Granulator for dust pollution prevention coating material

A granulator and coating technology, which is applied in the direction of raw material extrusion granulation, motor vehicles, multi-axis trolleys, etc., can solve the problems of reduced production efficiency and quality, uneven particle size of coatings, and uneven manual strength, and achieve reduction Labor intensity, protection of the production environment, and the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

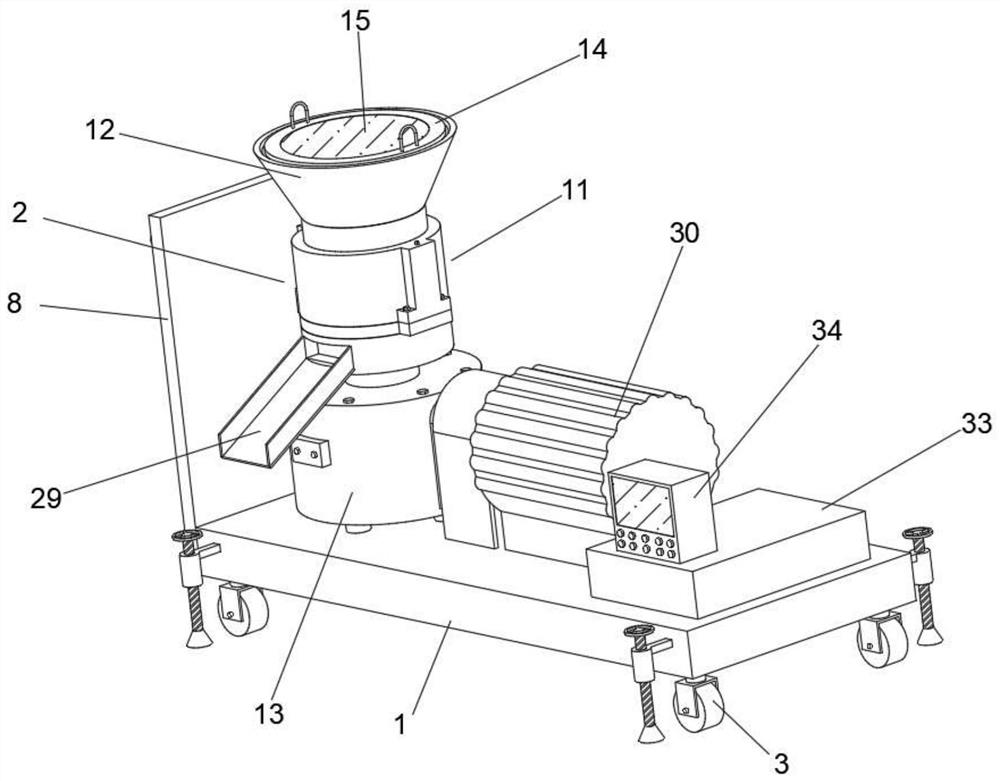

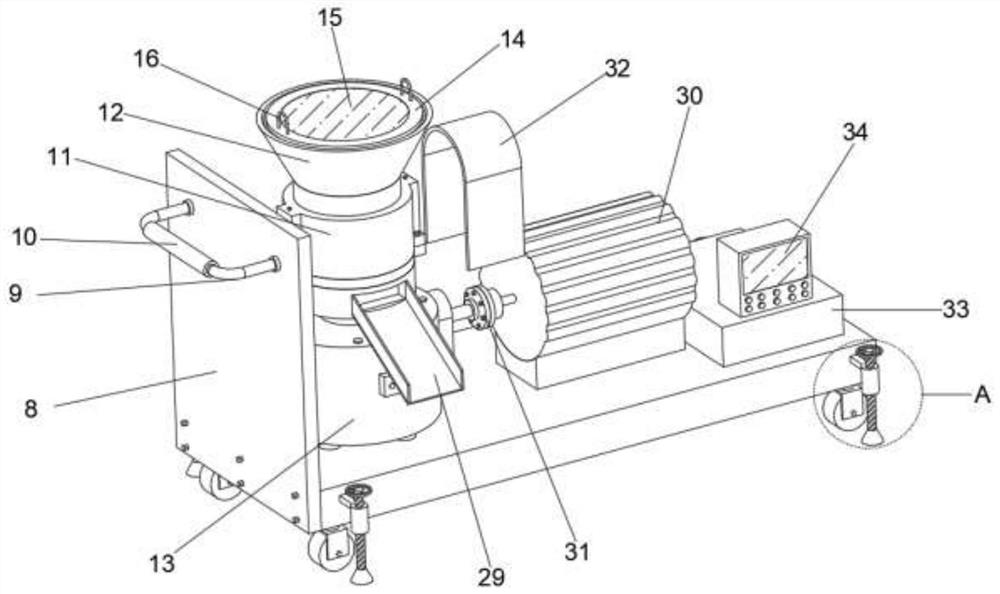

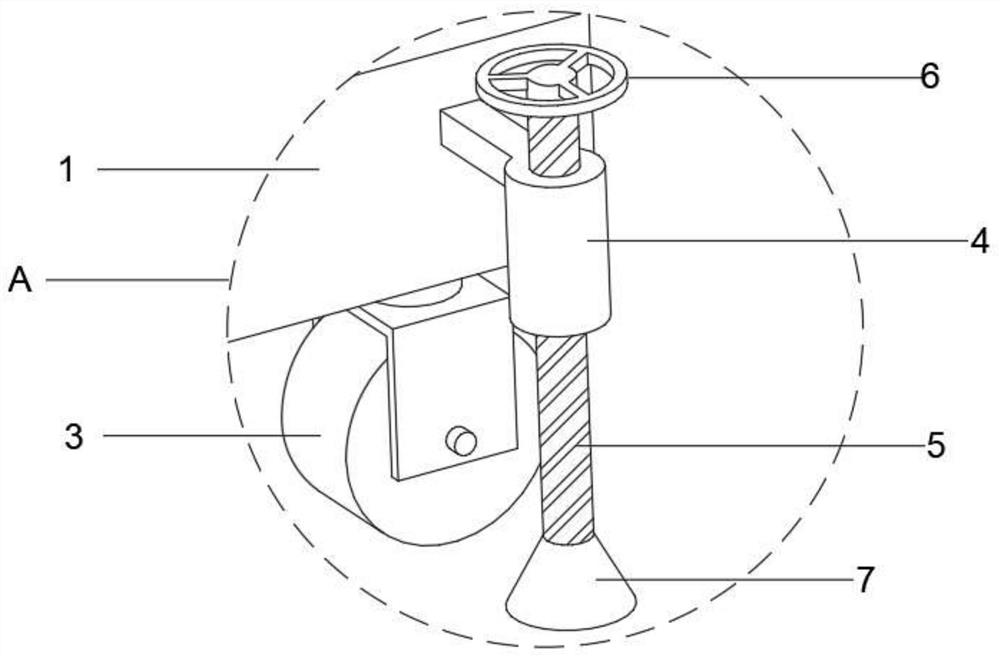

[0025] Example: such as Figure 1-7 As shown, a granulator for dust-proof coatings includes a vehicle board 1 and a granulation mechanism 2, four universal wheels 3 are fixedly connected to the bottom four corners of the vehicle board 1, and the front and rear ends of the vehicle board 1 are fixedly connected to two wheels. A fixed screw sleeve 4, the internal thread of the fixed screw sleeve 4 is connected with an adjusting screw 5, the top of the adjusting screw 5 is fixedly connected with a rotating disk 6, the bottom end of the adjusting screw 5 is fixedly connected with a fixed foot cup 7, and the left side of the top of the vehicle plate 1 is provided with The granulation mechanism 2, the granulation mechanism 2 includes a material box 11, a transmission box 13 and a cover plate 14, the bottom of the material box 11 is fixedly connected with a transmission box 13, the transmission box 13 is fixedly connected with the vehicle plate 1, and the top of the material box 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com