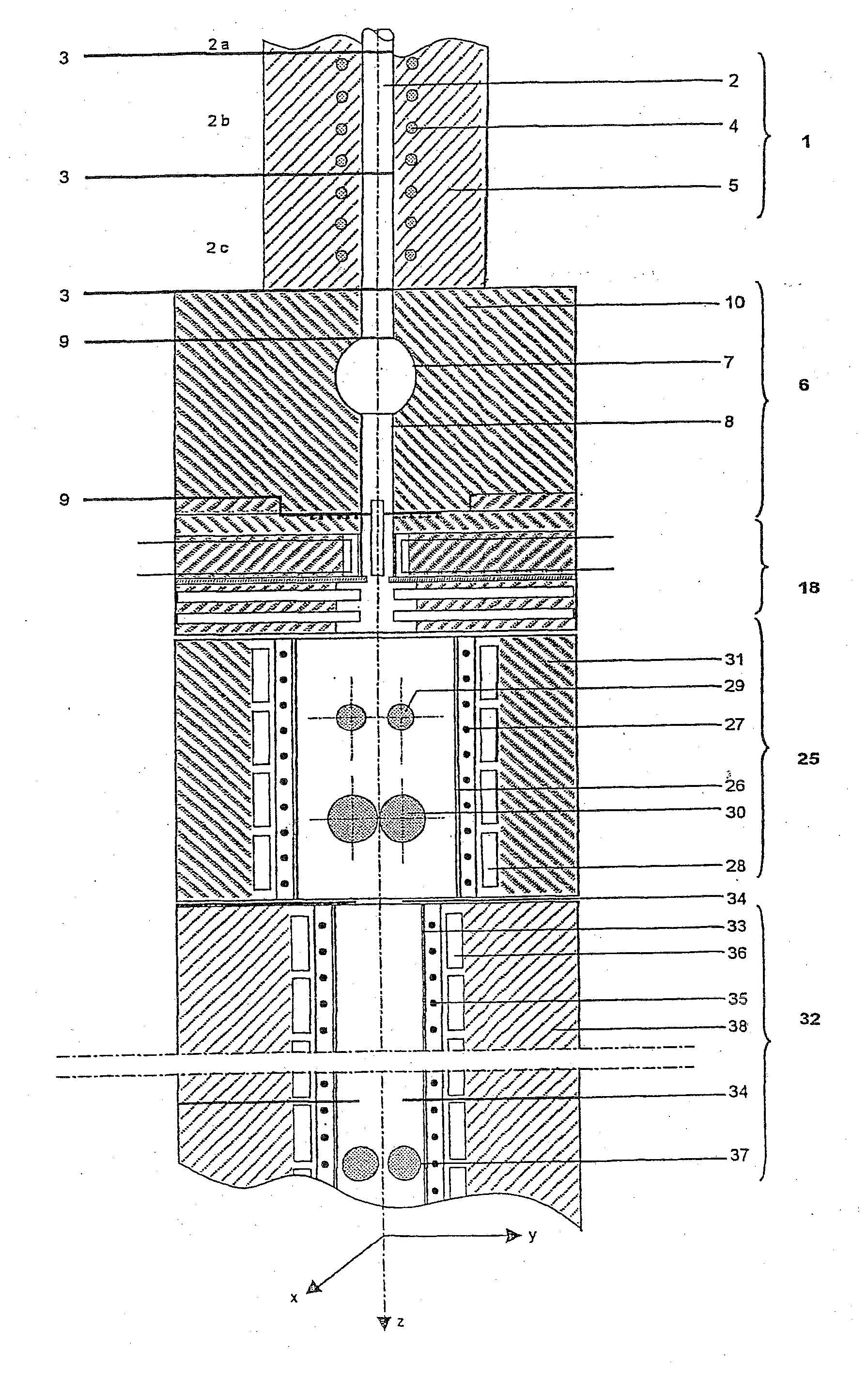

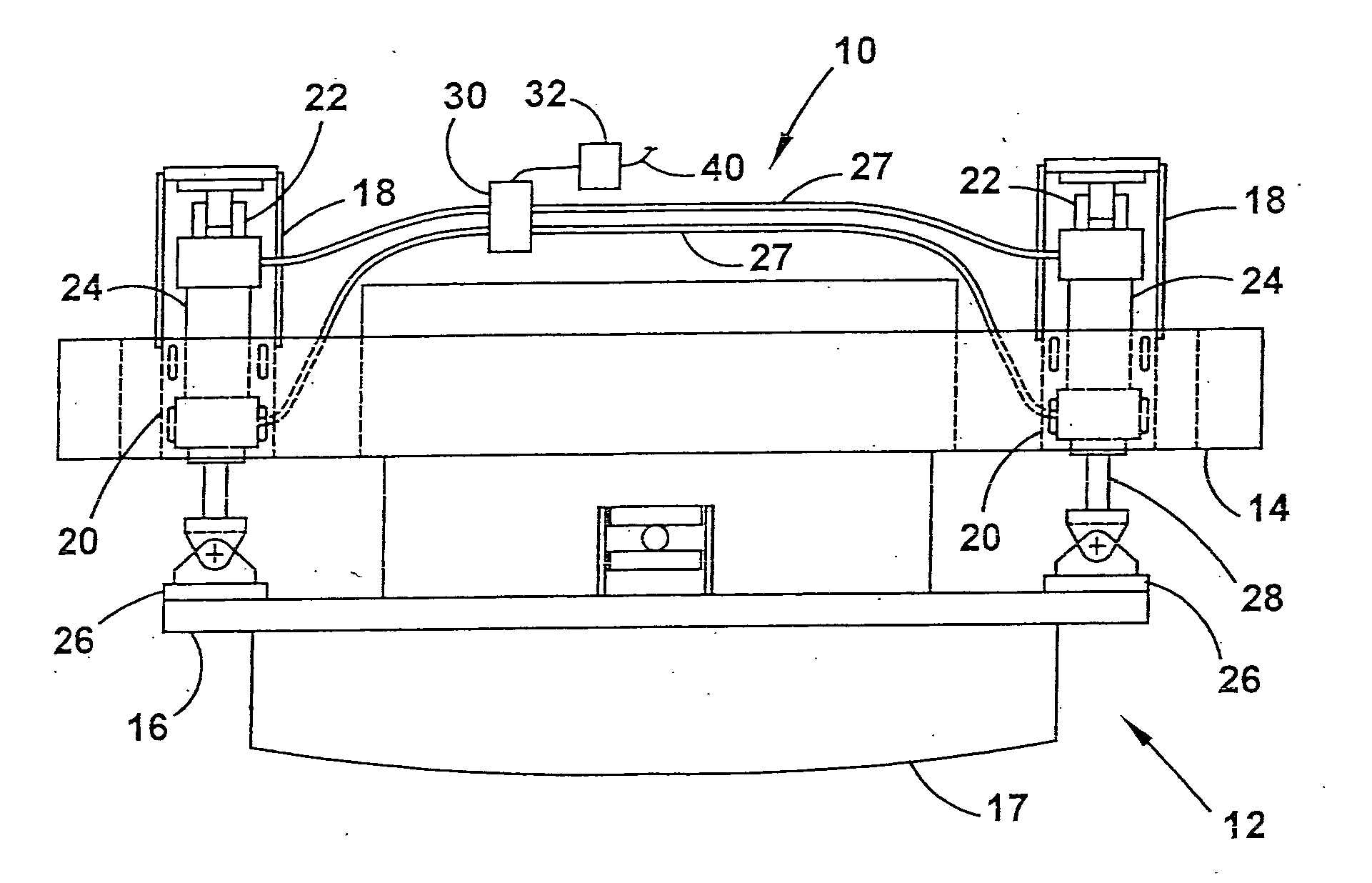

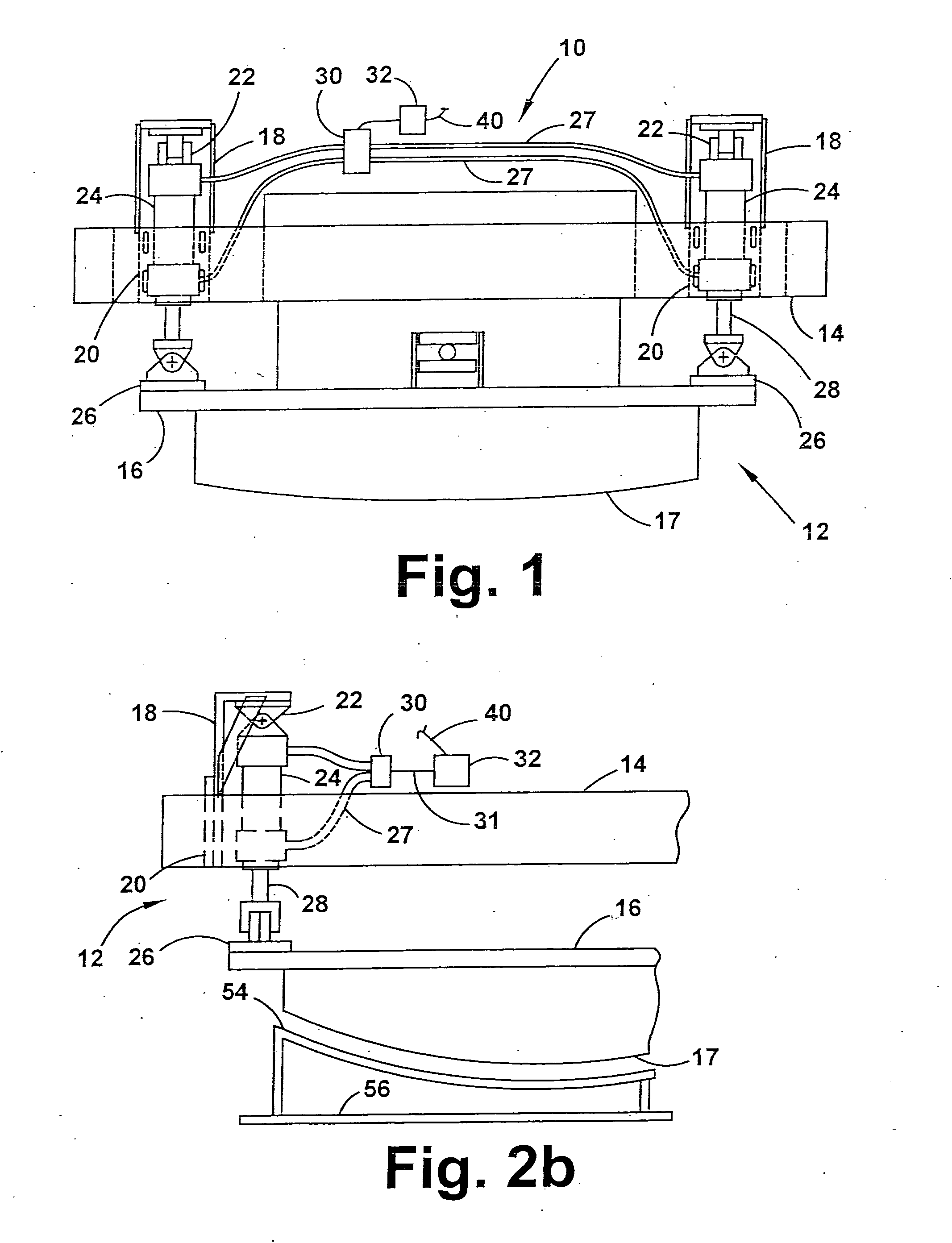

Overflow Downdraw Glass Forming Method and Apparatus

InactiveUS20070068197A1Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Submerged combustion melting processes for producing glass and similar materials, and systems for carrying out such processes

Processes of controlling submerged combustion melters, and systems for carrying out the methods. One process includes feeding vitrifiable material into a melter vessel, the melter vessel including a fluid-cooled refractory panel in its floor, ceiling, and / or sidewall, and heating the vitrifiable material with a burner directing combustion products into the melting zone under a level of the molten material in the zone. Burners impart turbulence to the molten material in the melting zone. The fluid-cooled refractory panel is cooled, forming a modified panel having a frozen or highly viscous material layer on a surface of the panel facing the molten material, and a sensor senses temperature of the modified panel using a protected thermocouple positioned in the modified panel shielded from direct contact with turbulent molten material. Processes include controlling the melter using the temperature of the modified panel. Other processes and systems are presented.

Owner:JOHNS MANVILLE CORP

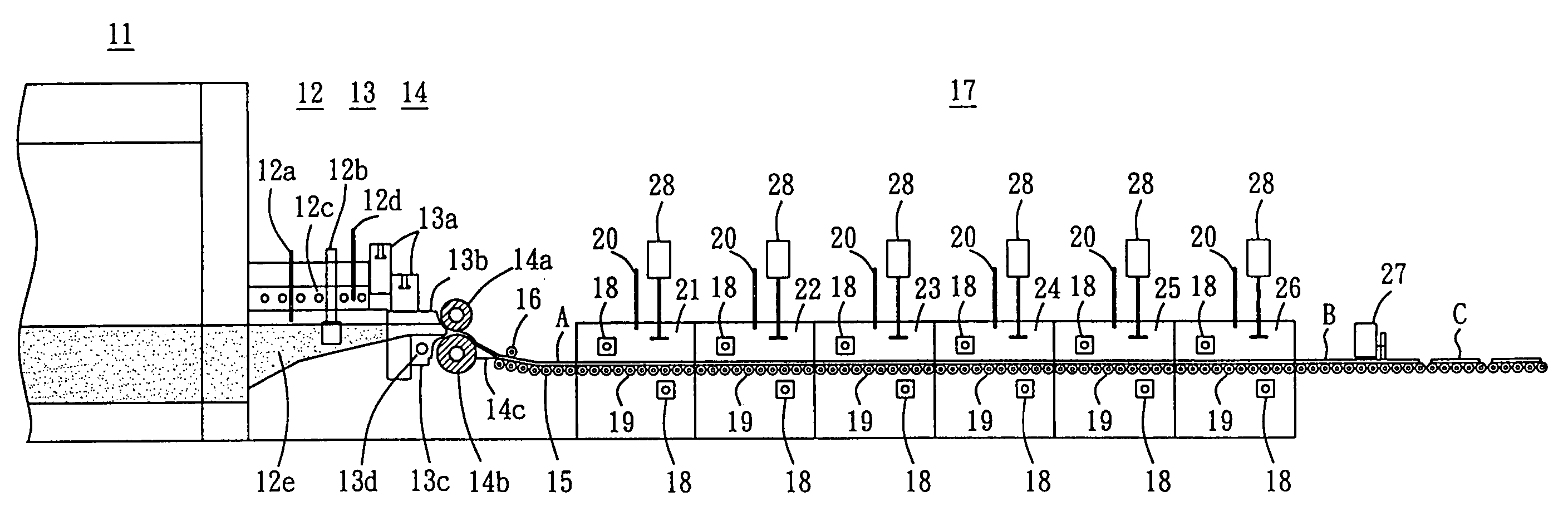

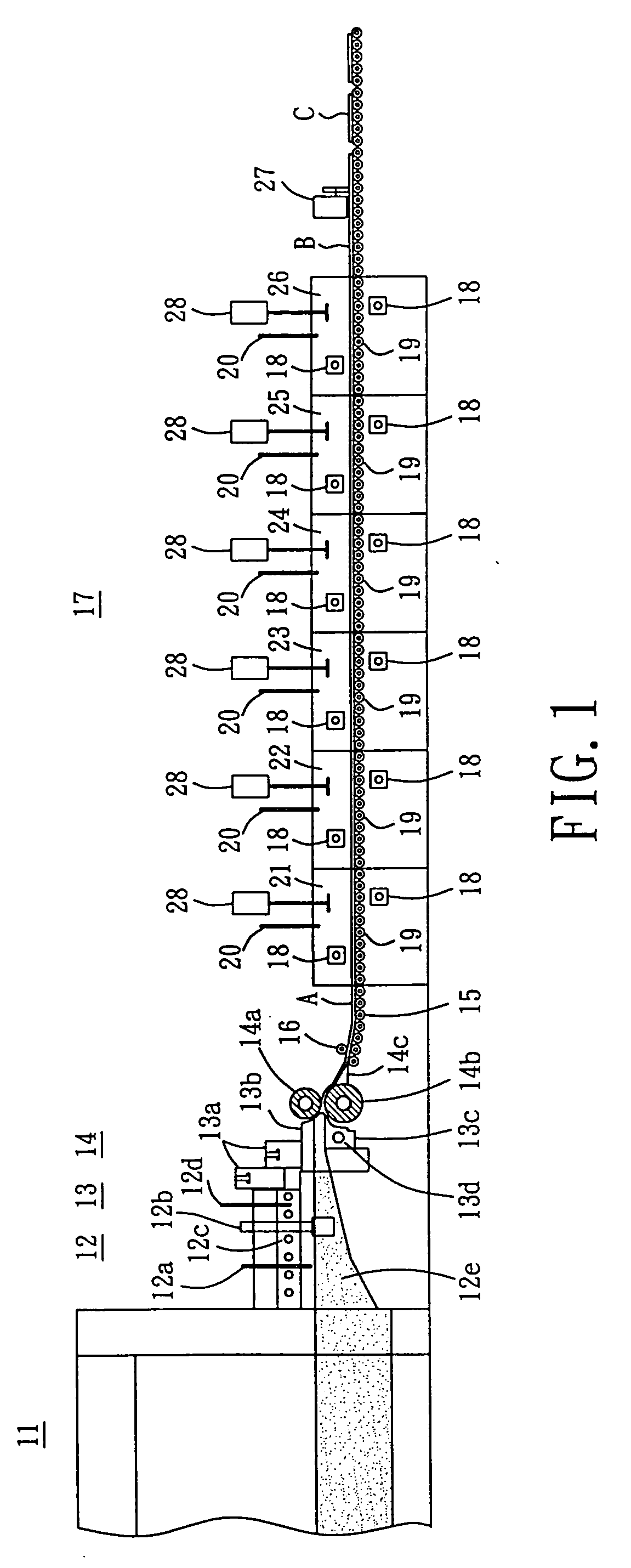

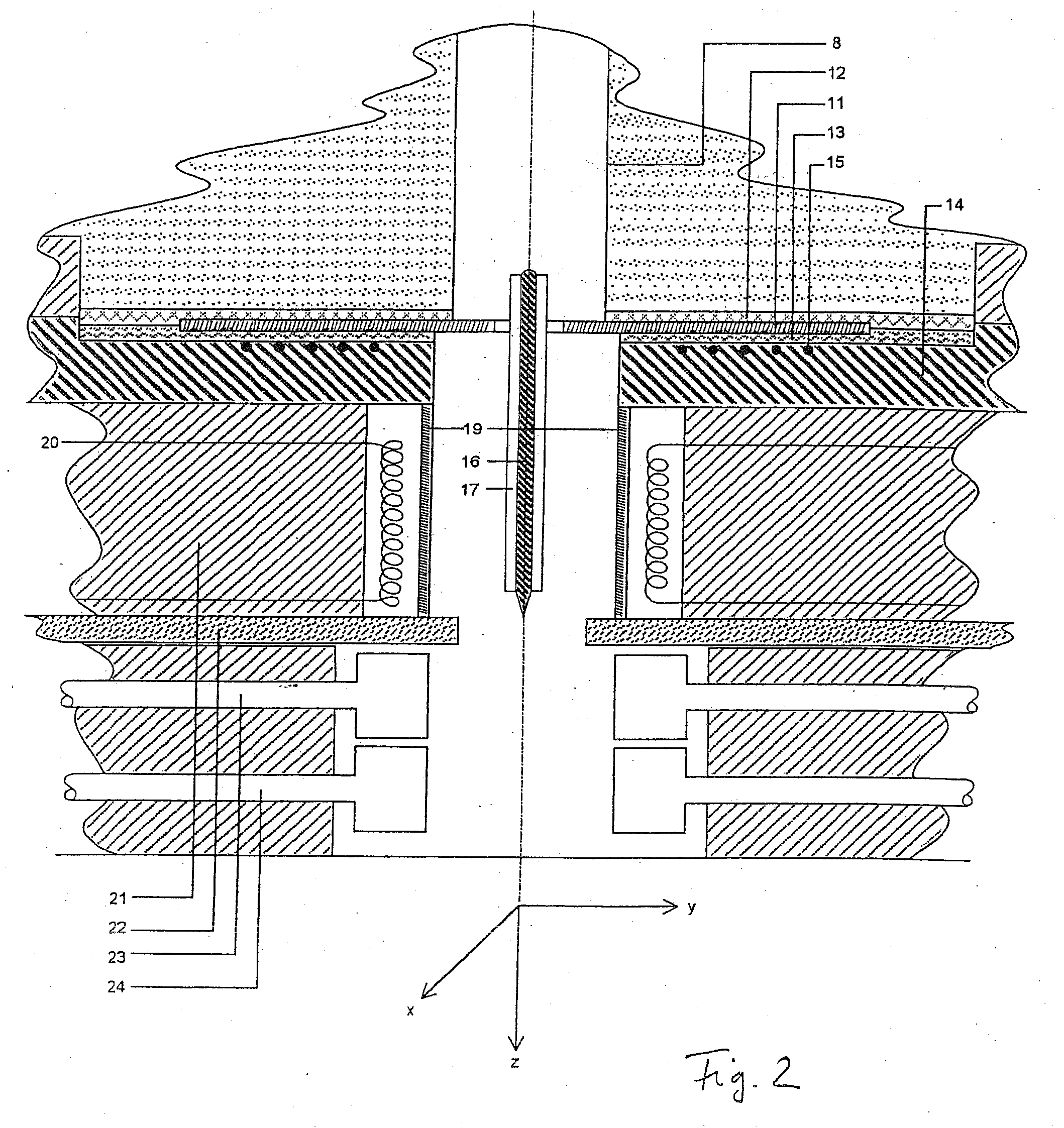

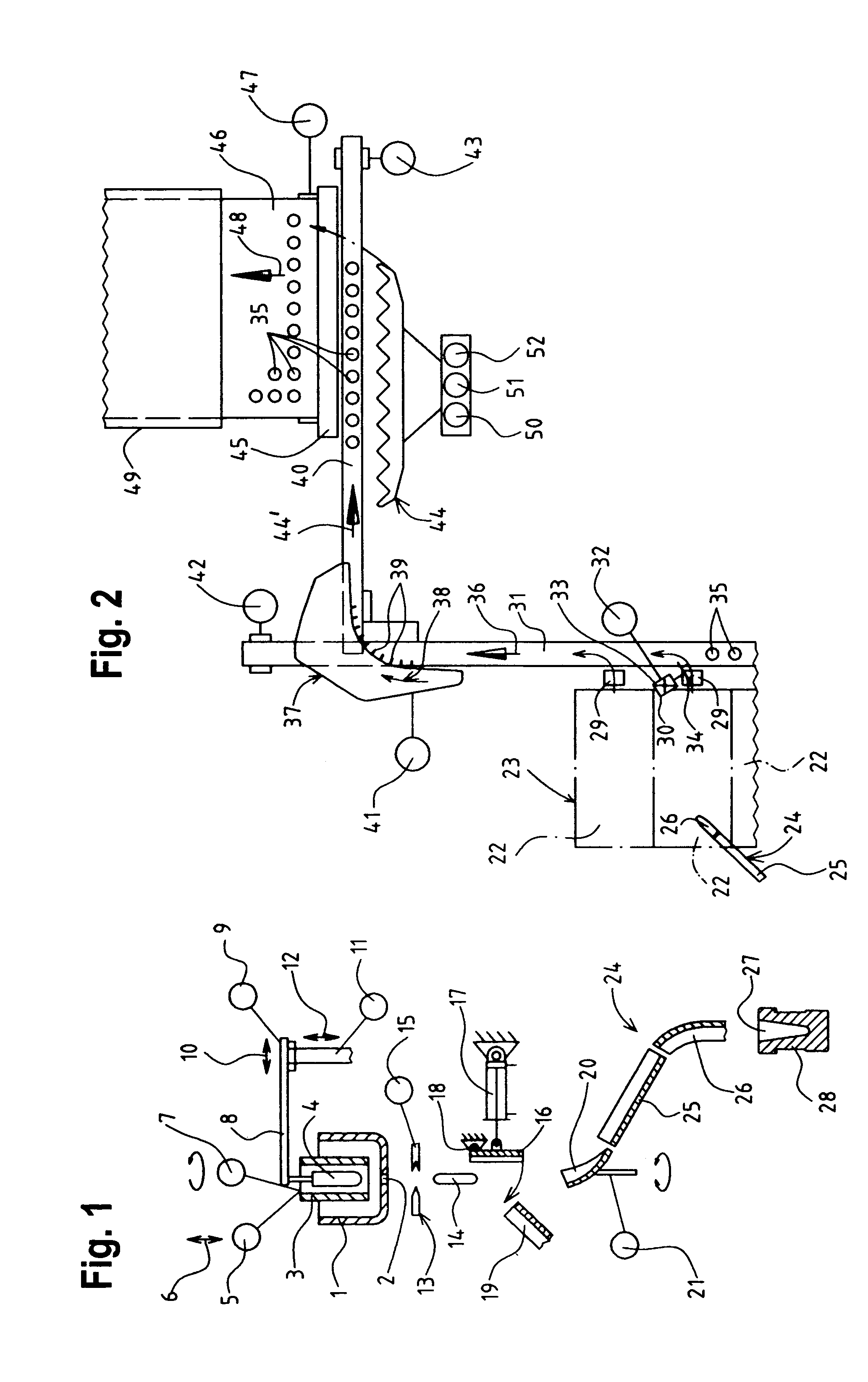

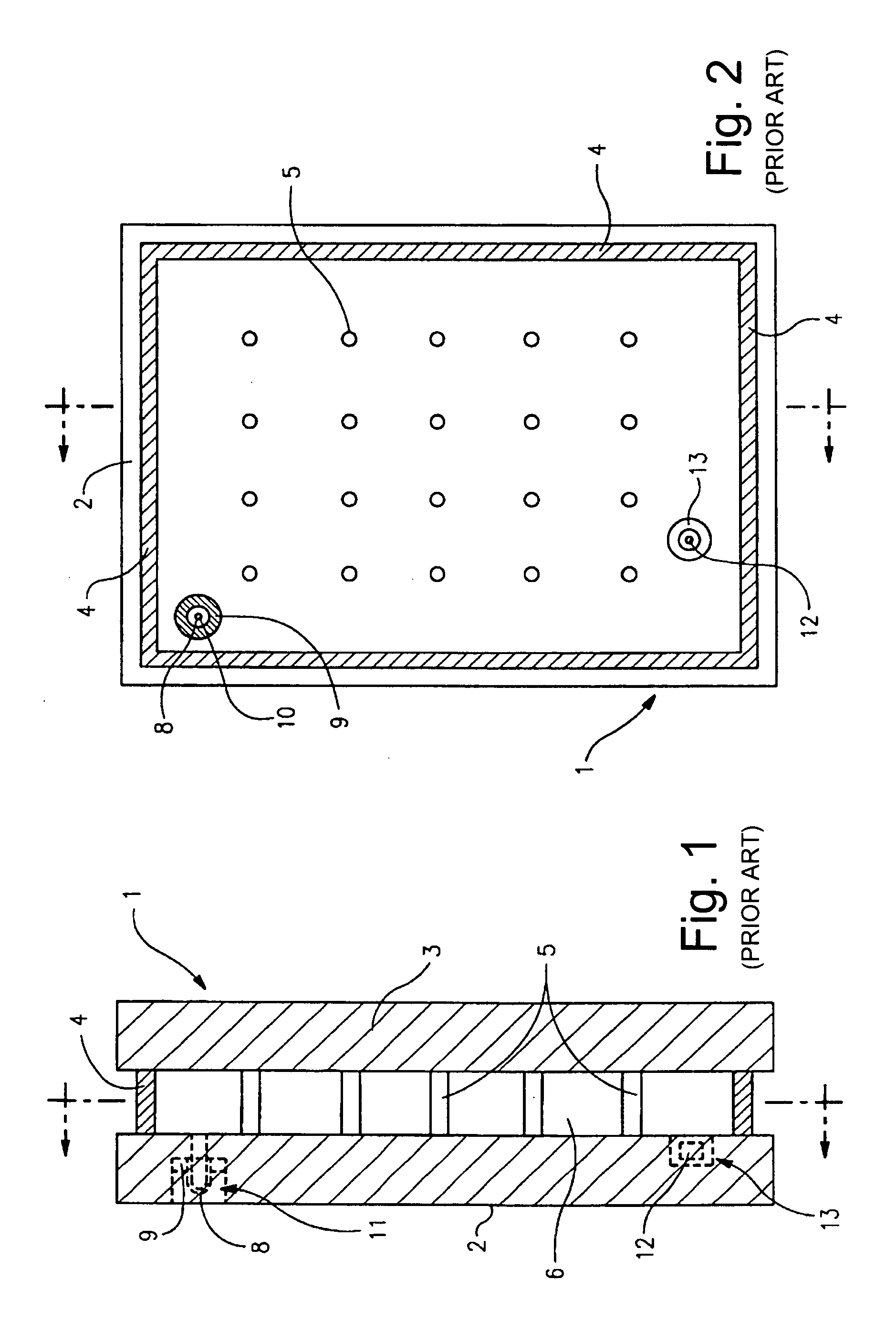

Process and device for manufacturing glass sheet

InactiveUS7231786B2Minimizes warpGlass furnace apparatusGlass drawing apparatusFlat glassGlass sheet

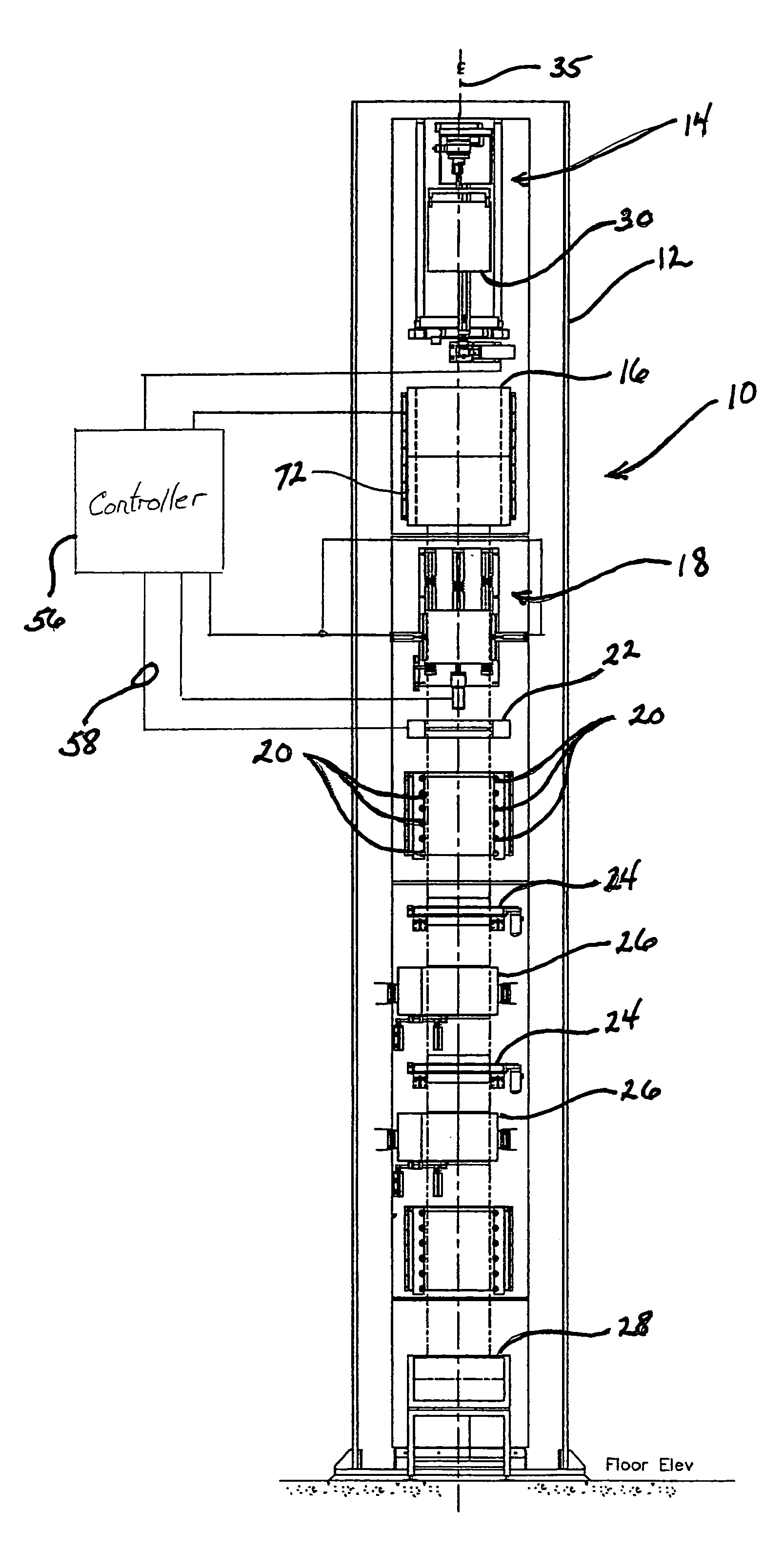

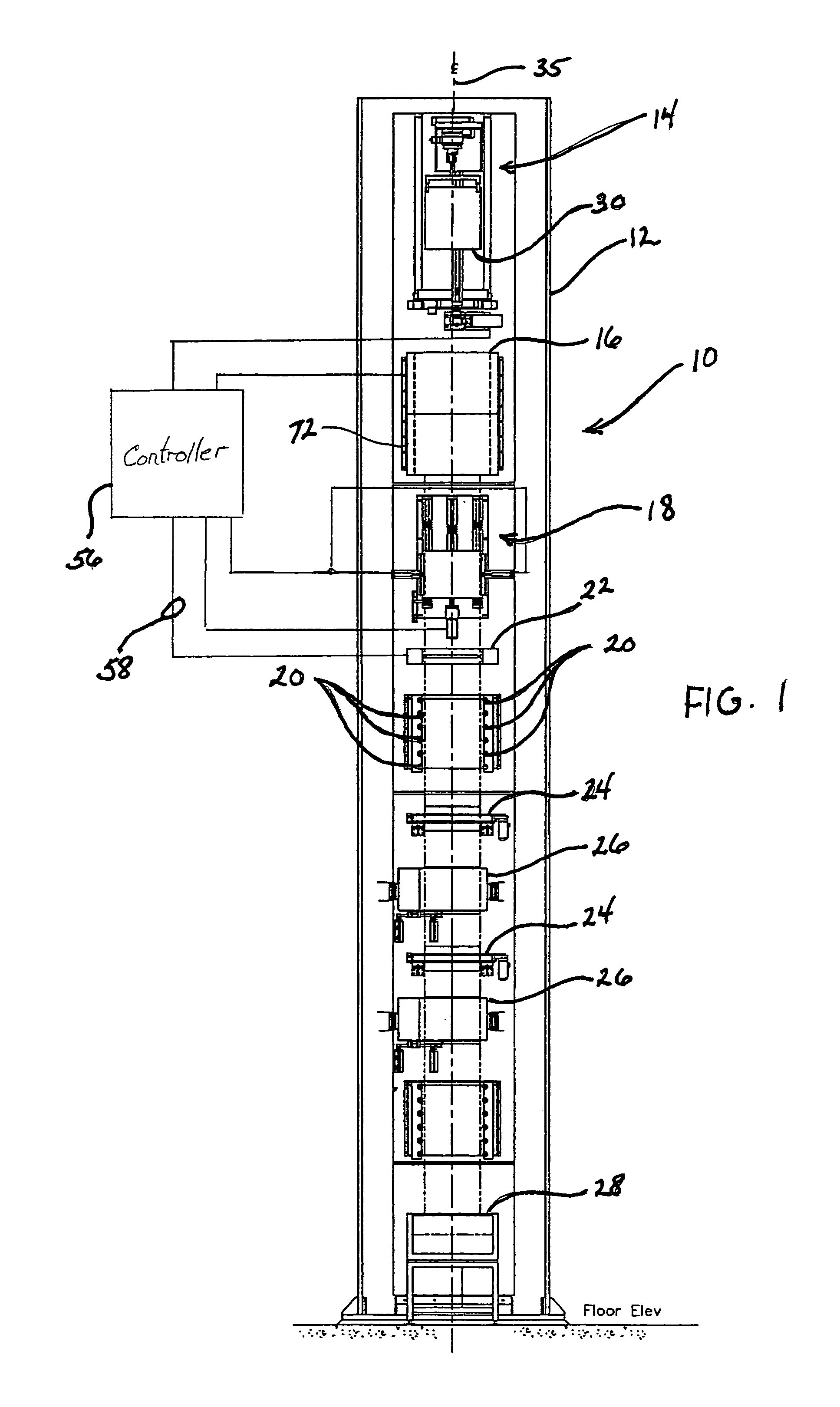

The present invention relates to a process for manufacturing flat sheets of a glass-based material and to an apparatus therefor. The process comprises providing a glass preform, heating the glass preform in a furnace, forming a gob and a pre-sheet, removing the gob and drawing the glass pre-sheet into a flat glass sheet. Also provided is an apparatus for drawing a glass preform into a glass sheet, the apparatus comprising a draw furnace, stretching arms for stretching and drawing the pre-sheet into a glass sheet, and opposing edge rollers for applying a downward force on the glass sheet. The draw furnace may include a plurality of individual heating elements, the temperature of each heating element capable of being separately controlled. The apparatus may further include an annealing furnace for annealing the glass sheet.

