Production process for press-riveting nuts on punch press

A pressure riveting nut and production process technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of easy generation of burrs, impact of drilling, low production efficiency and low quality, so as to reduce the generation of burrs, reduce the Effects of burrs, increased productivity, and quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

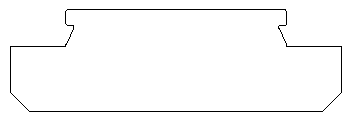

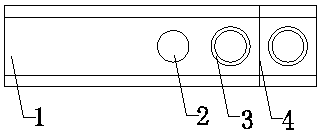

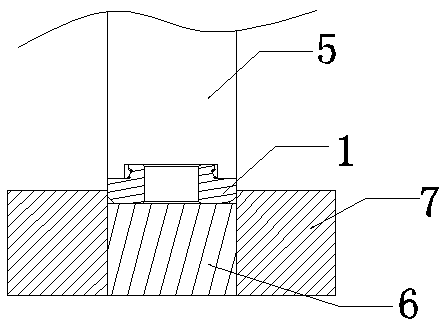

[0022] Refer to attached Figure 1-3 , a production process of a rivet nut on a punch press according to the present invention. After the raw material strip is processed by multiple drawing and forming processes, the width of the raw material strip is the same as the length of the rivet nut, and a The table top extends in the length direction. Therefore, when producing the rivet nut, it is necessary to cut out the distance of the width of the rivet nut in the length direction of the raw material strip. After the raw material strip is processed, the following steps are performed:

[0023] a. Put the raw material strip with the same cross-section as the rivet nut on the mold;

[0024] b. Use the driving device to move the raw material strip along the length direction of the raw material strip, so that the raw material strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com