Patents

Literature

36results about How to "Improve hydrolysis yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel process for preparing germanium dioxide (GeO2)

ActiveCN102774877AReduce lossesHigh degree of automationGermanium dioxideGermanium dioxideHydrolysis

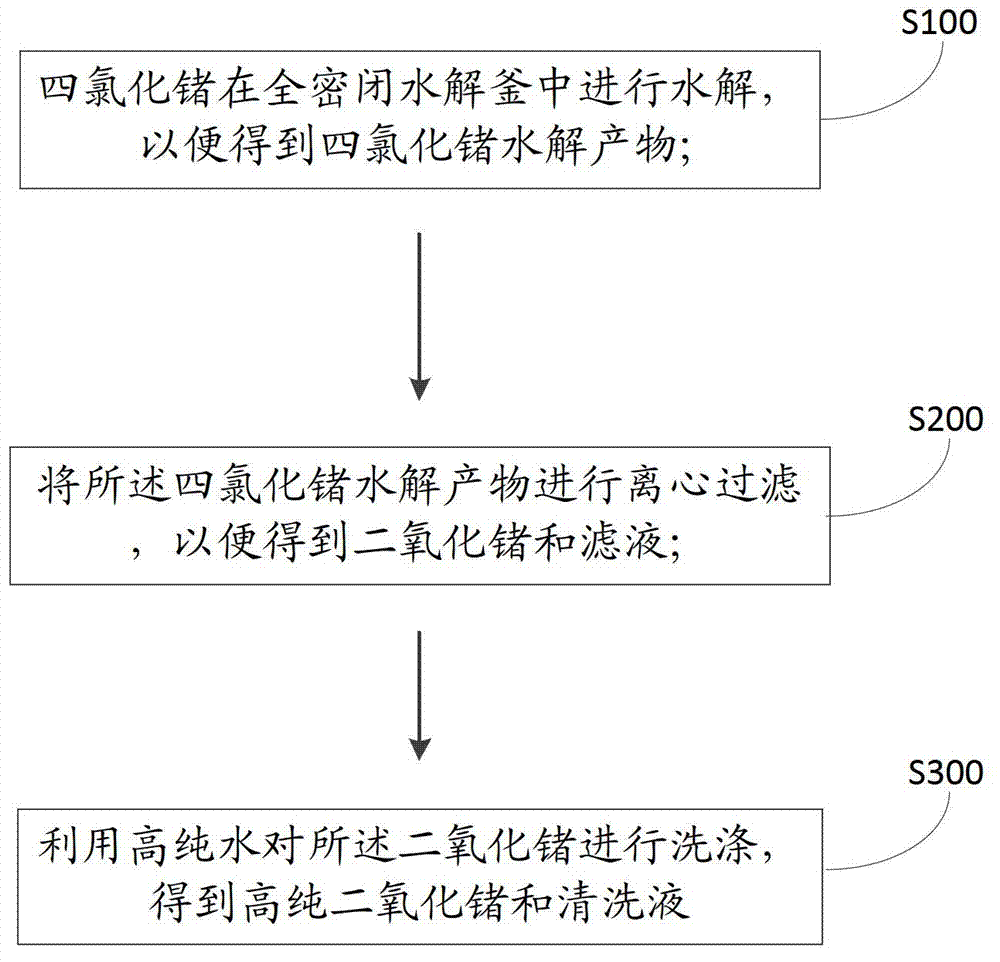

The invention provides a method for preparing germanium dioxide (GeO2). According to the embodiment of the invention, the method comprises the following steps: hydrolyzing the germanium tetrachloride(GeCl4) in a fully-closed hydrolysis reactor to obtain the hydrolysis product of the GeCl4, centrifuging and filtering the hydrolysis product of the GeCl4 to obtain the GeO2 and the filtrate, and cleaning the GeO2 by high-purity water to obtain the high-purity GeO2 and the cleaning solution. According to the embodiment of the invention, the GeO2 hydrolyzing, filtrating and washing method and device have the advantages of high degree of automation, high GeO2 hydrolysis yield, good solid-liquid centrifugal separation effect, low production costs, less metal loss and environment friendliness.

Owner:云南驰宏国际锗业有限公司

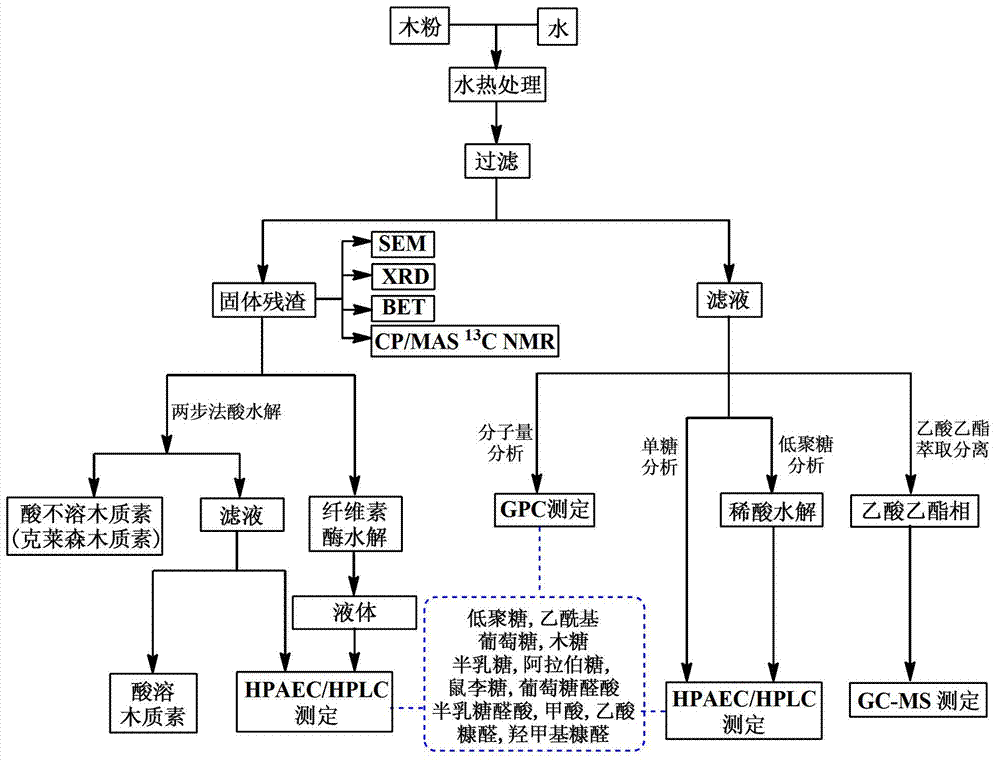

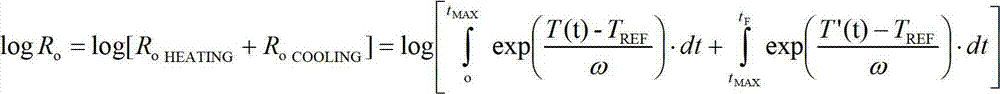

Preprocessing method for lignocellulose raw material

ActiveCN102864668AIncrease hydrolysis rateHigh recovery rateFibrous raw materialsFermentationPretreatment methodHigh pressure

The invention discloses a preprocessing method for a lignocellulose raw material, which comprises the following steps: (1) fully mixing the crashed lignocellulose raw material with water, and then standing for 2-4 hours, and transferring a mixture into a high-pressure reactor; heating the high-pressure reactor from room temperature to 180-240 DEG C under the protection of inert gases, and then immediately and quickly cooling the reactor to the room temperature through condensate water, wherein the strength factor is 2.40-4.17 and the pressure is a saturated vapor pressure at 1.19-3.45MPa at corresponding temperature; and (2) performing solid-liquid separation on the product obtained in the step (1), thereby obtaining a solid-phase product and a liquid-phase product. The preprocessing method for the lignocellulose raw material has the advantages of low cost, no pollution to environment, low energy consumption, high hydrolysis rate of hemicellulose, high recovery rate, and the like.

Owner:BEIJING FORESTRY UNIVERSITY

Foaming agent of waterproof foam concrete, preparation method and construction method

InactiveCN101698581AFormula refiningImprove stabilityBuild-up roofsBuilding insulationsFoam concreteFoaming agent

The invention relates to foaming agent of waterproof foam concrete, a preparation method and a construction method, which belongs to the fields of construction materials, a preparation method thereof and an architectural method thereof. The foaming agent of the invention comprises the following raw materials in part by weight: 30 to 35 parts of keratinous albumen powder, 4 to 5 parts of Ca(OH)2, 1.5 to 2.5 parts of NaHSO3, 270 to 320 parts of water, 0.8 to 1.5 parts of sodium dodecyl benzene sulfonate (SDBS), 0.2 to 0.7 part of sodium dodecyl sulfate, 0.8 to 1 part of gelatin and 0.5 to 1 part of trolamine. The weight of sulphamic acid is matched with that of Ca(OH)2 and NaHSO3, and the pH value of the mixed three materials reaches 7.

