Multi-station rewinding cutting machine

A cutting machine and multi-station technology, applied in the field of machinery, can solve problems such as long production cycle, easy to form wrinkles of products, and production quality cannot be guaranteed, and achieve the goal of solving uneven adhesion, improving production quality and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

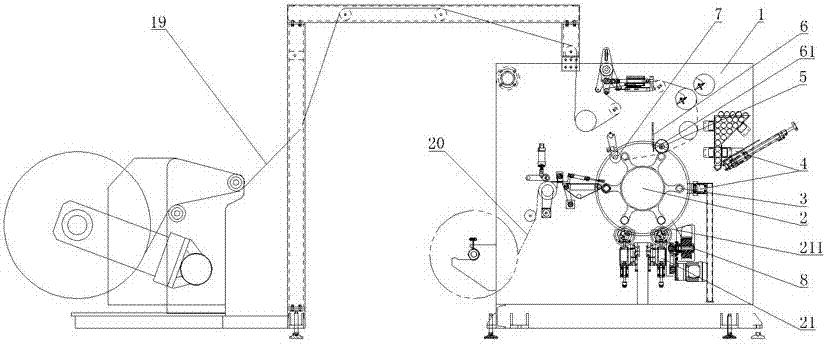

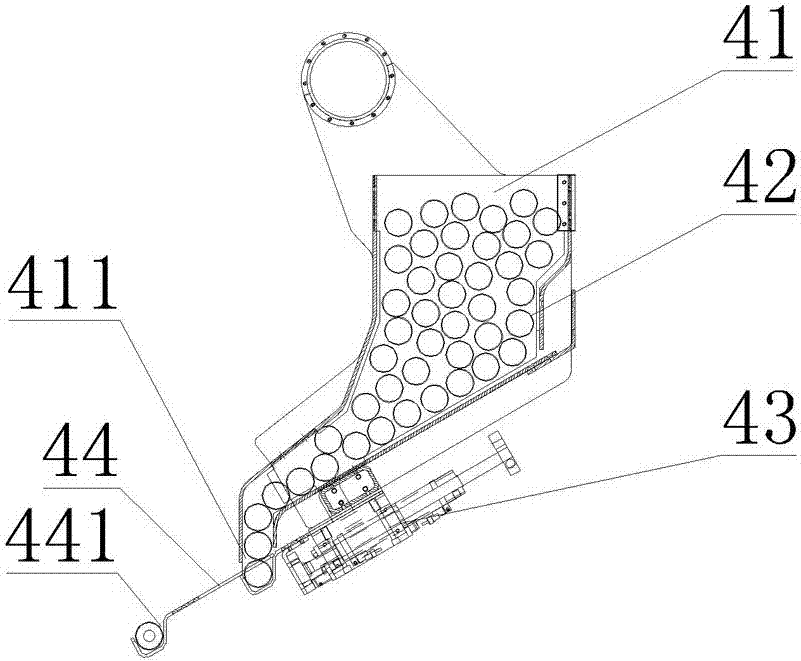

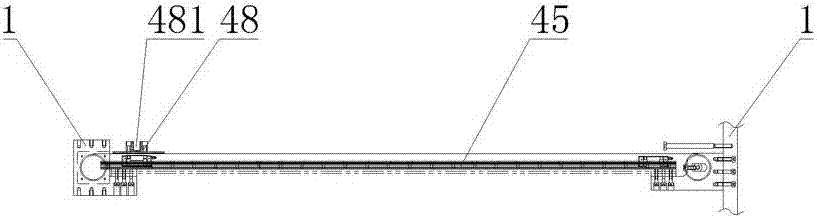

[0020] As shown in the figure, a multi-station rewinding and cutting machine has a frame 1, and the frame 1 is provided with a rotating shaft 2, and the rotating shaft 2 is driven by a motor. Tube roller 3, paper tube roller 3 is used for sheathing paper tube 42, and is provided with paper tube loading and unloading device 4, winding device, tailing material device and cutting device 21 sequentially along said rotating shaft 2, and paper tube loading and unloading device 4 is used To install or disassemble the paper tube 42 on the paper tube roller 3, the winding device is used to wind the tape 19 on the paper tube 42, and cut the tape 19 to a fixed length. Rolled on the paper tube 42, the cutting device 21 is used to cut the rolled cleaning tape to a fixed length. The paper tube loading and unloading device 4 has a storage box 41, a feeding cylinder 43, a paper tube moving frame 44, and a transmission bar 45. , moving seat 47, limit seat 48 and pneumatic chuck 46, paper tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com