Automatic core filling production line for three-way catalytic converters

A three-way catalytic converter and production line technology, applied in the stacking of objects, unstacking of objects, conveyors, etc., can solve problems such as low production efficiency, ensure production quality, and cannot effectively meet production needs, so as to improve production efficiency and production quality, meeting production needs, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

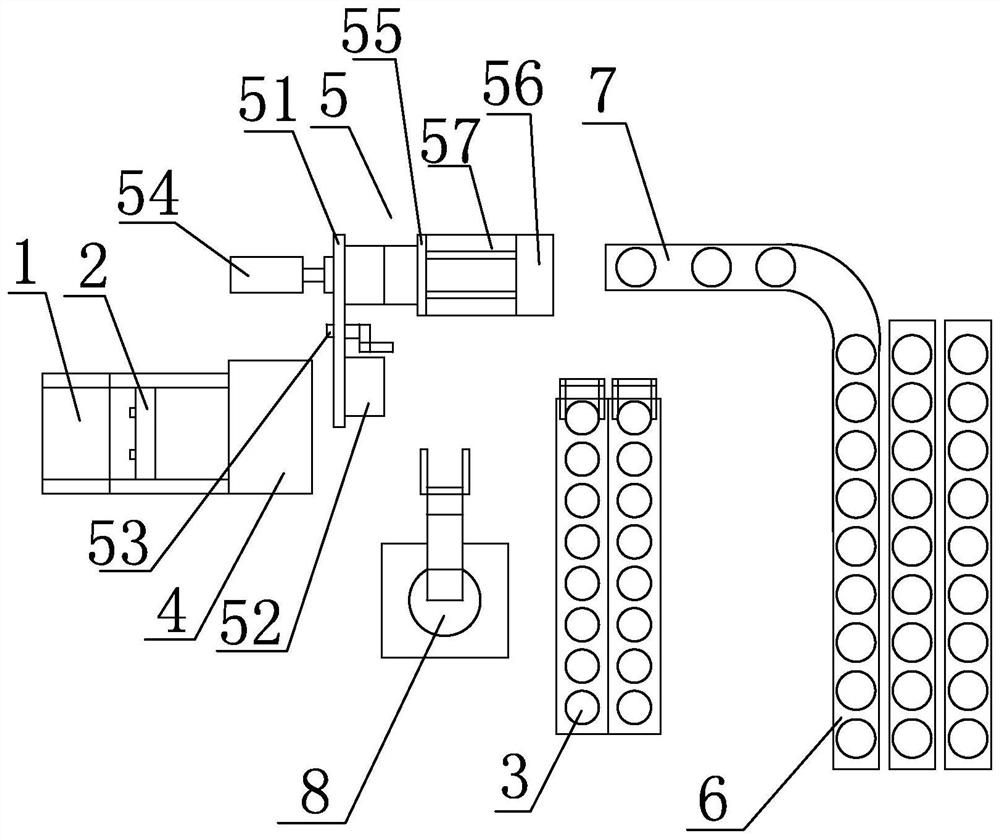

[0024] Such as figure 1 As shown, the three-way catalytic converter automatic core filling production line has a structure including a handling robot 8, a liner stacking mechanism 1 arranged on one side of the handling robot 8, a carrier liner loading and unloading and wrapping device 4, a core filling mechanism 5, and a carrier stacking device. The conveyor frame 3 and the shell stacking conveyor frame 6, the shell stacking conveyor frame 6 is connected to one end of the shell conveyor belt 7, the other end of the shell conveyor belt 7 is close to the core filling mechanism 5, and the liner grabbing mechanism 2 is arranged above the liner stacking mechanism 1, The liner grabbing mechanism 2 is close to the carrier liner loading and unloading and wrapping device 4 .

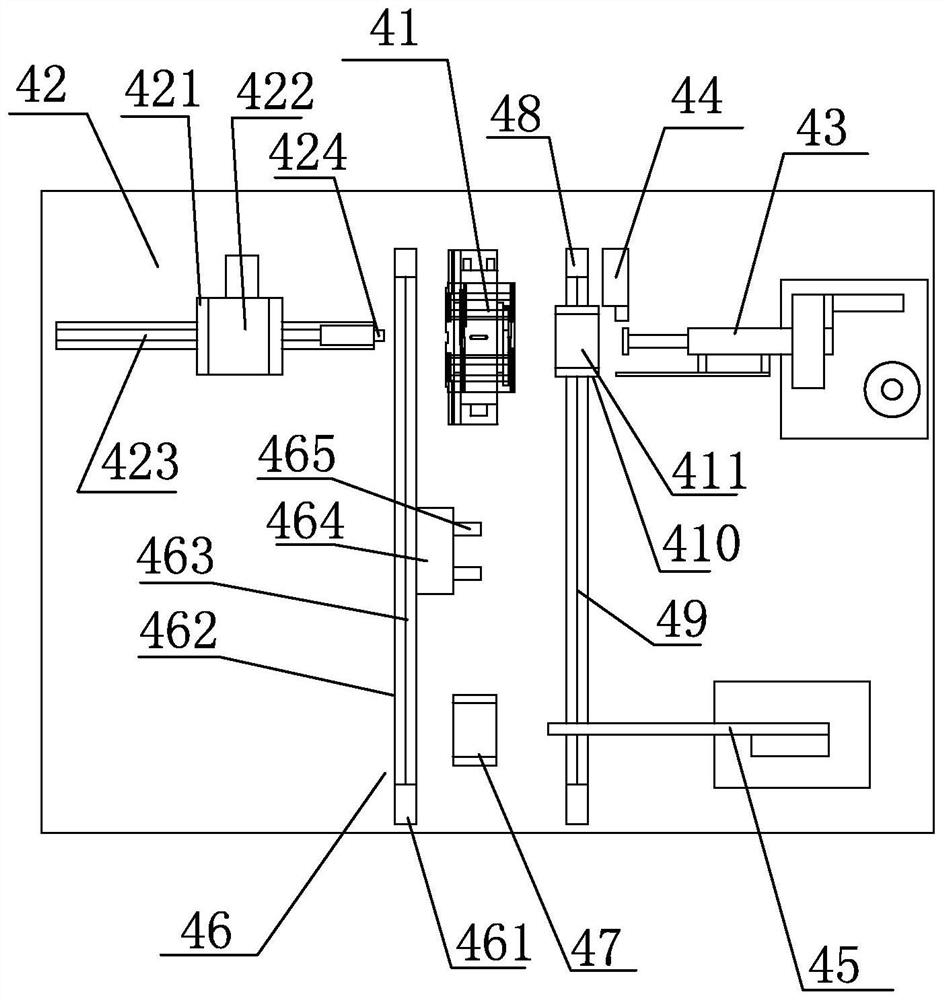

[0025] The core filling mechanism 5 includes a rotating support plate 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com