Thick-copper copper substrate etching process

A copper substrate and process technology, applied in the field of PCB production, can solve the problems of poor precision, high hole processing cost, and inability to process special-shaped through holes, etc., to achieve the effect of reducing processing cost, improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

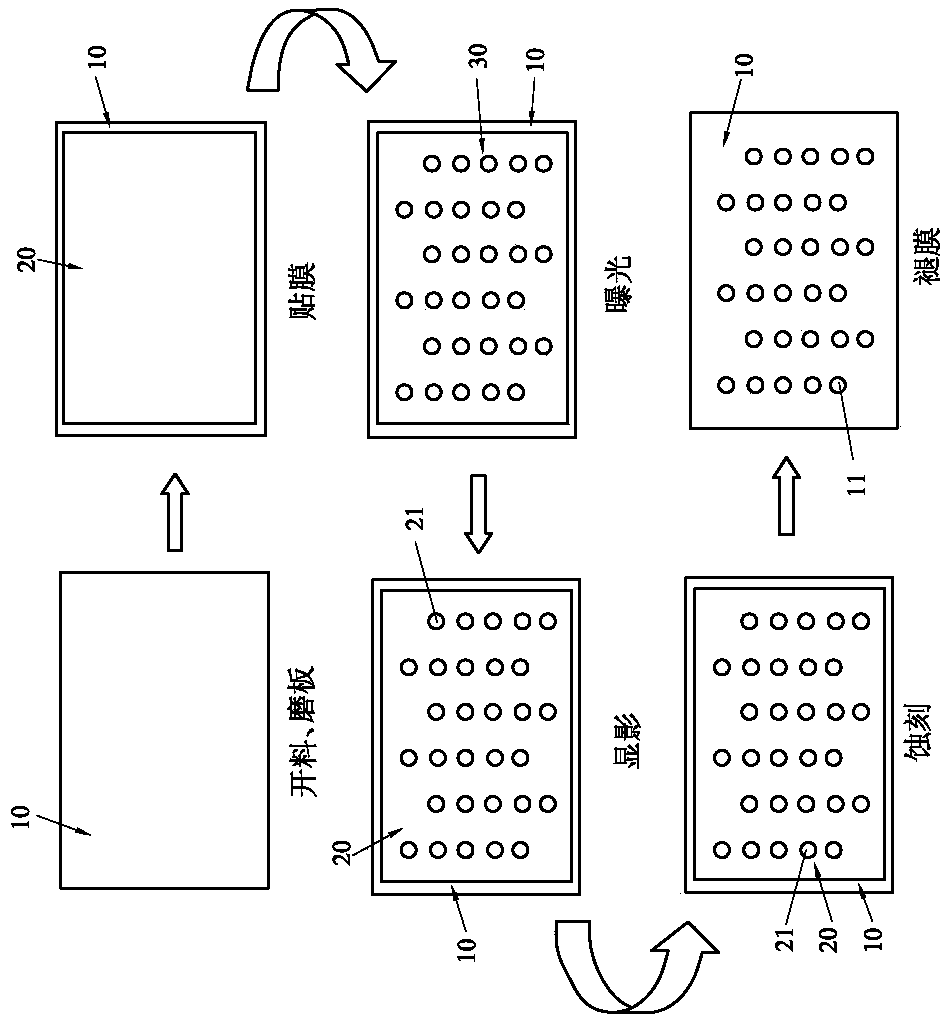

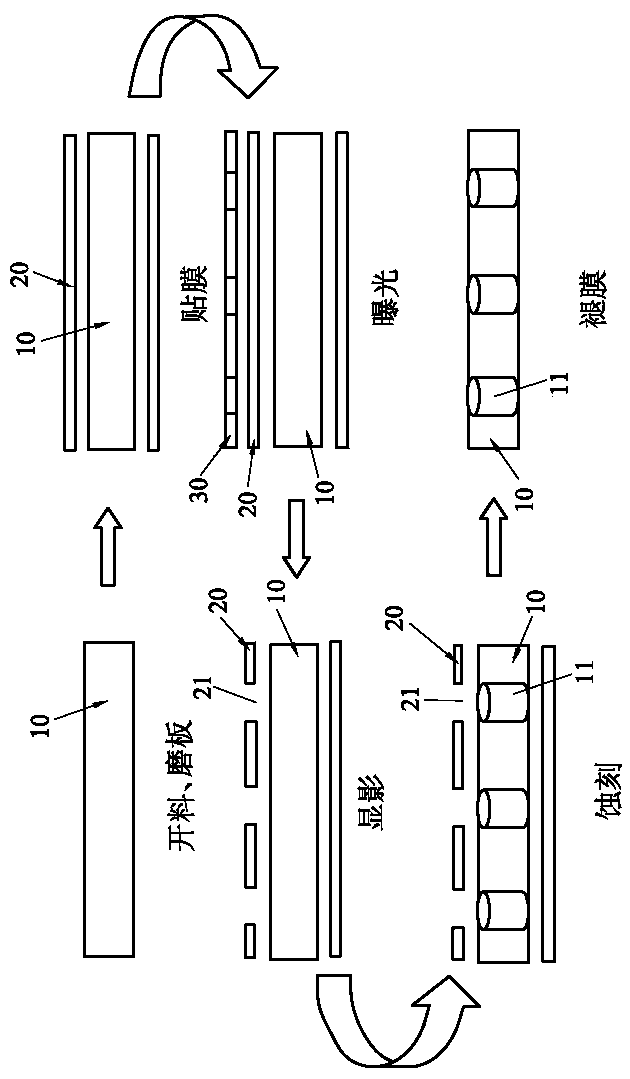

[0024] The invention discloses a pitting process for a thick copper copper substrate, which includes the following steps:

[0025] (1) Cutting: Cut thick copper and copper substrates to 10 sizes according to product requirements.

[0026] (2) Grinding: Grinding the thick copper-copper substrate 10 to appropriately increase the roughness of the surface of the thick copper-copper substrate 10 while cleaning the surface. In this embodiment, during the grinding process, the size of the wear scar is controlled to be 12-16mm, the mass concentration of pozzolan used is 15-25%, the temperature is controlled at 80-90°C, and the speed is controlled at 2.0-2.5m / min.

[0027] (3) Film sticking: sticking resist ink or dry film 20 on the surface of the thick copper-copper substrate 10 . In this embodiment, the film sticking is carried out at a temperature of 110-130° C., and the speed is controlled at 1.2-1.4 m / min.

[0028] (4) Exposure: the image is transferred to the resist ink or dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com