Owner:CORNING INC

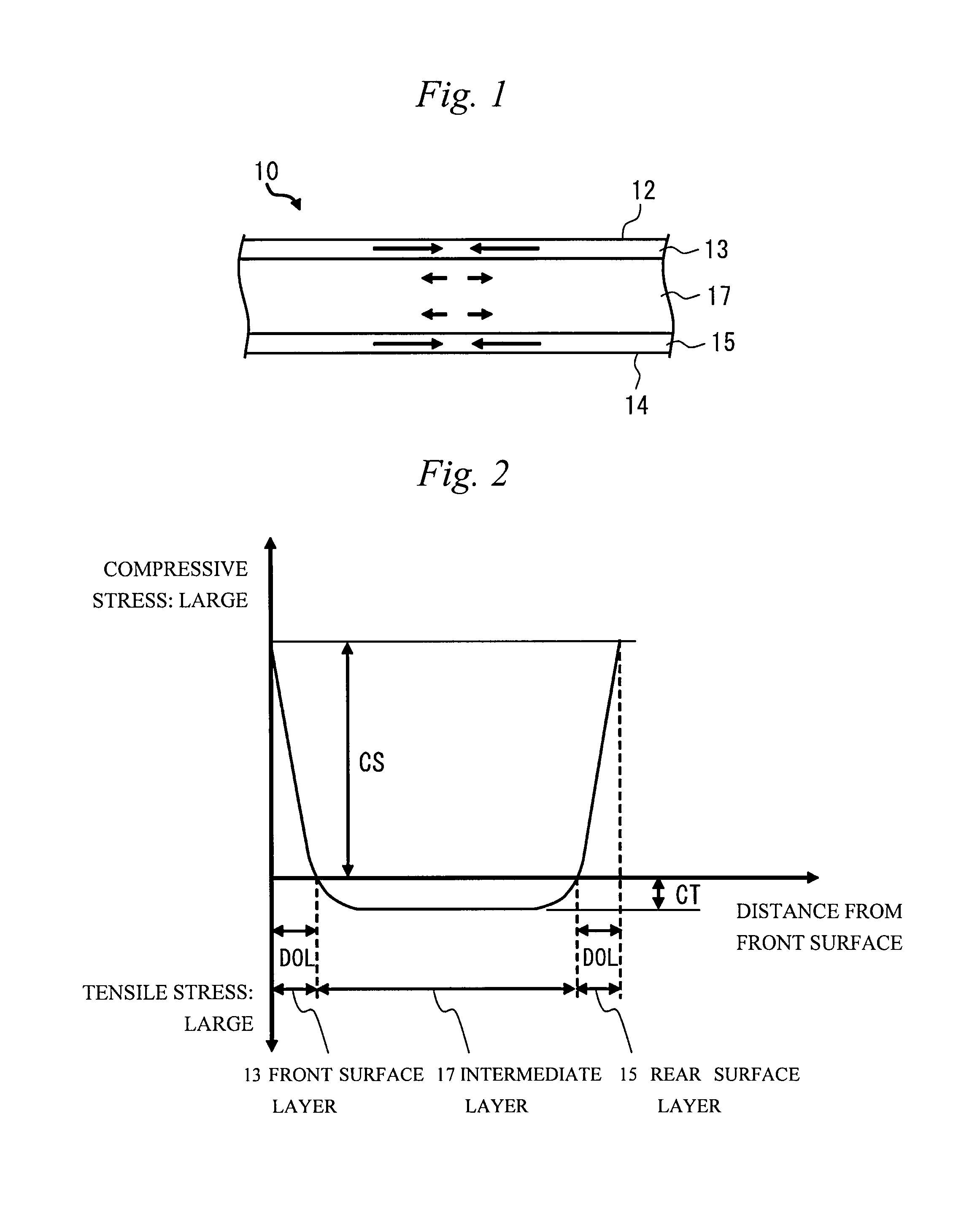

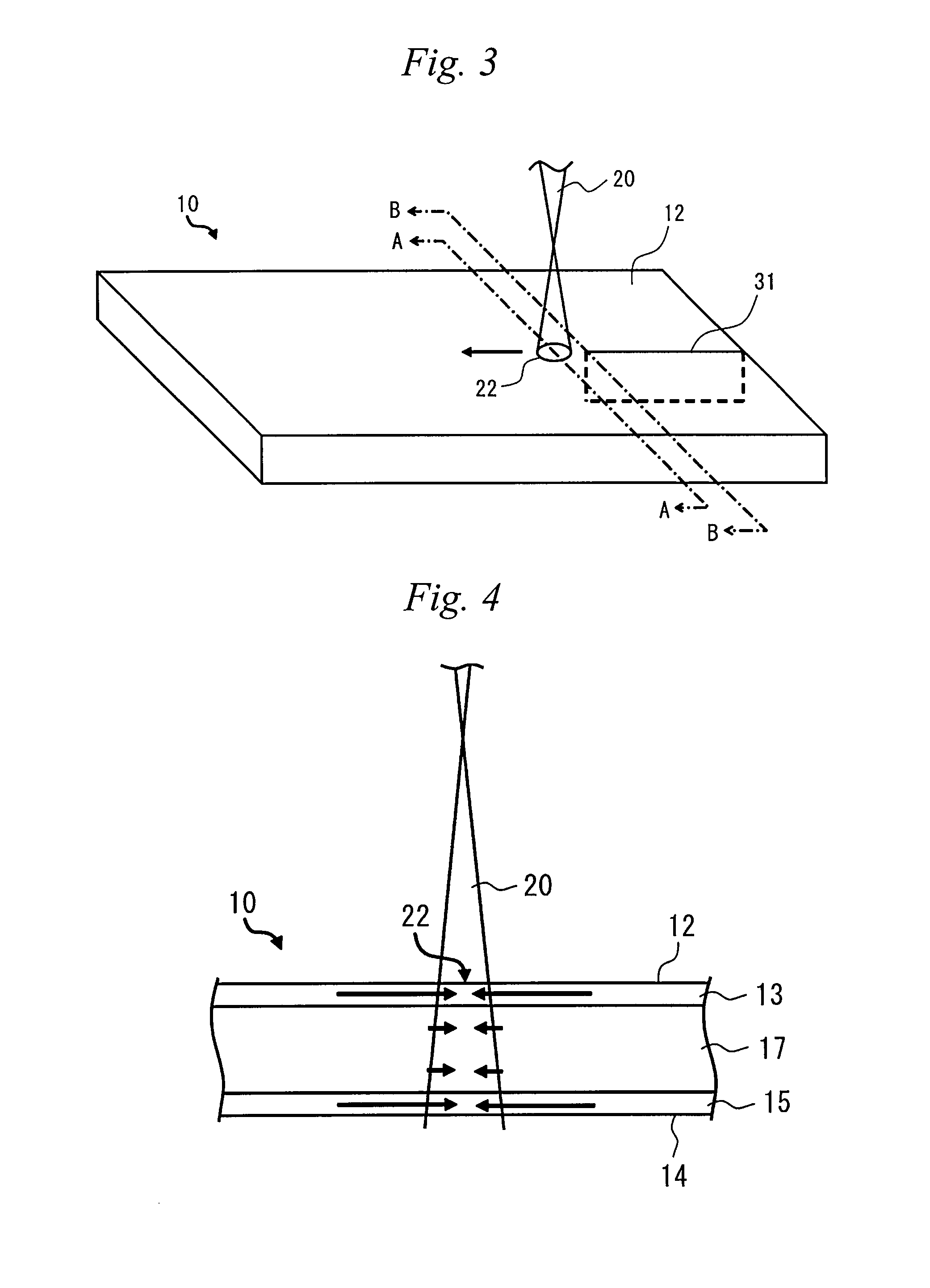

Cutting method for reinforced glass plate and reinforced glass plate cutting device

InactiveUS20140165652A1Quality improvementBlowing machine gearingsGlass reforming apparatusSurface layerOptoelectronics

The invention relates to a method for cutting a strengthened glass sheet in which, when a strengthened glass sheet 10 including a front surface layer 13 and a rear surface layer 15 which have a residual compressive stress, and an intermediate layer 17 which has an inside residual tensile stress, is cut by moving an irradiation region 22 of a laser beam so as to have a predetermined curvature radius, an irradiation energy per unit irradiation area of a laser beam 20 to be irradiated on the strengthened glass sheet 10 is increased as a curvature radius decreases. Thereby, it is possible to cut a strengthened glass sheet using a laser beam without causing a deterioration of quality.

Owner:ASAHI GLASS CO LTD

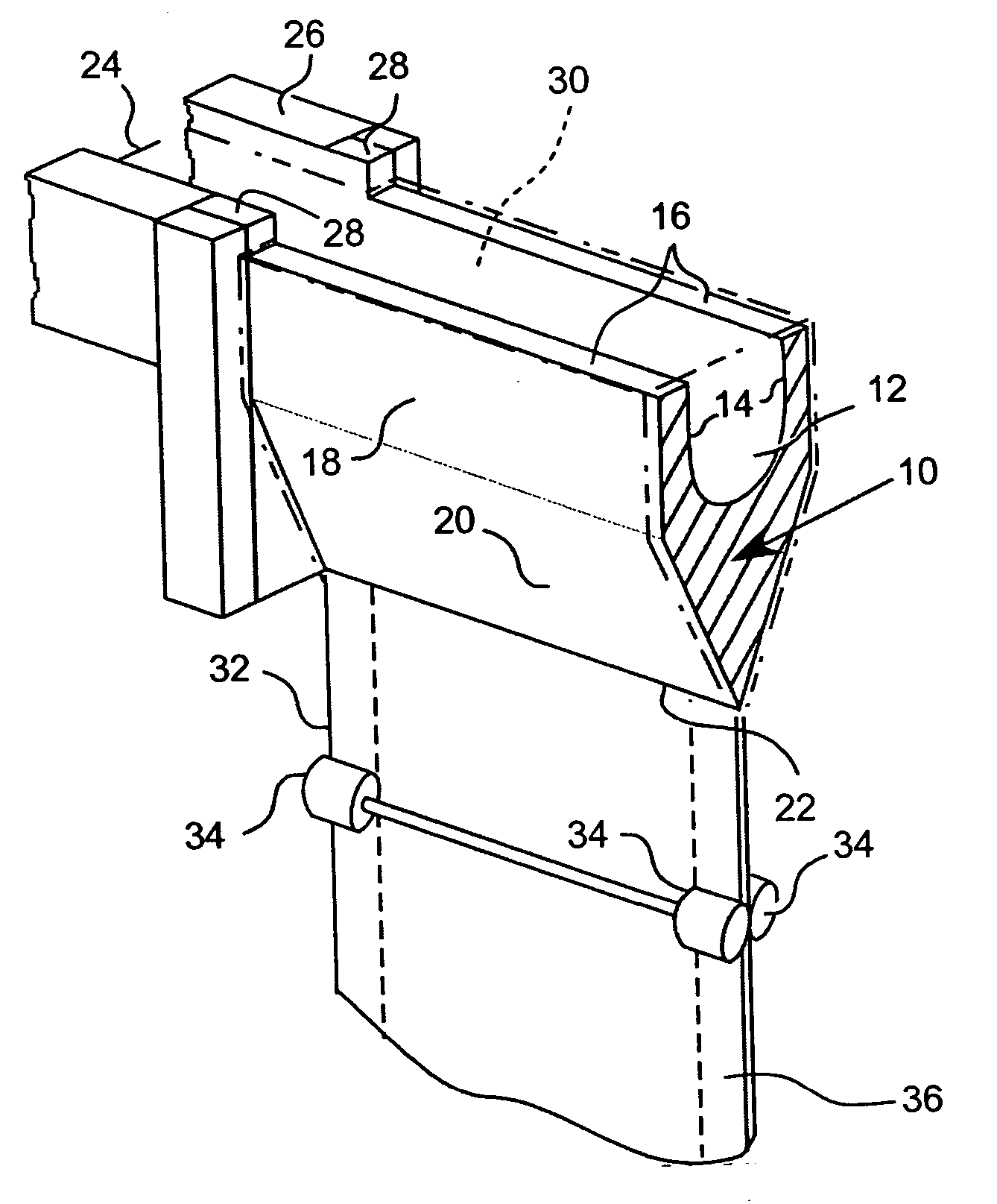

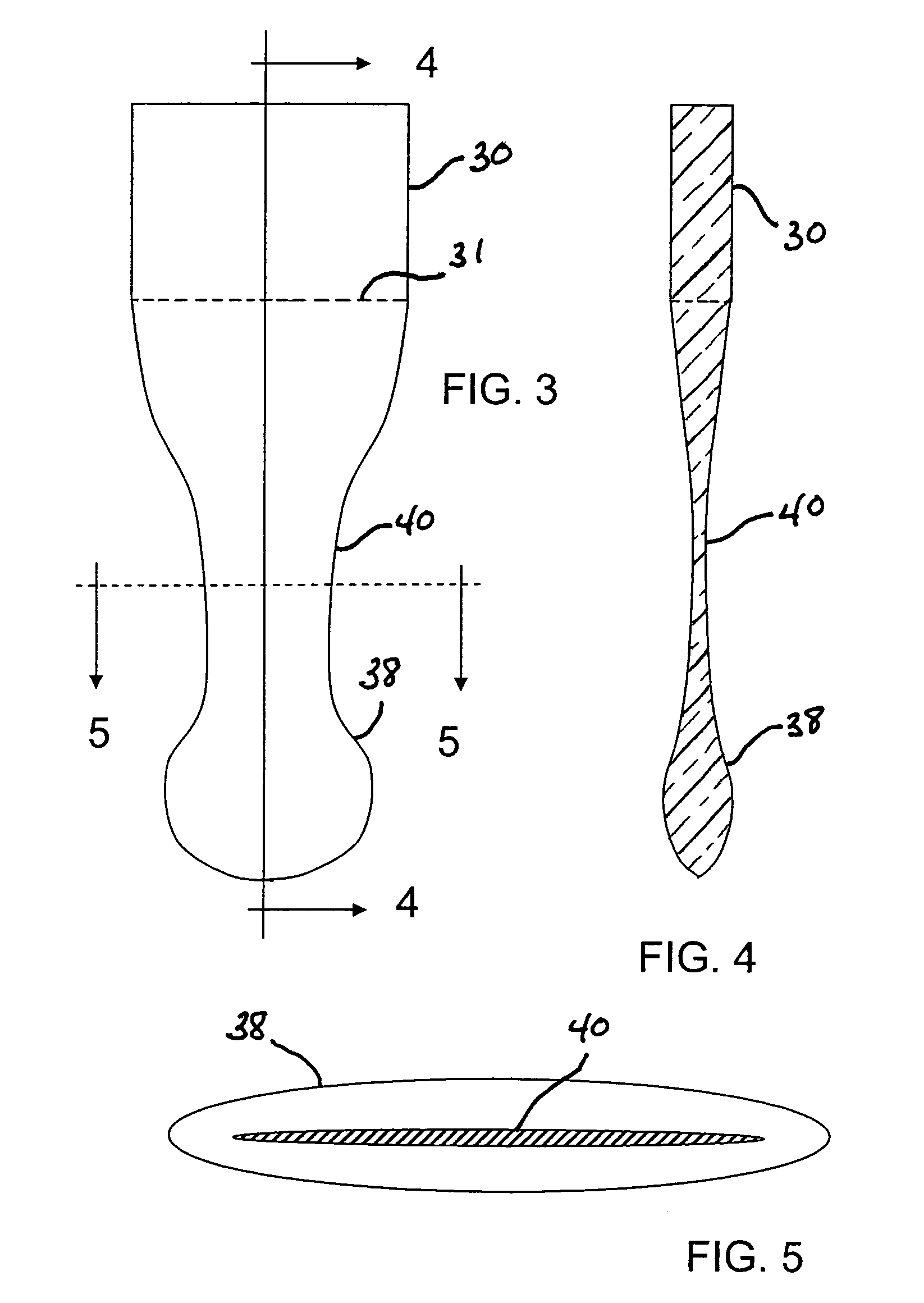

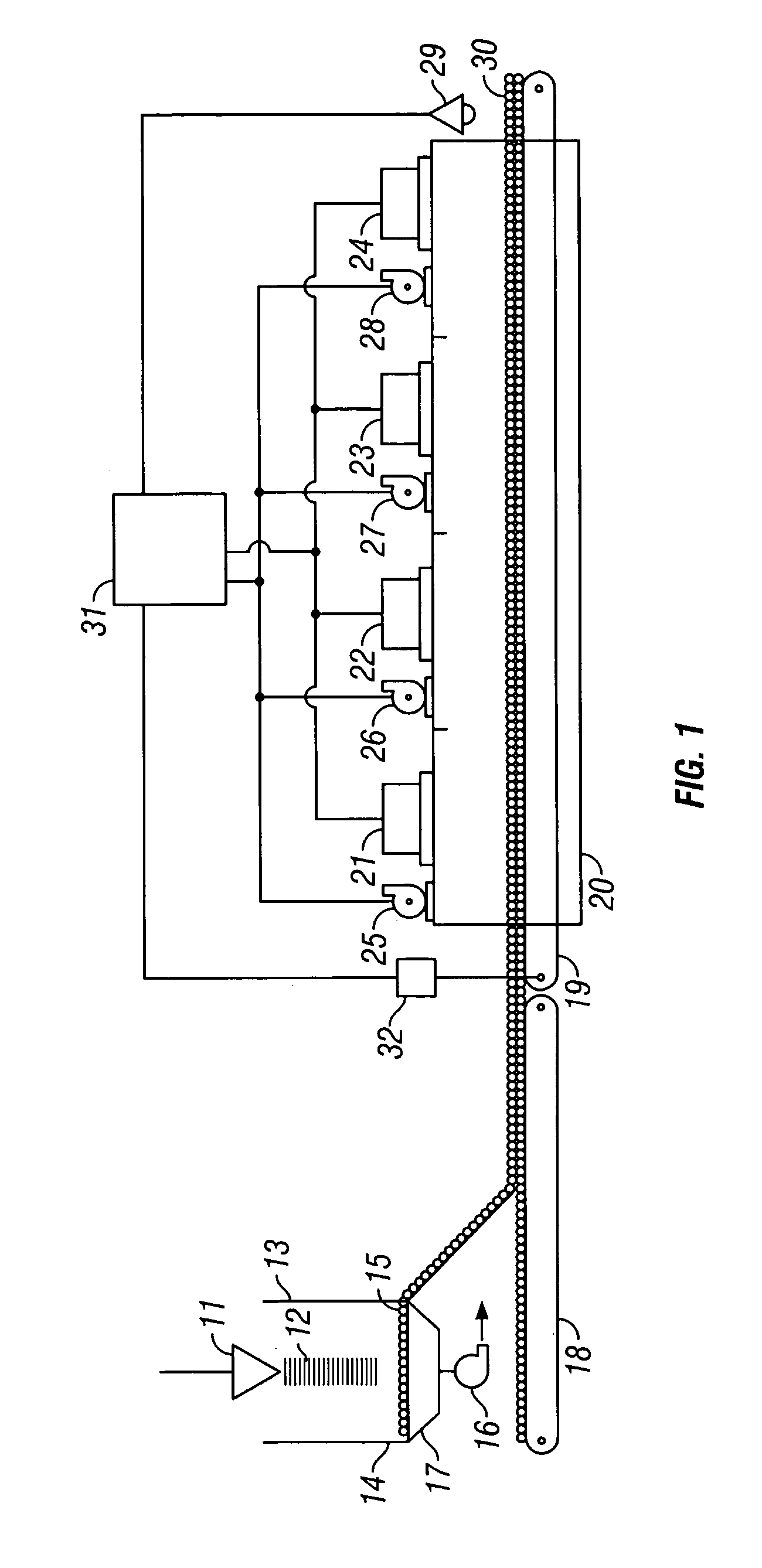

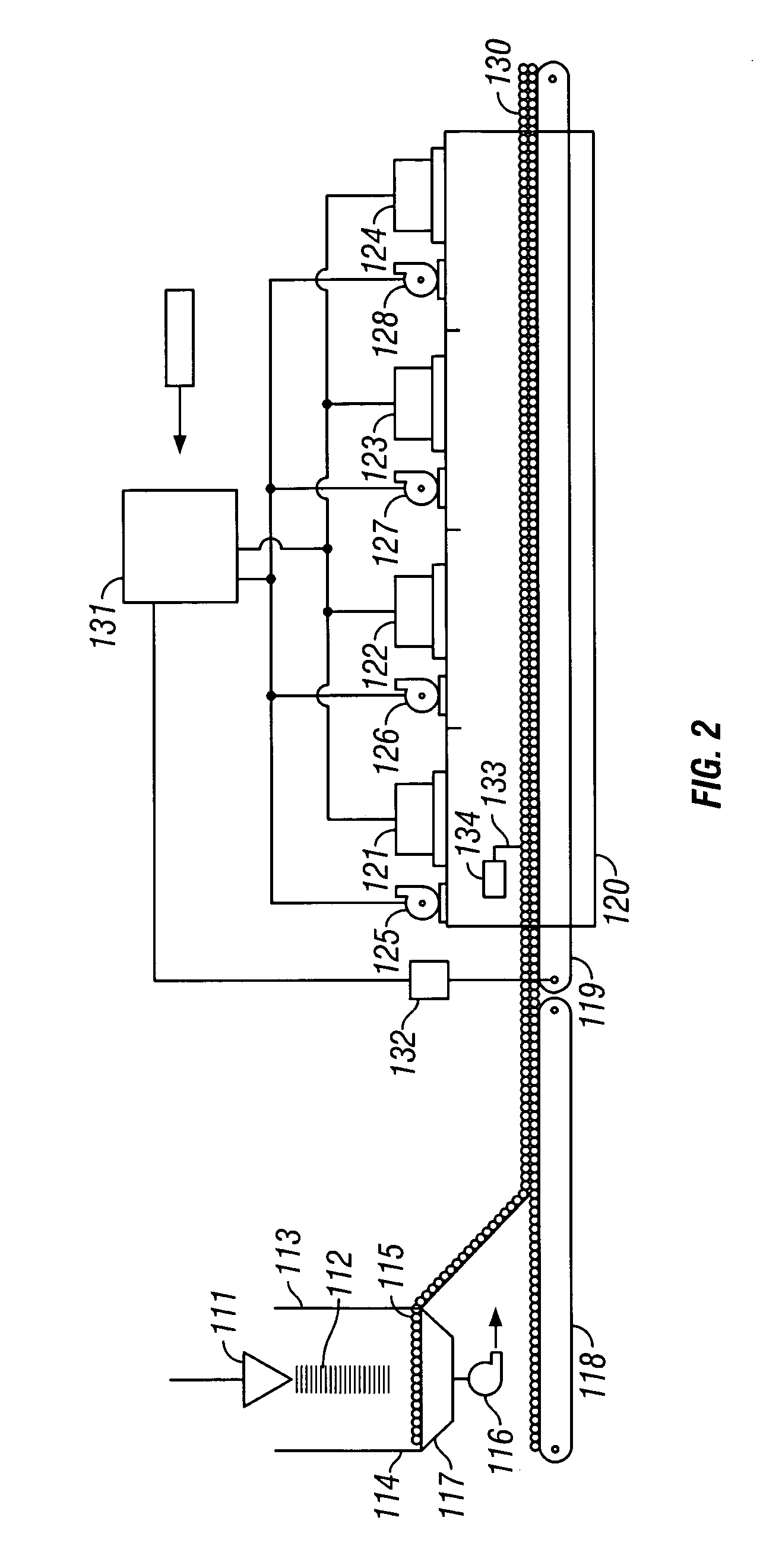

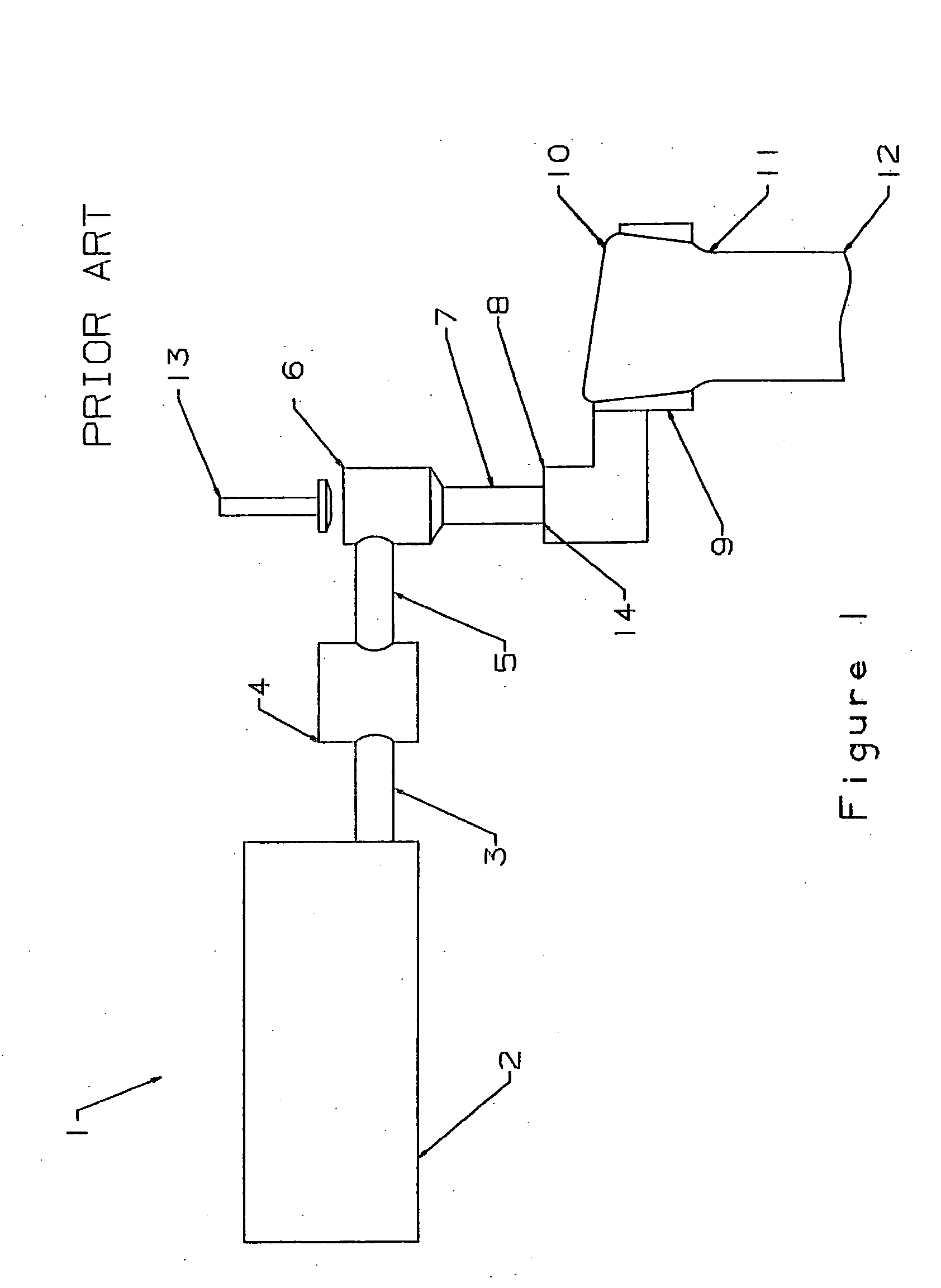

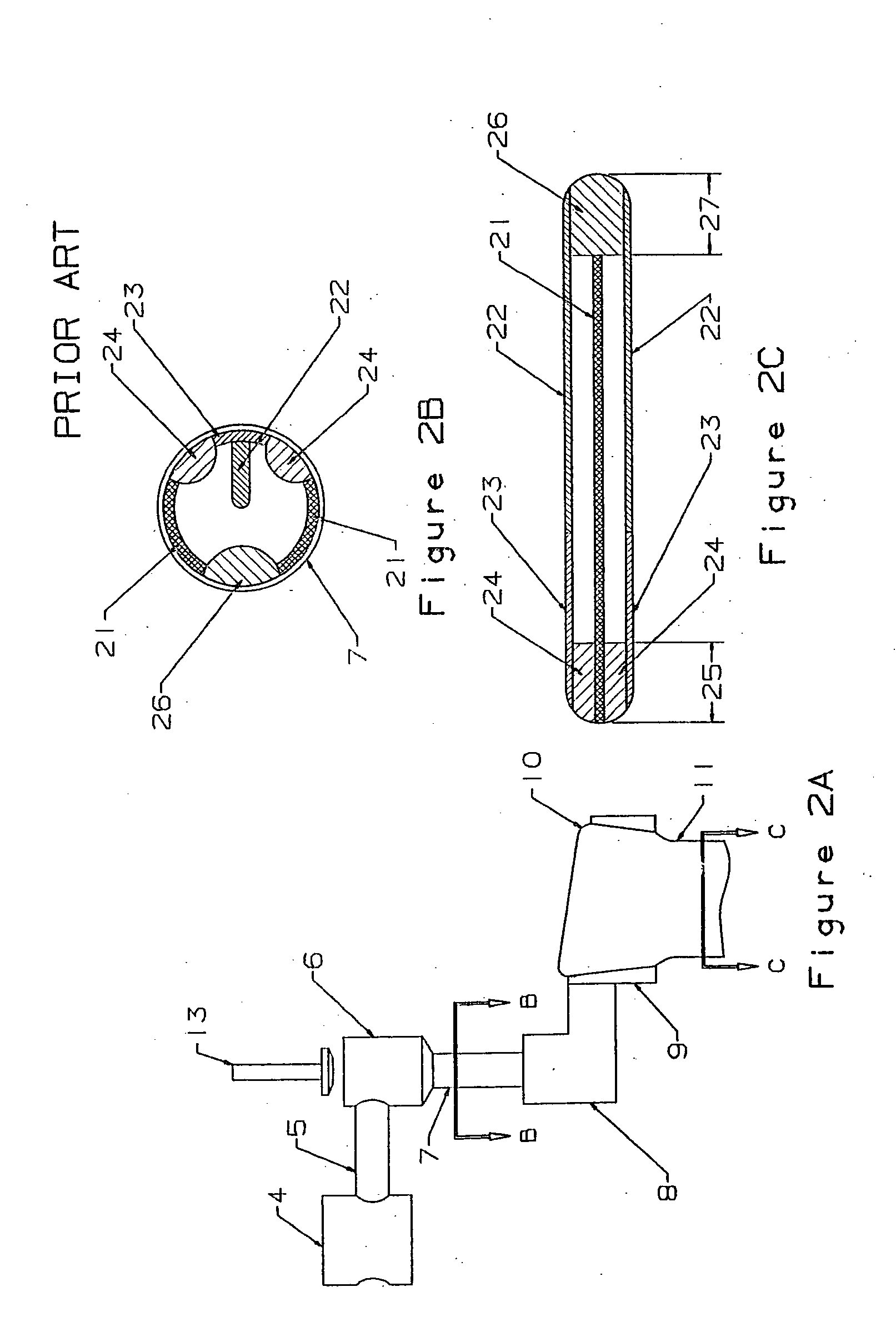

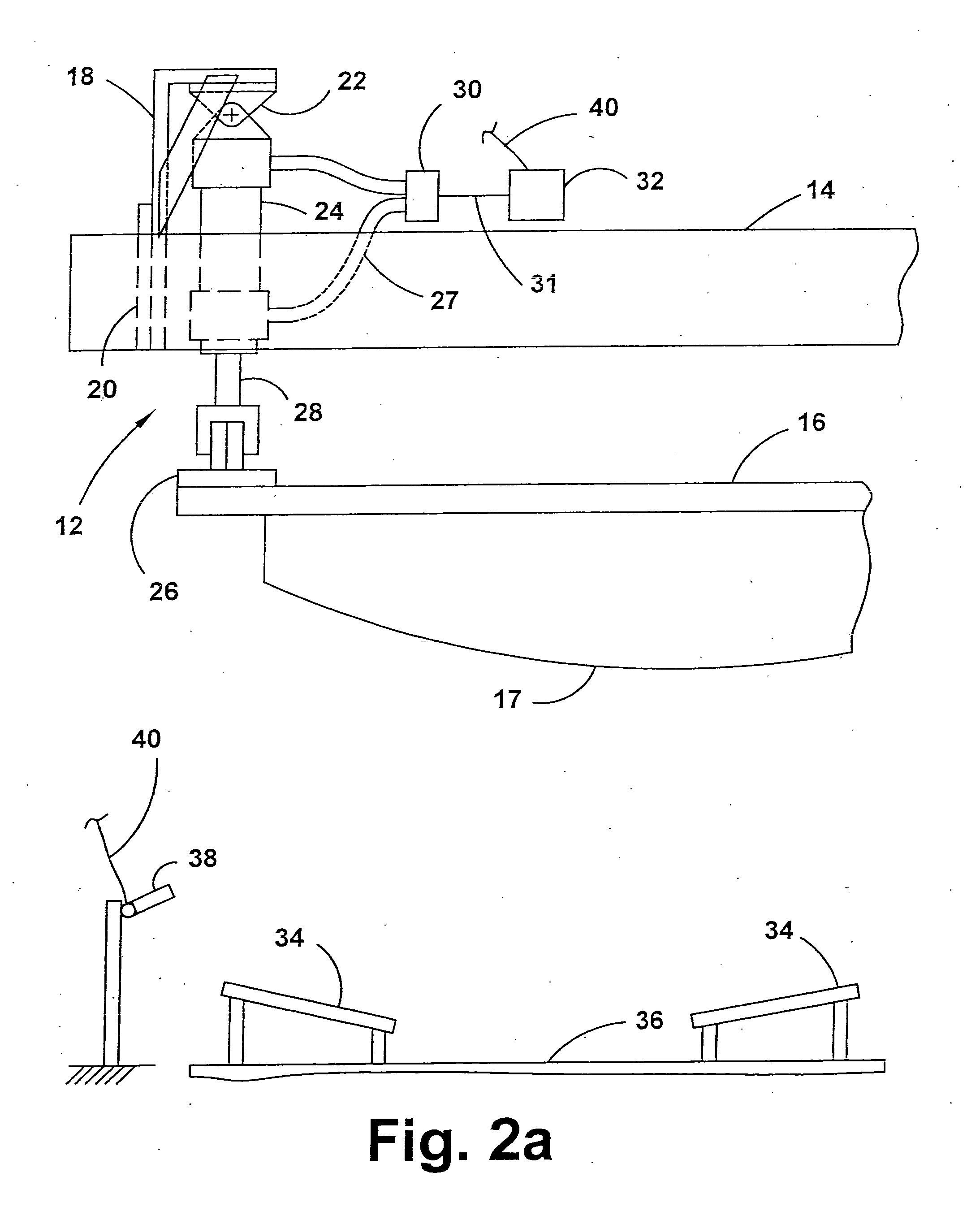

Process and device for manufacturing glass sheet

InactiveUS20060021385A1Minimizes warpGlass furnace apparatusGlass drawing apparatusFlat glassGlass sheet

