A Modular Design Asphalt Foaming Equipment and Its Automatic Control System

A technology of modular design and foaming equipment, applied in roads, buildings, road repair and other directions, can solve the problems of not considering the influence of flow characteristics, affecting the accuracy of asphalt flow, etc., to improve work efficiency and utilization, easy to automate Control and ensure the effect of foaming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

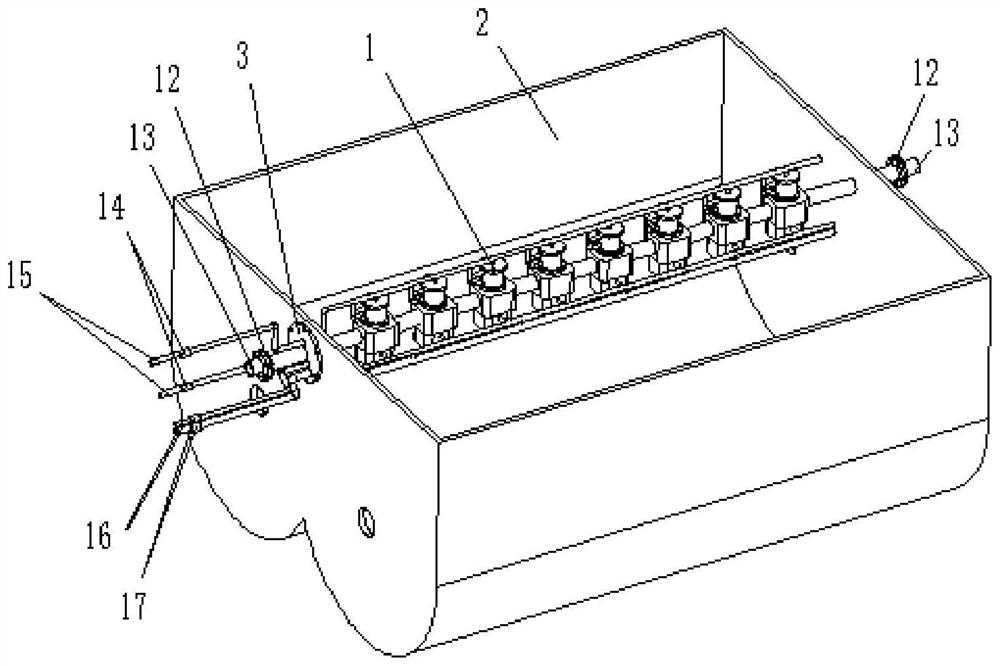

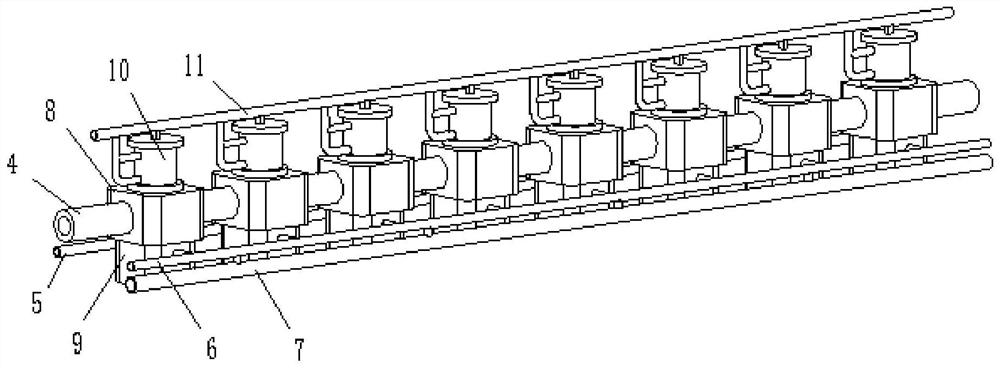

[0046] Embodiment 1: The modularized asphalt foaming equipment and its automatic control system described in the present invention are applied to a batch mixing station.