Owner:廖传海

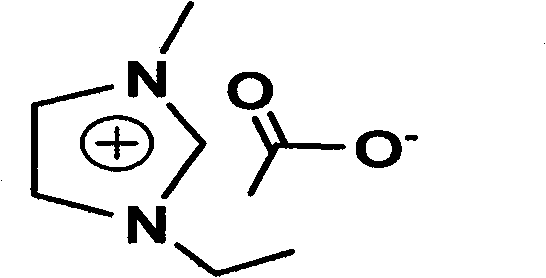

Application of ionic liquid to preparation of reducing sugar by cellulose hydrolysis

InactiveCN102071266ALow viscosityEasy to operateFructose productionGlucose productionCelluloseIon exchange

The invention relates to dissolution of straws and hydrolysis of celluloses, in particular to a method for preparing reducing sugar by dissolving the straws and hydrolyzing the celluloses in ionic liquid. The method comprises the following steps of: adding 1-ethyl-3-methylimidazole acetate serving as a straw solvent into Fe3+-containing aqueous solution and reacting in the presence of acidic ionic liquid serving as a catalyst under normal pressure at the temperature of between 110 and 140 DEG C for 0.5 to 5 hours; quenching with cold water; neutralizing with alkali liquor to prepare cellulose hydrolyzate; and measuring reducing sugar content by a 3,5-dinitrosalicylic acid method, wherein the reducing sugar in the hydrolyzate and the ionic liquid can be separated by an ion exchange method and the ionic liquid can be repeatedly used. Experiment results show that the reducing sugar yield is up to 93 percent to the maximum extent. Compared with the conventional straw cellulose hydrolysis method, the method has the advantages of solving the problems of complicated pretreatment, low hydrolysis activity, high corrosion to equipment, high cellulose solvent viscosity, inconvenience of operation and the like and providing a new approach for full utilization of the straws.

Owner:JIANGNAN UNIV

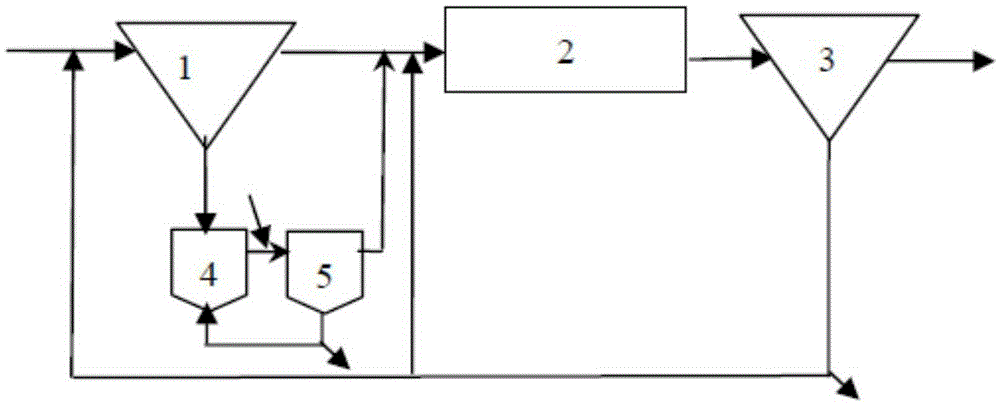

A method for strengthening denitrification and dephosphorization by hydrolyzing and fermenting mixed sludge from sewage plant

ActiveCN104118971BPromote degradationSimple structureMultistage water/sewage treatmentActivated sludgeVolatile fatty acids

The invention creatively provides a method for strengthening nitrogen and phosphorus removal by using the hydrolysis and fermentation of mixed sludge of a sewage plant. According to the method, part of activated sludge returns to a primary sedimentation tank and is mixed with primary sedimentation sludge, so as to be subjected to precipitation and concentration, the precipitated and concentrated mixed sludge enters a hydrolysis tank which can consist of a separate reactor and can also consist of two series reactors, and is subjected to hydrolysis and fermentation in the hydrolysis tank, so as to produce easily-degradable organic matters (rbCOD) or volatile fatty acids (VFAs), and after the process is completed, a hydrolyzed mixed solution which is rich in VFA, or supernatant is introduced into an anaerobic tank or anoxic tank of a biological pool, thereby realizing the aim of strengthening nitrogen and phosphorus removal. The method provided by the invention has the advantages that the carbon source insufficiency of inlet water can be effectively improved, the biological nitrogen and phosphorus removal function can be strengthened, and the addition of an external commercial carbon source is reduced or canceled; the method is applicable to the new construction of sewage plants and is also applicable to the upgrading and reconstruction of the existing sewage plants.

Owner:刘智晓

Collagen and its preparing process

InactiveCN1683550AImprove hydrolysis yieldAdd flavorFermentationBulk chemical productionOil and greaseForeign matter

The present invention relates to collagen and its preparation process. The preparation process includes eliminating foreign matter and scale from fish skin, washing, chopping in meat chopper, adding deionized water and heating inside a container, hydrolyzing with hydrolyzing proteinase, secondary hydrolyzing with flavoring hydrolase, heating to inactivate, letting stand to laminate, eliminating upper oil and grease layer, filtering the hydrolyze, defatting in a supercritical CO2 equipment, microfiltering to obtain filtrate, and spray drying to obtain collagen powder. The collagen powder has high solubility, high yield and good taste. The collagen may be used widely in food, cosmetics, medical supplementary material, enzyme and bioactive matter carrier, etc.

Owner:青岛博恩生物科技有限公司

Preparation method for bacteriostatic seabuckthorn seed polypeptide

InactiveCN103421873AHigh dissolution rateImprove hydrolysis yieldFood preservationAnimal feeding stuffEscherichia coliPhytase

The invention provides a preparation method for bacteriostatic seabuckthorn seed polypeptide. The preparation method comprises the following steps: soaking seabuckthorn seed slag for treatment, conducting hydrolytic treatment on the seabuckthorn seed slag with complex enzyme of tannase and phytase, hydrolyzing protein in zymolyte with the combination of acidic protease and papayotin, standing polypeptide hydrolysate at a low temperature for one night, removing macromolecular impurities through low-temperature high-speed centrifugation, and concentrating and drying centrifugation supernatant fluid to obtain the bacteriostatic seabuckthorn seed polypeptide. Extracorporeal bacteriostatic cultivation experiments show that the polypeptide has a favorable restraining effect for common bacteria such as colibacillus coli and salmonella. The polypeptide is good in taste, has no side effects, and can be added into food or fodder as a preservative agent.