The present invention relates to a process for manufacturing flat sheets of a glass-based material and to an apparatus therefor. The process comprises providing a glass preform, heating the glass preform in a furnace, forming a gob and a pre-sheet, removing the gob and drawing the glass pre-sheet into a flat glass sheet. Also provided is an apparatus for drawing a glass preform into a glass sheet, the apparatus comprising a draw furnace, stretching arms for stretching and drawing the pre-sheet into a glass sheet, and opposing edge rollers for applying a downward force on the glass sheet. The draw furnace may include a plurality of individual heating elements, the temperature of each heating element capable of being separately controlled. The apparatus may further include an annealing furnace for annealing the glass sheet.

Owner:CORNING INC

Overflow downdraw glass forming method and apparatus

InactiveUS7681414B2Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

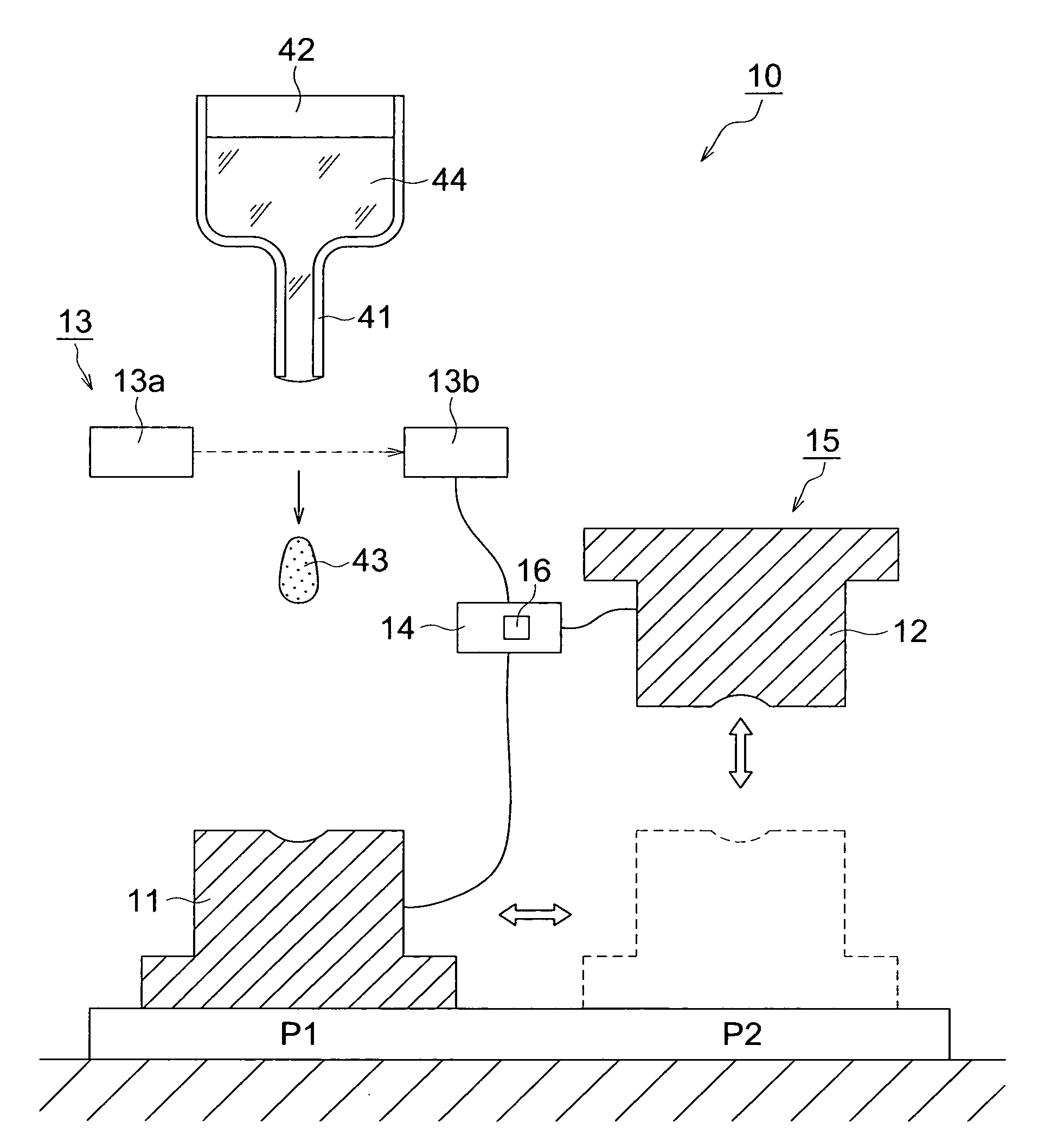

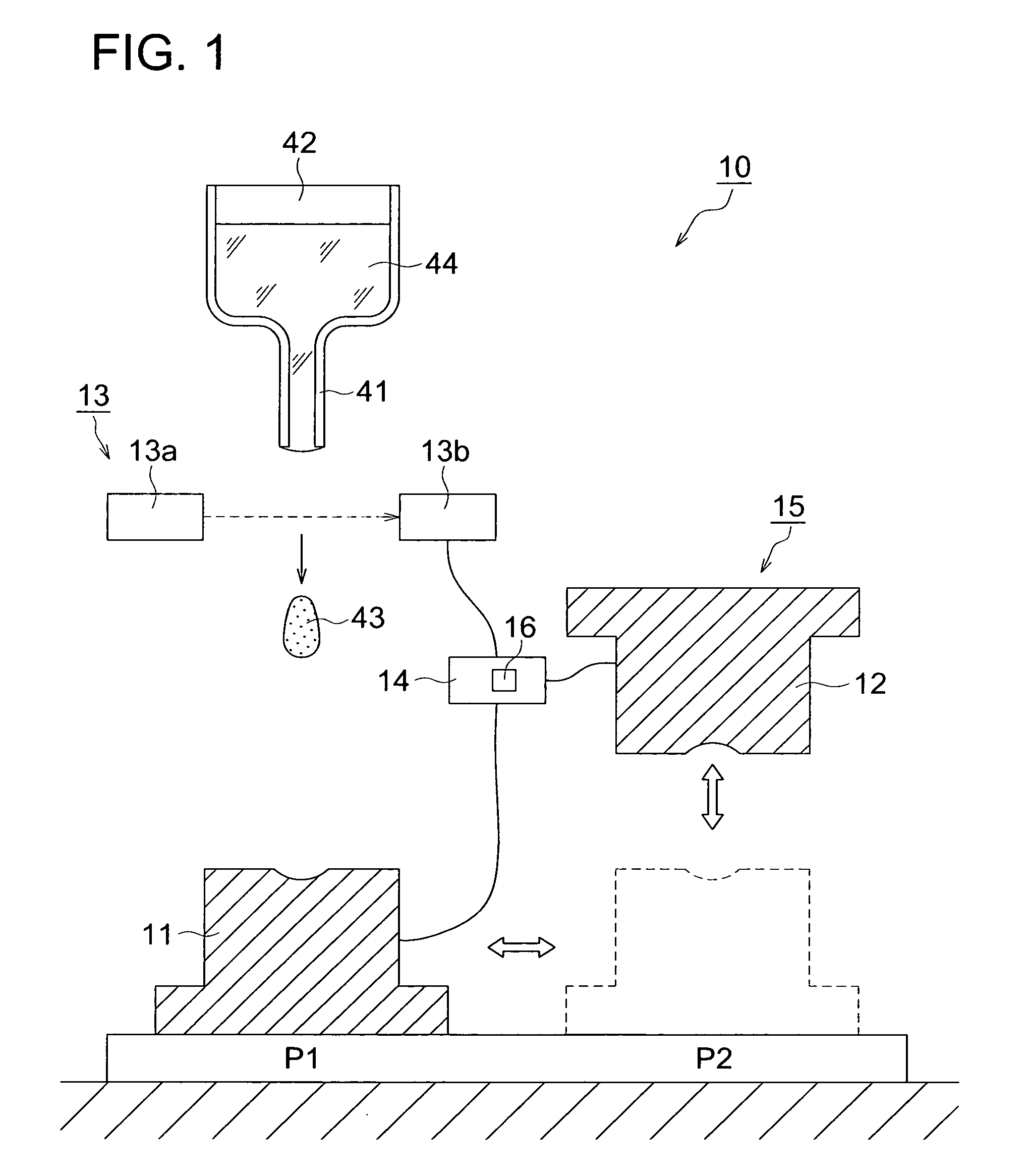

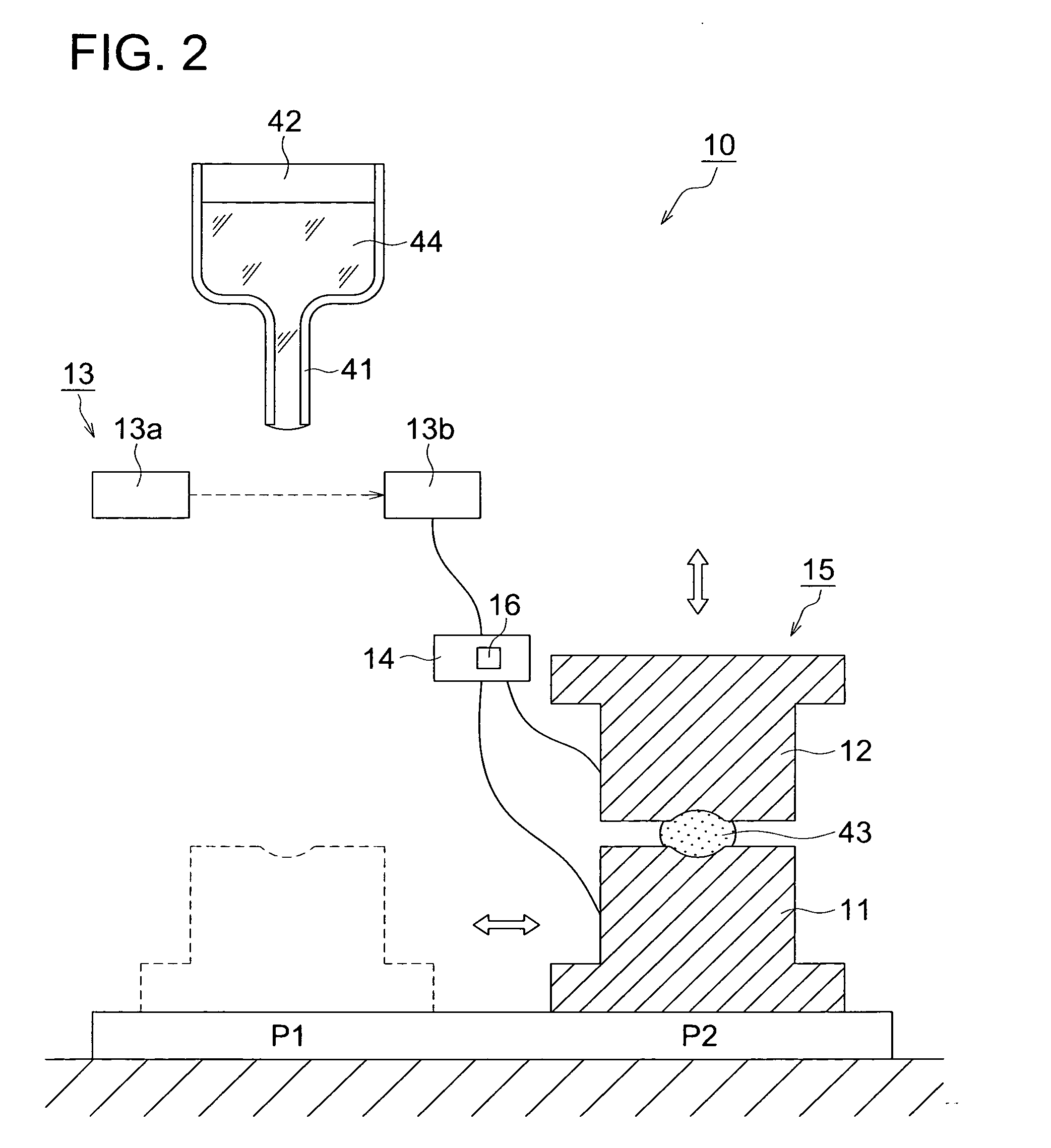

Manufacturing method of glass molded body, manufacturing apparatus of glass molded body, and glass molded body

InactiveUS20100120601A1Quality improvementImprove accuracyGlass pressing apparatusSensitive elementsShell moldingManufactured apparatus

A process for producing a glass molding, in which a glass molding of stable quality can be efficiently produced through minimizing of temperature fluctuation of molten glass drops at pressure molding operation; and an apparatus for production of a glass molding used in this process. Molten glass drops are fed into an inferior die by causing the molten glass drops to fall from above toward the inferior die. The arrival of molten glass drops having fallen at a given location is detected, and pressurization of the molten glass drops by means of molding dies is initiated upon the passage of a given time since the detection.

Owner:KONICA MINOLTA OPTO

Control of product in curing ovens for formaldehyde-free glass fiber products

ActiveUS20060009569A1Improve mechanical propertiesThermometer detailsLayered productsGlass fiberFormaldehyde free

A system for curing a binders applied to glass fibers is disclosed. The curing of the binder is accomplished by passing the binder coated glass fibers through a curing oven having one or more temperature zones. The temperature of the binder coated glass fibers is monitored and the temperature in the curing oven is adjusted to ensure proper heating of the glass fibers thereby ensuring uniform curing of the binder composition. Temperature measurements are made either as the product traverses the oven or as the cured product exits the curing oven. The invention is particularly useful for curing acrylic thermoset binders and formaldehyde-free binders.

Owner:JOHNS MANVILLE CORP

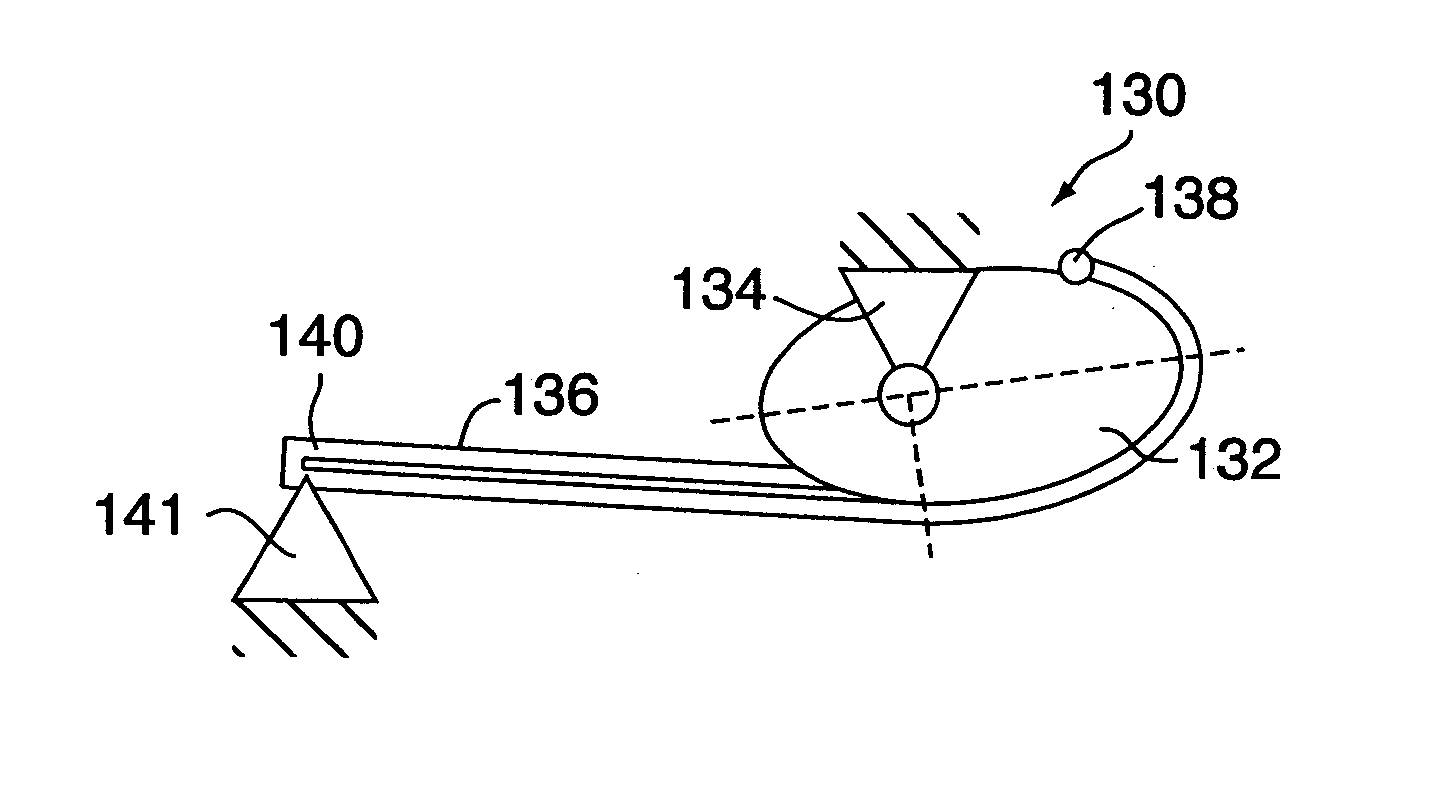

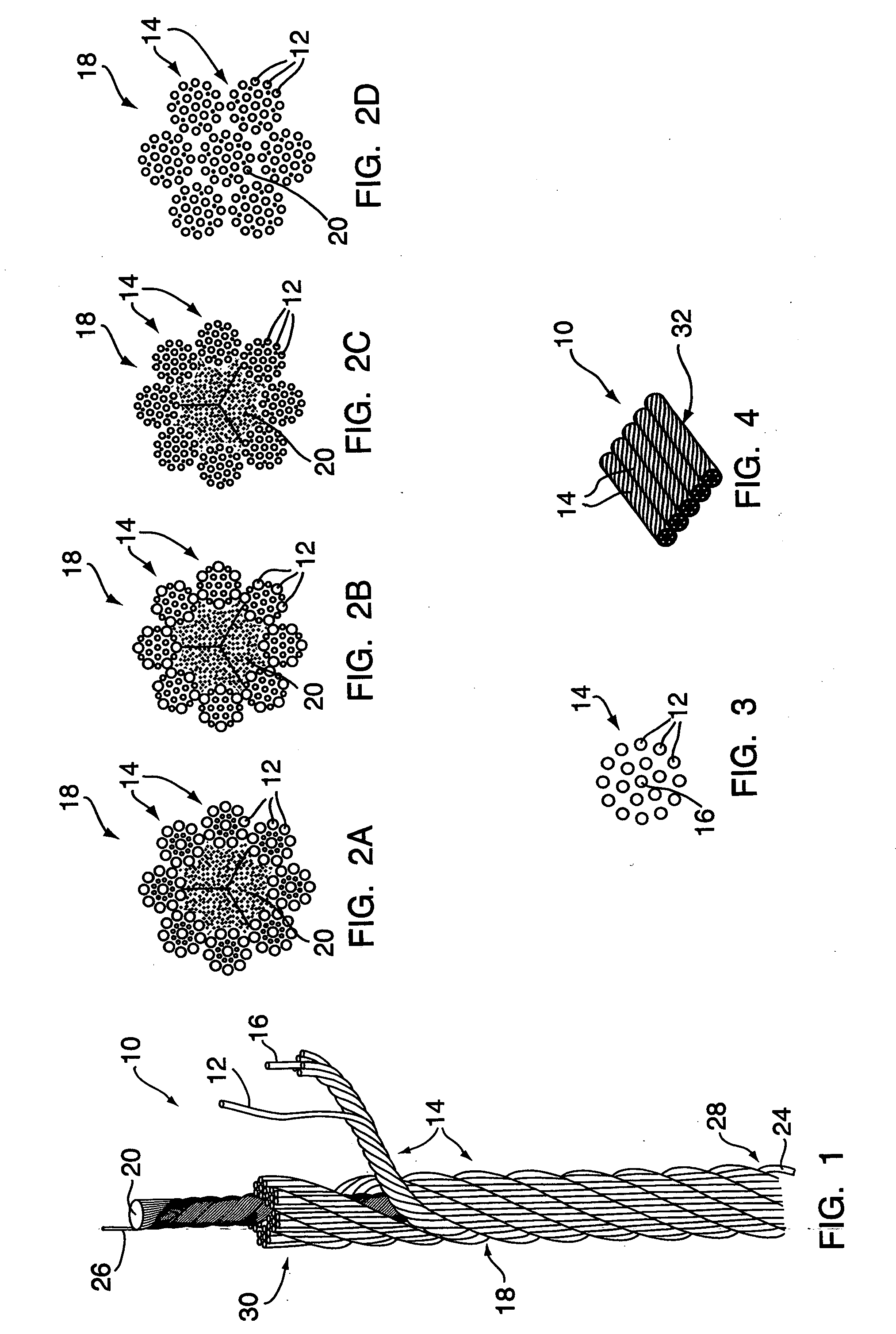

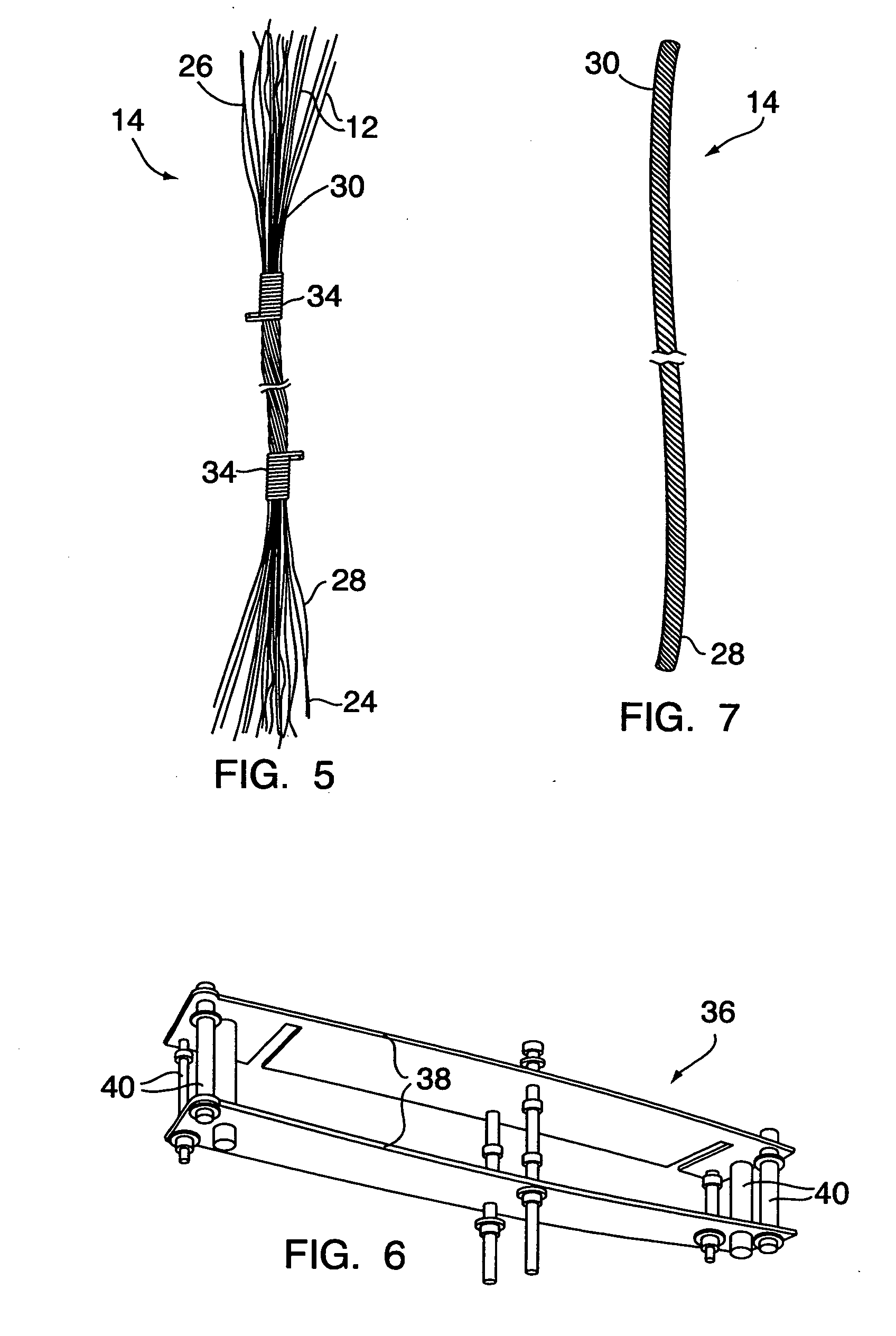

Shape memory alloy bundles and actuators

InactiveUS20050150223A1PowerfulSensitive elementsMechanical power devicesShape-memory alloyEngineering

A plurality of individual shape memory alloy (SMA) wires are formed into a SMA bundle to increase force output therefrom. The SMA bundle has a parent shape and a deformed shape. The SMA bundle in the deformed shape resumes its parent shape once the SMA bundle is heated to generate increased force output. The SMA wires can be configured into strands, ropes, arrays or other shapes. The SMA material is also used in a variety of actuators for generating substantially continuous motion.

Owner:RAYTHEON TECH CORP

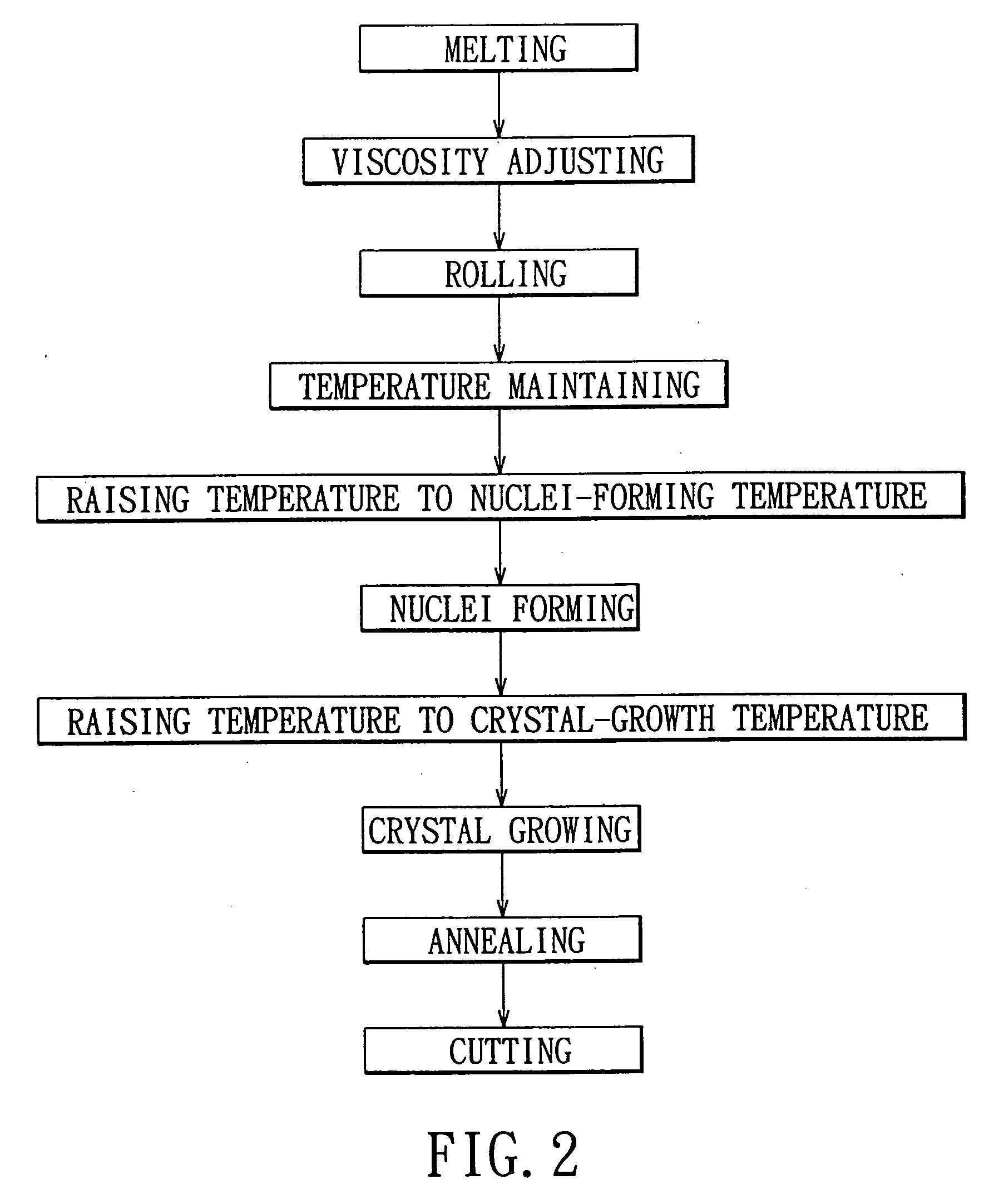

Continuous method and system for manufacturing a crystallized glass plate

InactiveUS20050016214A1Relieve pressureReduce stressRibbon machinesGlass furnace apparatusGlass sheetViscosity

A continuous method for manufacturing crystallized glass plates includes the steps of melting a raw crystallizable glass material to form molten glass, adjusting the molten glass to have a predetermined viscosity, rolling the molten glass to form a belt of crystallizable glass, and passing the belt of crystallizable glass through a crystallization tunnel so as to form a belt of crystallized glass.

