A kind of nitrile rubber glove and dipping equipment thereof

A nitrile glove, dipping technology, applied in gloves, protective clothing, coatings, etc., can solve the problems of uneven adhesion, easy precipitation of glue, bubbles, etc., to achieve uniform adhesion, without affecting processing quality and efficiency, The effect of high degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of nitrile rubber glove, its formula is: 110-120 parts of nitrile latex; 0.5-0.9 parts of sodium polyacrylate; 0.9-1.1 parts of potassium hydroxide; 0.5-0.6 parts of 4-methyl-6-tert-butylphenol sulfur 0.5-2 parts; zinc oxide 0.4-3 parts; accelerator EZ0.3-3; dispersant NNO 0.2-0.6 parts.

[0033] The nitrile gloves made of the above formula have good tensile strength, which can reach 21.5Mpa, and the elongation at break can reach 550%. Under the conditions of temperature 25°C and humidity 60%, the degradation rate is 75%. . However, the viscosity of this material is 2500-3000MPa·s, and its viscosity is relatively high, so its dipping production has certain difficulties, and its thickness and bubbles generated during the dipping process are difficult to control.

Embodiment 2

[0035] This embodiment provides a nitrile rubber glove dipping equipment, which is used to overcome the related problems in the production process of the gloves of the above materials.

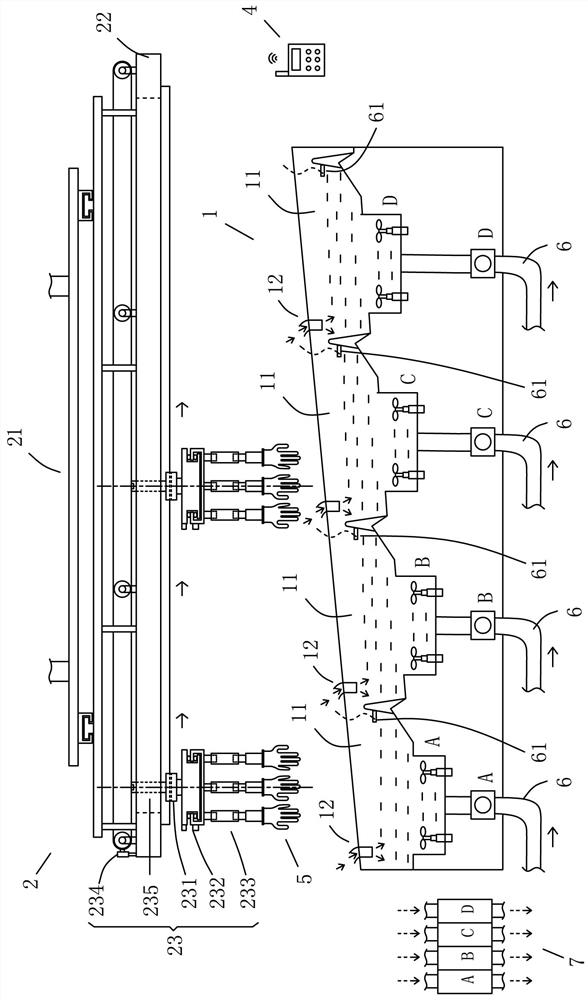

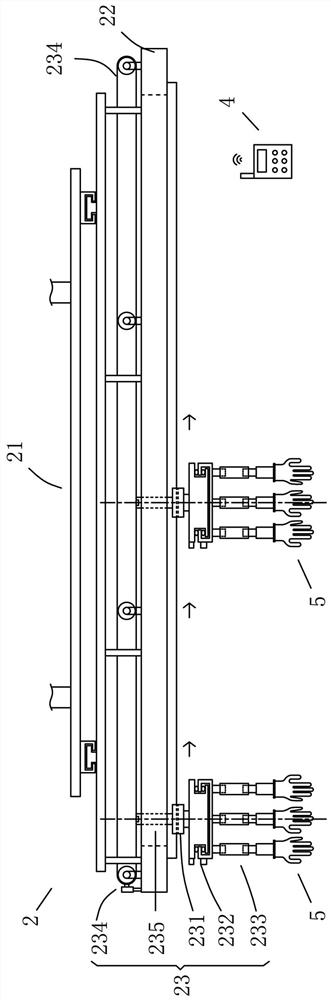

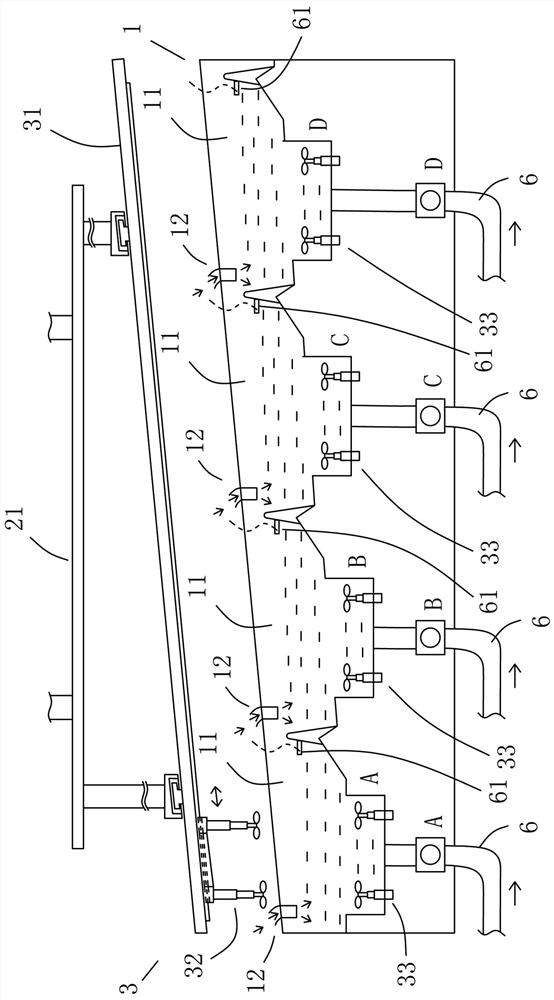

[0036] Please also refer to Figure 1 to Figure 5 , a kind of nitrile glove dipping equipment provided by the present invention is now described. Described a kind of nitrile glove dipping equipment, comprises dipping tank 1, conveying mechanism 2, stirring mechanism 3 and control mechanism 4, dipping tank 1 is used to accommodate nitrile glue; There are a plurality of hand molds 5, which are used to drive a plurality of hand molds 5 to dip into the glue solution and rotate the plurality of hand molds 5 in the glue solution, so that the glue solution is evenly attached to the surface of the plurality of hand molds 5, and used to drive A plurality of hand molds 5 are pulled away from the glue; the stirring mechanism 3 is arranged above the dipping tank 1 and at the inner bottom, which is used t...

specific Embodiment approach

[0044] As a specific implementation of a kind of nitrile glove dipping equipment provided by the present invention, please refer to Figure 1 to Figure 5 , the conveying assembly 23 includes a slider 231, a rotary table 232 and a telescopic rod 233, the slider 231 is slidably connected to the sliding end of the second sliding assembly 22, and can slide along the length direction of the conveying mechanism 2; the rotary table 232 is located at the lower end of the slider 231 , can rotate circumferentially in the horizontal plane, and the rotation angle is controlled by the control mechanism 4; there are multiple telescopic rods 233, all of which are vertically arranged at the lower end of the rotary table 232, and can be vertically telescopic, and the multiple hand models 5 are respectively One-to-one correspondence is connected to a plurality of flexible lower ends, and a plurality of hand molds 5 are lifted vertically by means of a plurality of telescopic rods 233 respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com