Owner:SHANXI UNIV

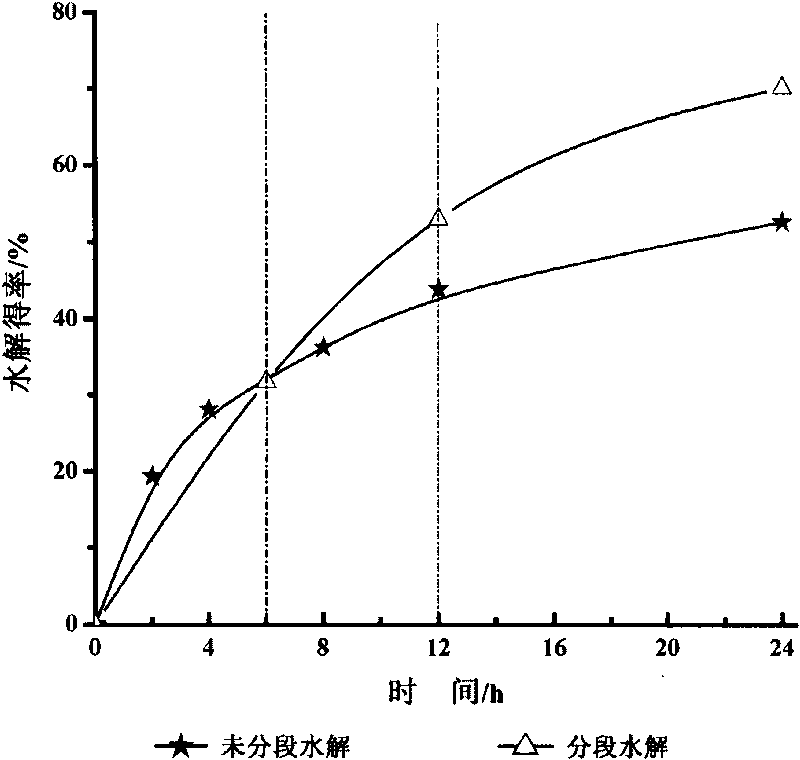

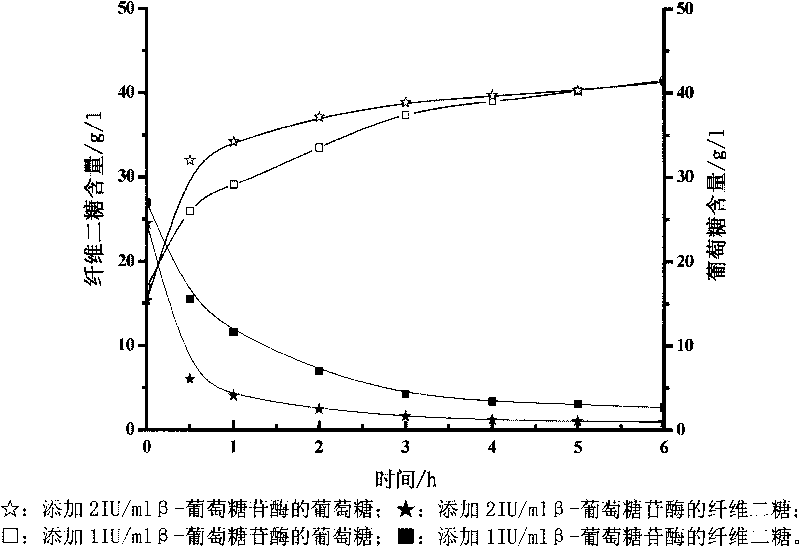

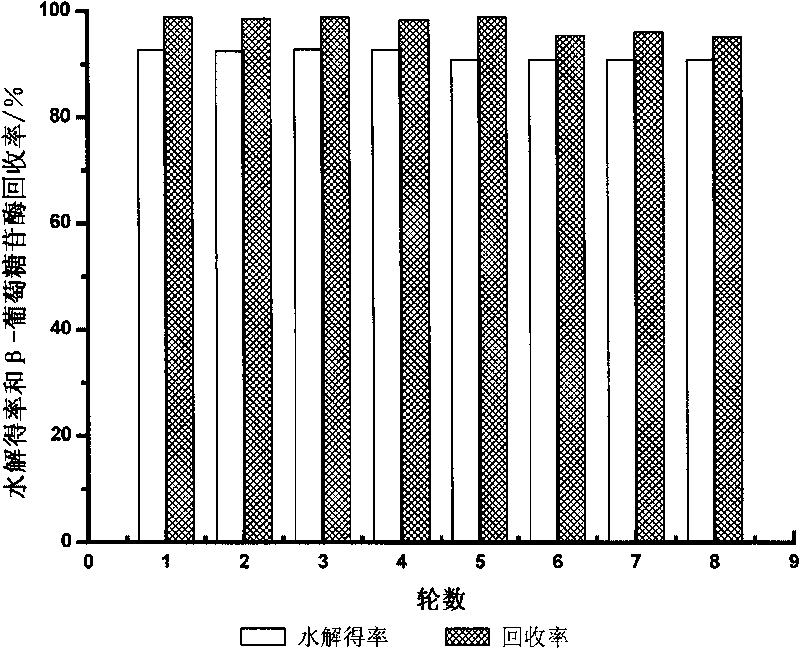

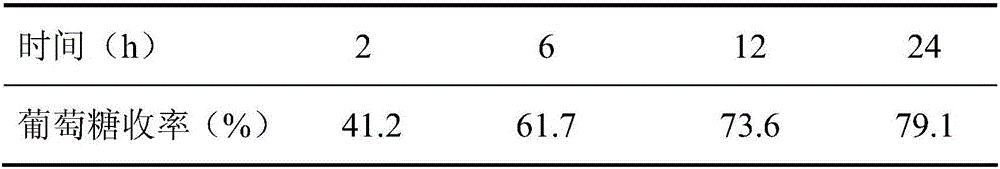

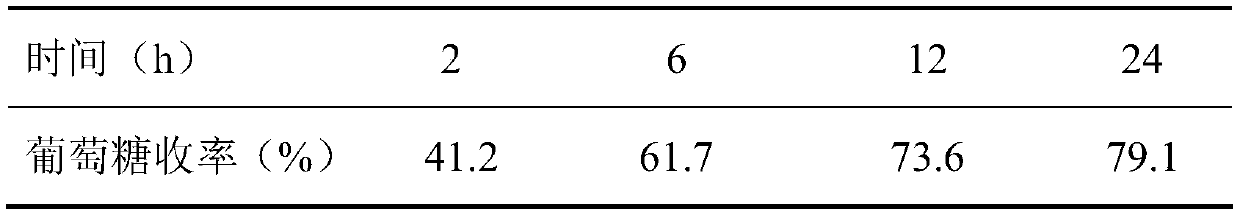

Method for performing enzyme hydrolysis on wood fiber raw material

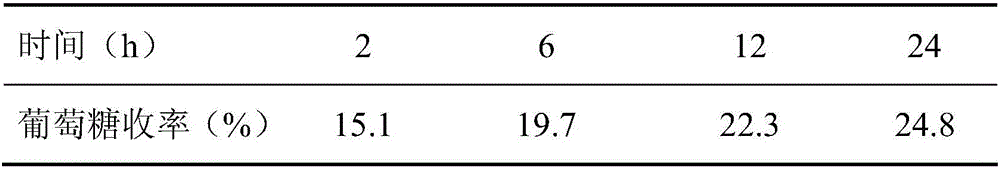

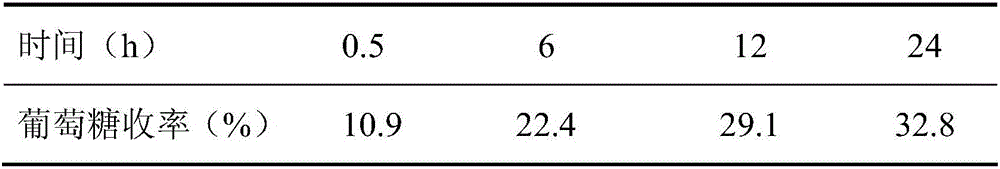

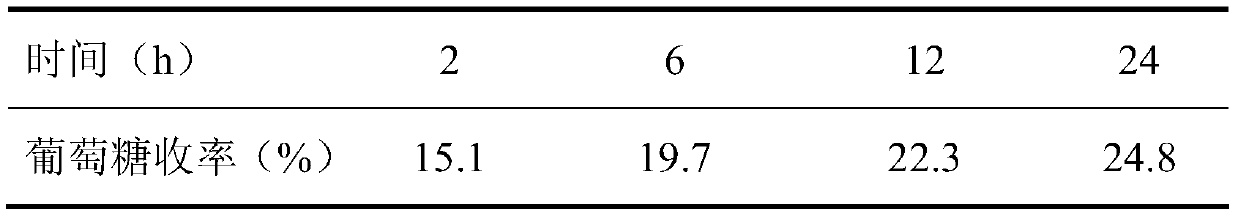

The invention discloses a method for performing enzyme hydrolysis on a wood fiber raw material, which uses the pretreated wood fiber as a raw material and is characterized in that the method adopts processes of stage enzymolysis and ultra-filtration to recycle cellulase and beta-glucosidase. Due to timely removal of cellobiose and glucose in the reaction process, the method greatly relieves the inhibiting effect of a reaction product on the cellulase, improves the hydrolysis yield of cellulose and the efficiency of converting the cellobiose into the glucose, and can obviously shorten the time of enzymolysis reaction.

Owner:NANJING FORESTRY UNIV

Green method for increasing cellulose enzymolysis efficiency in rice straws by utilizing lactic acid/guanidine hydrochloride to extract hemicellulose

InactiveCN106480128AImprove enzymatic hydrolysis efficiencyHigh yieldFermentationSolventIonic liquid

The invention belongs to the fields of lignocellulose utilization and energy and chemical application, and discloses a green method for increasing a cellulose enzymolysis efficiency in rice straws by utilizing lactic acid / guanidine hydrochloride to extract hemicellulose. The green method includes: taking the lactic acid / the guanidine hydrochloride as a solvent to preprocessing the rice straws, filtering and separating to obtain residues, and drying to obtain preprocessed rice straws; taking the rice straw residues as a base material, and subjecting the base material to enzymolysis by cellulose so as to obtain a liquid sugar which mainly comprises glucose. The green method has the advantages that the enzymolysis efficiency of the rice straws can be increased effectively, a yield rate of fermentable reducing sugar is increased, and the defects of high cost and environmental unfriendliness of an ionic liquid preprocessing process are overcome.