Owner:TA HSIANG CONTAINERS IND +1

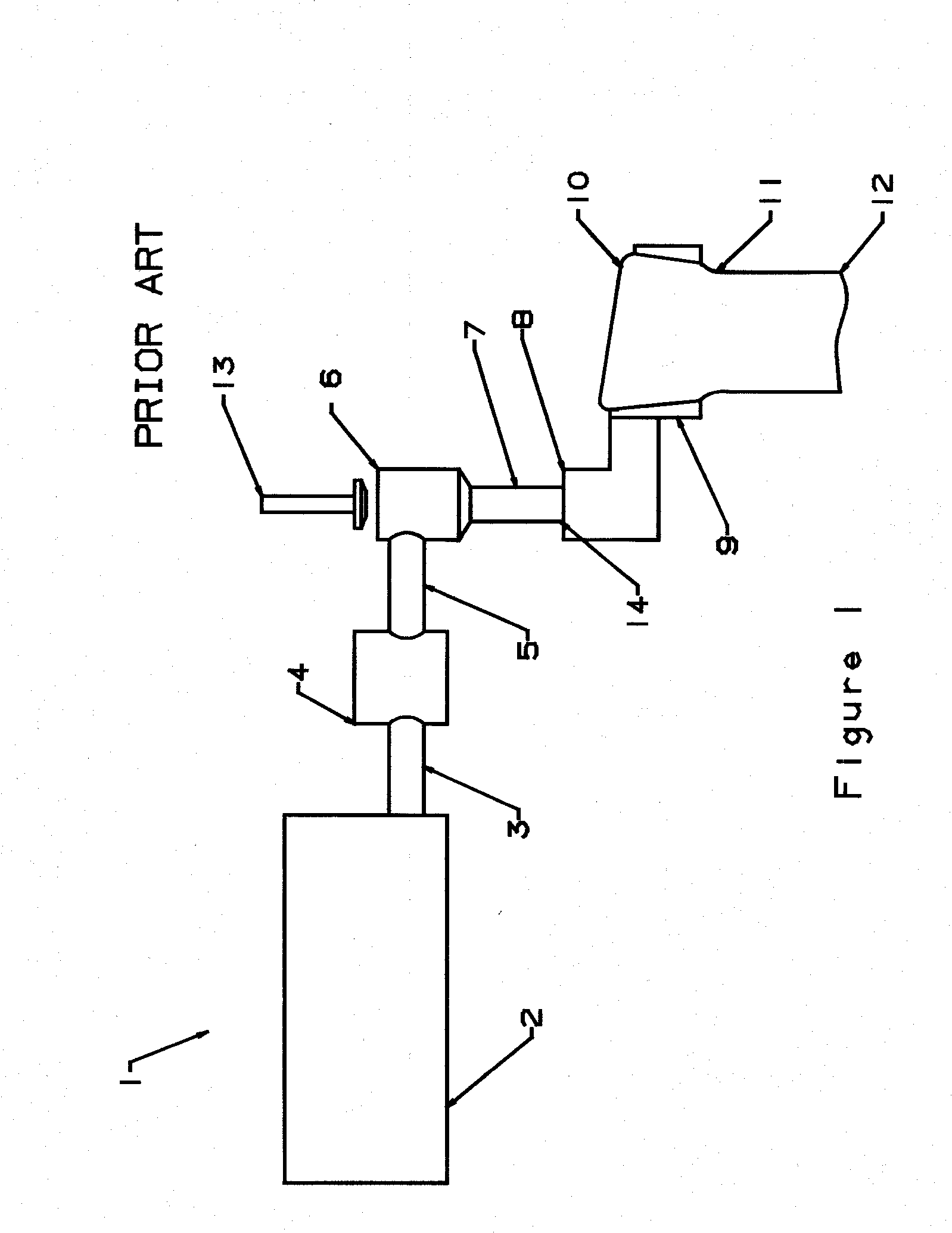

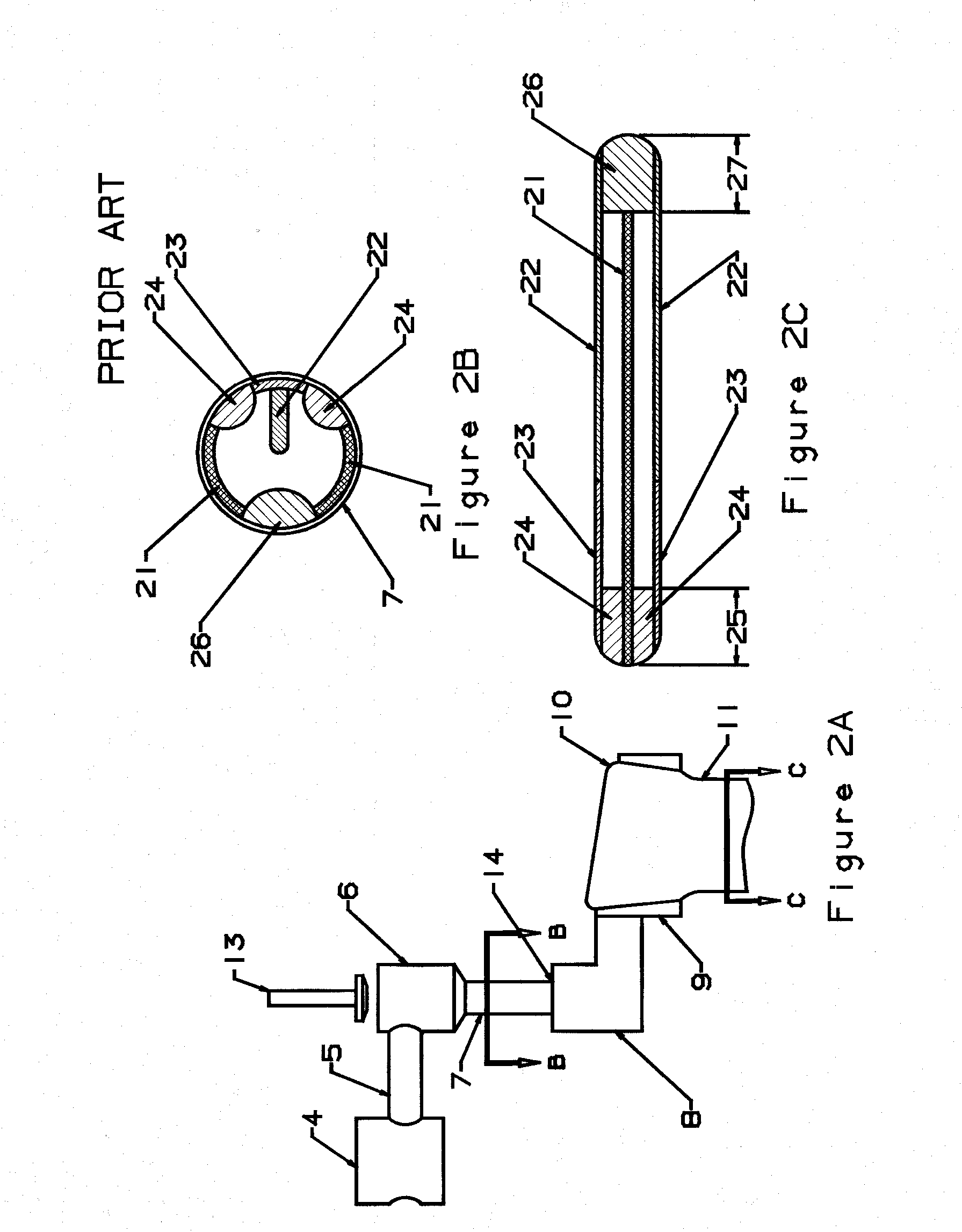

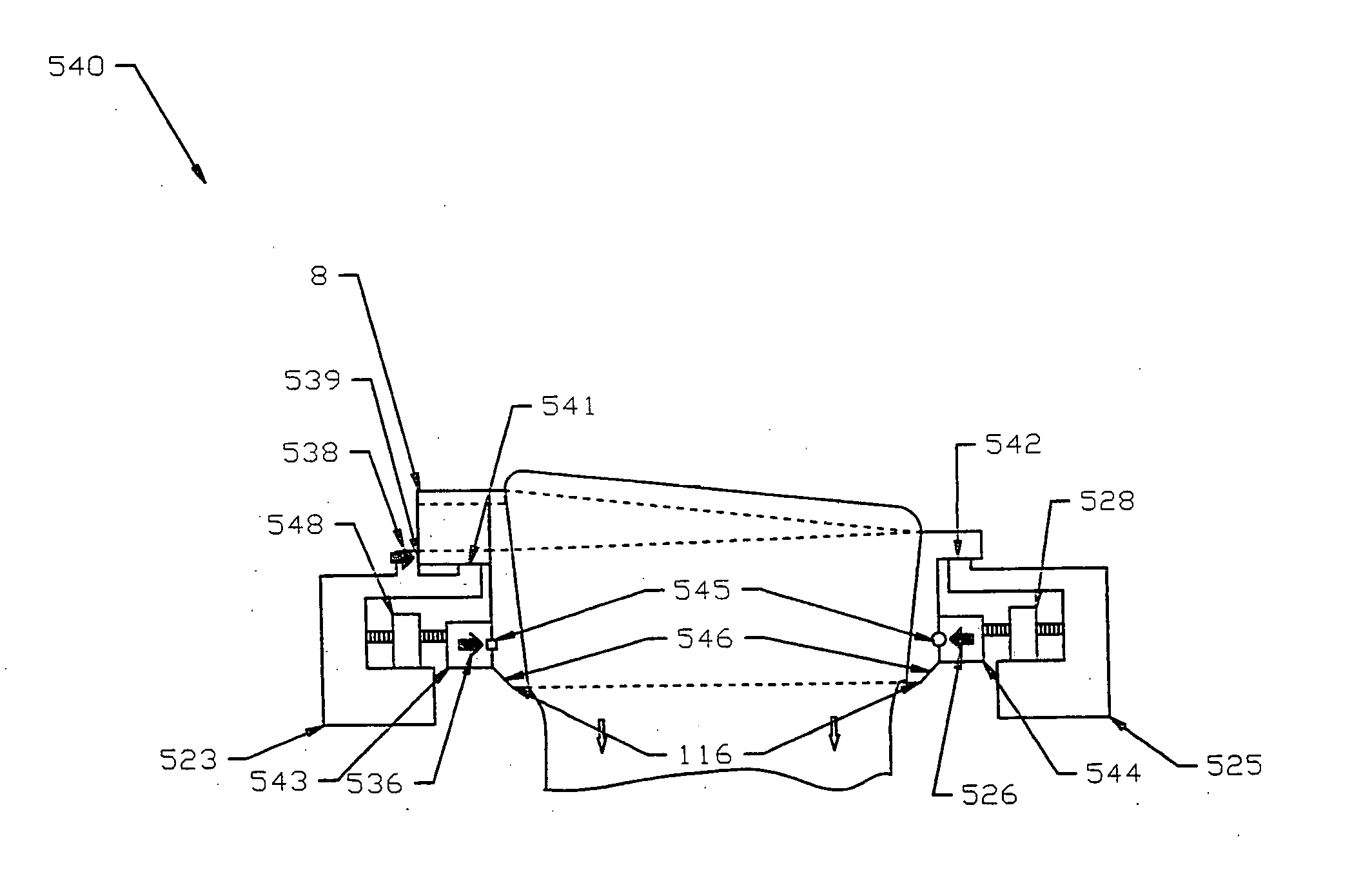

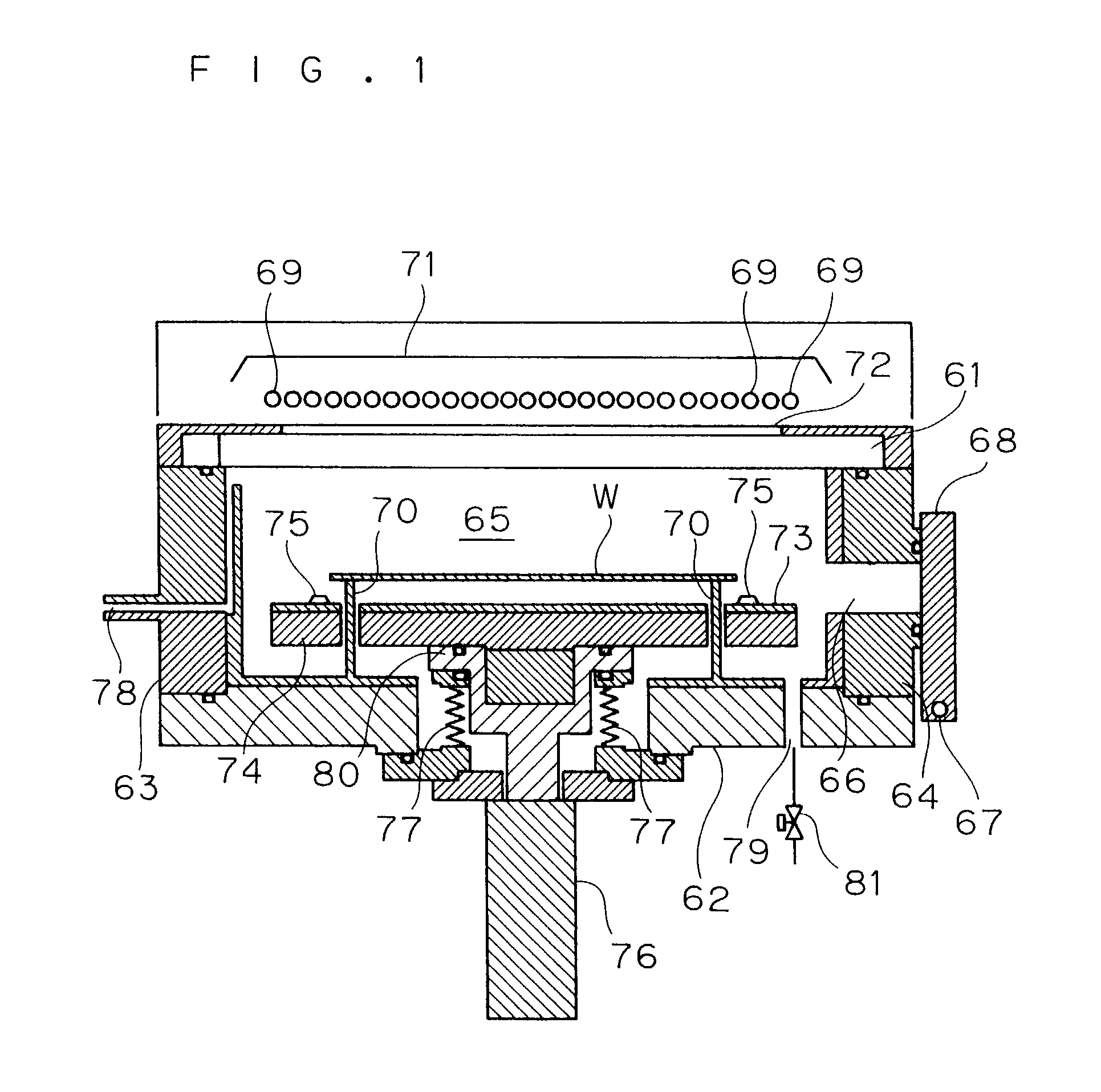

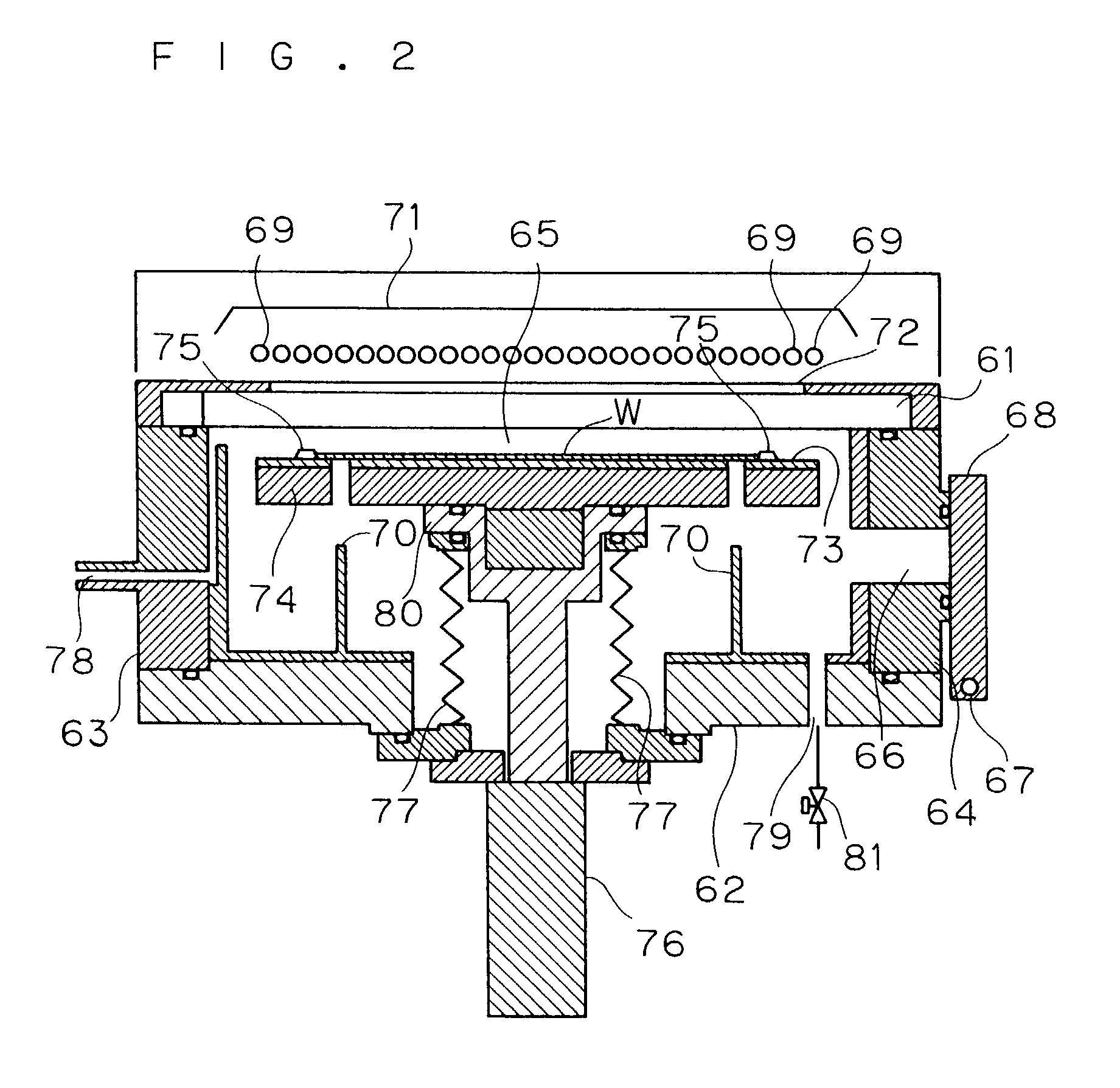

Sheet glass forming apparatus

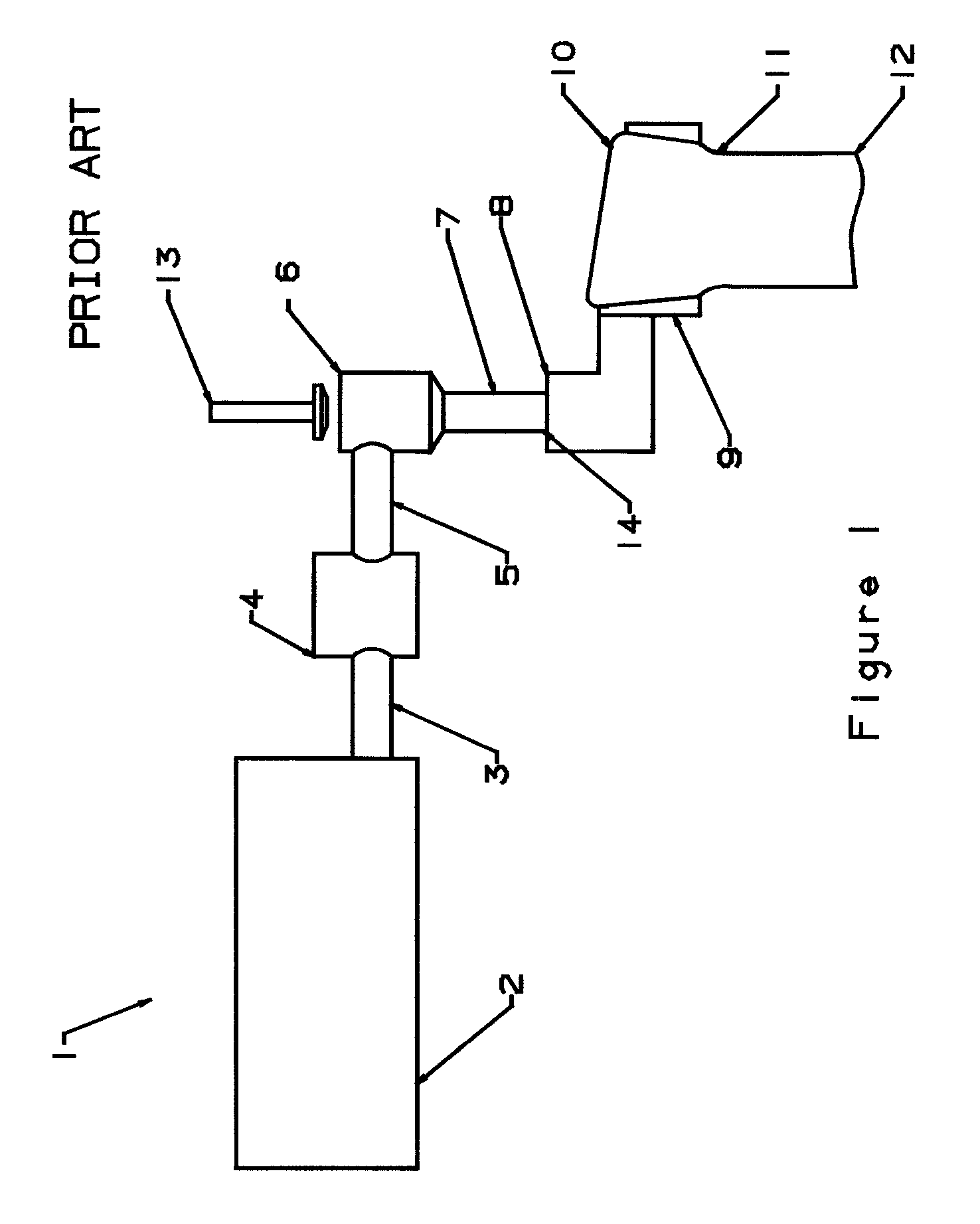

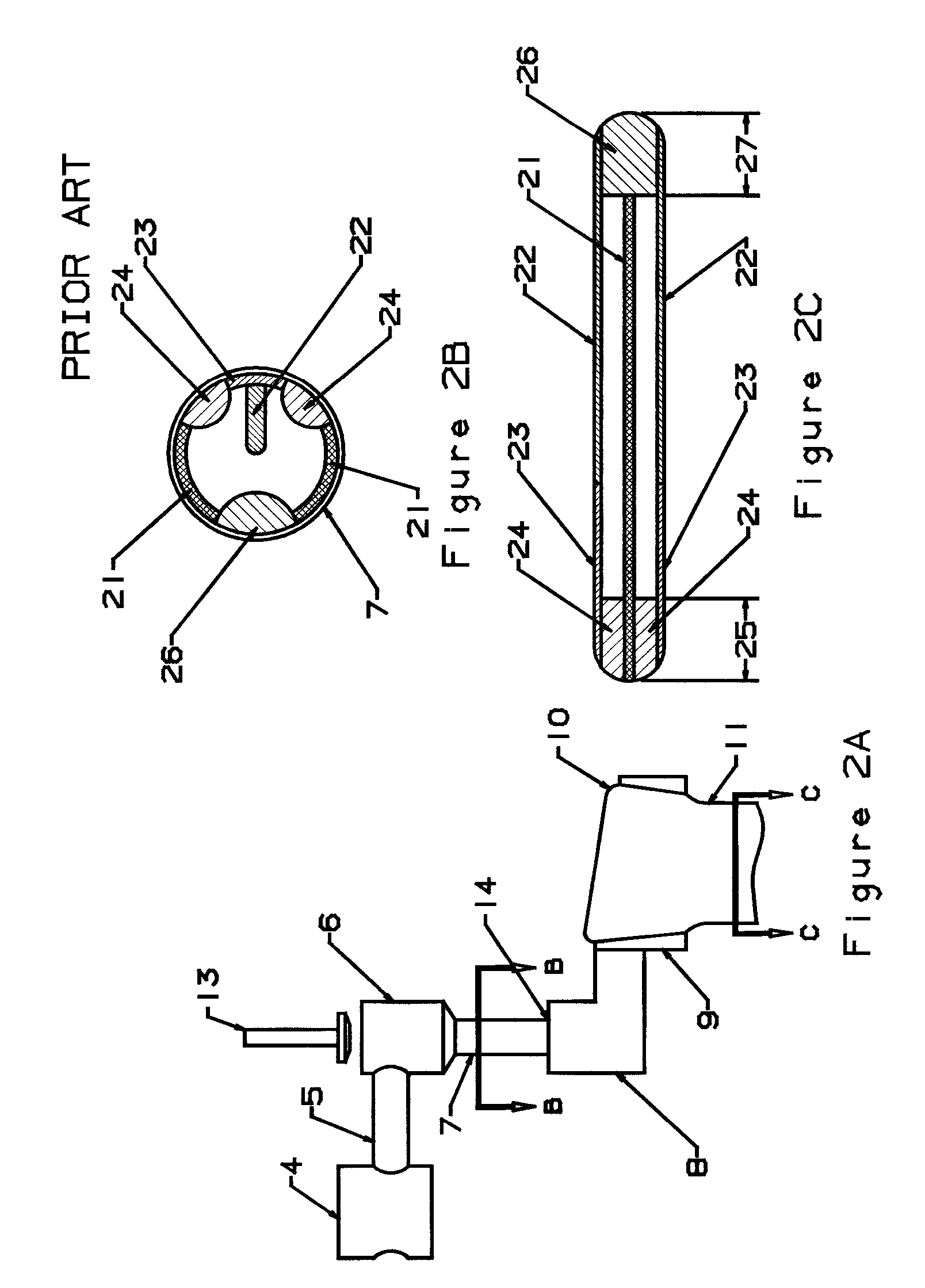

InactiveUS20050138966A1Reduce unevennessBlowing machine gearingsGlass furnace apparatusFlat glassThumb opposition

The present invention alters the flow path at the inlet of the sheet glass forming apparatus to improve quality. The bottom of the downcomer pipe is preferably shaped to alter the character of the vortex flow in the quiescent flow zone between the pipes. In another embodiment, a bead guide provides hydraulic stresses that are in opposition to the surface tension stress and thus reduces the influence of surface tension on the formation of thick beads on the edges of the sheet. The present invention also measures the temperature of the glass by immersing thermocouples in the glass, at locations where any defects caused by the immersion are in the glass that forms the unusable edges of the sheet. In another embodiment, the support structure for the trough is altered to substantially reduce the aging of the trough due to thermal creep.

Owner:CORNING INC

Method and device for producing thin glass panes

InactiveUS20080184741A1Quality improvementImprove productivityBlowing machine gearingsRibbon machinesUnit of lengthGlass sheet

The method of making thin glass panes includes conveying a glass melt through a vertical inlet to a drawing tank with a slit nozzle; drawing a glass ribbon downward from the slit nozzle; setting a total throughput by setting length and cross section of the inlet and by heating and cooling the inlet to control glass melt viscosity so that pressure in the inlet decreases; and setting a throughput per unit of length in a lateral direction along the glass ribbon via nozzle system geometry and by heating and cooling of the drawing tank and slit nozzle to control melt viscosity, so that glass does not wet an underside of the slit nozzle near a breaking edge. The setting of the total throughput and the throughput per unit length are largely decoupled to simplify process control. An inventive apparatus for performing the method is also disclosed.

