Wood board splicing machine and board splicing method thereof

A jigsaw machine and wood technology, applied in the jointing of wooden veneers, veneer presses, plywood presses, etc., can solve the problems of incomplete heating time, insufficient strength, uneven pressing, etc., to improve production efficiency and production quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

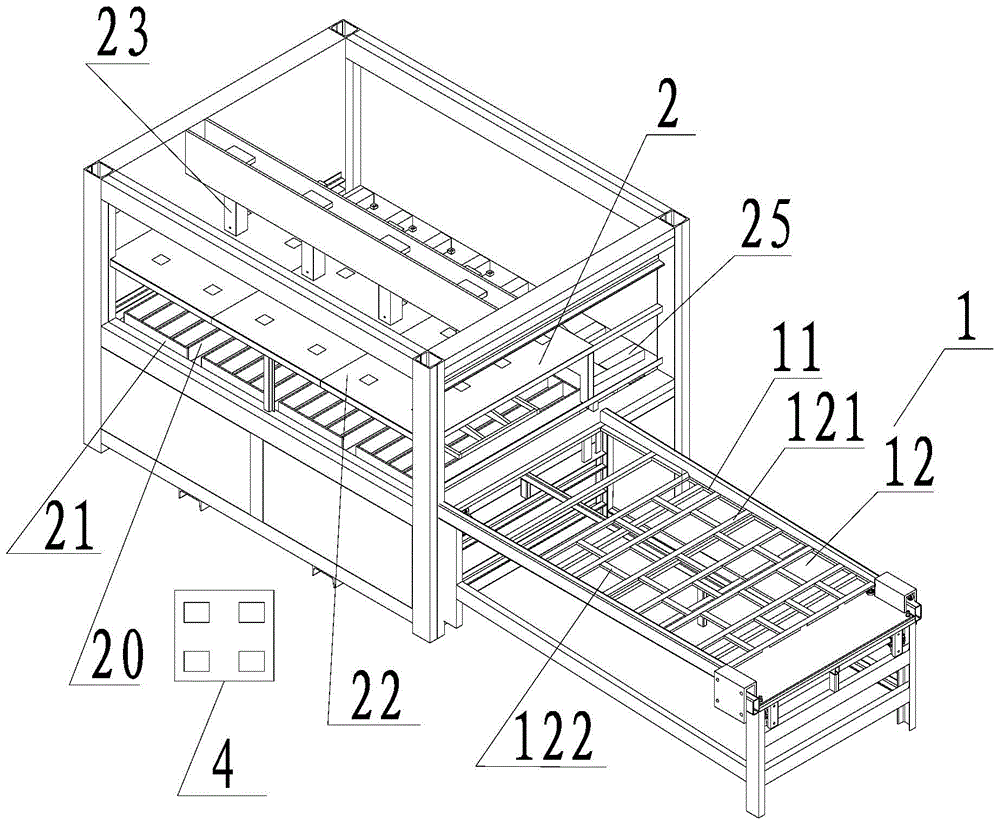

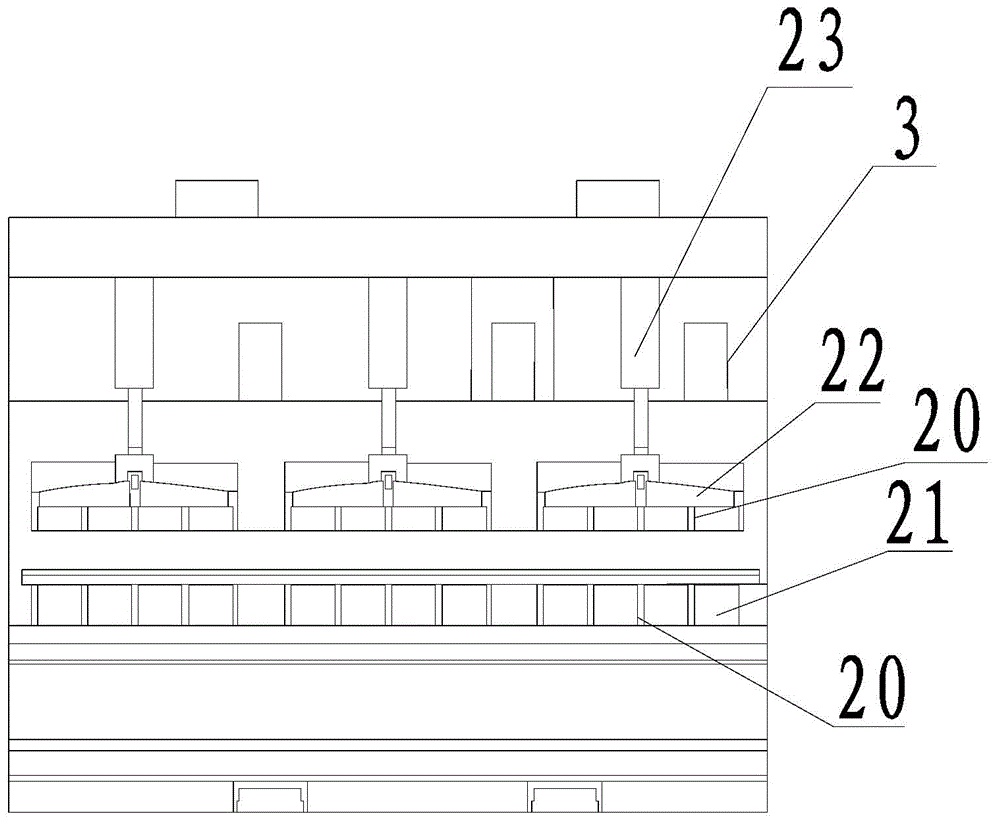

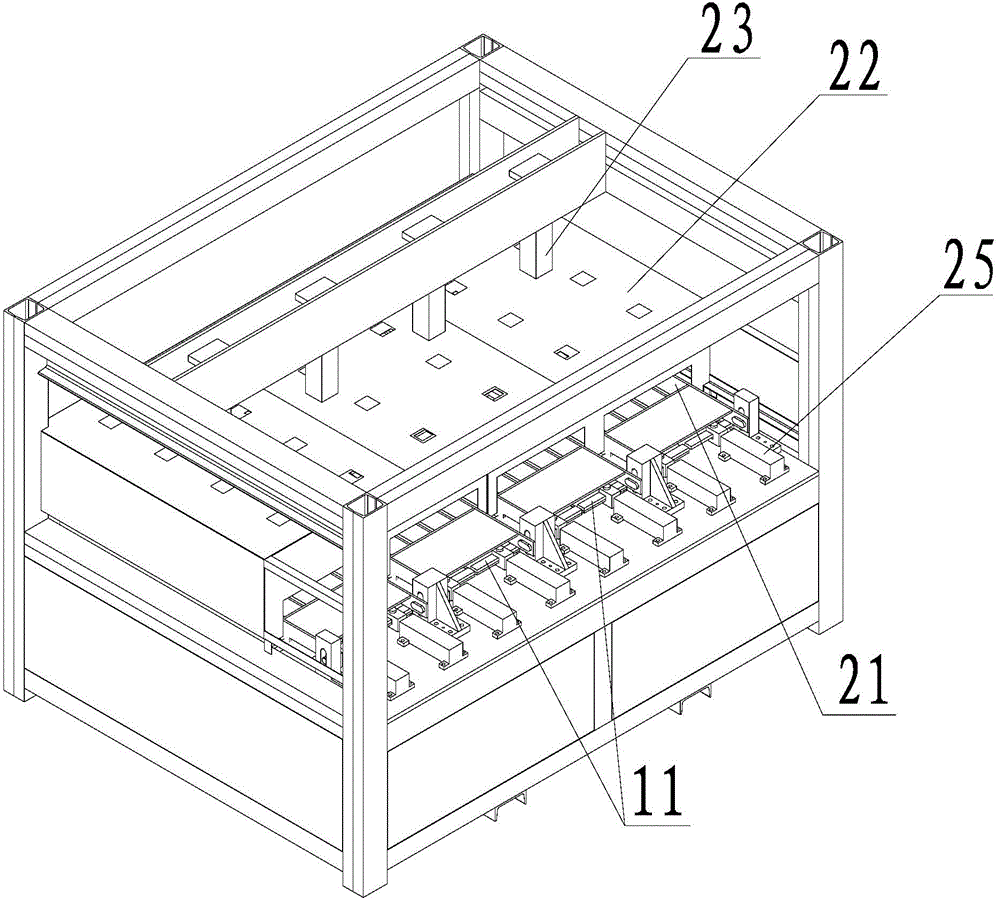

[0030] See figure 1 and figure 2 , a specific embodiment of the present invention, a wood jigsaw machine, comprising a feeding device 1, a compacting device 2, and a heating device 3, wherein the feeding device 1 is connected to the compacting device 2, and the heating device 3 is located on the compacting device 2 above; in order to make the jigsaw machine realize automatic control, in the embodiment of the present invention, the jigsaw machine also includes a numerical control device 4, and the numerical control device 4 is connected to the feeding device 1, the pressing device 2 and the heating device 3, and controls the feeding device 1. The operation of the pressing device 2 and the heating device 3. In the specific embodiment of the present invention, the numerical control device 4 can control the feeding device 1, the pressing device 2 and the heating device 3 through a wired or wireless connection, which are not shown in the drawings of the embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com