Owner:GUANGDONG UNIV OF TECH

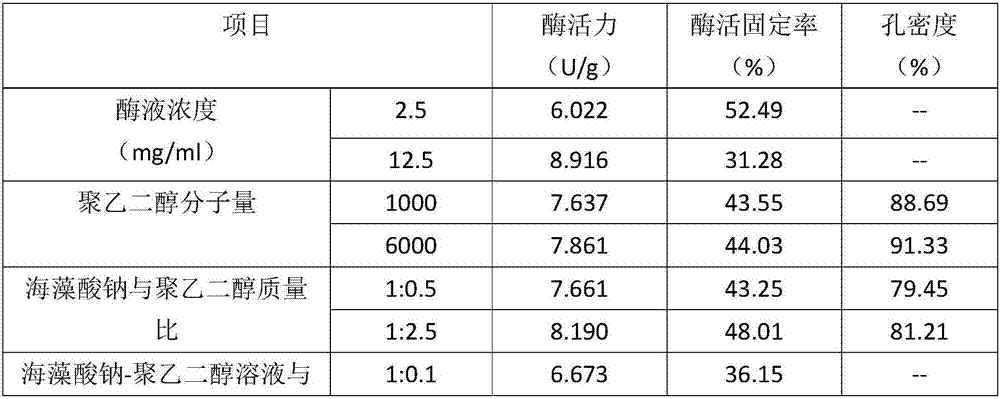

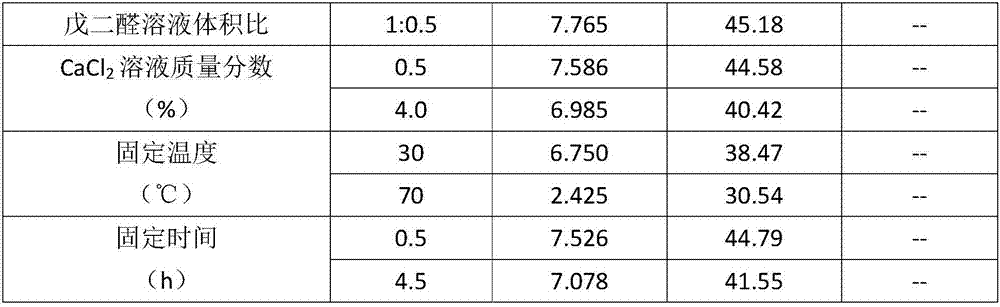

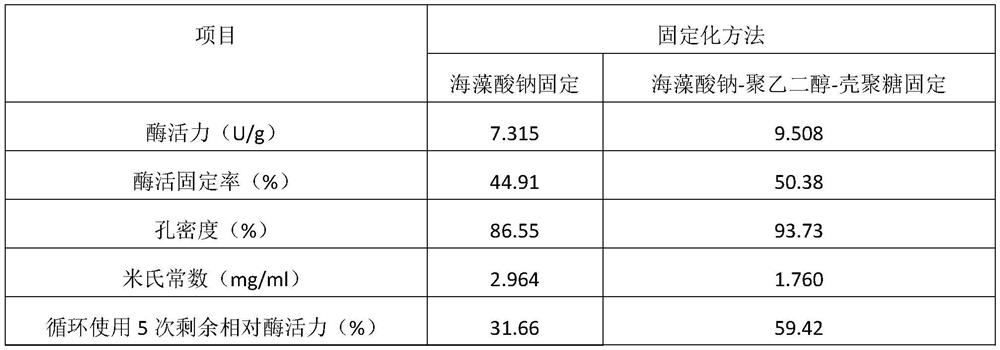

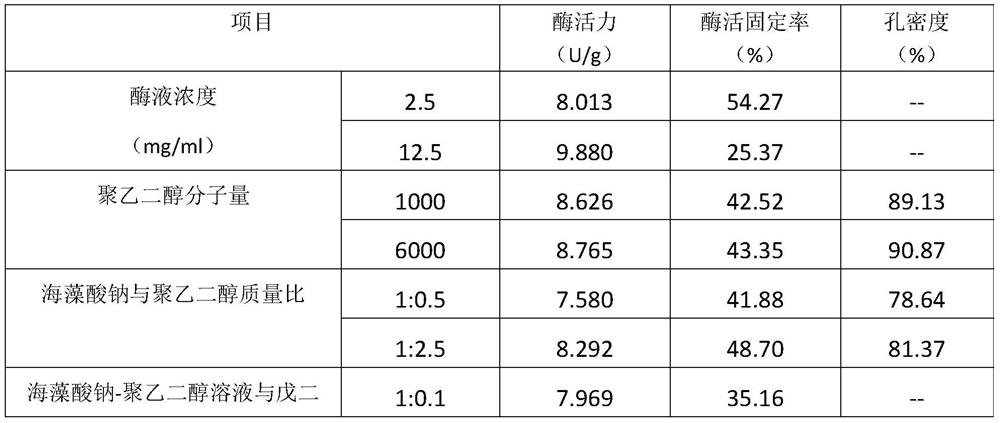

Method for preparing immobilized cellulase and method for hydrolyzing cellulose through immobilized cellulase

PendingCN108004229AImprove enzyme fixation rateImprove recycling effectOn/in organic carrierGlycosylasesIon exchangePolyethylene glycol

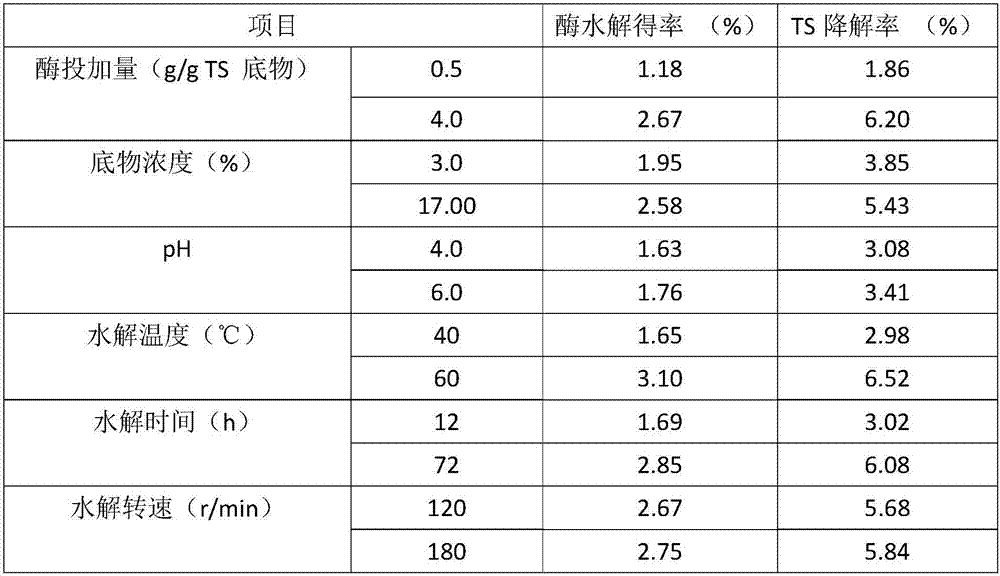

The invention provides a method for preparing immobilized cellulase and a method for hydrolyzing cellulose through the immobilized cellulase. The method for preparing immobilized cellulase is a crosslinked embedding method, sodium alginate serves as a carrier, gel is formed according to the principle that a ion exchange reaction happens between oxygen atoms of OH- and COOH- in sodium alginate andCa2+, glutaraldehyde serves as a crosslinking agent, polyethylene glycol serves as a pore-foaming agent and a hydrophilic agent, and by adding polyethylene glycol, the enzyme activity immobility and enzyme activity of the immobilized cellulase can be improved, the Michaelis constant is reduced, the pore density of the carrier surface is improved, and the reduction sugar content, enzyme hydrolysisyield and TS degradation rate of enzyme hydrolysis reaction are increased. In the process of hydrolyzing cellulose through the immobilized cellulase, the cellulase can be repeatedly used multiple times. The preparing and applying methods are easy to operate, mild in immobilizing conditions, low in investment and friendly to the environment.