Owner:SCHOTT AG

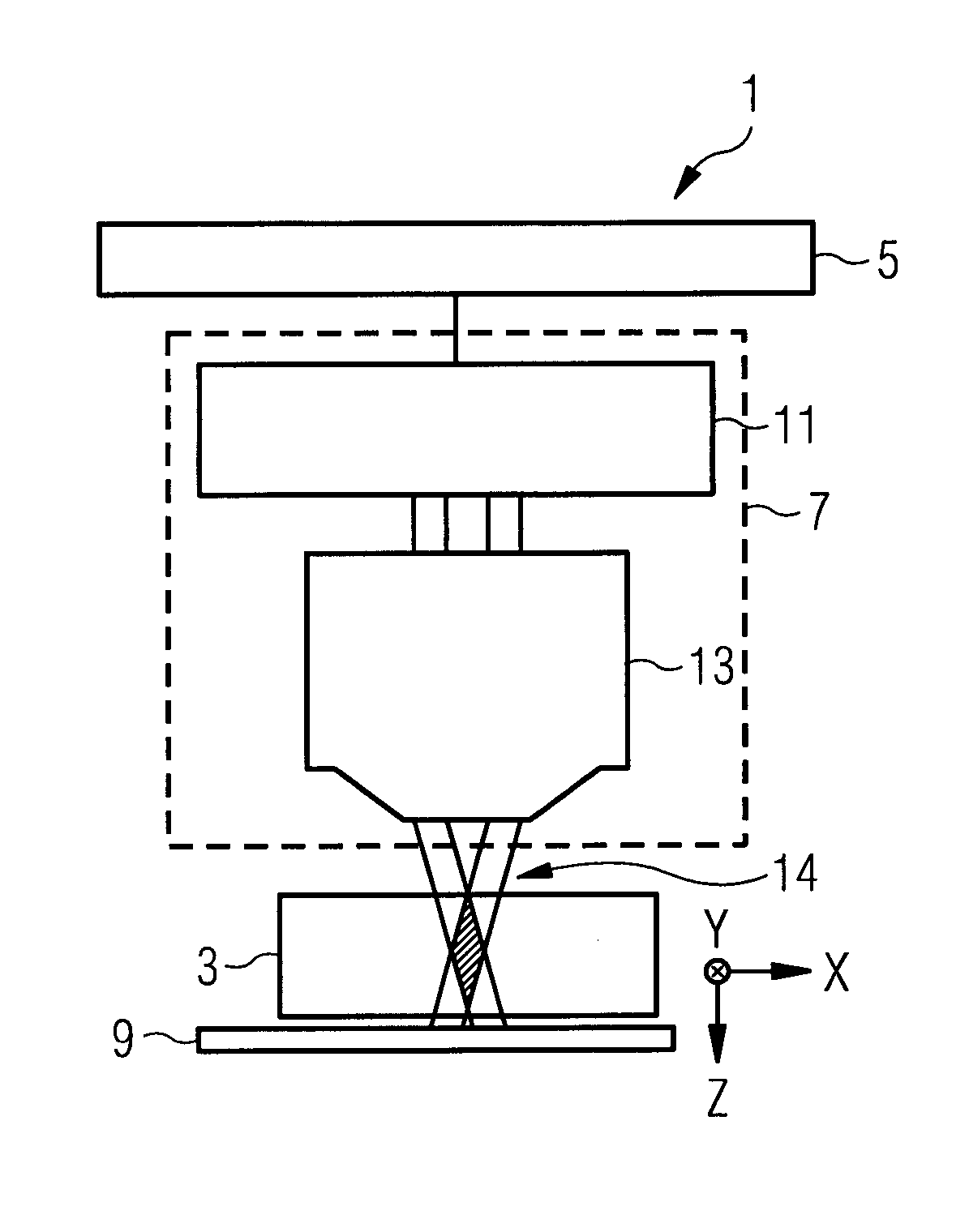

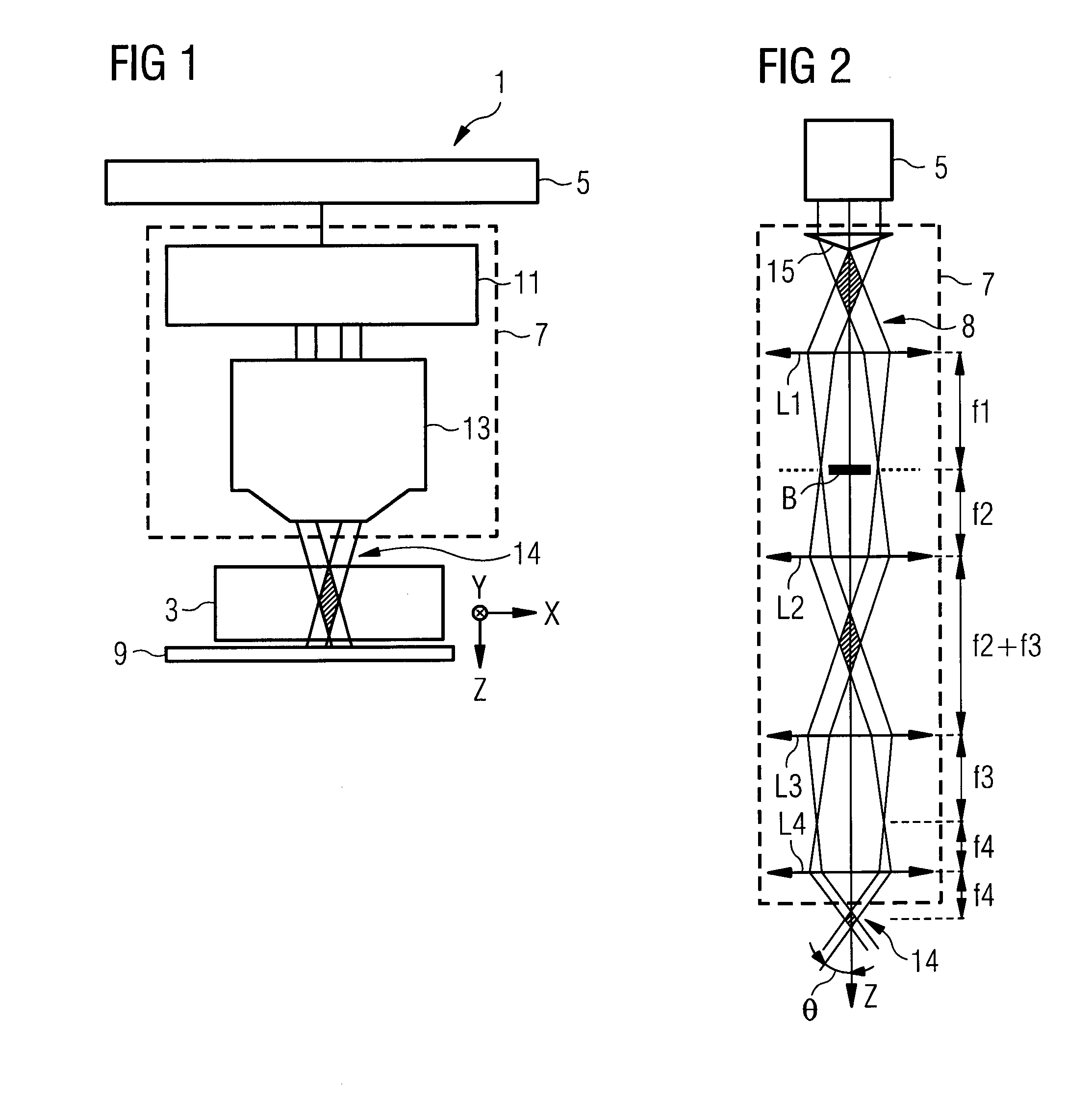

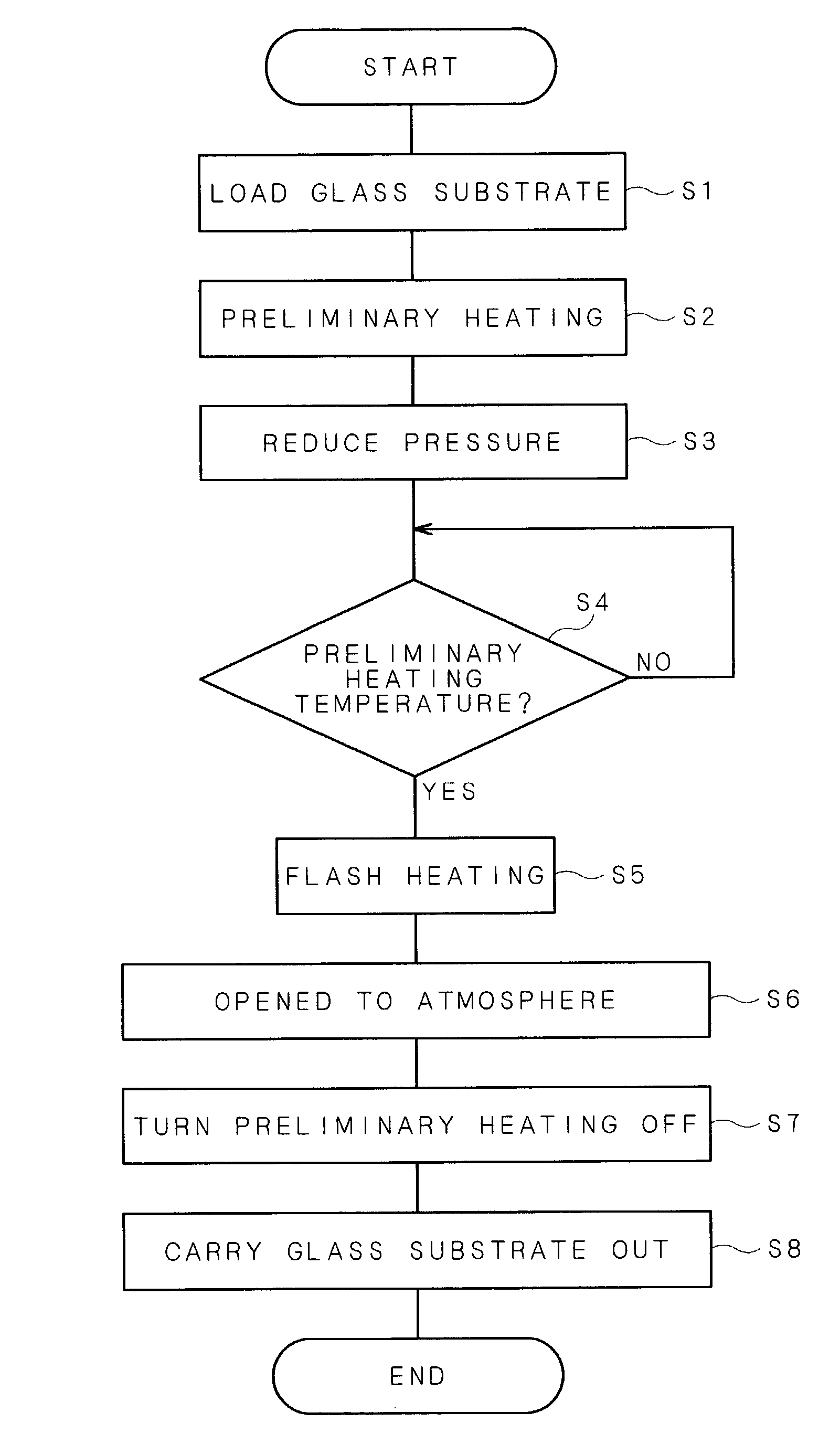

Heat treatment apparatus and heat treatment method of substrate

ActiveUS7255899B2Well formedExcellent characteristicsBlowing machine gearingsGlass furnace apparatusAmorphous siliconIrradiation

A heat diffusion plate and a heating plate are placed in a heat treatment chamber in this order. The heating plate is used for preliminarily heating a glass substrate to a temperature in a range from 200° C. to 400° C. The glass substrate thus preliminarily heated is subjected to a heat treatment by flash light irradiation by a xenon flash lamp. The flash light irradiation makes it possible to uniformly heat an amorphous silicon film on the glass substrate, and consequently to be poly-crystallized. Thus, it becomes possible to provide a heat treatment technique capable of carrying out a uniform heat treatment on the silicon film on the glass substrate sufficiently.

Owner:DAINIPPON SCREEN MTG CO LTD

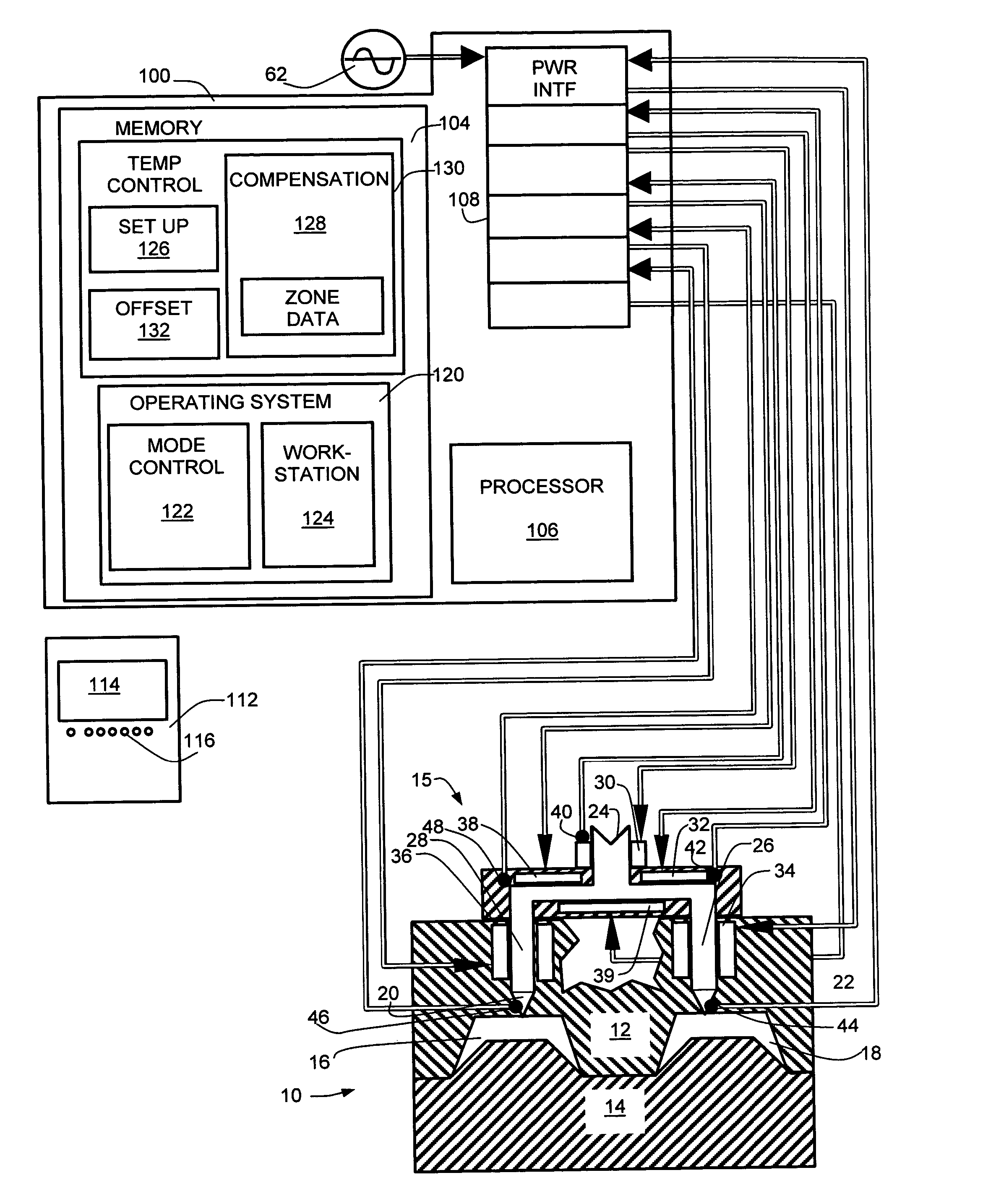

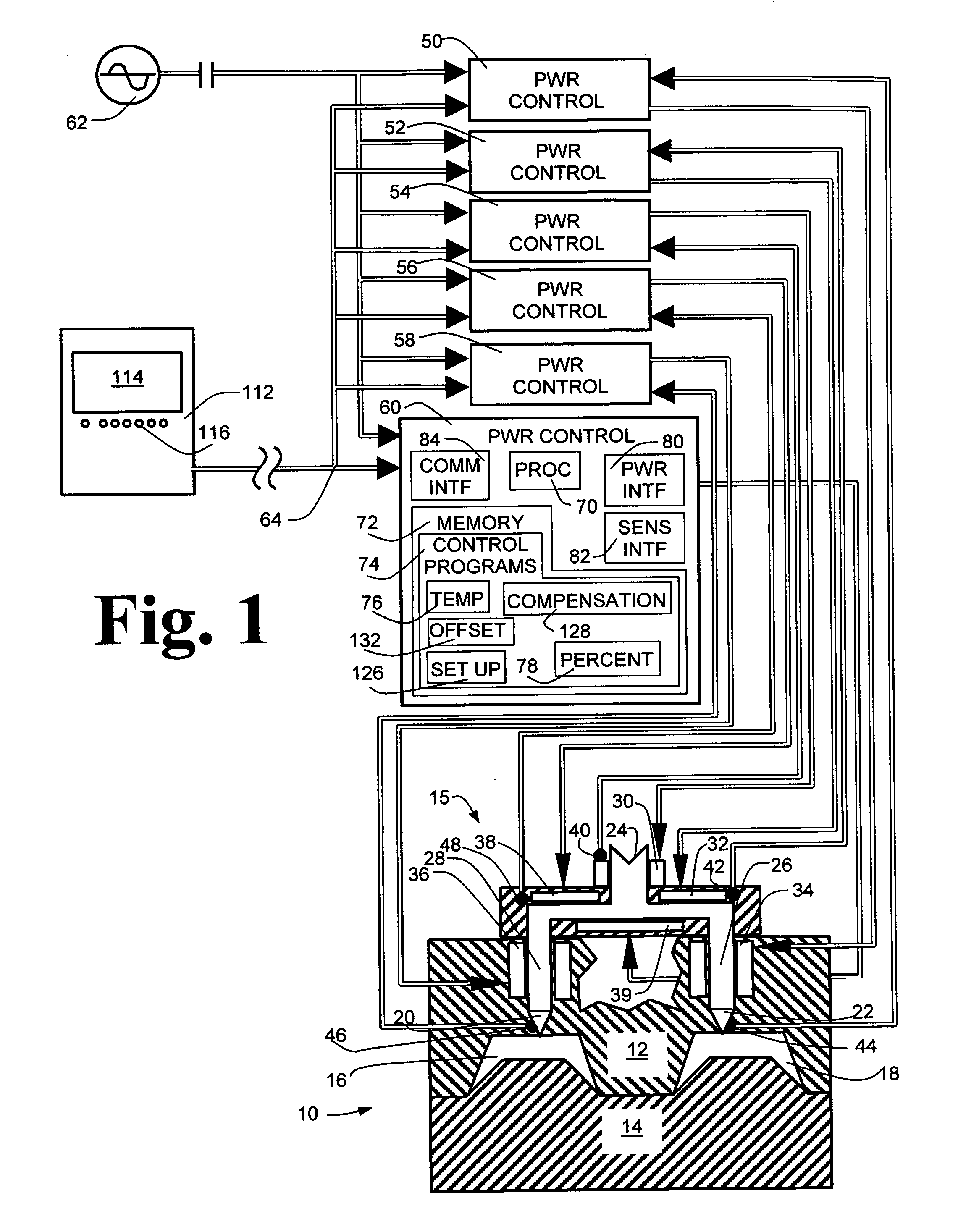

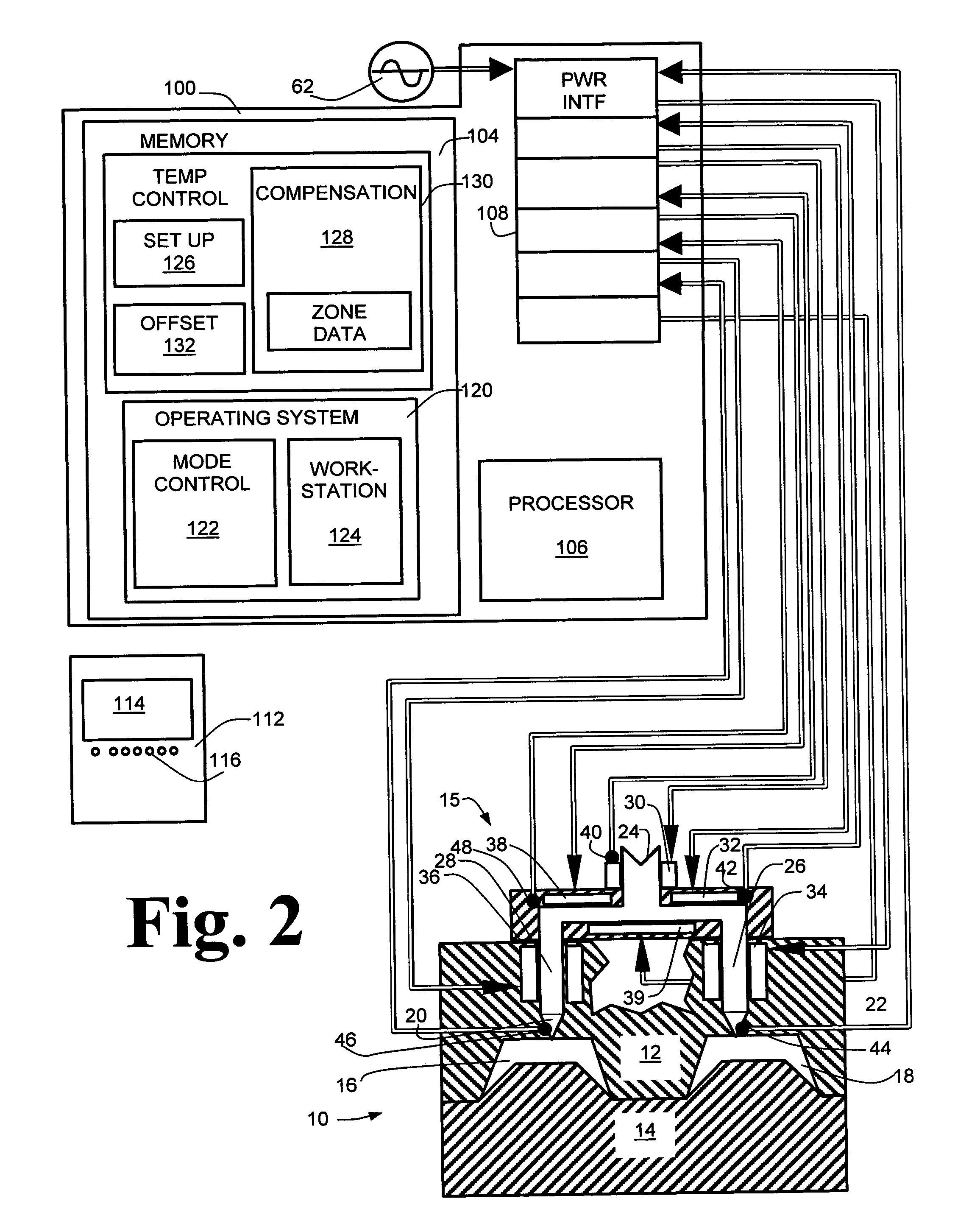

Temperature control

ActiveUS7020540B2Temperatue controlStatic/dynamic balance measurementTemperature controlControl zone

A method and apparatus are disclosed for controlling temperature of a plant comprising plural temperature control zones, wherein an effective control parameter for a first zone for which a signal representing measured temperature is available is produced according to an algorithm relating measured temperature, a desired temperature and a control parameter associated with a device affecting temperature in the first temperature control zone, the effective control parameter is summed with an offset value representing a proportional offset of the effective control parameter of a second temperature control zone relative to the effective control parameter of the first temperature control zone and the result is applied to control a device affecting temperature in the second temperature control zone. Advantageously, the offset value comprises a fixed amount and a variable amount, the variable amount accounting for dynamic differences in temperature control characteristics of the first and second temperature control zones.

Owner:D M E CO

Hood tilt mechanism for curved glass processing

InactiveUS20050178158A1Shorten the timePrecise positioningBlowing machine gearingsGlass transportation apparatusHOOD assemblyEngineering

A glass forming assembly for forming complex shaped glass, with the glass forming assembly having a hood assembly including a hood lift superstructure movable horizontally back and forth over a cold ring and a cooling shuttle and movable vertically relative to the cold ring and the cooling shuttle, and a hood frame supported by the hood lift superstructure by a hood tilt mechanism. The hood tilt mechanism includes an air cylinder assembly actuable to tilt the hood frame relative to the hood lift superstructure, which allows for proper orientation of the glass prior to dropping it on the cooling shuttle, thus allowing for reduced glass chipping and cracking.

Owner:AUTOMOTIVE COMPONENTS HOLDINGS

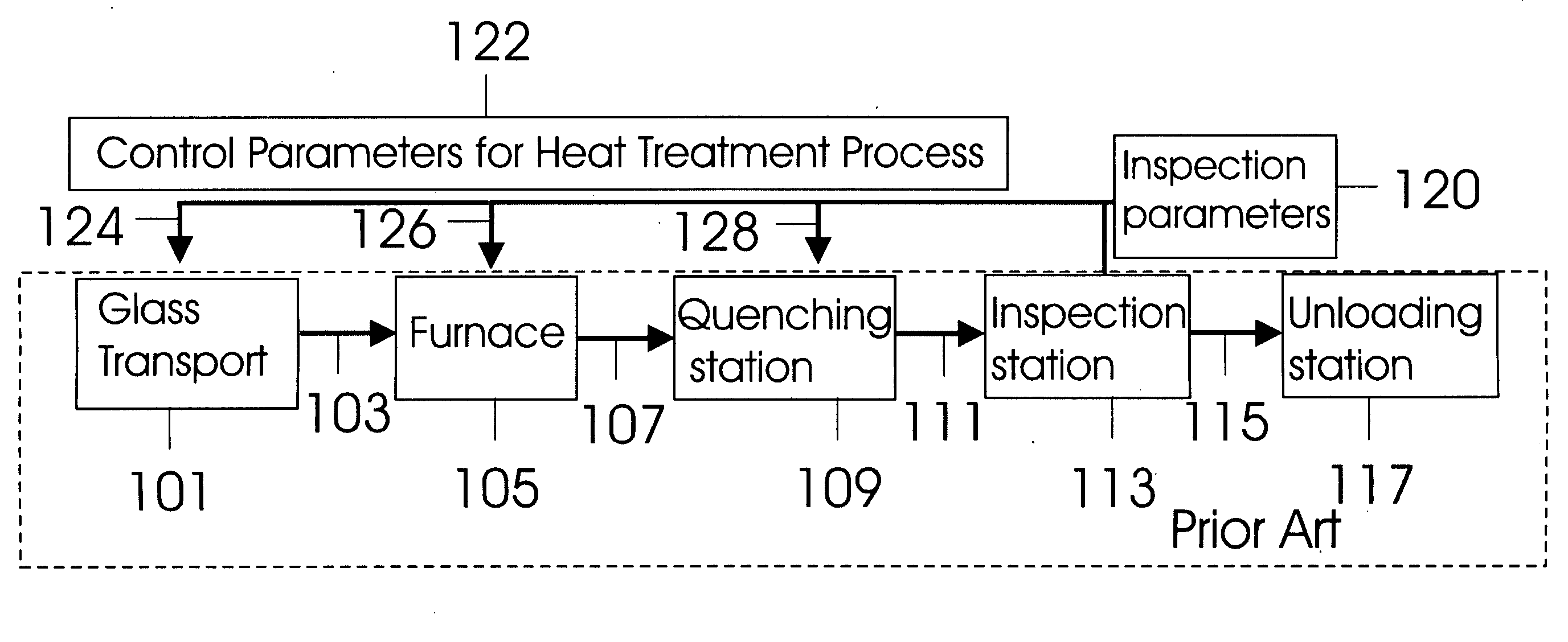

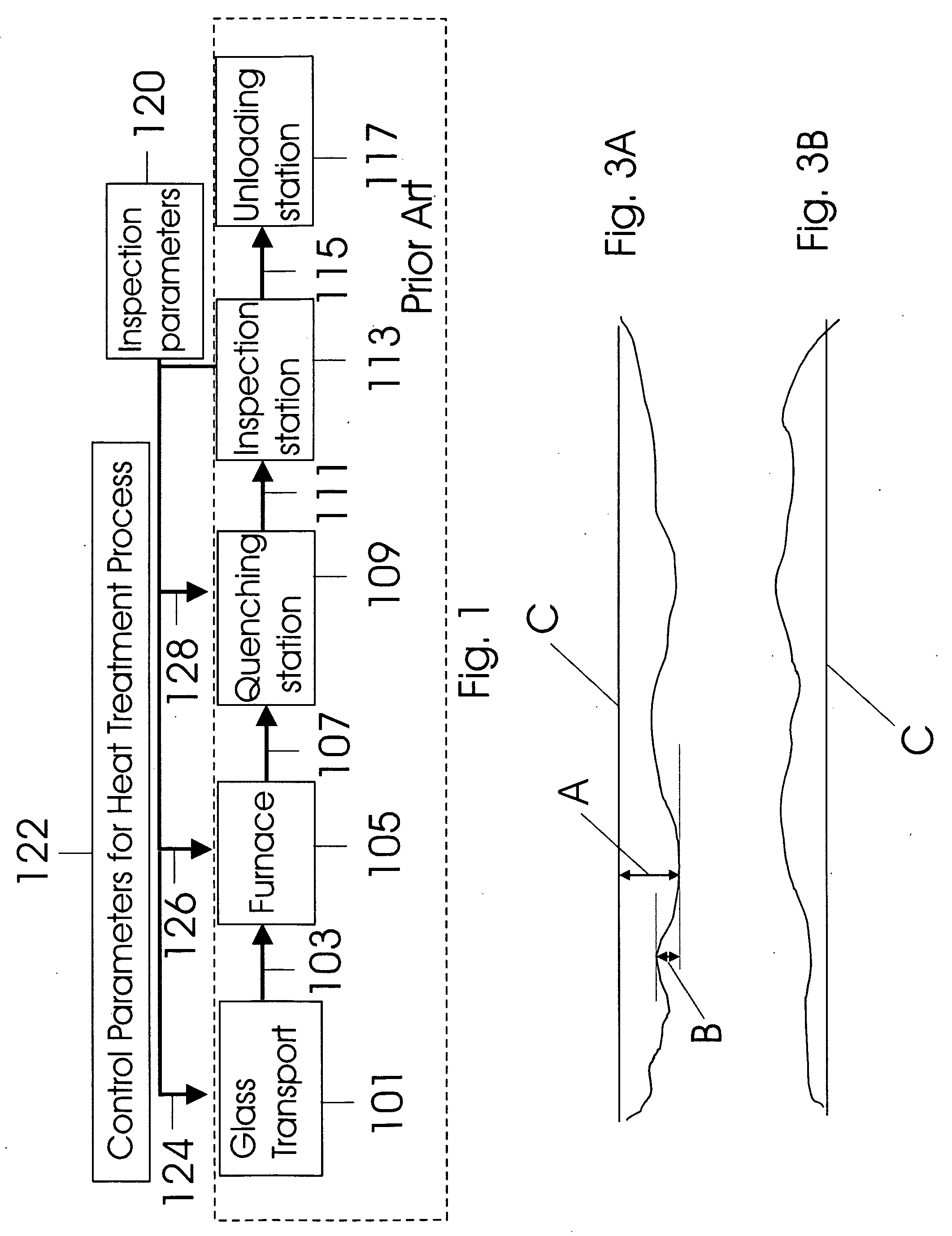

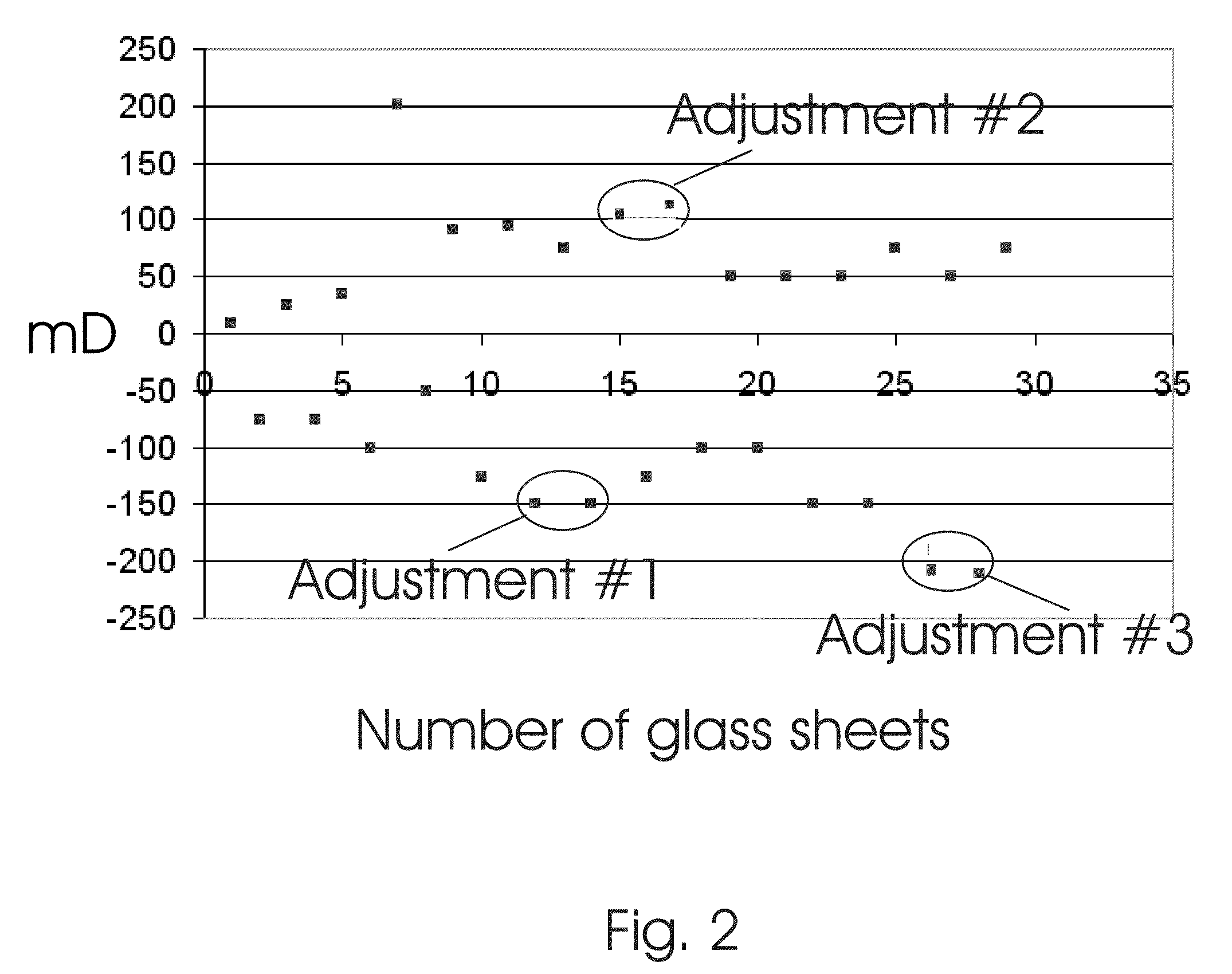

Closed loop control system for the heat-treatment of glass

InactiveUS20090199594A1Reduce laborWeaken energyBlowing machine gearingsGlass furnace apparatusControl systemClosed loop

A method and apparatus for controlling the process used in the heat treatment of glass measures the quality of the glass following the heat treatment process. Inputs to the control system for the heat treatment process derive from the automated inspection of glass following heat treatment. Outputs from the control system for the heat treatment process may adjust one or more parameters in the heat treatment process including a furnace or heating setting, a transport setting, and a quench or cooling setting.