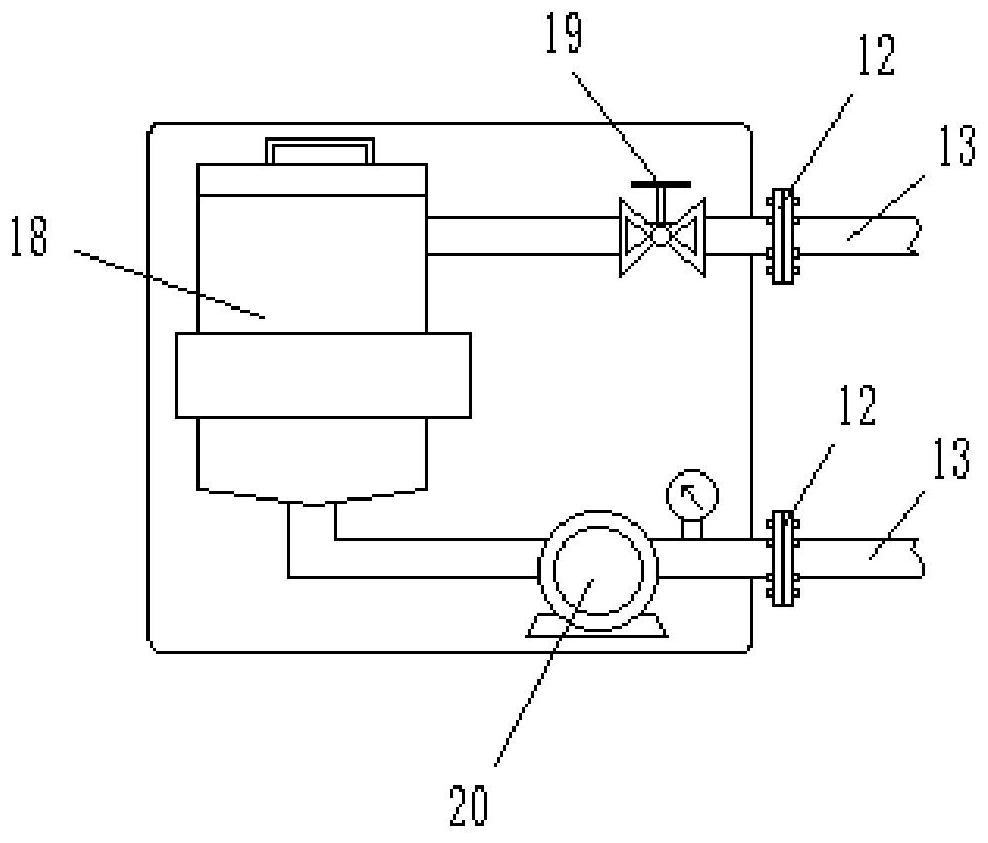

[0047] Such as figure 1, the foamed asphalt spraying rod 1 designed as an independent module is installed in the mixing chamber 2 of the batch mixing station as a whole, and the two ends are fixed by the support plate 3 erected by the spraying rod. Place the asphalt supply system, the foaming water supply system, the humidifying water system, and the air supply system outside the mixing chamber 2. The automatic control system of the modular design of asphalt foaming equipment is connected to the control system of the batch mixing plant, and the model of the batch mixing plant, the type of asphalt used, and the percentage of foamed asphalt are input in the user interface of the computer or touch screen. Design the pipe diameter of each system by yourself, and then connect each pipe. The input end of the asp...

Embodiment 2

[0051] Embodiment 2: The modular design of asphalt foaming equipment and its automatic control system described in the present invention is applied to a continuous mixing station.

[0052] Such as Figure 9 The two ends of the foamed asphalt spraying rod 1 are fixed at the entrance of the mixing tank 30 of the continuous mixing station through the spraying rod erecting support plate 3; the asphalt supply system, foaming water supply system, humidifying water system and air supply system are respectively installed in the continuous Mixing station mixing drum 30 external. The installation and connection methods of the remaining components and the control method of the automatic control system are the same as those mentioned in Embodiment 1.

Embodiment 3

[0053] Embodiment 3: The modular design of asphalt foaming equipment and its automatic control system described in the present invention is applied to the vehicle-mounted cold recycling machine 31 .

[0054] Such as Figure 10 , Figure 11 , the two ends of the foamed asphalt spraying rod 1 are fixed above the milling rotor on the vehicle-mounted cold recycling machine 31 through the spraying rod erecting support plate 3; the asphalt supply system, the foaming water supply system, the humidifying water system and the air supply system are installed on On-vehicle cold regeneration fuselage 31. The automatic control system of the present invention is connected with the operating systems of the asphalt tank truck 32, the water tank truck 33 and the vehicle-mounted cold recycling machine 31. Input the model of the vehicle-mounted cold recycling machine 31 in the user interface of the computer or touch screen, and then automatically calculate the required amount of asphalt, foame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com