A kind of production method of circular PU air filter element

A production method and technology of air filter elements, which are applied in household appliances, other household appliances, household components, etc., can solve the problems of long preparation time, high cost, and low production efficiency, so as to improve quality stability, reduce raw material waste, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

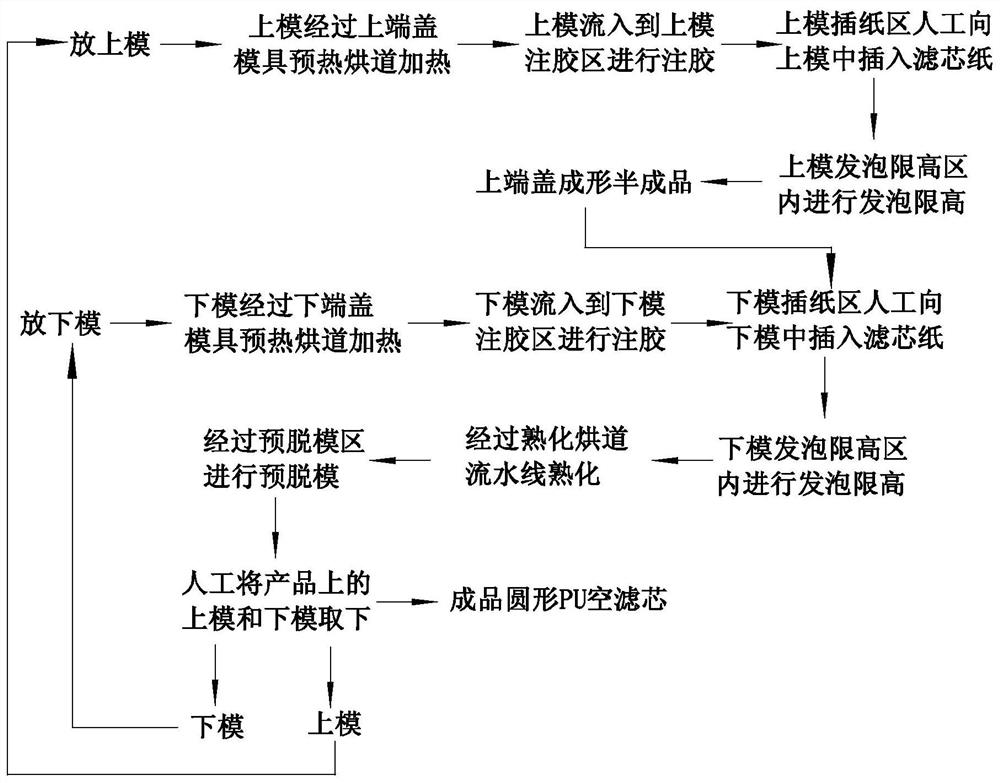

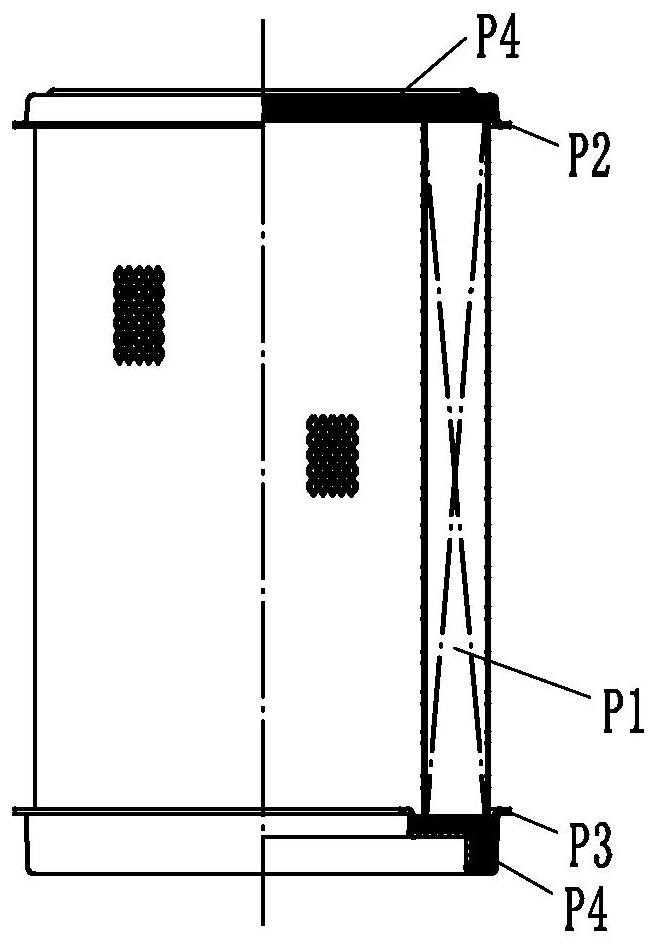

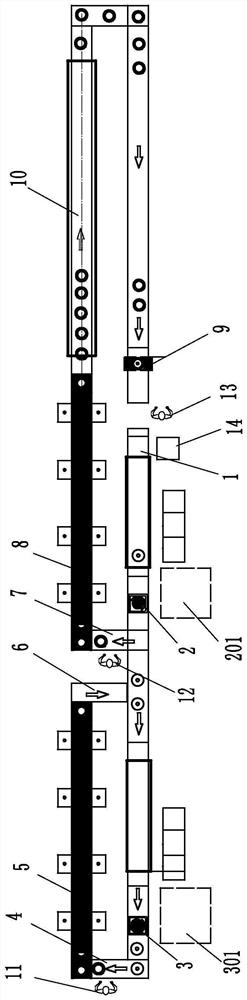

[0052] Embodiment 1: a kind of circular PU air filter core production method, the production device that adopts is circular PU air filter core production line (such as Figure 3-Figure 4 shown), including the mold conveying line 1, the upper end cover glue injection and foaming line, the lower end cover glue injection and foaming line, the curing oven line 10 and the pre-demolding area 9, and the mold conveying line includes the upper and lower mold conveying lines 101 And the upper mold delivery line 102 of the lower floor, that is, the mold delivery line adopts an original upper and lower double-layer mold delivery structure, so that the upper and lower molds can be put in one place at the same time. The upper end cover glue injection and foaming line includes an upper mold glue injection area 3, an upper mold paper insertion area 4, an upper mold foaming solidification heat preservation height limit area 5 and an extended buffer line section 6 after the upper end cover is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com