Owner:LITESENTRY CORP

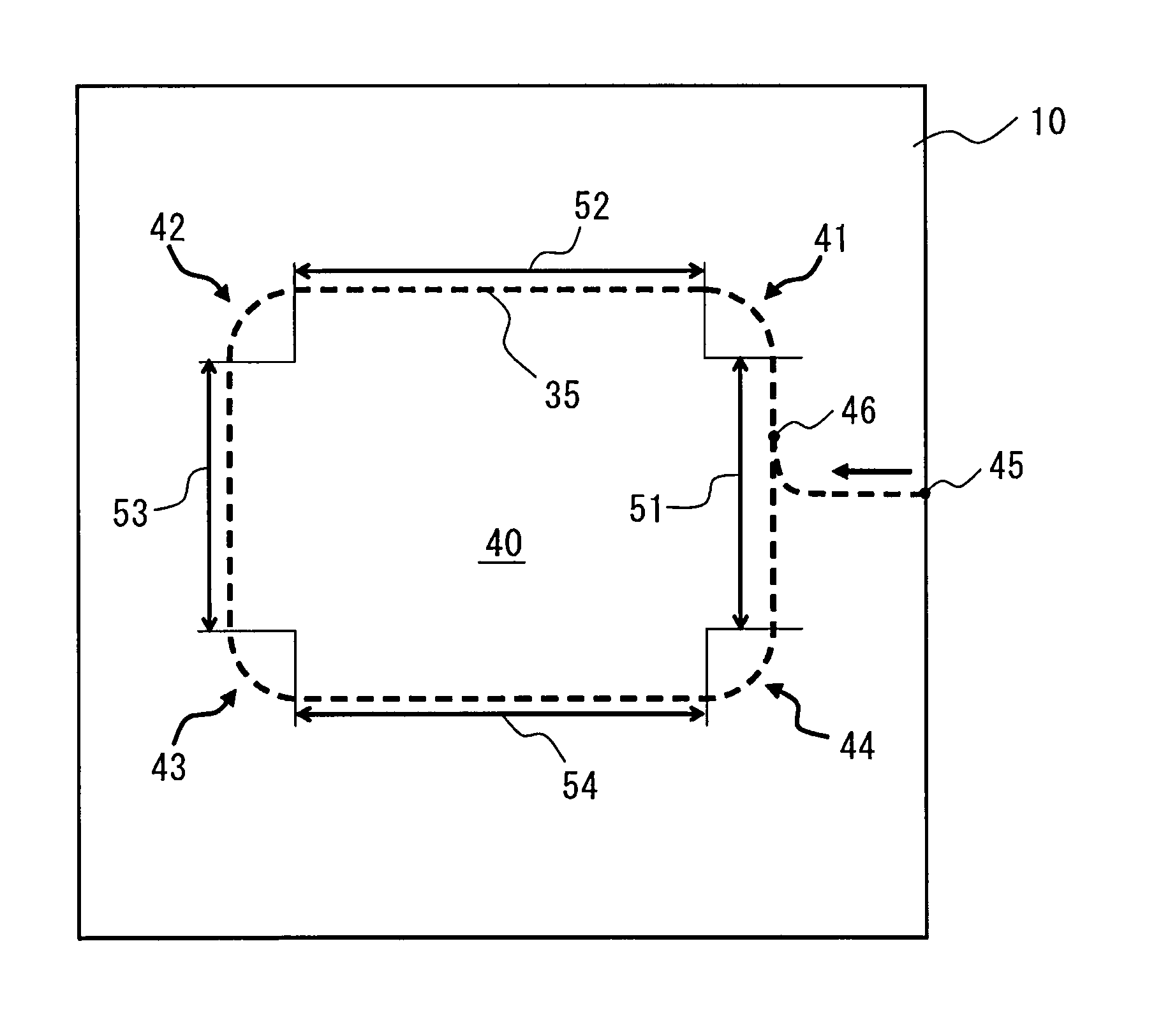

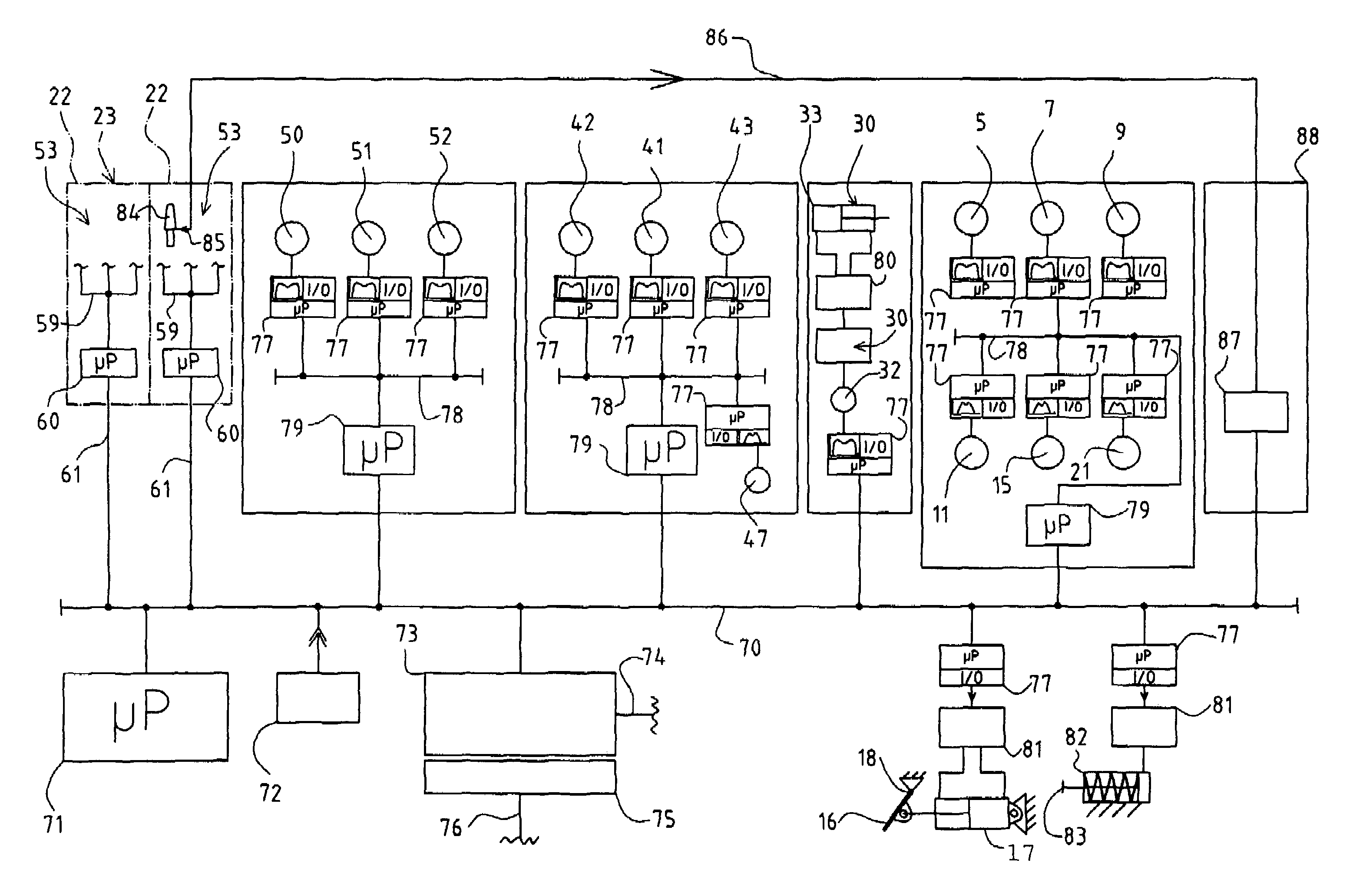

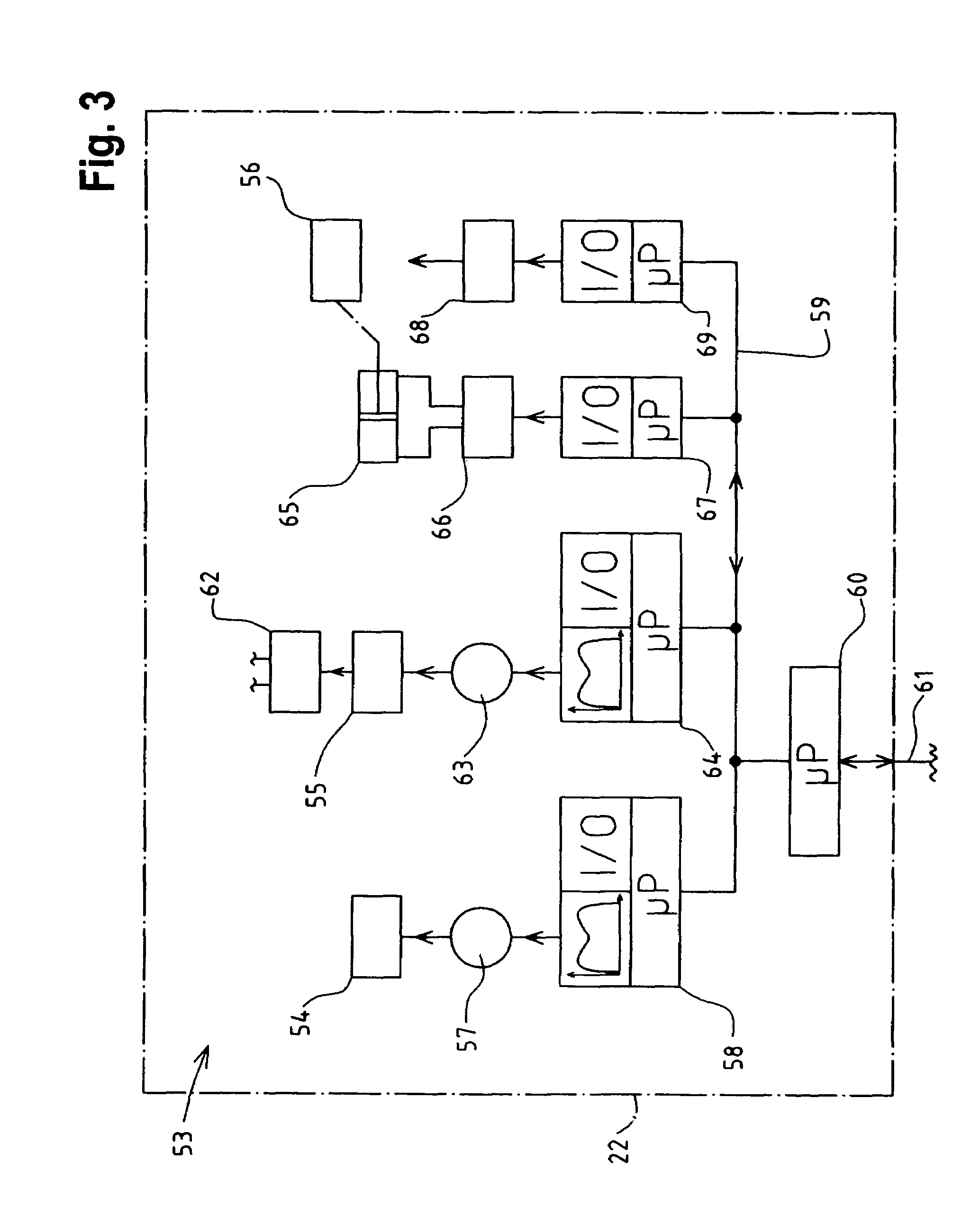

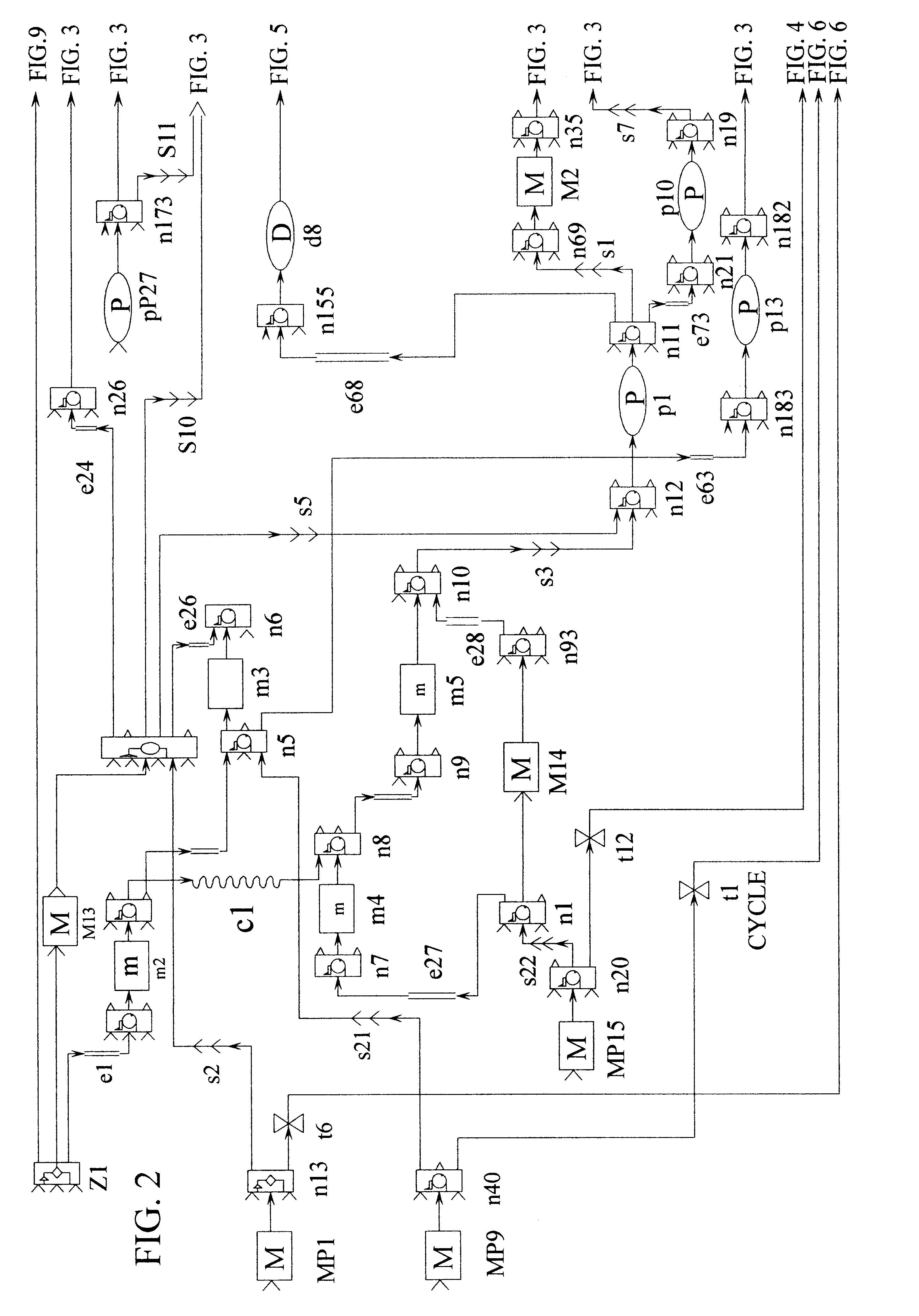

Electronic control for glass moulding machines

InactiveUS7054710B2Fast inputEasy accessBlowing machine gearingsSensitive elementsModem deviceEngineering

Sections (22) of an I.S. glass forming machine (23) have a plurality of mechanisms which can be respectively driven by a first drive. Each first drive is allocated a controller which is connected to a first sequencer (60) via a first bus (59). All first sequencers (60) are connected to a second bus (70) to which a second sequencer (71), a manually-operated device (72), a PC (73) with an Internet connection (74) and a modem (75) are connected. Peripheral devices of the I.S. glass forming machine (23) each have at least one third drive (5, 7, 9, 11, 15, 21, 32, 41, 42, 43, 50, 51, 52, 17, 82). Each third drive is connected to a first control device (77). In the case of the third drives (17, 82) associated first control devices (77) are directly connected to the second bus (70), whereas in the other cases a plurality of first control devices (77) are connected to a third bus (78) which is connected to the second bus (70) via a second control device (79).

Owner:HEYE INT

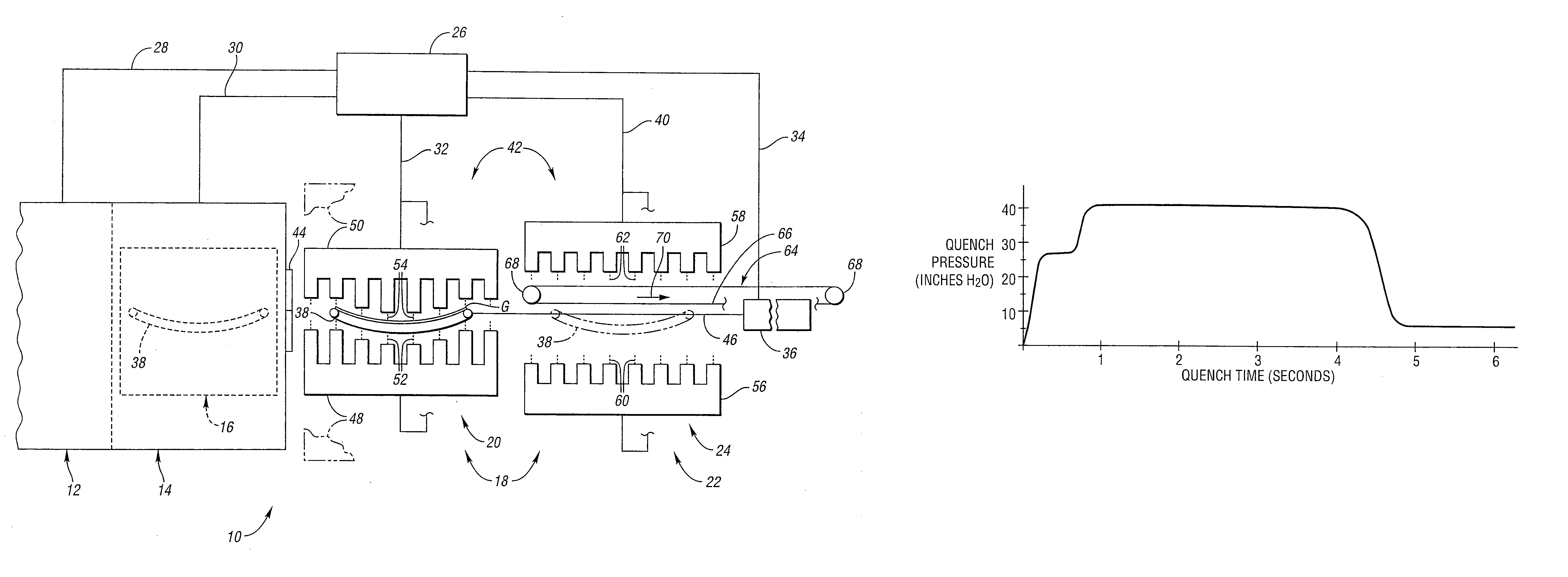

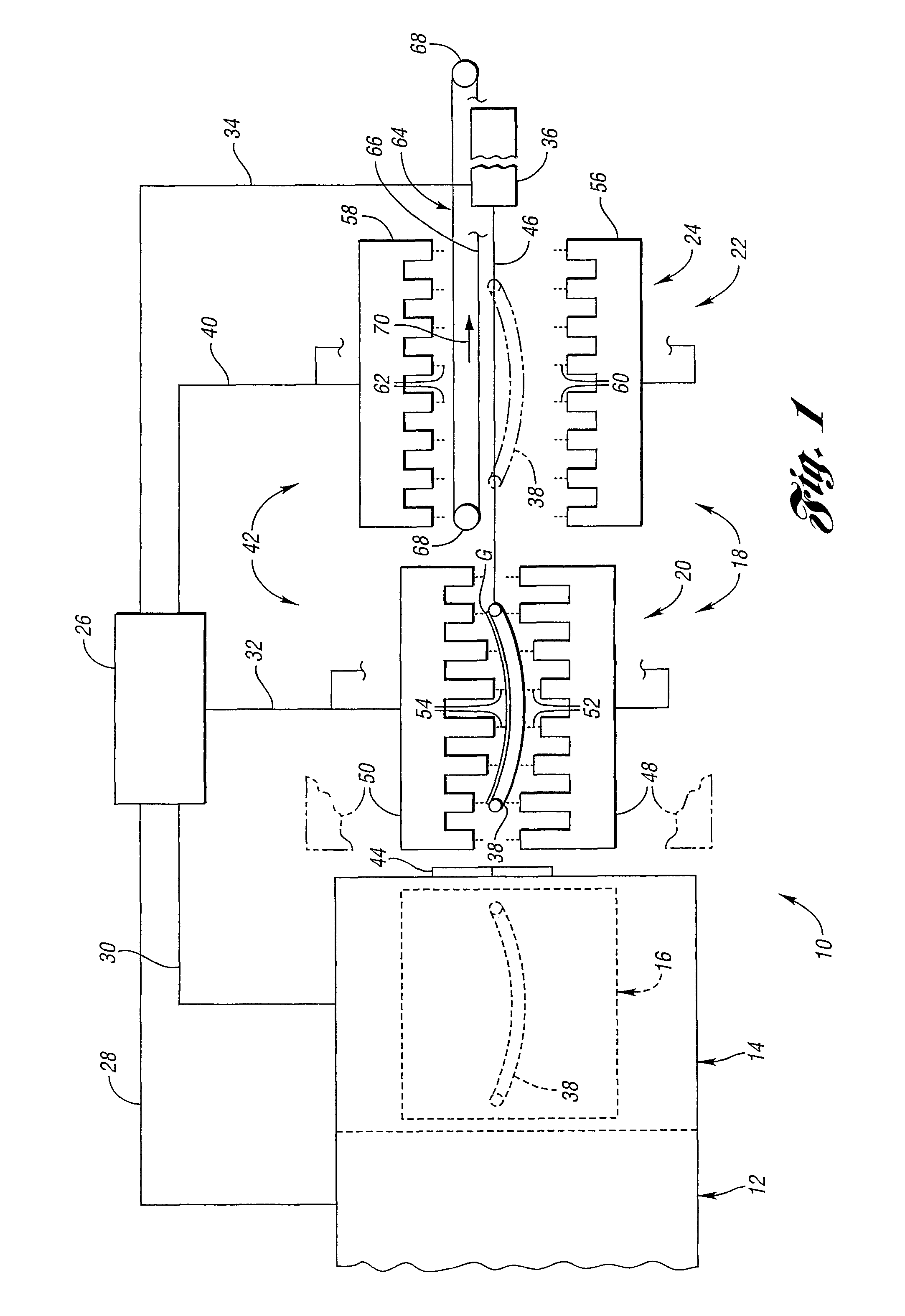

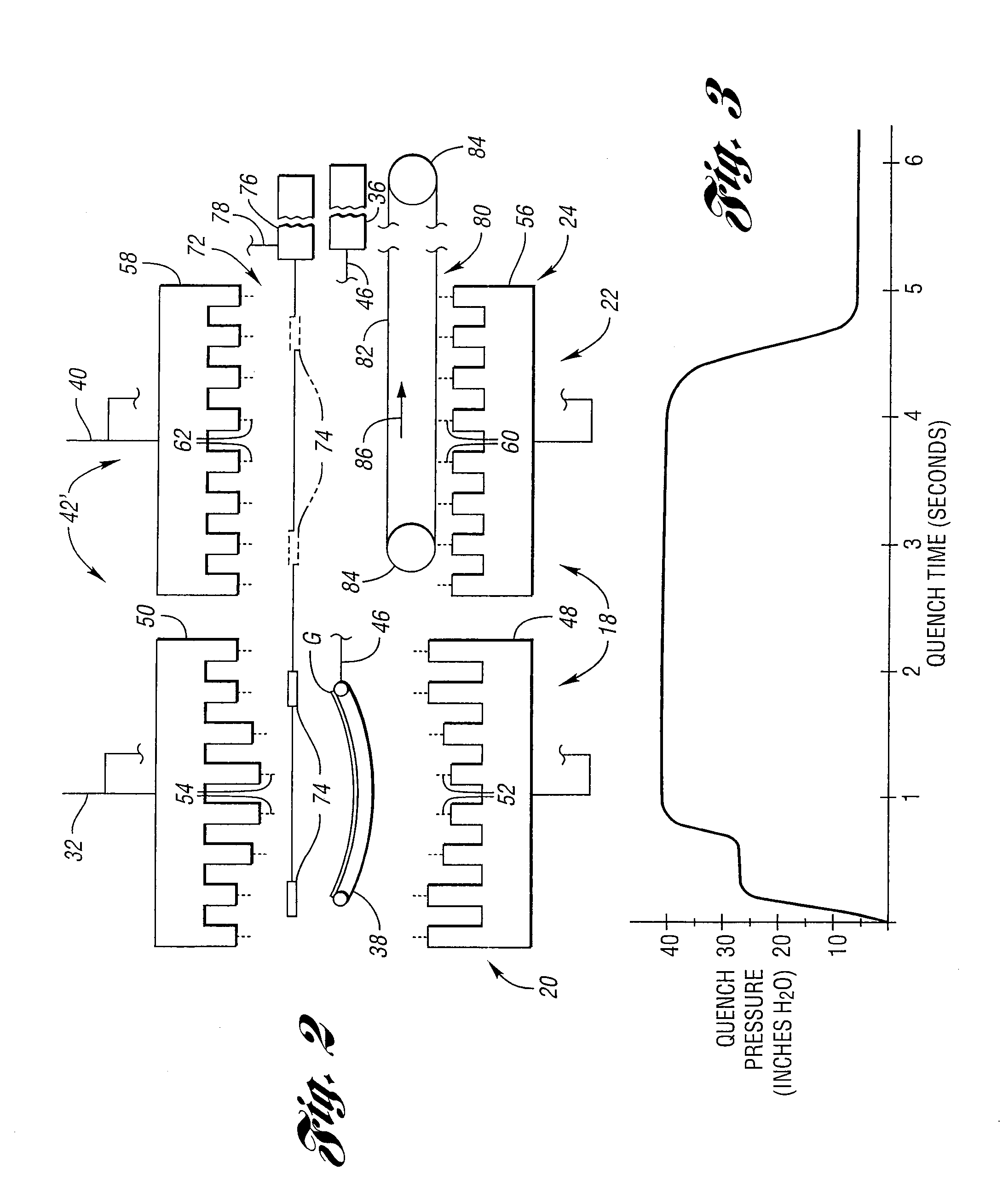

Method for quenching formed glass sheets

ActiveUS8074473B2Reduce processing timeGlass furnace apparatusGlass blowing apparatusCycle timeQuenching

Owner:GLASSTECH

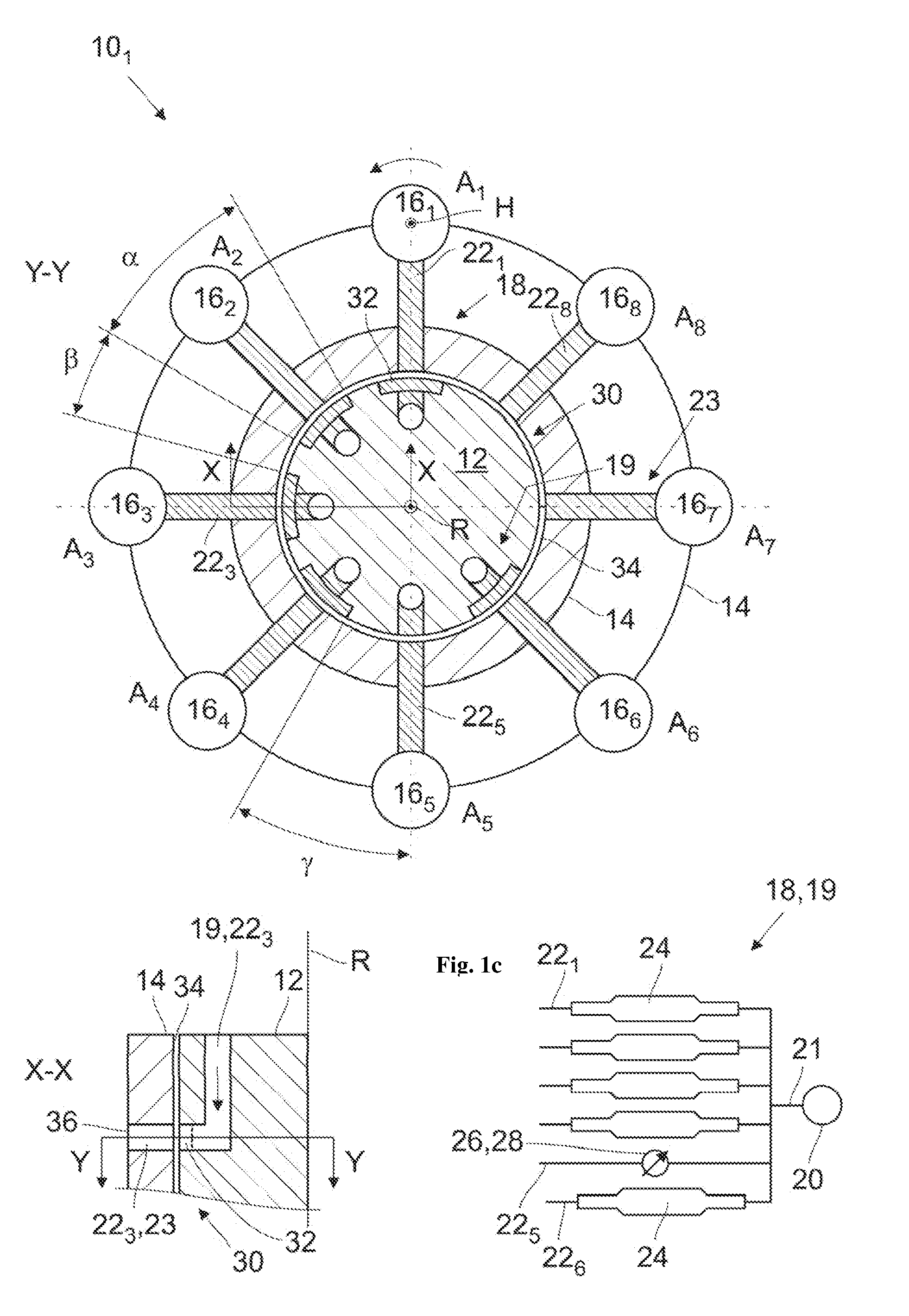

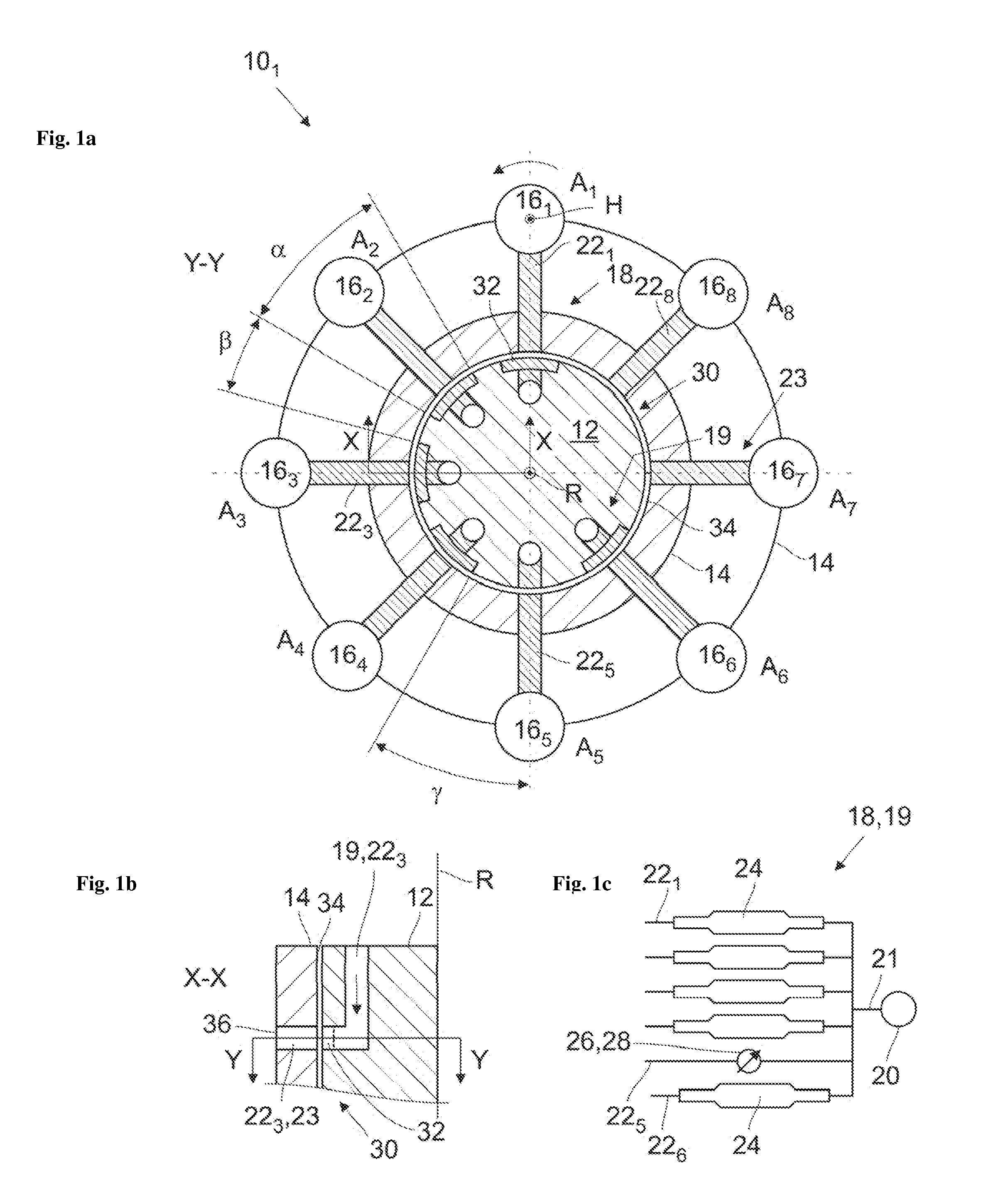

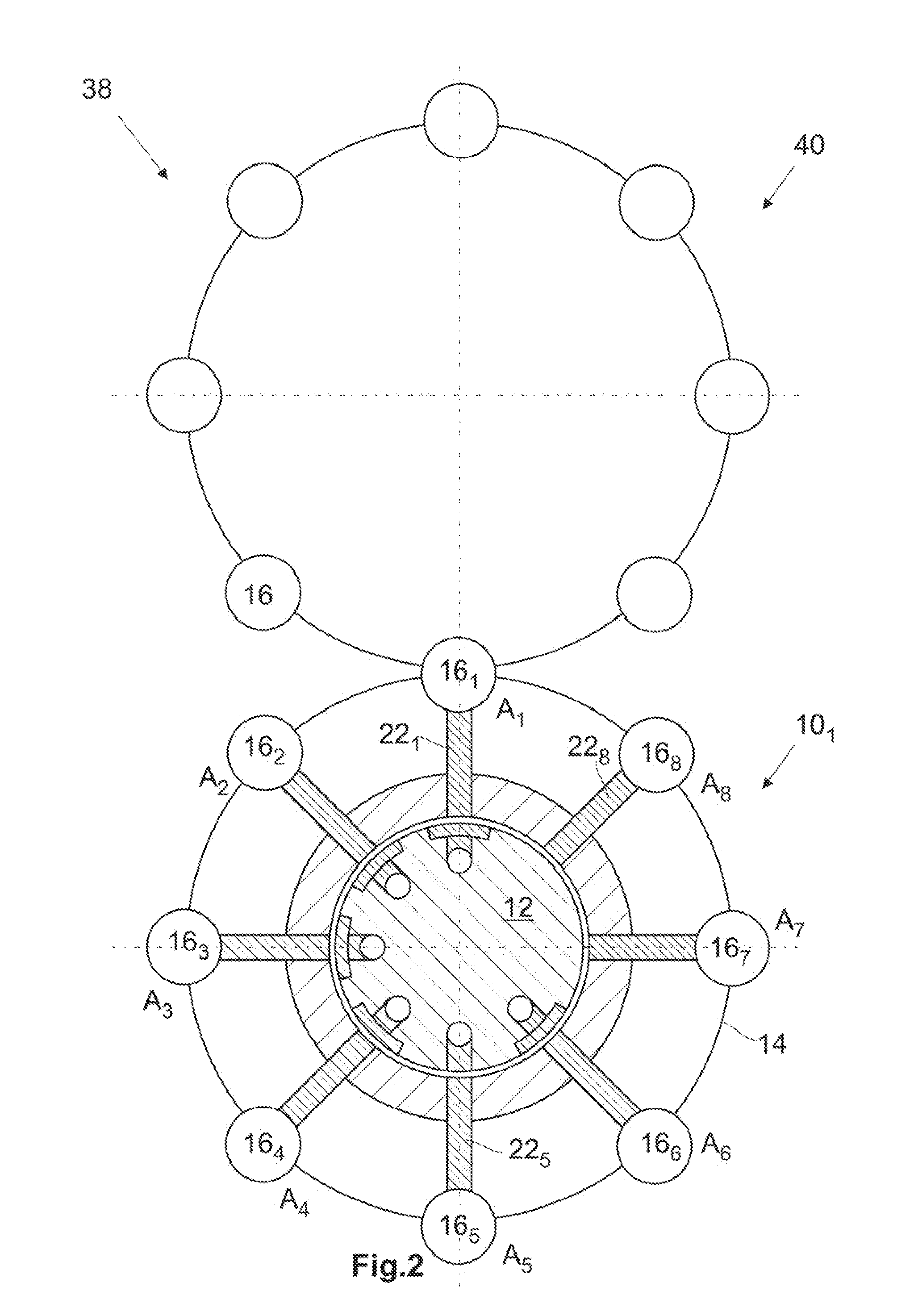

Glass processing device and bottom machine therefor for manufacturing glass containers

ActiveUS20140373574A1Delamination tendency is not reducedReduced tendency of delaminationBlowing machine gearingsGlass reforming apparatusEngineeringGlass container

A bottom machine is provided for a glass processing device to manufacture glass containers from glass tubes. The bottom machine includes one or a plurality of holding units for holding the glass container or glass tube, with the holding units being mounted so as to rotate around an axis of rotation of the bottom machine in order to convey the glass container or glass tube to various processing positions, a pressure source for supplying a gas flow, a duct system communicating with the pressure source for directing the gas flow to the holding units and for feeding the gas flow into the glass tube or into the glass container, with the duct system being designed to be free of gaps.

