System for automatically transporting concrete and pouring and preparing precast beam

An automatic transportation and concrete technology, which is applied in the direction of manufacturing tools, ceramic molding workshops, supply devices, etc., to achieve the effects of broad application prospects, economical cost savings, and improved production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

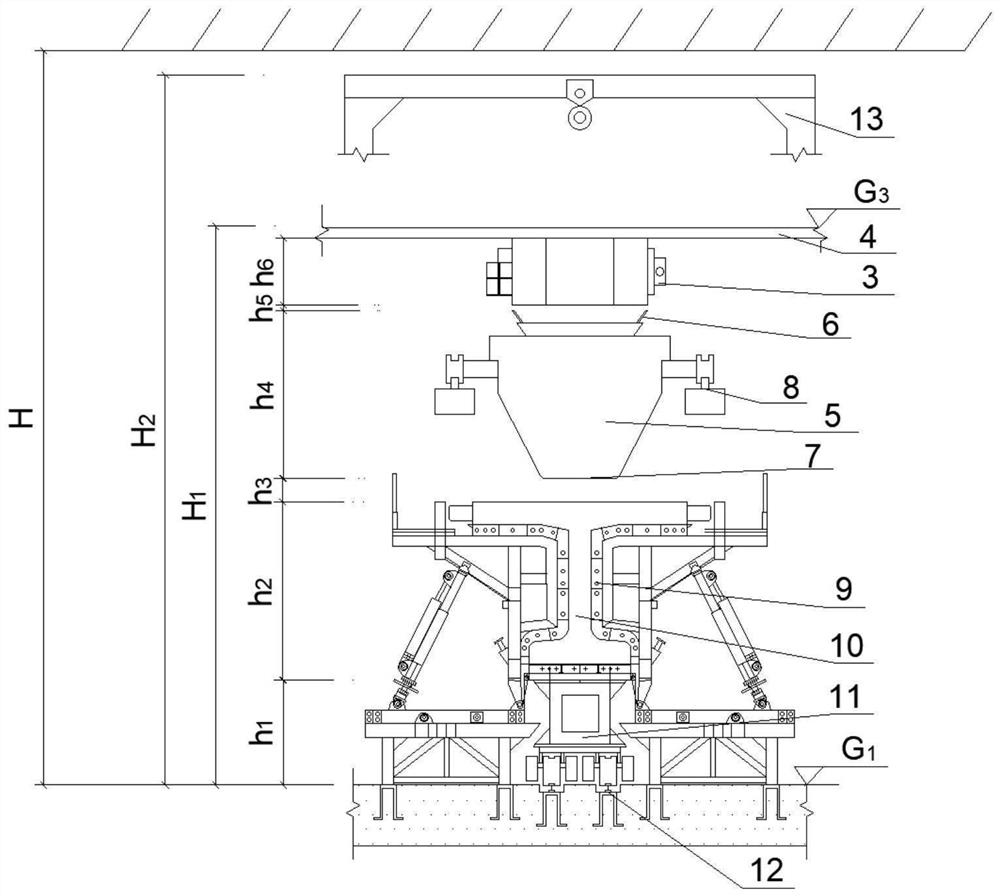

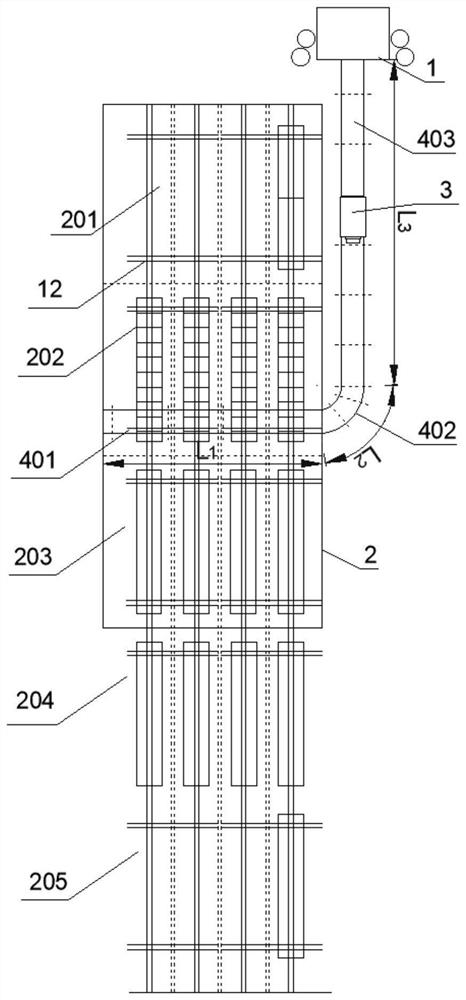

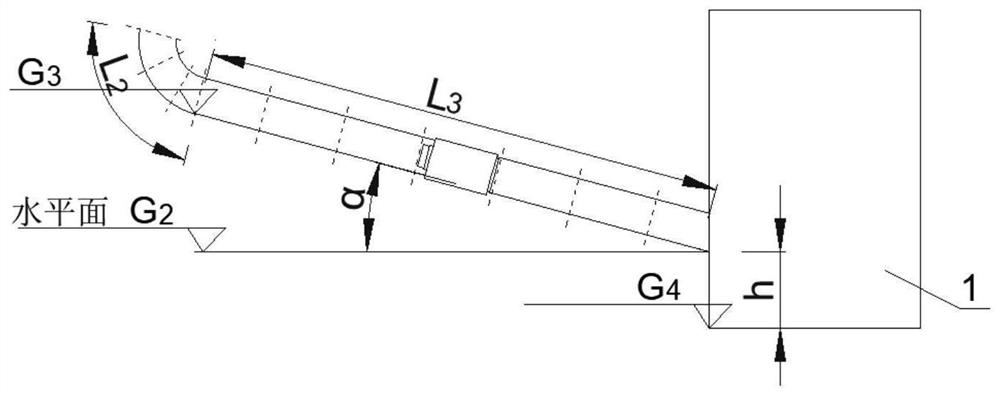

[0070] refer to figure 1 , figure 2 , image 3 , this embodiment provides a system for automatically transporting concrete and pouring and preparing precast beams, which is used to transport the concrete in the mixing plant 1 to the precast beam pouring area 202 in the plant area 2, and realize the precast beams in the precast beam pouring area 202 Concrete pouring preparation, the system includes a concrete automatic transport unit and a concrete automatic pouring unit, the concrete automatic transport unit includes a feeder track 4 and a torpedo tank 3, and the feeder track 4 extends from the mixing station 1 to the precast beam pouring Above the area 202, the torpedo tank 3 is connected to the feeder track 4 for transporting the concrete in the mixing station 1 to the prefabricated beam pouring area 202, and the concrete automatic pouring unit includes a distributing machine 5 and a distributing machine track 8 , steel mold system 9, transfer trolley 11 and ground rail 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com