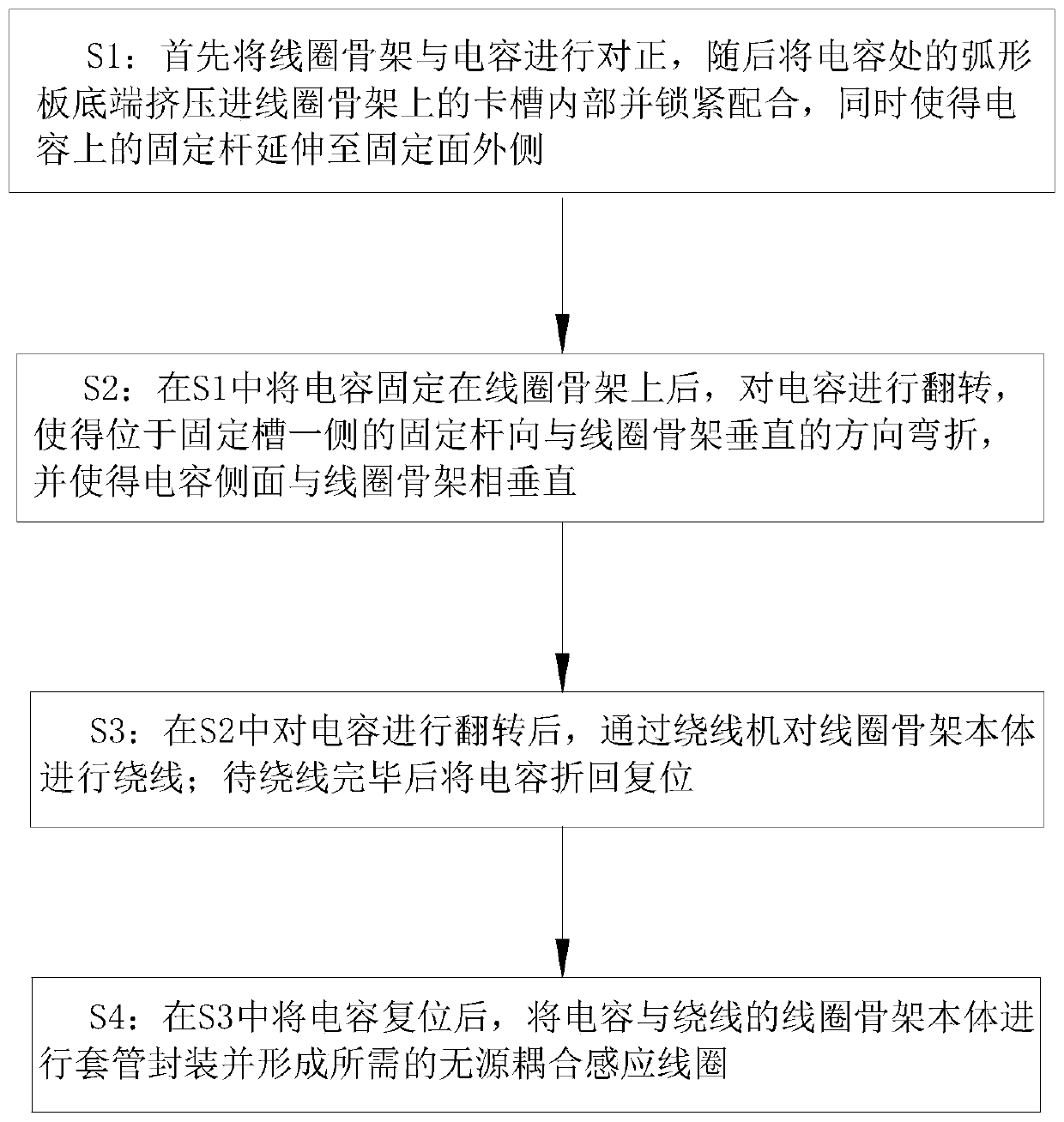

Manufacturing method of passive coupling induction coil

The technology of an induction coil and a manufacturing method, which is applied in the field of passive coupling induction coil manufacturing, can solve problems such as difficult positioning and stable fixing of capacitors, difficulty in disassembly and maintenance, and reduction of production efficiency and production quality of induction coils, so as to improve production efficiency , Simplify the production process and production difficulty, improve production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