Owner:BEIJING UNIV OF CHEM TECH

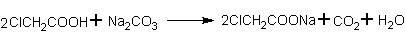

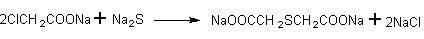

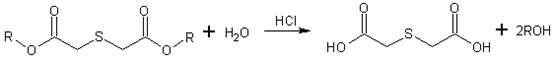

Method for preparing thiodiglycolic acid

InactiveCN102001981AConvenient sourceReduce manufacturing costSulfide preparationAlcoholDiethyl ester

The invention discloses a method for preparing thiodiglycolic acid, which comprises the following steps: adding thiodiglycolic acid dialkyl ester in acidic liquid; heating and refluxing for 1 to 6 hours; recovering a byproduct, namely alcohol, and water; and cooling the residual reaction mixture, crystallizing, filtering and drying and obtaining finished product. The thiodiglycolic acid dialkyl ester may be thiodiglycolic acid dimethyl ester, thiodiglycolic acid diethyl ester, thiodiglycolic acid dipropyl ester or thiodiglycolic acid dibutyl ester. In the method, the process is simple, the reaction yield is high, the product colour and luster and purity are high, extractant is not used, the mother liquid can be recycled, and the environment in an entire preparation process is good. The method has a bright industrial application prospect.

