Automatic production system of high borosilicate glass kettle

A technology of high borosilicate glass and production system, applied in glass blowing, glass blowing mold, glass forming and other directions, can solve the problems of low production efficiency, low processing precision, inaccurate positioning, etc., and improve efficiency , Improve production efficiency, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

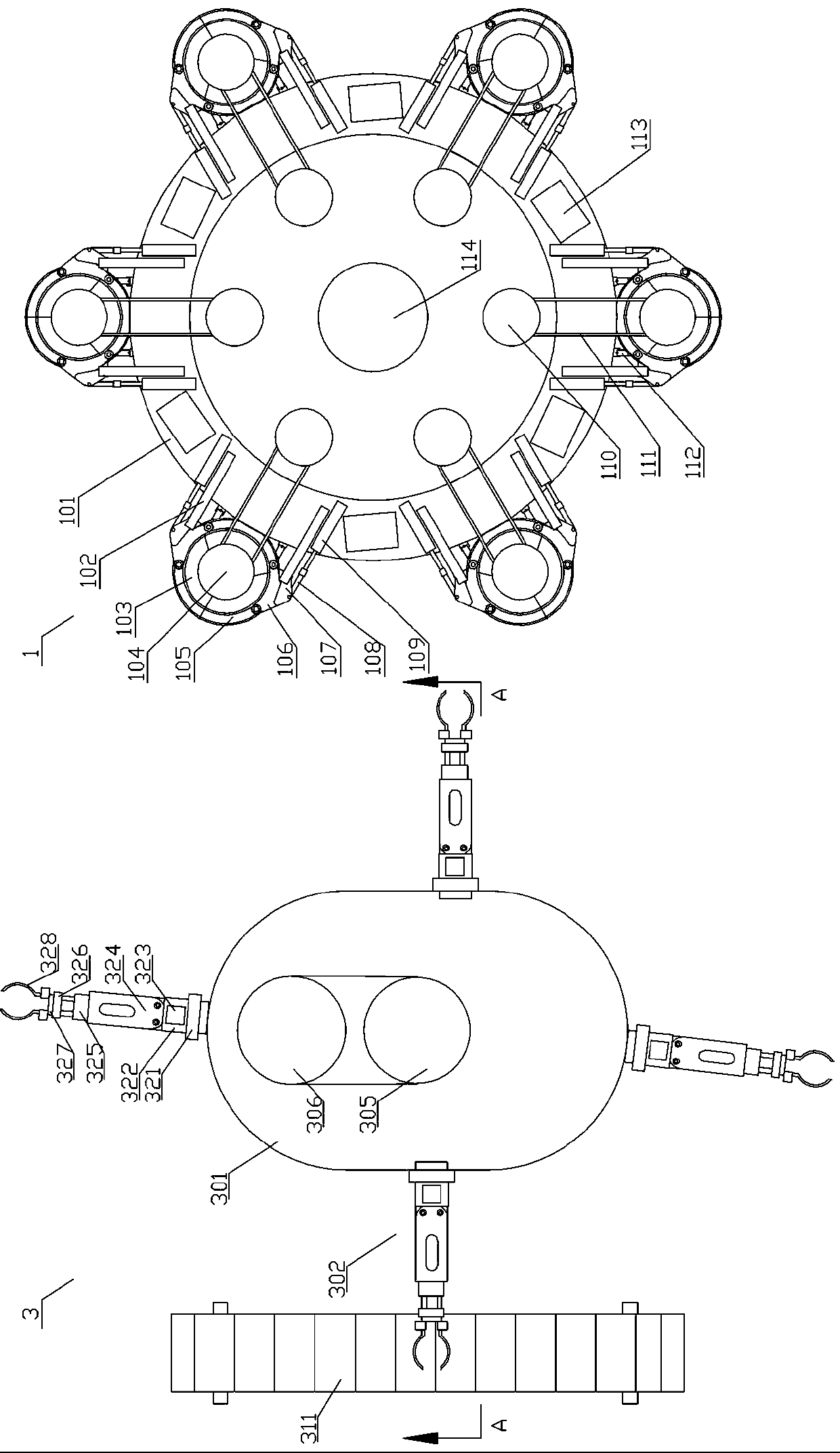

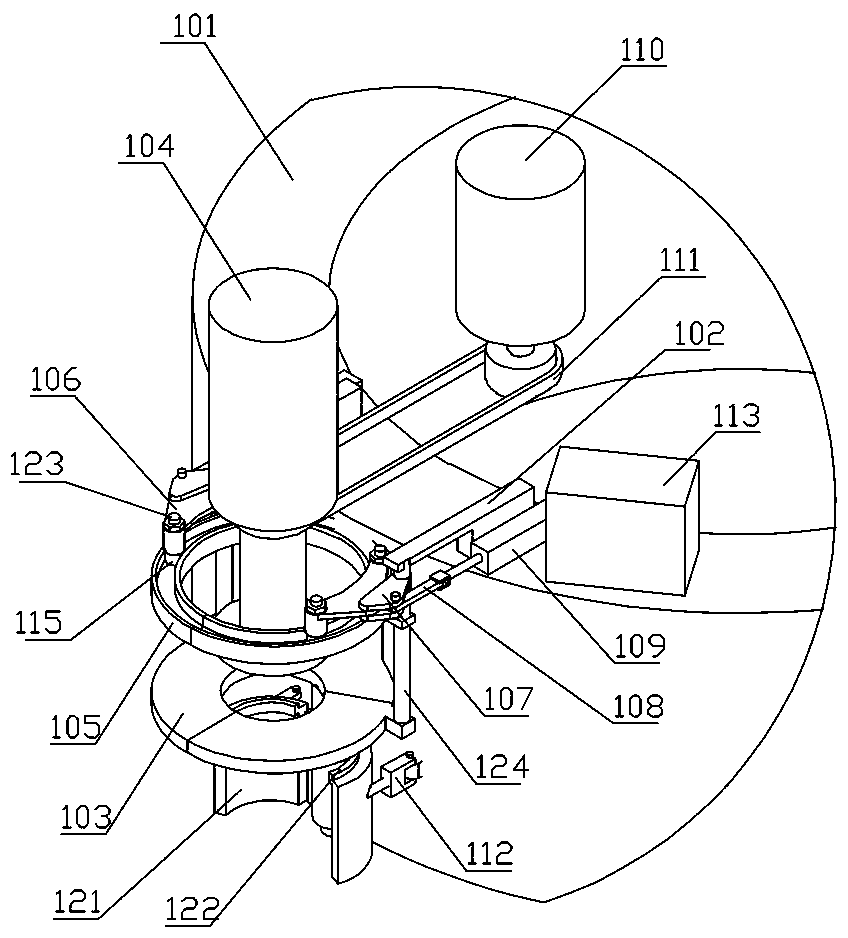

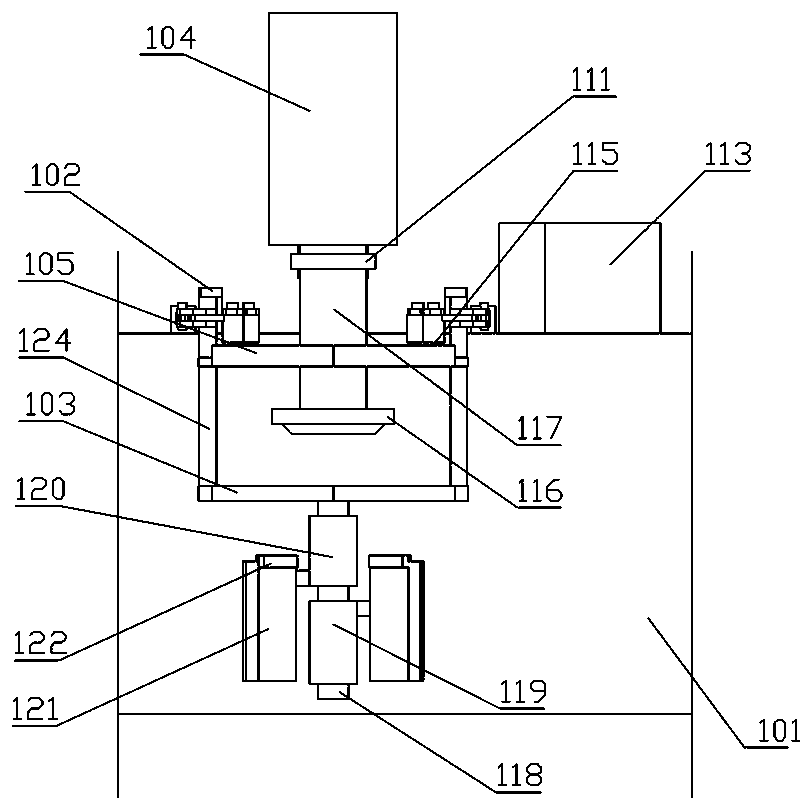

[0022] see Figure 1-10, this embodiment includes a high borosilicate glass pot blowing machine forming equipment 1, a high borosilicate glass pot forming mold 2, a high borosilicate glass pot blanking device 3, the high borosilicate glass pot blowing machine forming equipment 1 includes a rotatable The ring frame 101 and the motor A114 of the control frame rotation, the ring frame 101 is evenly equipped with at least three (specifically six) glass pot blowing machines, and each glass pot blowing machine is equipped with an electrical control box 113, the glass pot blowing machine includes a glass blank clamping plate 103 placed horizontally, a through hole is provided in the center of the glass blank clamping plate 103, and vertical connecting column sleeves 124 are arranged on both sides, and the glass blank clamping plate 103 The top is equipped with an annular slideway 105 coaxial with it, and the annular slideway 105 is fixedly connected with the glass blank clamping plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com