Rotary foaming mold frame

A foaming mold, rotary technology, applied in the field of foaming mold frame, can solve the problems of limited flip angle, inaccurate repeating angle, unable to adjust the angle, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

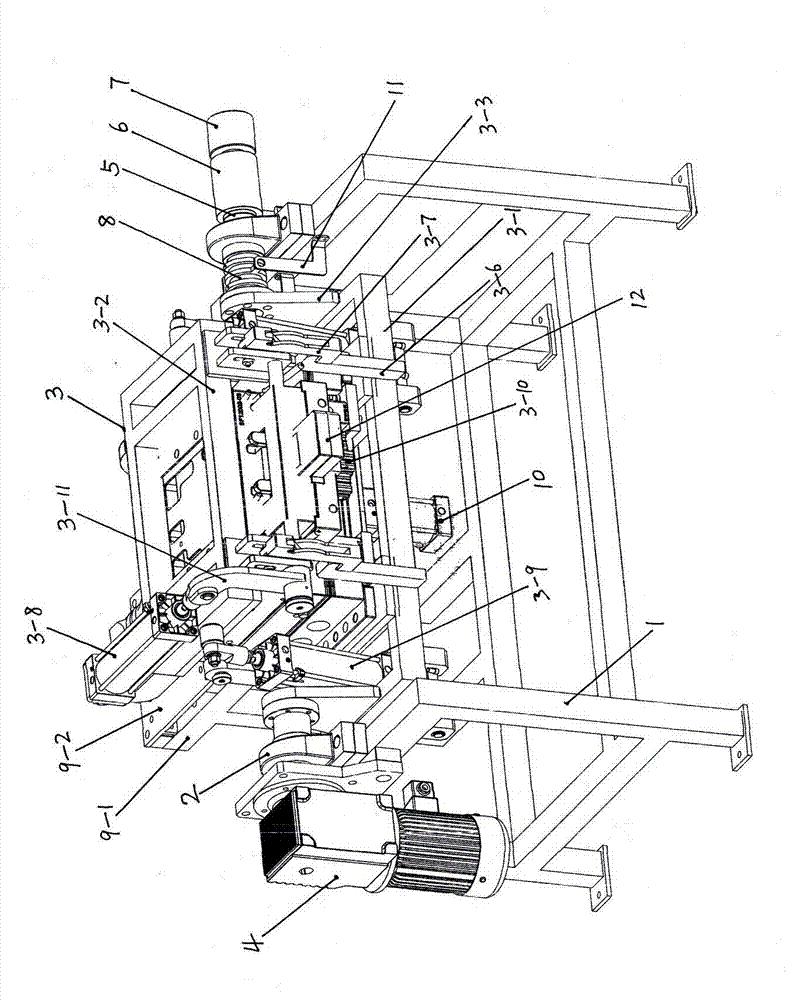

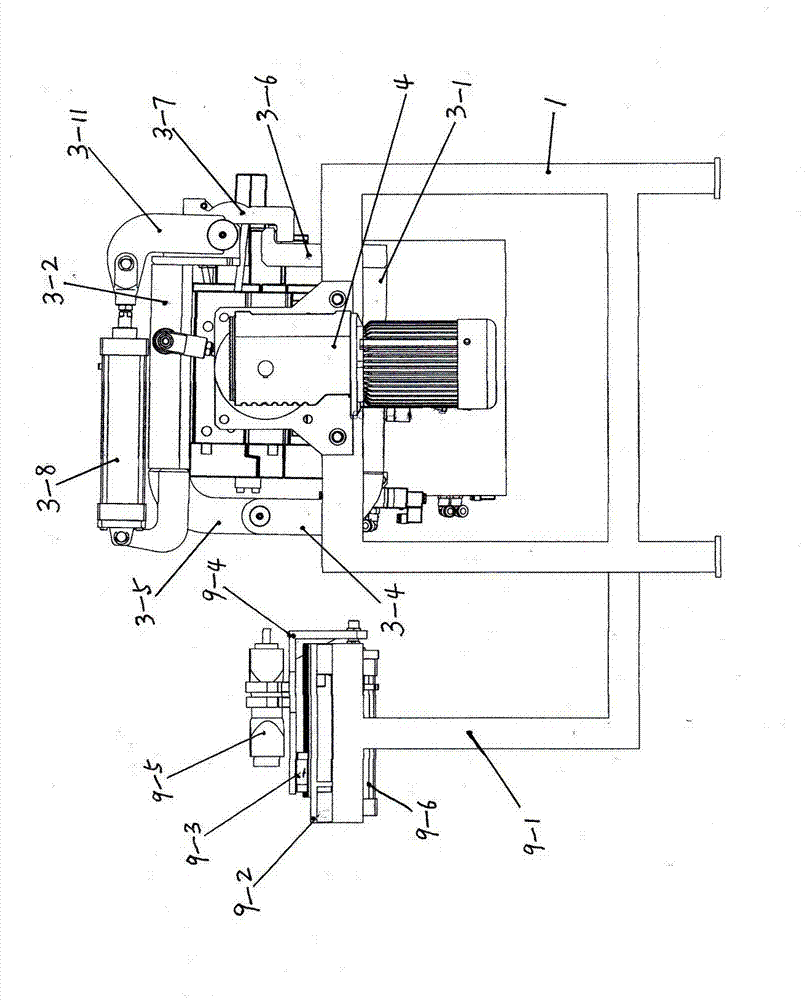

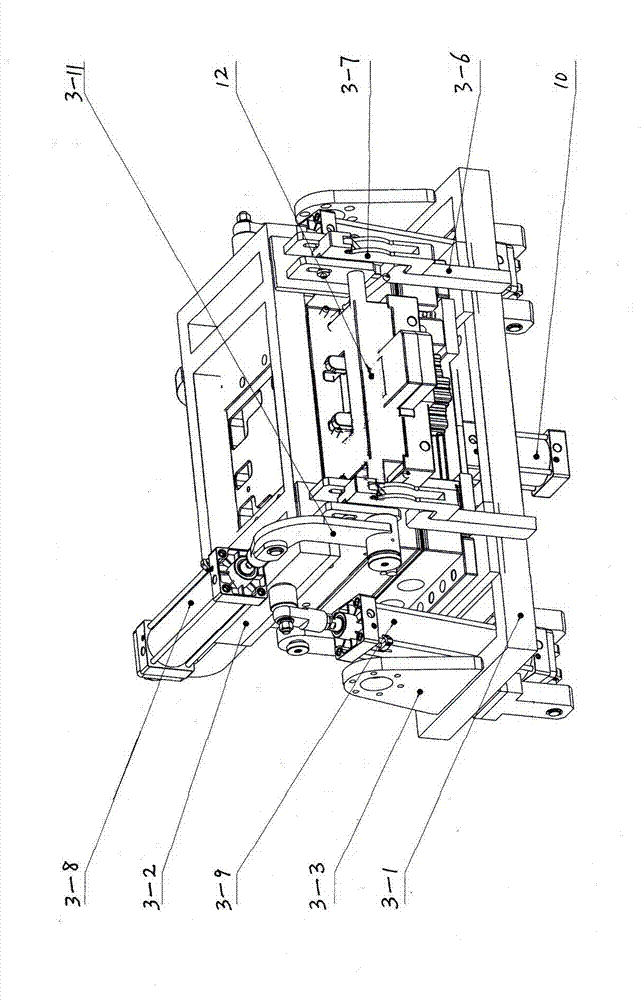

[0015] refer to figure 1 —6, it includes the main frame 1, the bearing housing 2 is fixed on both sides of the upper part of the main frame; there is also a rotating mechanism 3, the rotating mechanism includes the lower frame 3-1 and the upper frame 3-2, and the lower frame both sides are provided with connections Plate 3-3, one end of the lower frame is connected with the lower hinge 3-4, one end of the upper frame is connected with the upper hinge 3-5, the upper and lower hinges are corresponding and connected by hinge shafts, the other end of the lower frame is connected with the lower lock Tight hook 3-6, the other end of the upper frame is connected with the upper locking hook 3-7, the upper frame is fixed with the locking cylinder 3-8, the cylinder rod end of the locking cylinder is connected with the pin shaft and the locking arm 3- One end of 11 is connected, and the other end of the locking arm is welded with a shaft sleeve 3-12, and a locking shaft 3-13 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com