Owner:三门峡奥科化工有限公司

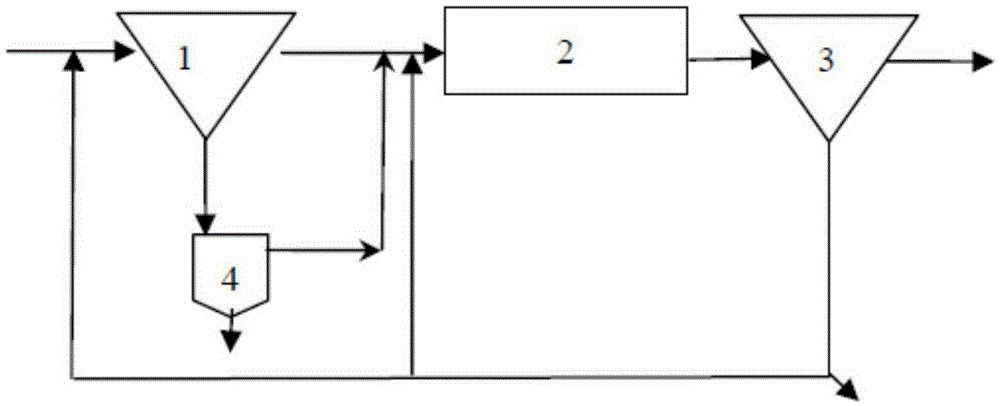

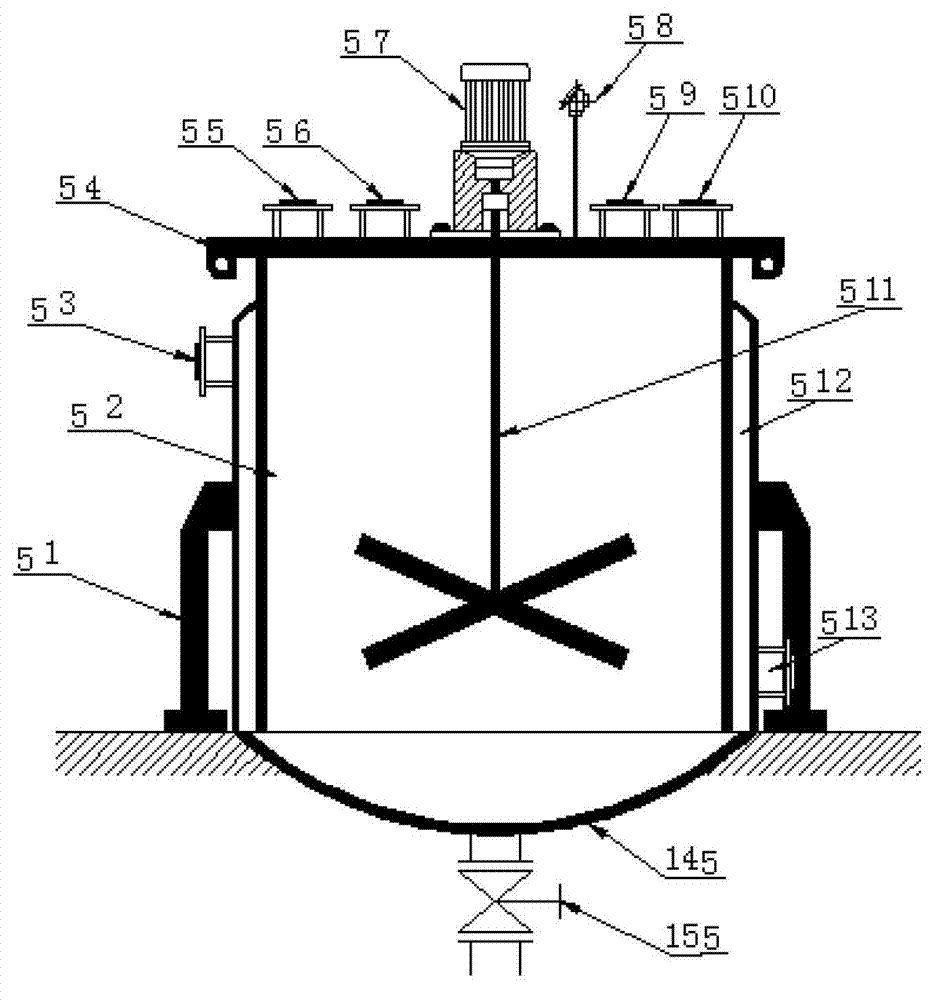

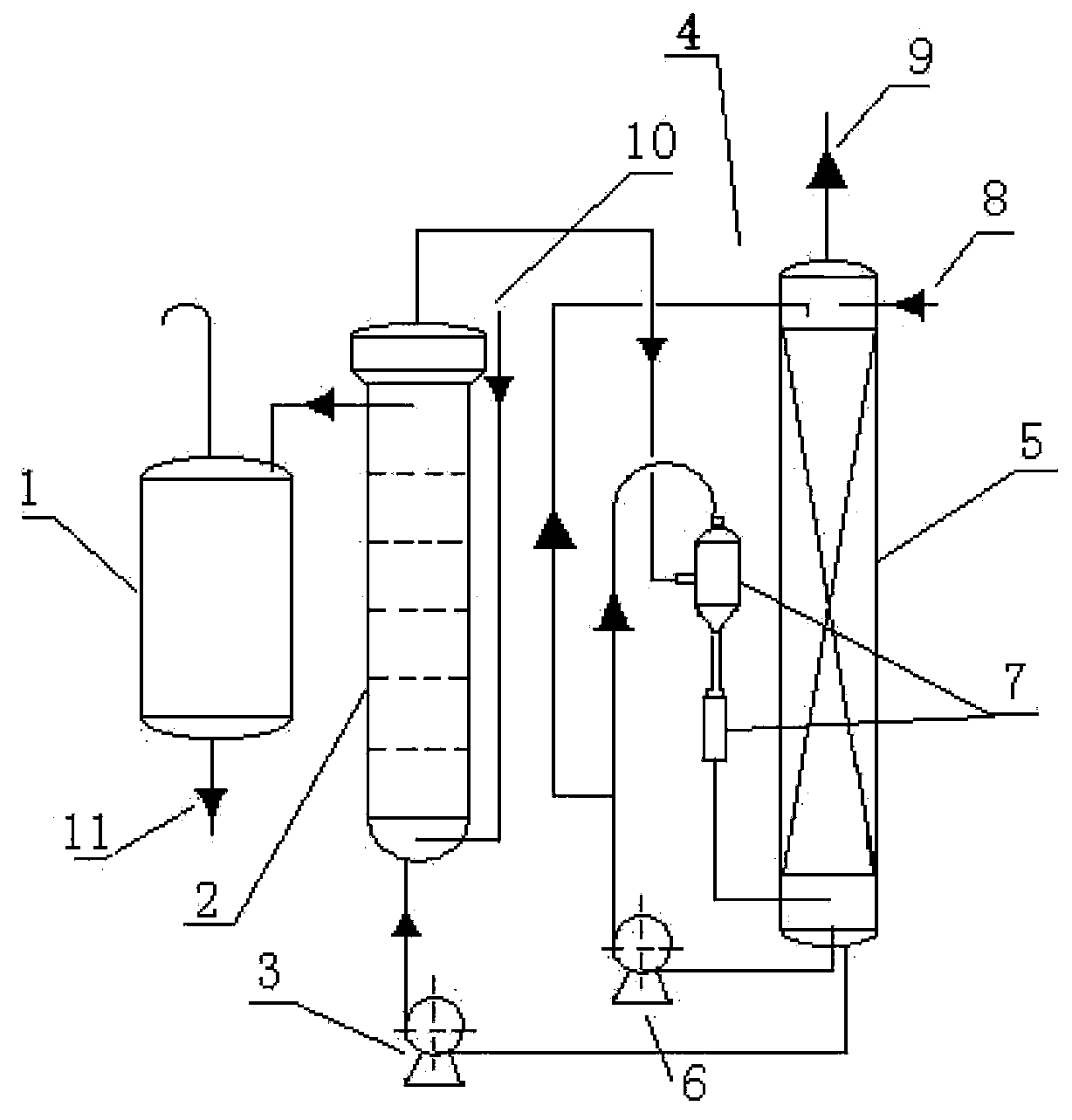

Germanium tetrachloride fully-closed hydrolysis device

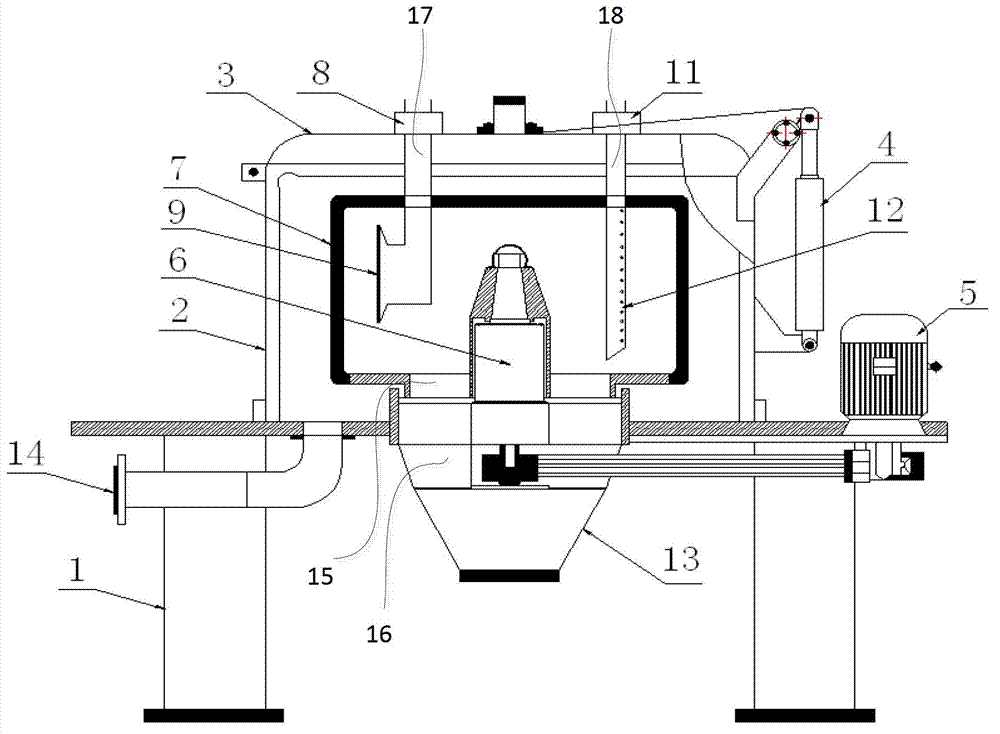

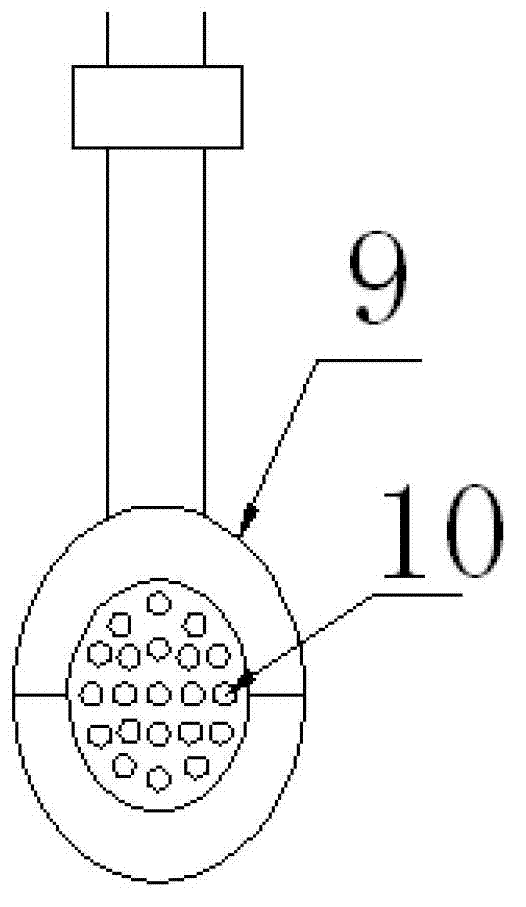

InactiveCN102784611AEnvironmental pressure to overcome corrosionImprove hydrolysis yieldChemical/physical/physico-chemical stationary reactorsFeed devicesDistillationHydrolysate

The invention provides a germanium tetrachloride fully-closed hydrolysis device. According to the embodiment of the invention, the hydrolysis device comprises a kettle body, an upper cover, a first feeding port, a second feeding port, an exhaust port and a discharging port, wherein a hydrolysis reaction space is formed in the kettle body; the upper cover is arranged at the top part of the kettle body; the first feeding port is arranged in the upper cover and is used for supplying germanium tetrachloride distillation fluid for the hydrolysis reaction space; the second feeding port is arranged in the upper cover and is used for supplying ultra-pure water for the hydrolysis reaction space; the exhaust port is arranged in the upper cover and is used for discharging hydrogen chloride gas generated in the hydrolysis reaction from the hydrolysis reaction space; and the discharging port is arranged in the bottom part of the kettle body and is used for discharging a hydrolysate. By utilizing the germanium tetrachloride fully-closed hydrolysis device, the germanium tetrachloride hydrolysis reaction can be carried out under the closed conditions.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Economic and high-efficiency methionine preparation method

ActiveCN109232335AAverage hydrolysis alkali reductionShort reaction timeSulfide preparationSide effectConstant power

The invention provides an economic and high-efficiency methionine preparation method. The economic and high-efficiency methionine preparation method comprises the process of hydrolyzing of hydantoin intermediate, such as 5-(beta-methylthio-ethyl)hydantoin, and comprises the following specific steps of (1) mixing the hydantoin intermediate and a small amount of alkaline, sending into a reactor in phase I, and performing loop-open hydrolyzing reaction under the conditions of constant-power low-frequency ultrasonic wave and certain temperature; (2) continuously treating the liquid material in step (1) in a reactor in phase II, thoroughly hydrolyzing under the conditions of power same with the power in step (1) and higher-frequency ultrasonic wave and lower-temperature atmosphere, so as to obtain a saponification liquid of methionine; acidifying, so as to obtain the methionine. The economic and high-efficiency methionine preparation method has the advantages that the hydrolysis reaction efficiency of the hydantoin intermediate in the preparation process of the methionine is improved, and the reaction time is shortened by one time; the reaction temperature is greatly reduced, the hydrolysis yield rate is increased while the generation of side effect is reduced, and the requirement on the material of the reactor is lower.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