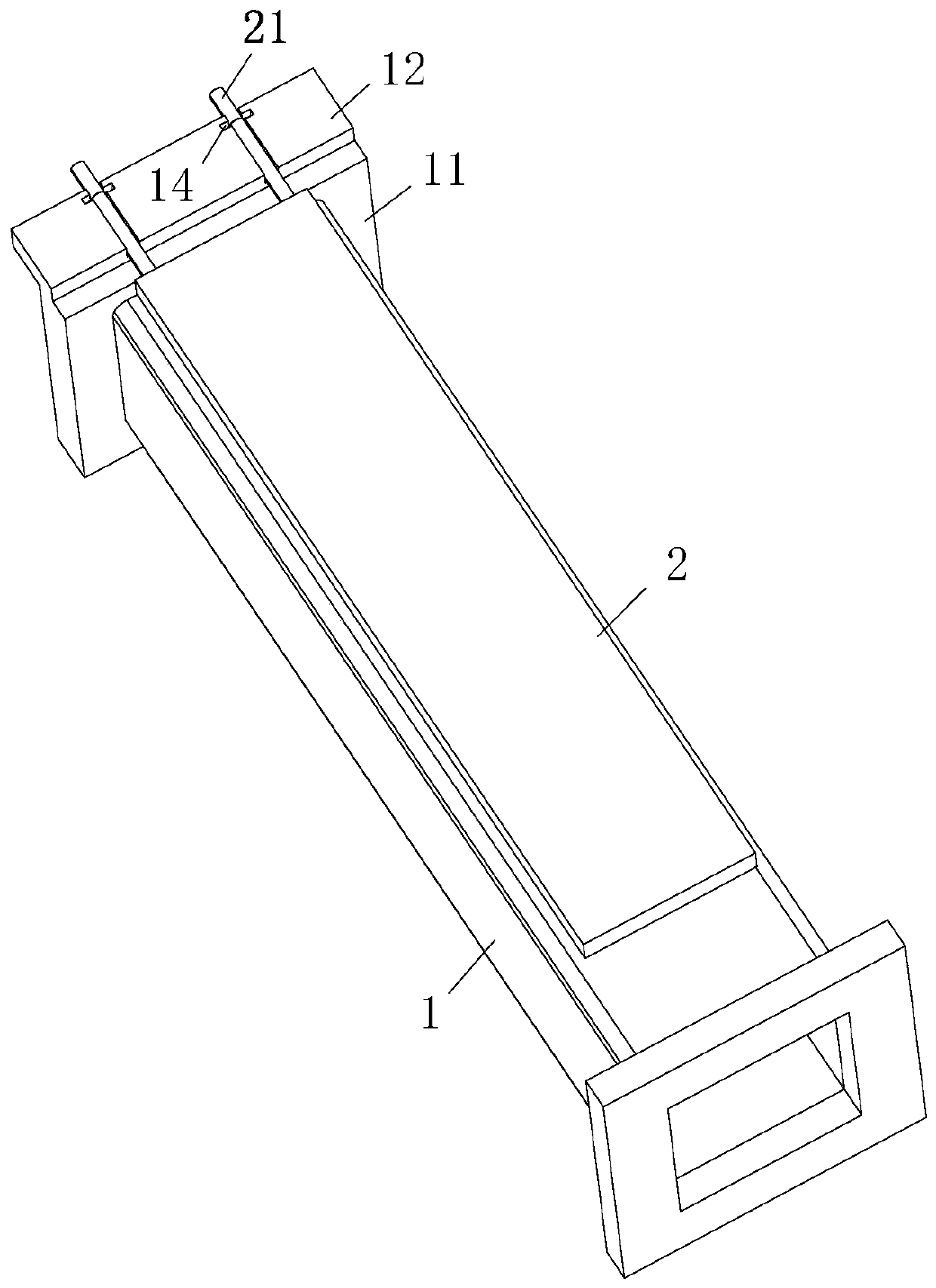

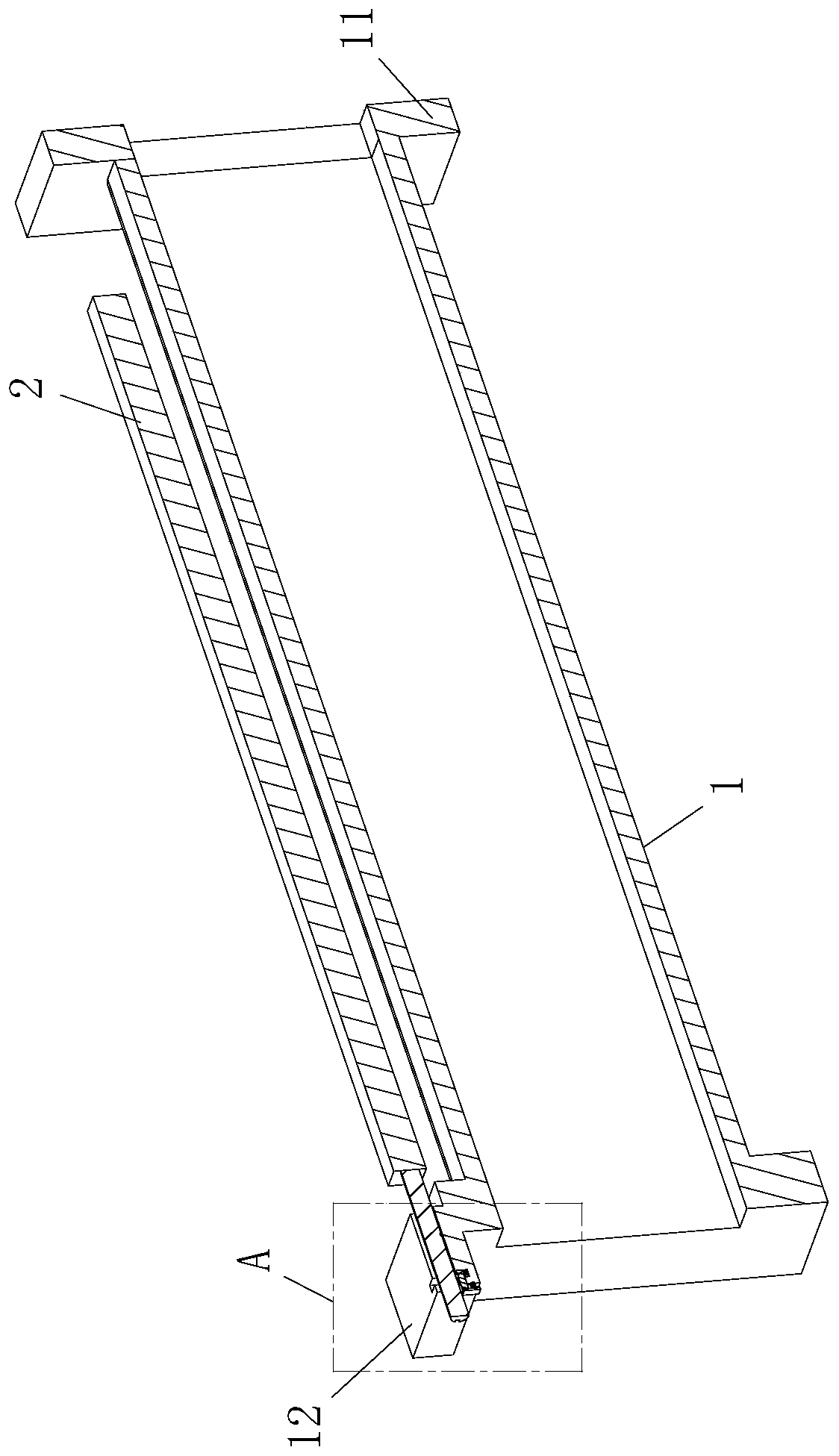

Examples

Embodiment approach

[0035] As an embodiment of the present invention, a layer of elastic layer 3 is provided on the bottom surface of the card slot 14, and the top surface of the elastic layer 3 is set as an arc-shaped surface matched with the side of the arc-shaped plate 22; A layer of elastic layer 3 is provided on the bottom surface of the slot 14. When the bottom end of the arc-shaped plate 22 is pressed into the inside of the slot 14, the arc-shaped plate 22 simultaneously squeezes the elastic layer 3 at the bottom end. 22 and the locking rod 16 are locked together, at this time, the elastic layer 3 exerts a force on the arc-shaped plate 22 under the effect of its own rebound force and makes the locking rod 16 and the second locking groove 23 on the arc-shaped plate 22 The side wall is contacted and pressed to reduce the shaking of the No. 2 locking groove 23 on the arc plate 22 relative to the locking rod 16, and increase the stability of the capacitor 2 on the arc plate 22 when it cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com