Owner:SCHOTT PHARMA AG & CO KGAA

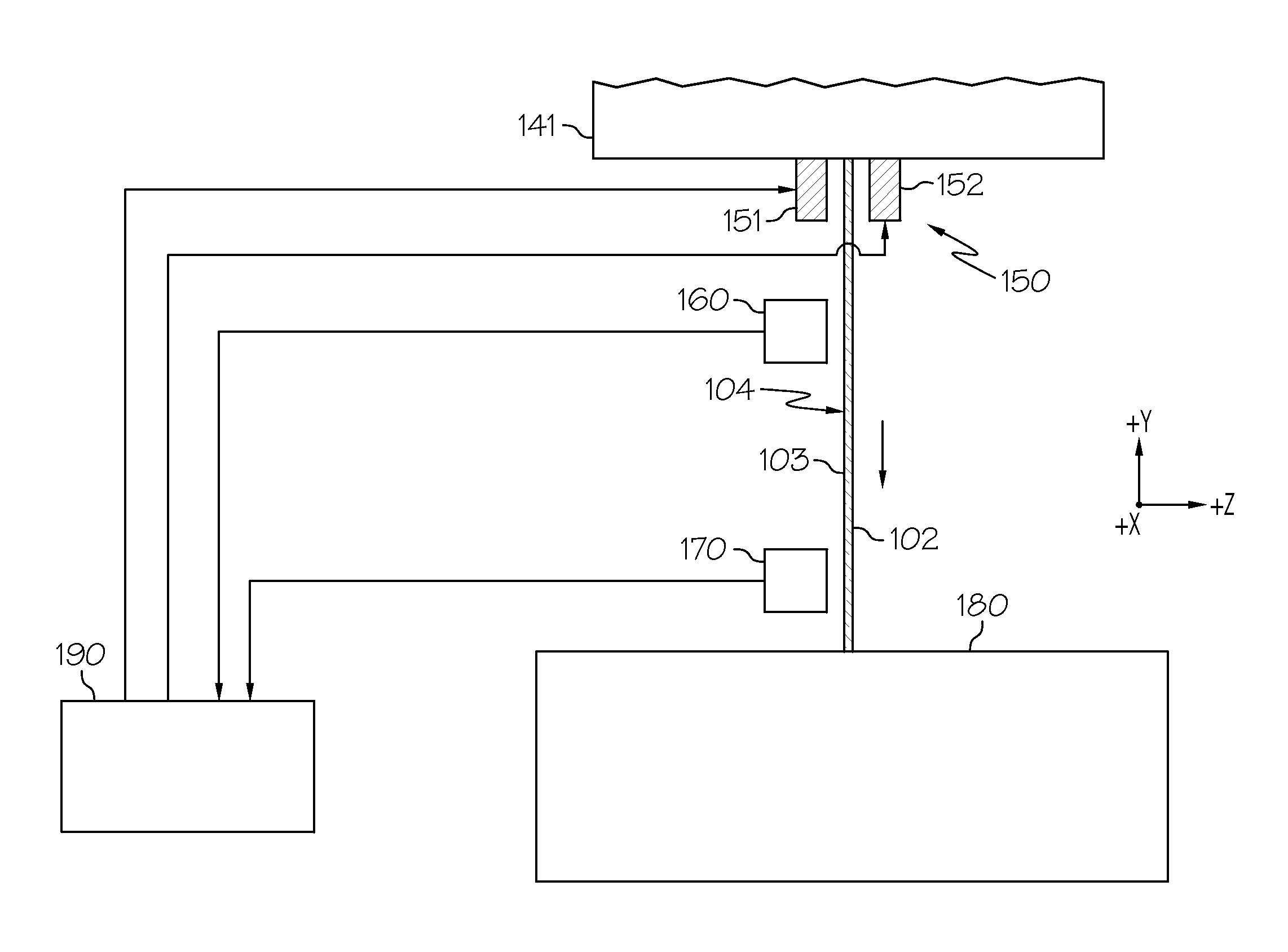

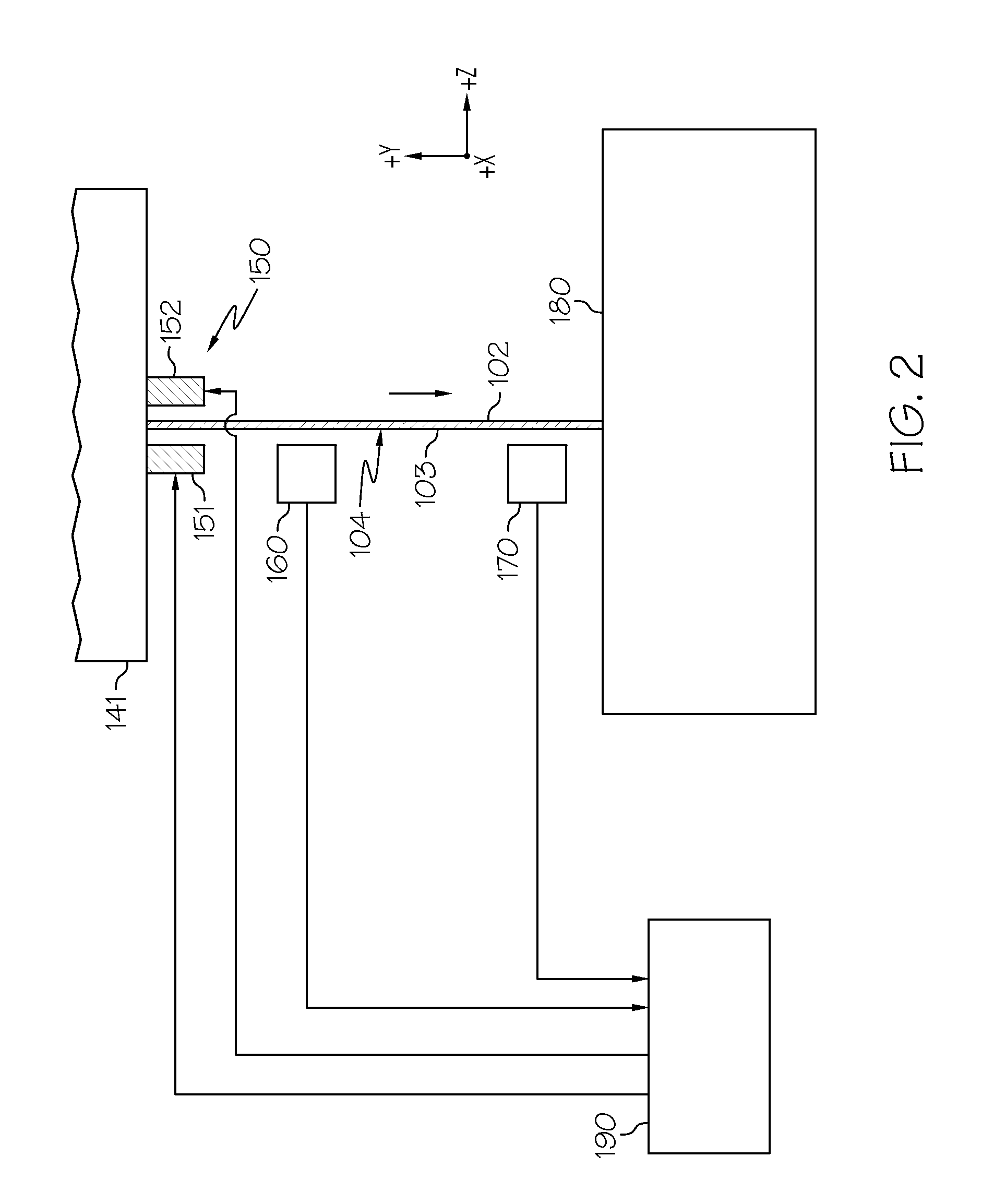

Methods And Apparatuses For Fabricating Continuous Glass Ribbons

InactiveUS20140137601A1Reduce distortion problemsGlass furnace apparatusGlass forming apparatusAutomatic controlEngineering

Methods and apparatuses for fabricating continuous glass ribbons are disclosed. The method includes forming the continuous glass ribbon by drawing the continuous glass ribbon from a draw housing in a drawing direction, heating at least one portion of a central region of the continuous glass ribbon at a heating location downstream of the draw housing, sensing a temperature of the continuous glass ribbon at a sensed temperature location downstream of the draw housing, and automatically controlling the heating of the at least one portion of the central region of the continuous glass ribbon based on the sensed temperature to mitigate distortion of the continuous glass ribbon.

Owner:CORNING INC

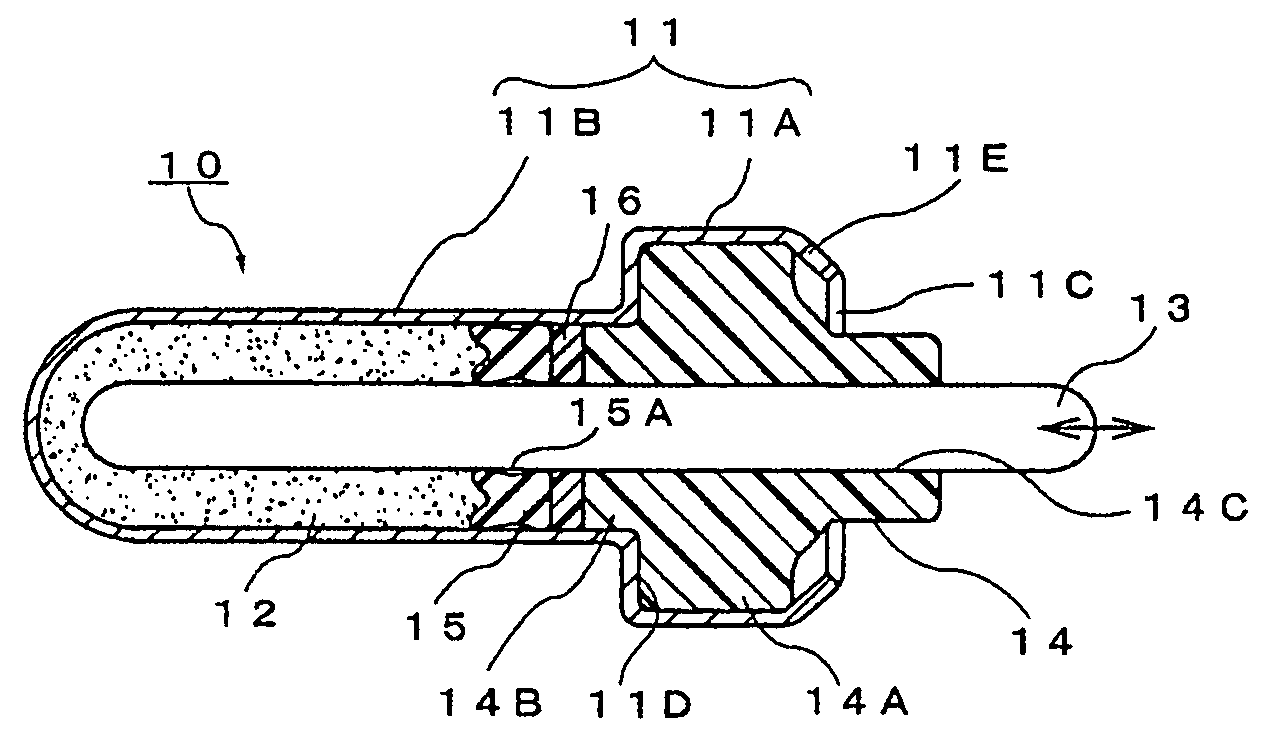

Thermoelement

ActiveUS7175102B2Increase sealing forceImprove responseTemperature control without auxillary powerCoolant flow controlThermocoupleMechanical engineering

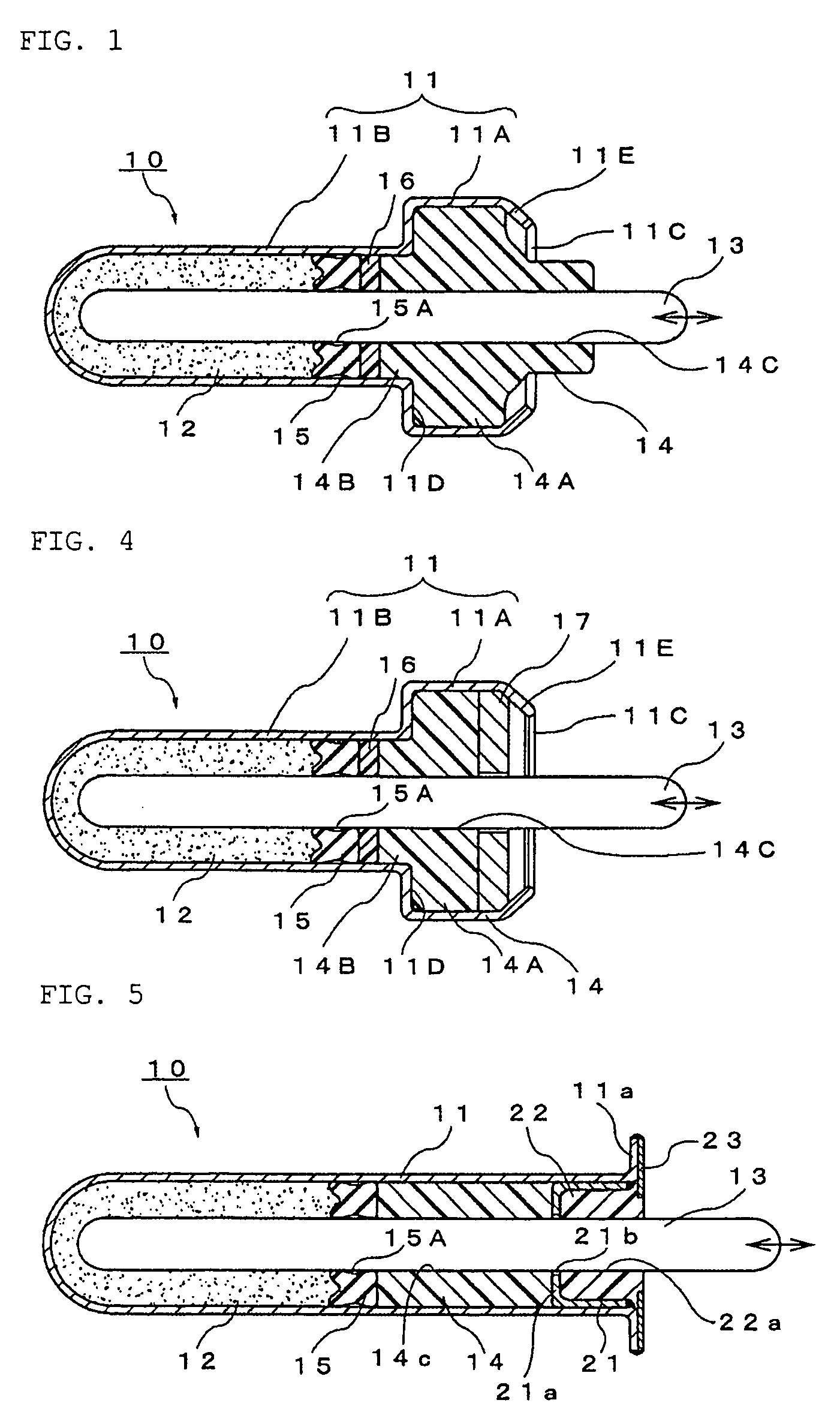

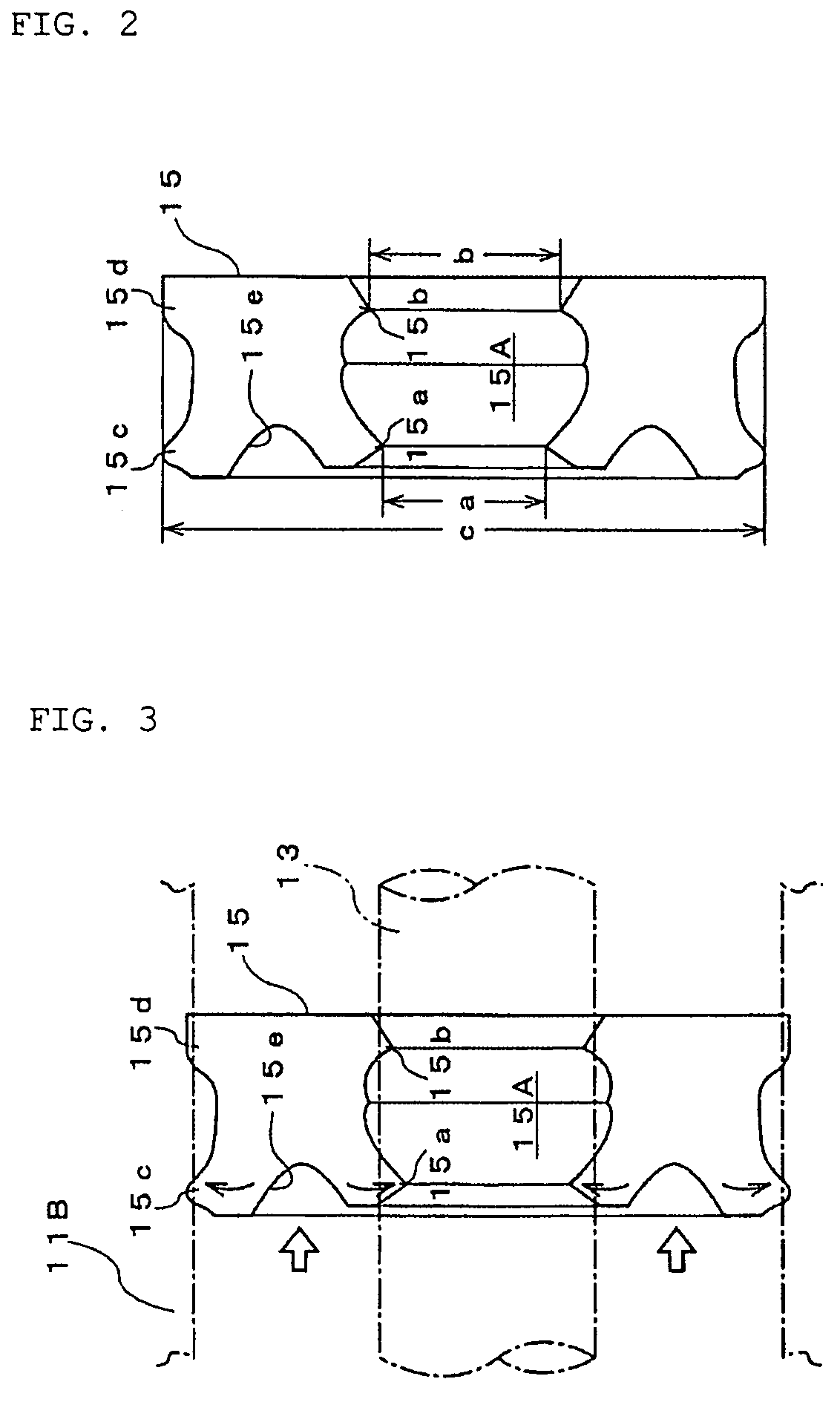

A thermal element of a simple structure which can have a reduced cost because a minimum required number of structural components are used, excels in response and endurance and enables forward and backward movement of a piston with the prescribed stroke under the effect of volume changes following the expansion and contraction of a thermally expandable body.A thermal element 10 containing a thermally expandable body (wax 12) inside a case 11 comprises a piston 13 arranged inside the case along the axial line thereof. The inward end of the piston borders on the inside of the thermally expandable body and the outward end thereof protrudes outwardly from one end of the case, thereby enabling the piston to move forward and backward following the expansion and contraction of the thermally expandable body. The piston is slidably held with a guide member 14 disposed in a portion at one end inside the case. Furthermore, a sealing member 15 is disposed in a portion at the inward end of the guide member inside the case and seals the thermally expandable body at the other end inside the case.

