Bamboo arrow rod straightening machine

A straightening machine and bamboo arrow shaft technology, which is applied in wood compression, wood treatment, wood processing equipment, etc., can solve problems that affect industrial production efficiency and production quality, are complicated and time-consuming, and improve production efficiency and production quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

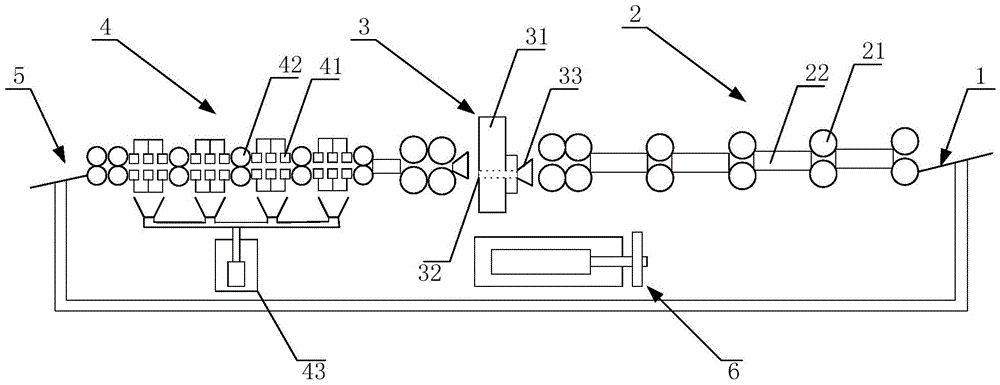

[0046] Please also refer to figure 1 , as shown in the figure, the bamboo arrow shaft straightening machine of the present invention includes a feed inlet 1, a heating and softening device 2, a fiber kneading and softening device 3, a cooling and shaping device 4 and a discharge port 5 along the transmission direction of the bamboo arrow shaft; The softening device 2 includes a plurality of transmission wheels 21 and heating pipes 22 arranged alternately, the transmission wheels 21 are respectively located at the two ends of the heating pipe 22 and the bamboo arrow shafts are driven through the heating pipes 22 for heating and softening; the fiber kneading and softening device 3 includes Turntable 31, eccentric hole 32 and conical nozzle 33 arranged at the front end of eccentric hole 32, the opening end of said conical nozzle 33 corresponds to the transmission wheel 21 of heating and softening device 2, and the bamboo arrow shaft driven by transmission wheel 21 is introduced in...

Embodiment 2

[0050] The biggest difference between this embodiment and Embodiment 1 is that the fiber kneading device includes a turntable and a conical nozzle. On the eccentric slot and can move along the eccentric slot, the large mouth end of the conical mouth corresponds to the transmission wheel of the heating and softening device, and guides the bamboo arrow shaft driven by the transmission wheel into the eccentric slot; this design can be used without changing the turntable. Next, adjust the eccentricity of bamboo arrow shafts with different softening requirements, as long as the distance between the tapered mouth and the eccentric slot is moved. The length of the eccentric slot is 1-2cm, and the distance from the center of the eccentric slot is 1-2cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com