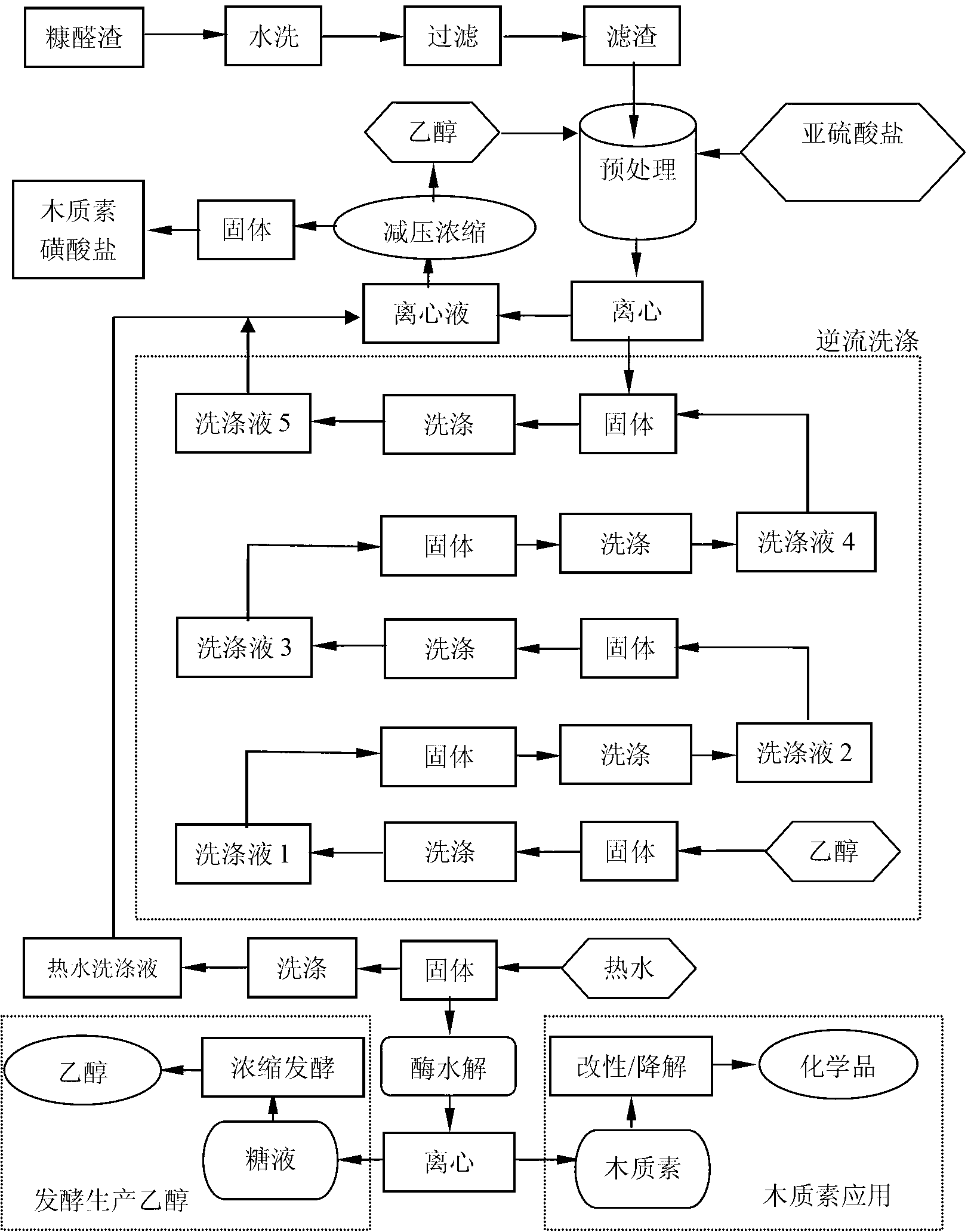

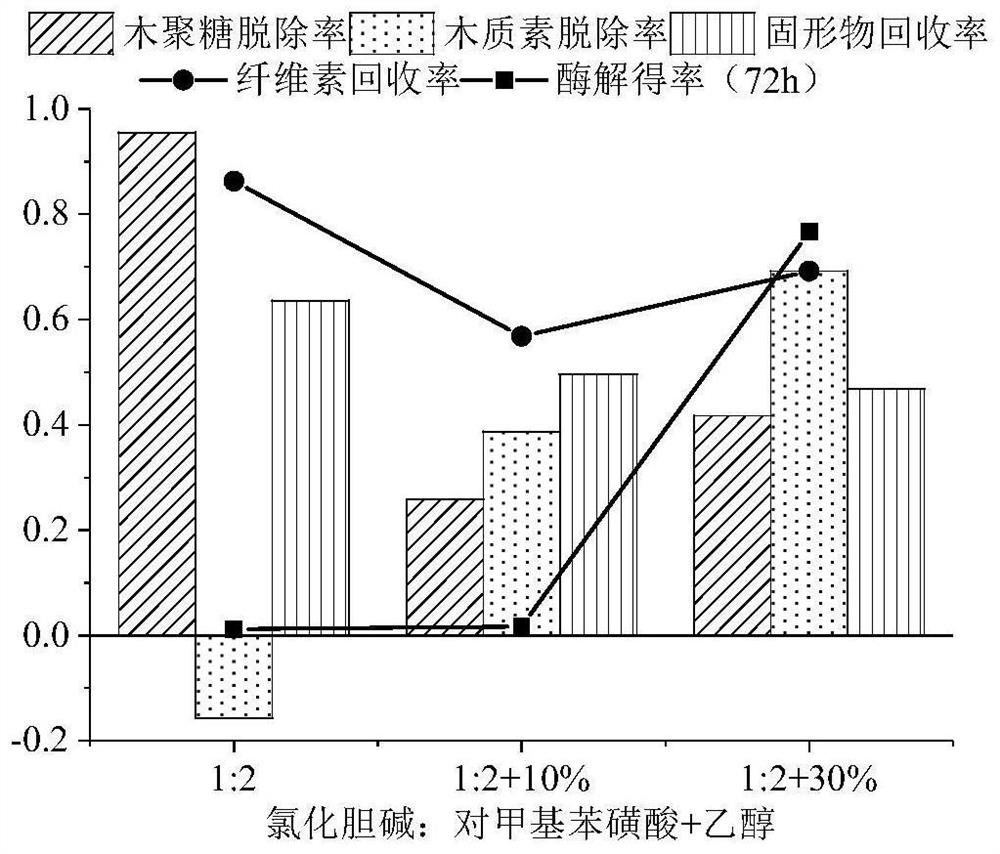

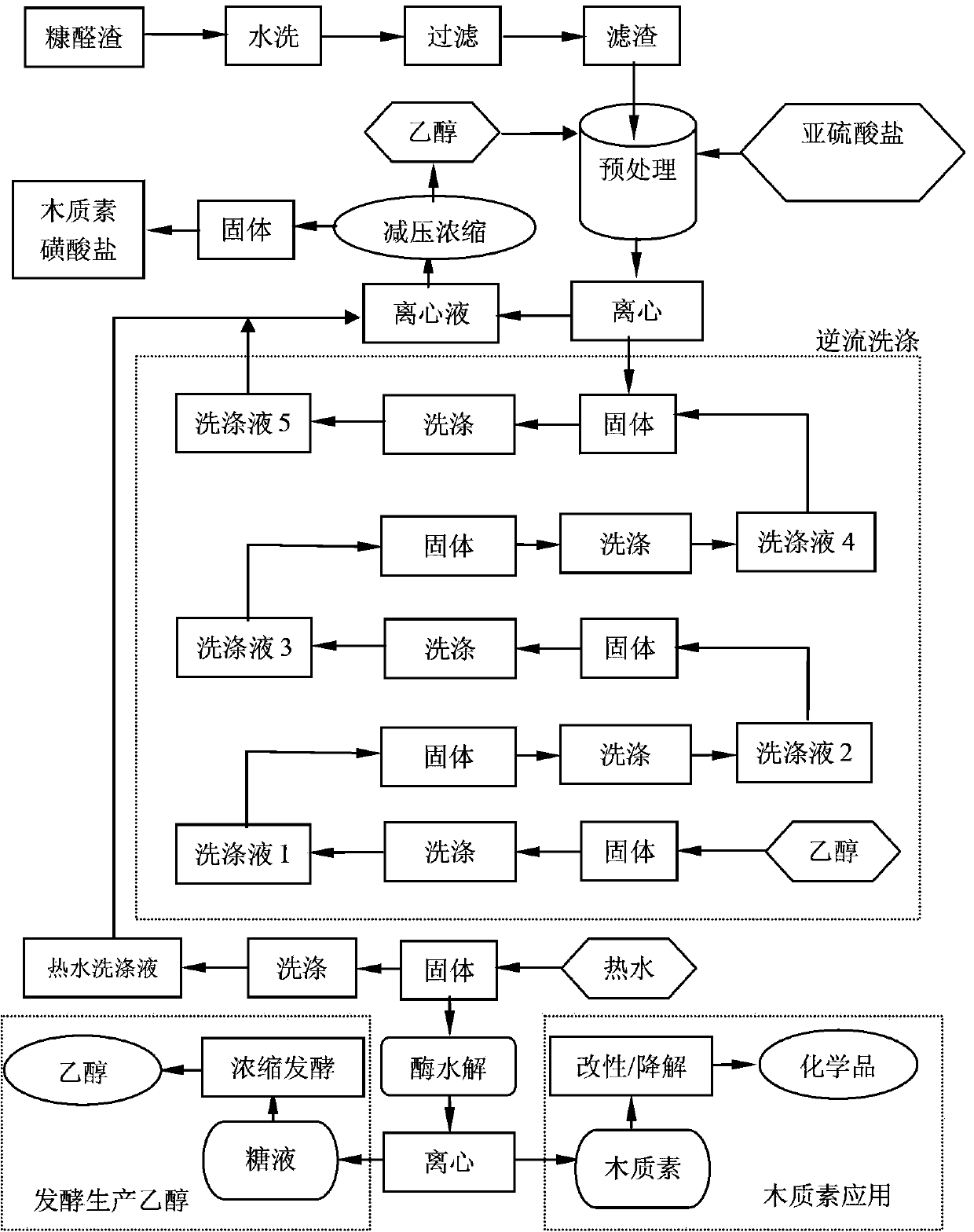

Method for preparing fermentable sugar and lignosulfonate from furfural residues

The invention provides a method for preparing fermentable sugar and lignosulfonate from furfural residues. The method comprises the following steps of 1, ethanol and sulfite-based pretreatment comprising that furfural residues reacts with sulfite in an ethanol solution and reaction products are subjected to solid-liquid separation, 2, countercurrent washing comprising that the solids obtained by the step 1 are subjected to multistage countercurrent washing by an ethanol washing liquid, 3, enzyme hydrolysis comprising that the solids subjected to the multistage countercurrent washing are subjected to cellulase hydrolysis, and 4, ethanol recovery comprising that the liquid obtained by the solid-liquid separation in the step 1 is mixed with the washing liquid recovered after the countercurrent washing in the step 2 and the mixed solution is subjected to pressure reduction condensation to form ethanol and lignosulfonate. The method utilizes combination of an organic solvent method and a sulfite method. Through the sulfite method, furfural residues are pretreated so that furfural residue sample hydrophily is improved and lignin removal and hydrolysis rate increasing are realized. Through the organic solvent method, the raw materials are pre-treated so that pretreatment liquid recovery and recycle are realized and a production cost is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

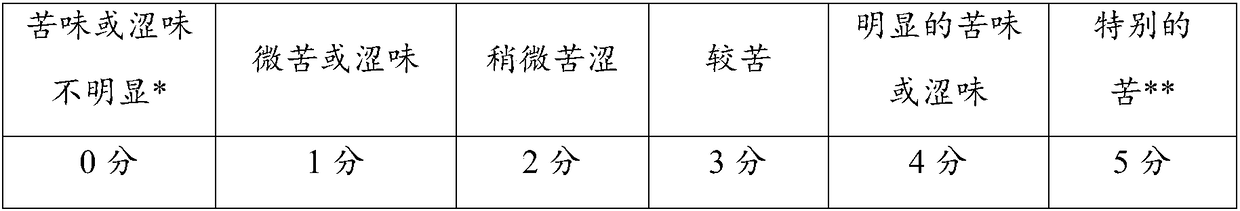

Food-grade wheat protein hydrolase, wheat gluten hydrolysis treatment method and application

The invention provides food-grade wheat protein hydrolase, a wheat gluten hydrolysis treatment method and application and relates to the technical field of wheat hydrolysis. The food-grade wheat protein hydrolase is mainly prepared from the following main raw materials including alkaline proteinase, papain, acidic proteinase, cellulase, a carrier and the like; the wheat protein hydrolase is prepared by scientifically compounding according to a wheat gluten powder structure; wheat gluten powder can be hydrolyzed and wheat gluten powder protein can be decomposed very well; the wheat protein hydrolase has a relatively high protein utilization rate; an enzymolysis product has no bitter and astringent tastes and has a rich flavor and a prominent mouthfeel; the problems that an existing enzymolysis product has a bitter taste and a common mouthfeel are improved; the invention further provides the wheat gluten hydrolysis treatment method; the wheat gluten powder is subjected to hydrolysis treatment by adopting the food-grade wheat protein hydrolase; the treatment method has moderate conditions and low energy consumption; comprehensive enzymolysis of the wheat gluten powder protein can be realized; the obtained enzymolysis product has no bitter and astringent tastes, has the rich flavor and the prominent mouthfeel, and has high content of acid-soluble protein.

Owner:HENAN YANGSHAO BIOCHEM ENG