Owner:NIPPON THERMOSTAT CO LTD

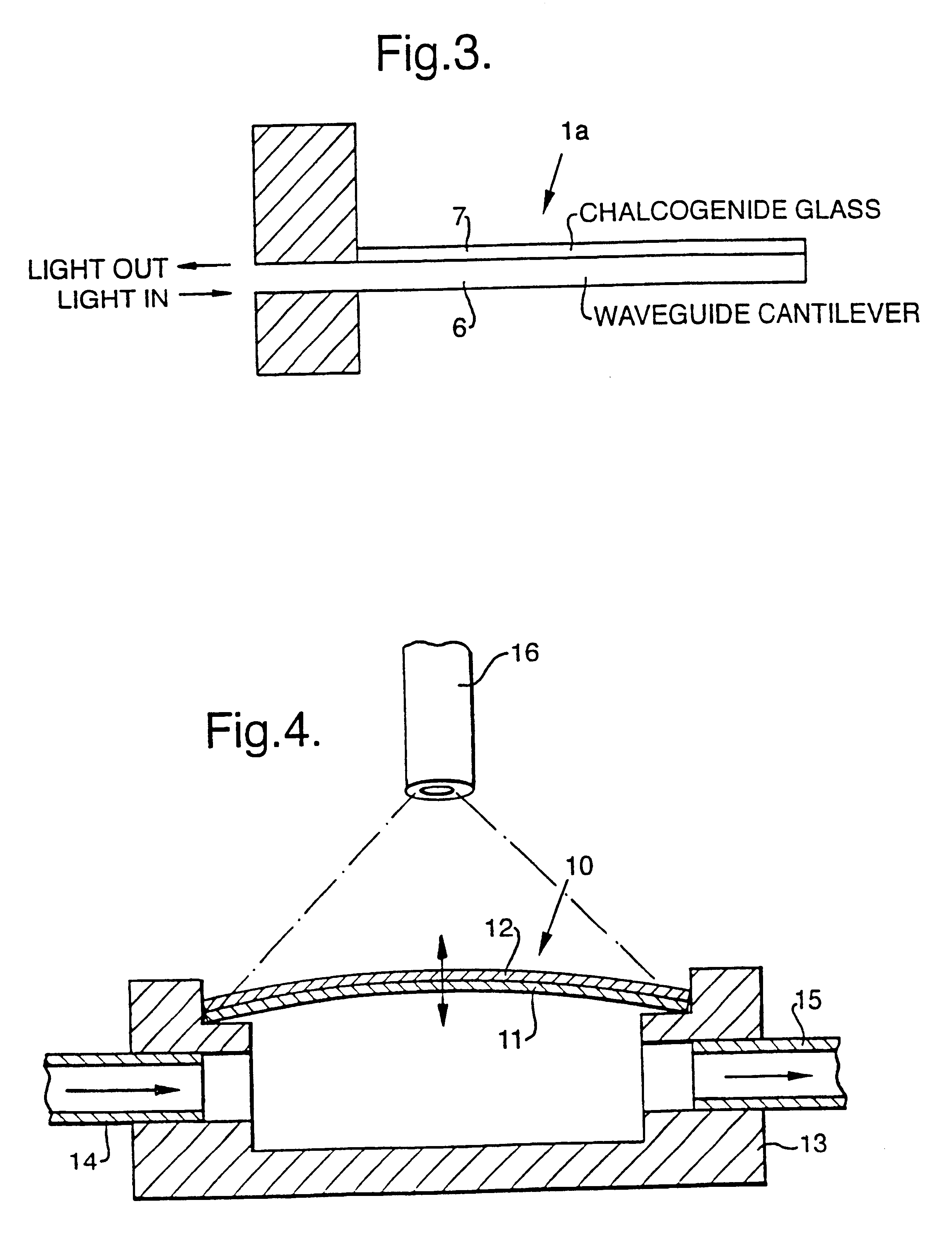

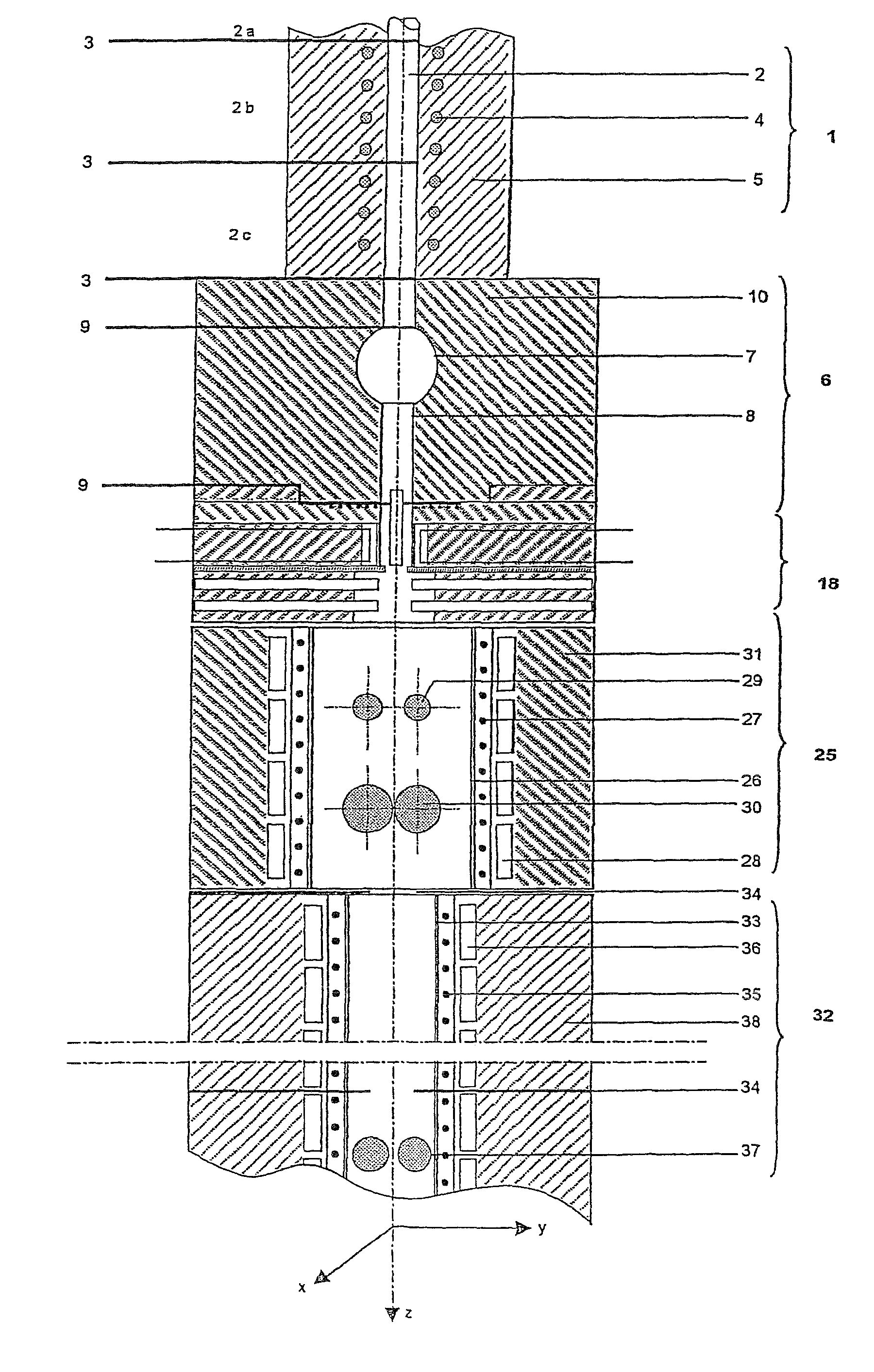

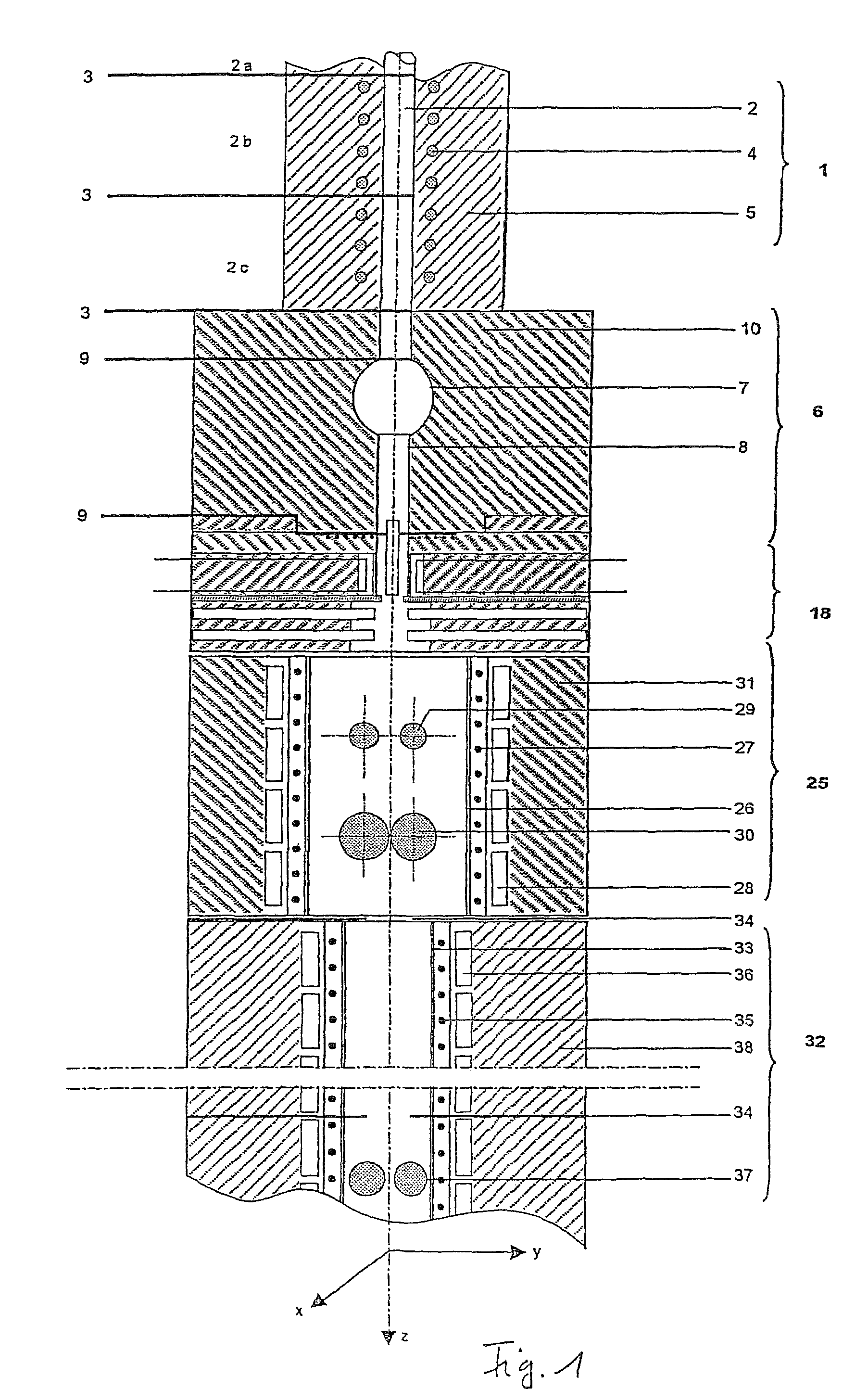

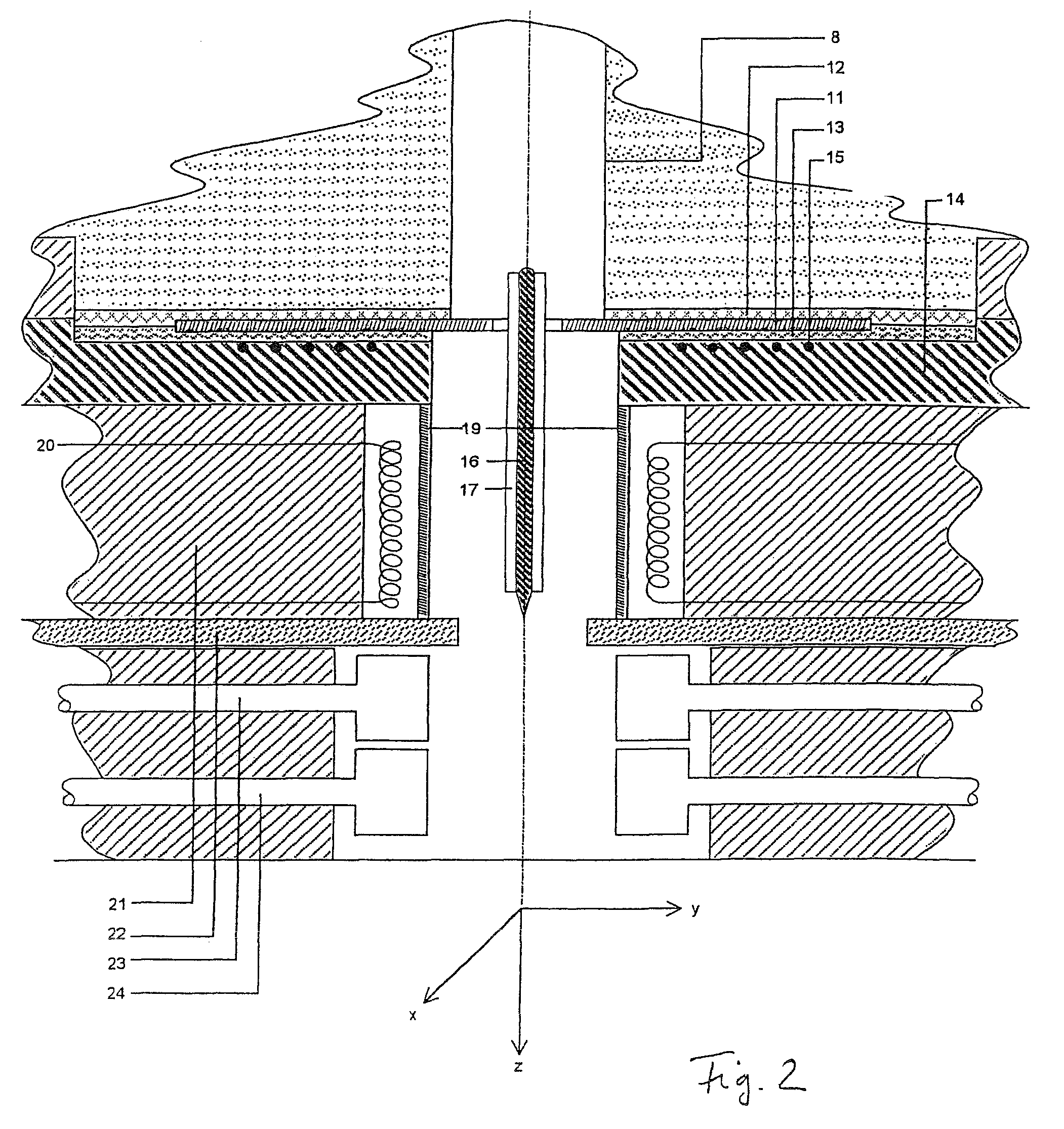

Opto-mechanical device

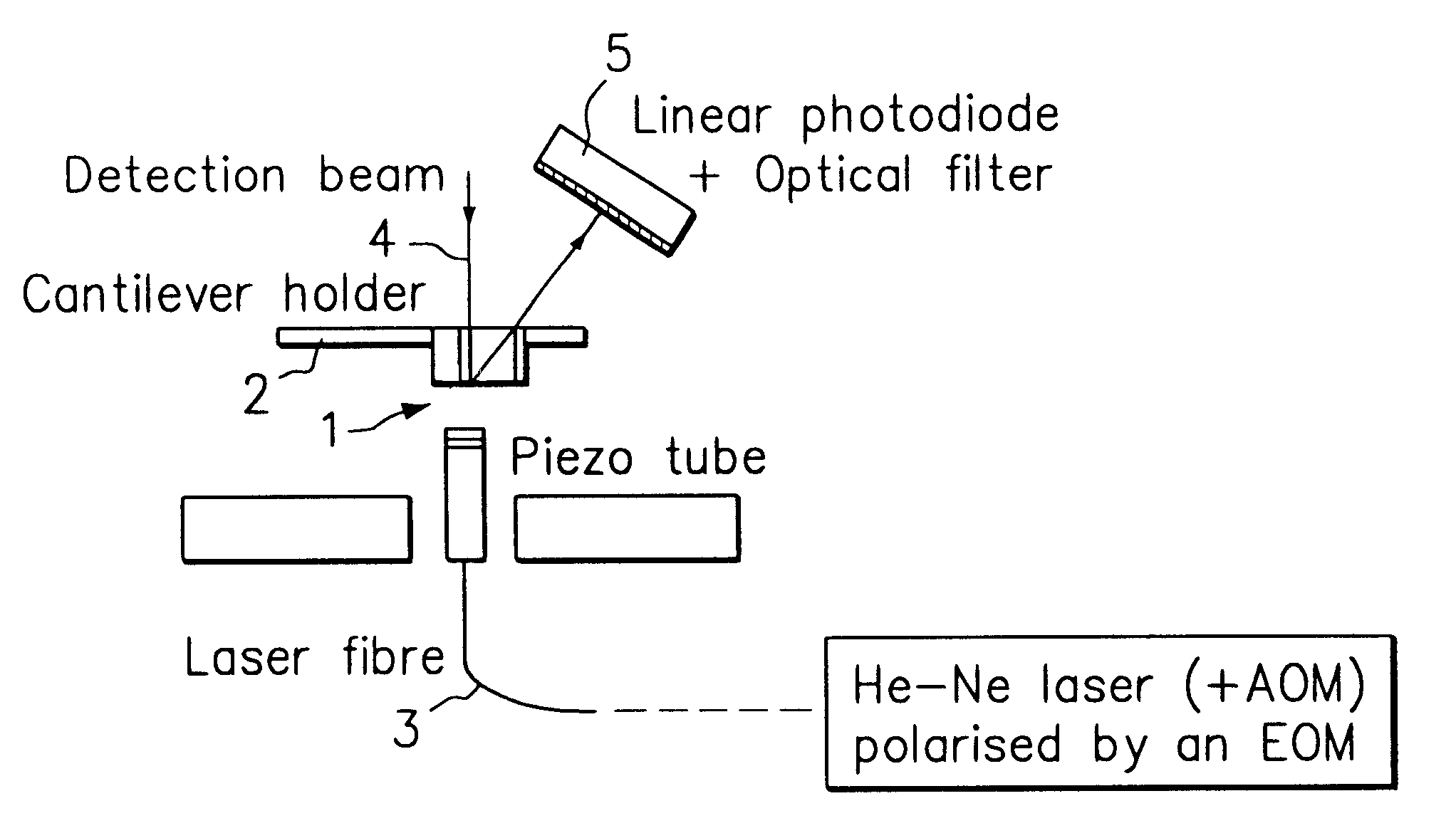

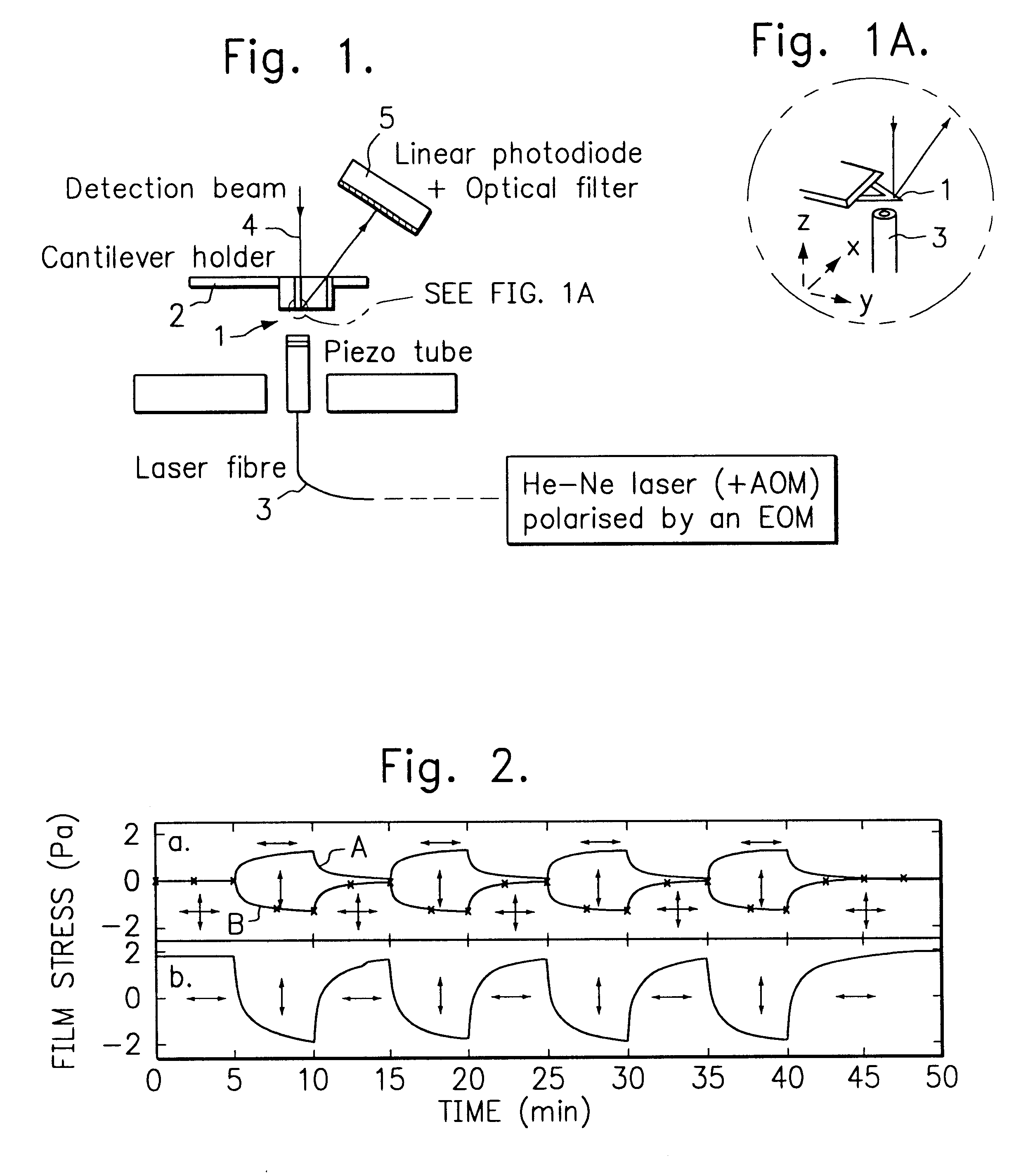

InactiveUS6392777B1Optimise its sensitivityLess rigidMicromanipulatorFlexible member pumpsChalcogenide glassSemiconductor

An opto-mechanical device is constituted by an optically responsive actuating member in which a mechanical strain occurs in response to changes in its illumination. The actuating member is preferably at least partly formed from a semiconducting glassy matrix such as a chalcogenide glass. Preferably the opto-mechanical device illuminates the actuating member with light which is preferably plane polarized. Preferably it also varies the polarization angle of the plane polarized light to cause a change in the strain generated in the actuating member.

Owner:CAMBRIDGE UNIV TECH SERVICES LTD

Method and device for producing thin glass panes

InactiveUS7735338B2Quality improvementImprove productivityBlowing machine gearingsRibbon machinesUnit of lengthGlass sheet

The method of making thin glass panes includes conveying a glass melt through a vertical inlet to a drawing tank with a slit nozzle; drawing a glass ribbon downward from the slit nozzle; setting a total throughput by setting length and cross section of the inlet and by heating and cooling the inlet to control glass melt viscosity so that pressure in the inlet decreases; and setting a throughput per unit of length in a lateral direction along the glass ribbon via nozzle system geometry and by heating and cooling of the drawing tank and slit nozzle to control melt viscosity, so that glass does not wet an underside of the slit nozzle near a breaking edge. The setting of the total throughput and the throughput per unit length are largely decoupled to simplify process control. An inventive apparatus for performing the method is also disclosed.

Owner:SCHOTT AG

Lighting solution for apparatuses for vacuum insulating glass (VIG) unit tip-off, and/or associated methods

ActiveUS8742287B2Reduce the possibility of damageComplicates designWindows/door improvementCharacter and pattern recognitionEngineeringLaser source

Certain example embodiments of this invention relate to apparatuses for sealing the tips of pump-out tubes of vacuum insulating glass (VIG) units, and / or associated methods. In certain example embodiments, a laser source used in sealing the pump-out tube is thermally insulated from the VIG unit and emits a laser beam through one or more windows in an oven towards a mirror located therein. The mirror is located so as to redirect the laser beam onto the pump-out tube to thereby seal it. For instance, a substantially horizontal laser beam emitted from a laser source located outside the oven enters into the oven through one or more windows and is reflected by a mirror towards the pump-out tube to be sealed. The repositioning of the laser source advantageously can change its effective focal length and / or the location of the laser beam, e.g., because of the fixed location of the mirror.

Owner:GUARDIAN GLASS LLC

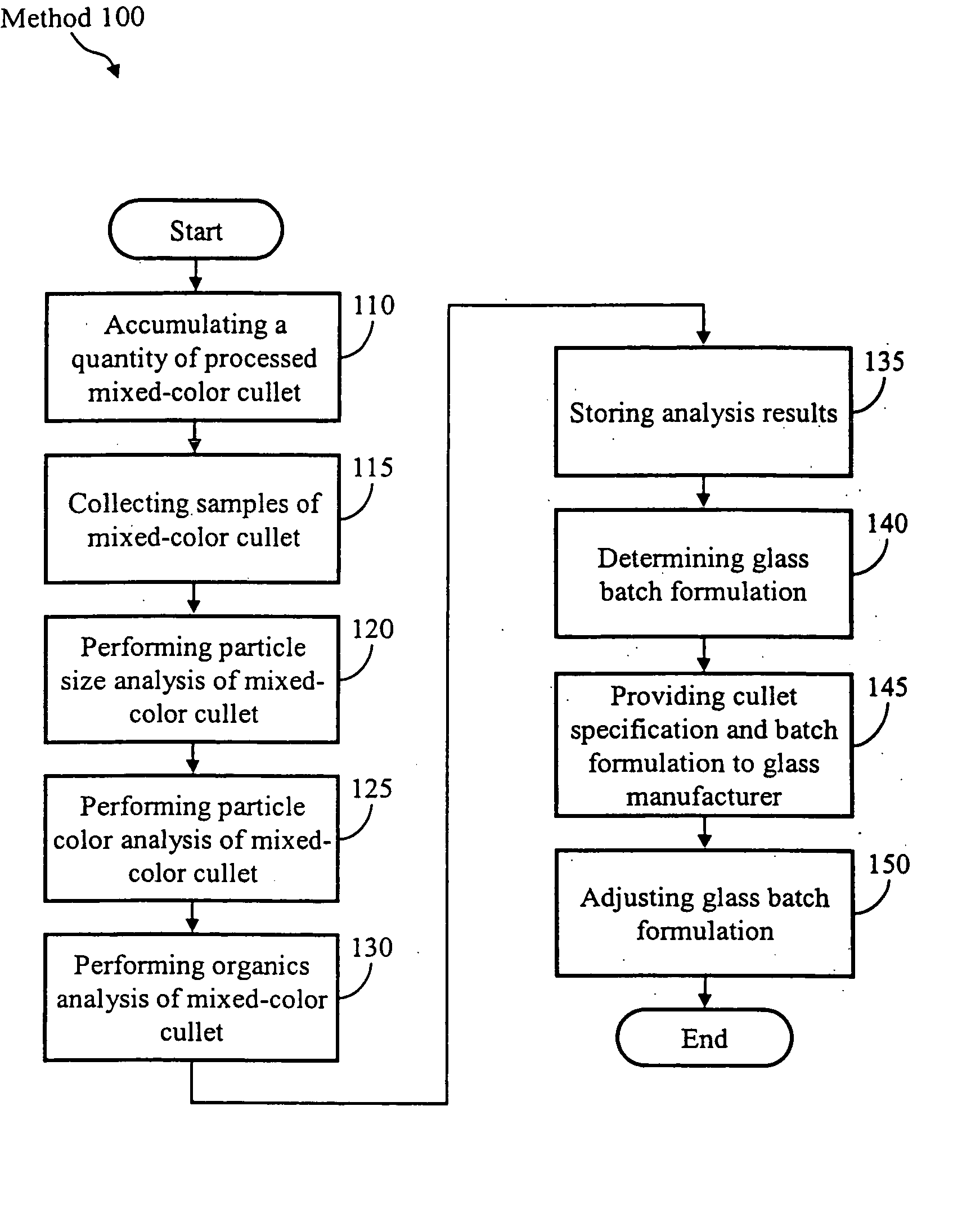

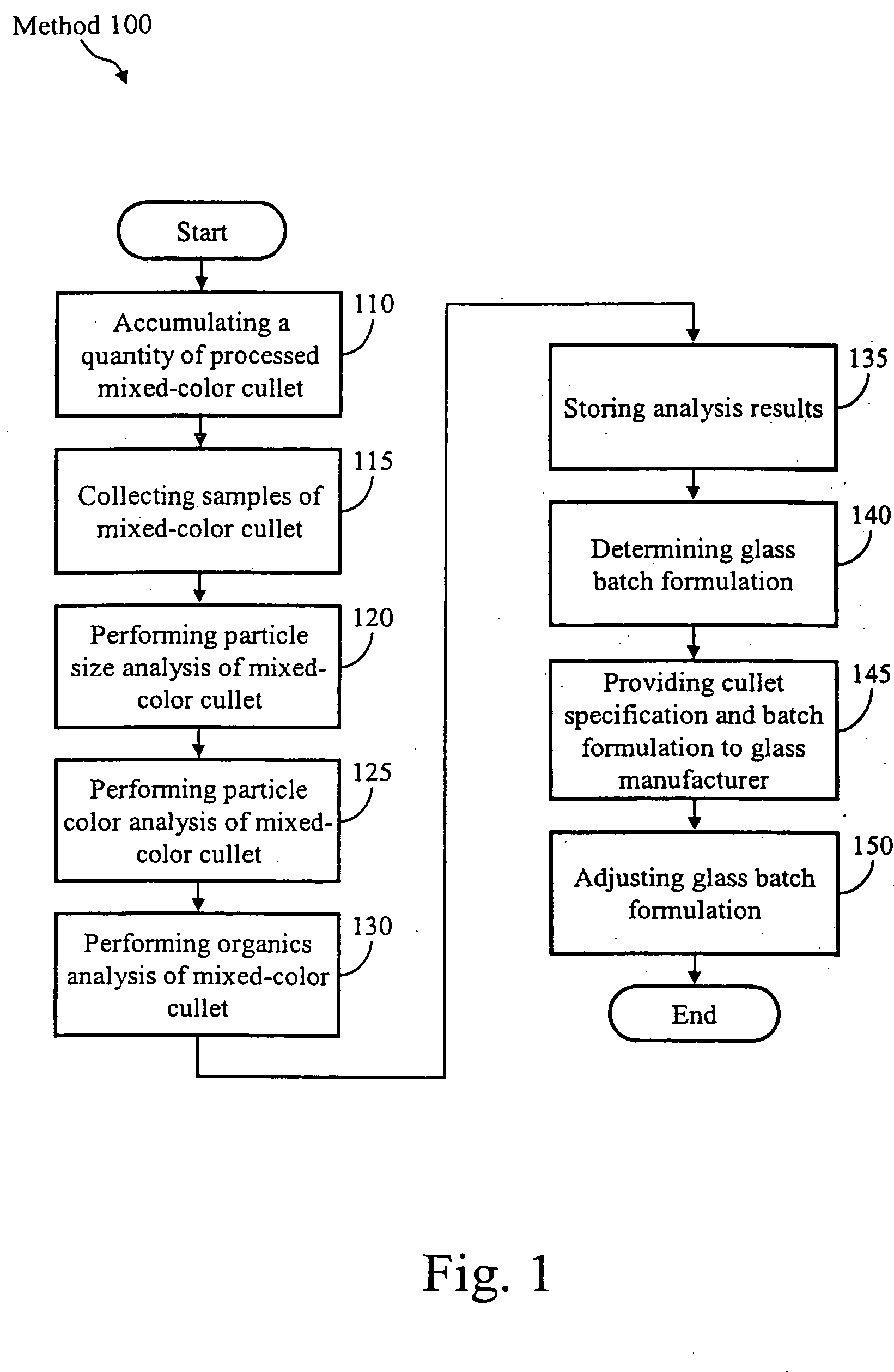

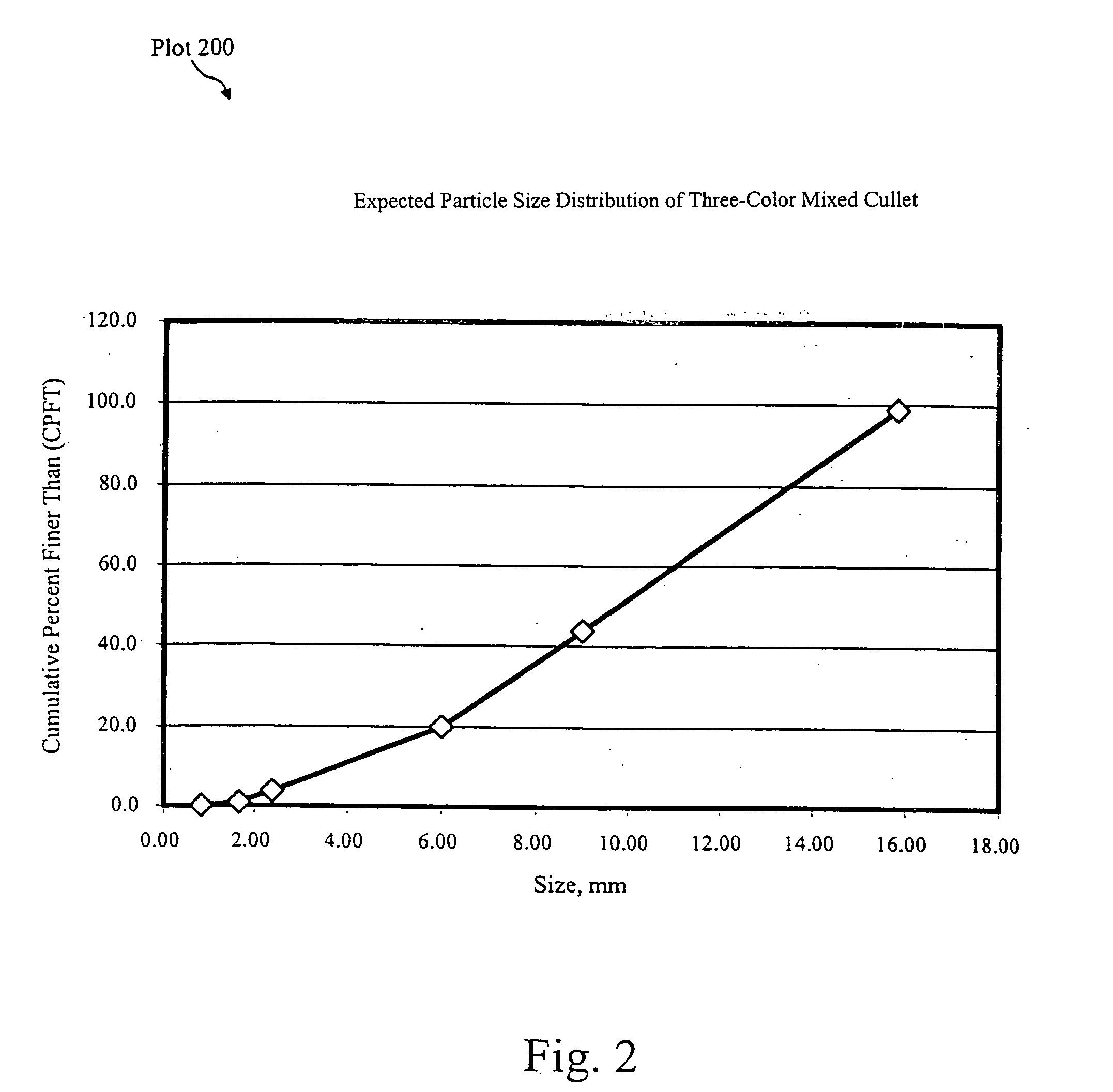

Method of analyzing mixed-color cullet to facilitate its use in glass manufacture

A method of determining the constituents and impurities in mixed-color cullet to facilitate use of mixed-color cullet in glass manufacture is provided. A glass batch formulation is adjusted based on the measured characteristics of supplied mixed-color cullet. More specifically, certain preferred aspects of the present invention include the steps of providing quantity of mixed-color cullet, collecting at least one sample of the mixed-color cullet, performing, either singularly or in combination, particle size analysis, particle color analysis, or organics analysis of the mixed-color cullet, optionally storing the analysis results, determining a glass batch formulation, providing the cullet specification and the batch formulation to a glass manufacturer, and adjusting glass batch formulation based on the cullet specification to ensure consistent glass quality.

Owner:CULCHROME LLC

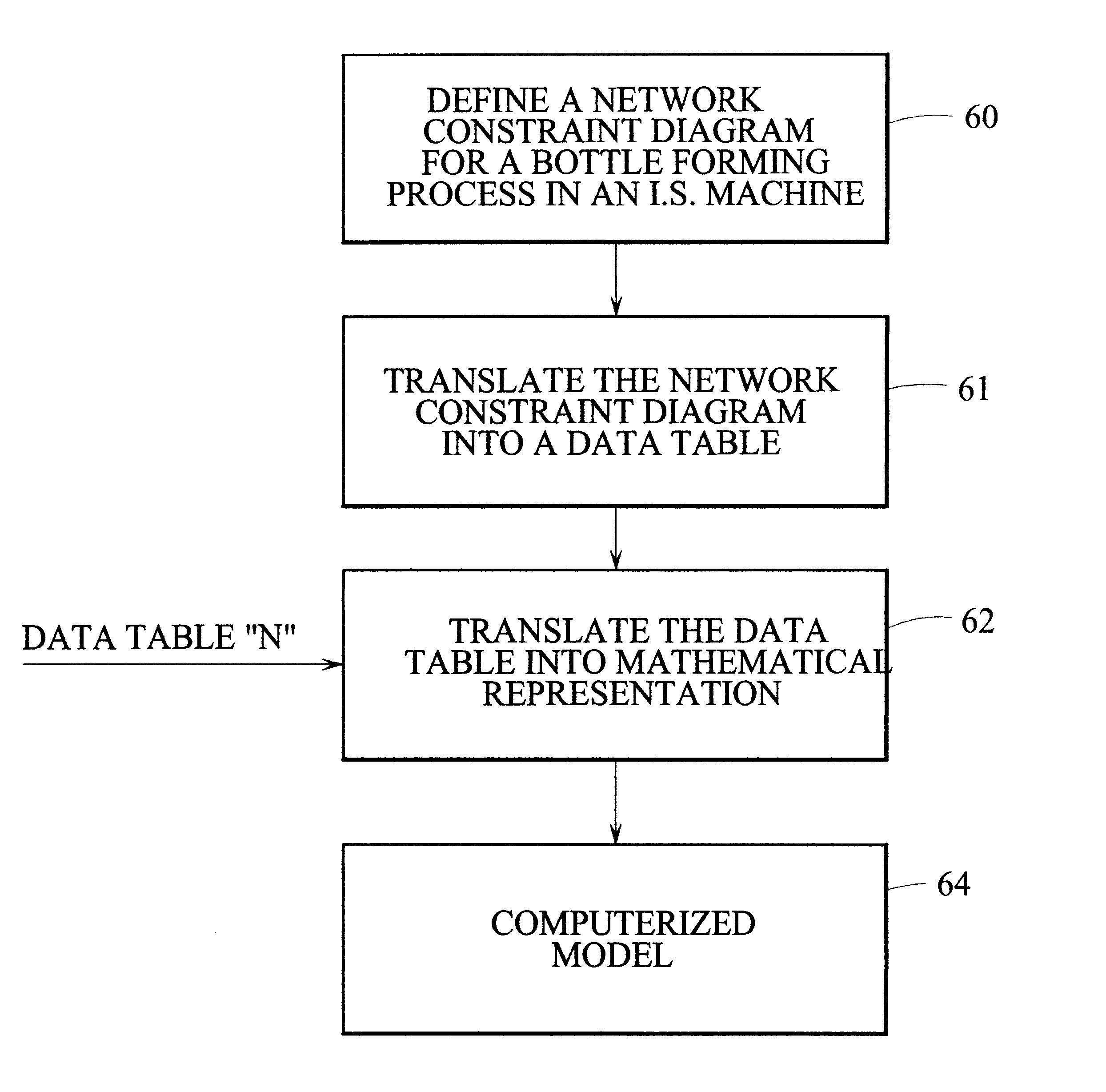

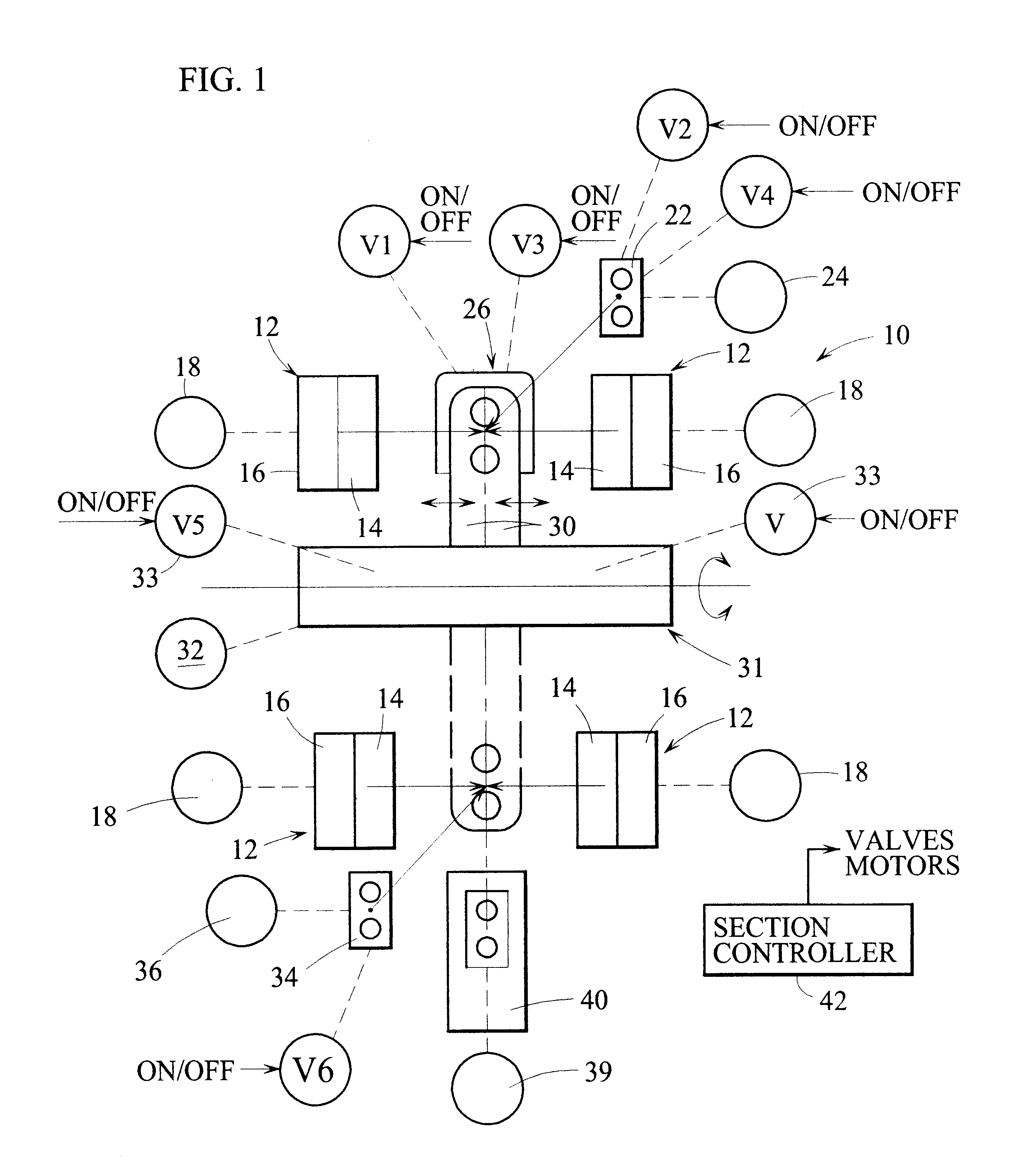

Control for an I.S. machine

InactiveUS6604383B2Easy to adjustEasy to operateBlowing machine gearingsComputer controlEngineeringBottle

A control for use with a glass forming machine which is controlled by a programmable sequencer which defines a machine cycle having a set cycle time. A computerized model of a mathematical representation of a network constraint diagram of the unwrapped bottle forming process is provided for determining whether, with the following inputs: the time in an unwrapped bottle forming process for each displacement to occur; the machine cycle time; the motion durations of each of the mechanisms from the retracted position to the advanced position and from the advanced position to the retracted position and the collision zones between interfering paths, a collision will result between the gob, the parison, the bottle or any mechanism.

Owner:EMHART GLASS SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com