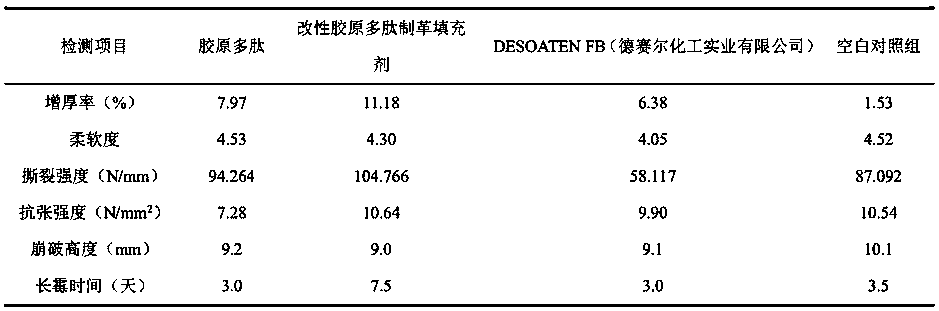

Method for preparing modified collagen polypeptide leather making filler from chrome-free polymetal tanning leather meal

ActiveCN109852742AModerate molecular weightHigh molecular weightTanning treatmentLeather impregnationEconomic benefitsOrganic chemistry

The invention relates to the technical field of leather making chemistry and engineering and provides a method for preparing a modified collagen polypeptide leather making filler from chrome-free polymetal tanning leather meal. According to the method for preparing the modified collagen polypeptide leather making filler from the chrome-free polymetal tanning leather meal, the pollution to environments caused by leather making can be reduced, the problem that leather meal of enterprises is difficult in treatment is solved, meanwhile, resources can be saved, the leather making cost is reduced, and meanwhile, the economic benefit of the enterprises is improved; the modified collagen polypeptide leather making filler prepared by the method is moderate in molecular weight and high in hydrolysisyield and has electropositivity and antibacterial and mildewproof properties; and when the modified collagen polypeptide leather making filler is applied to leather making procedures, an off shade phenomenon of leather can be avoided, the absorption of other anionic materials in the leather making procedures can be promoted, and the leather is endowed with mildew resistance.

Owner:宏兴汽车皮革(福建)发展有限公司

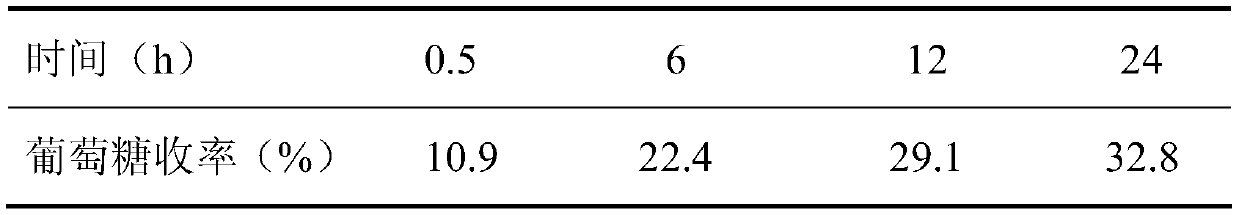

Pre-processing method for strengthening corncob and corncob residue efficient enzymatic hydrolysis

InactiveCN107893093AImprove the conversion rate of hydrolysisReduce loadBiofuelsFermentationPretreatment methodEnzymatic hydrolysis

The invention discloses a pre-processing method for strengthening corncob and corncob residue efficient enzymatic hydrolysis. The pre-processing method comprises the following steps: (1) preparing slurry; (2) conducting mechanical pre-processing; and (3) conducting enzymatic hydrolysis, so as to obtain a hydrolysate, so that the corncob and corncob residue efficient enzymatic hydrolysis is strengthened. The pre-processing method provided by the invention, by processing corncobs and corncob residues by virtue of a mechanical pre-processing way, can reduce physical dimensions of raw materials, reduce a degree of crystallinity and improve the specific surface area and swelling performance of the raw materials, and subsequently, the efficiency of enzymatic hydrolysis is improved, and a relatively high glucose concentration and relatively high glucose conversion rate are finally guaranteed; with the application of the method, high-value utilization of the corncobs and the corncob residues can be achieved, and meanwhile, input cost of the enzymatic hydrolysis is reduced, the efficiency of the enzymatic hydrolysis is improved and a raw material foundation is provided for subsequent processing and utilization or for production of high-value-added products; therefore, the application field and scope of the corncobs and the corncob residues are expanded.

Owner:TIANJIN UNIV OF SCI & TECH

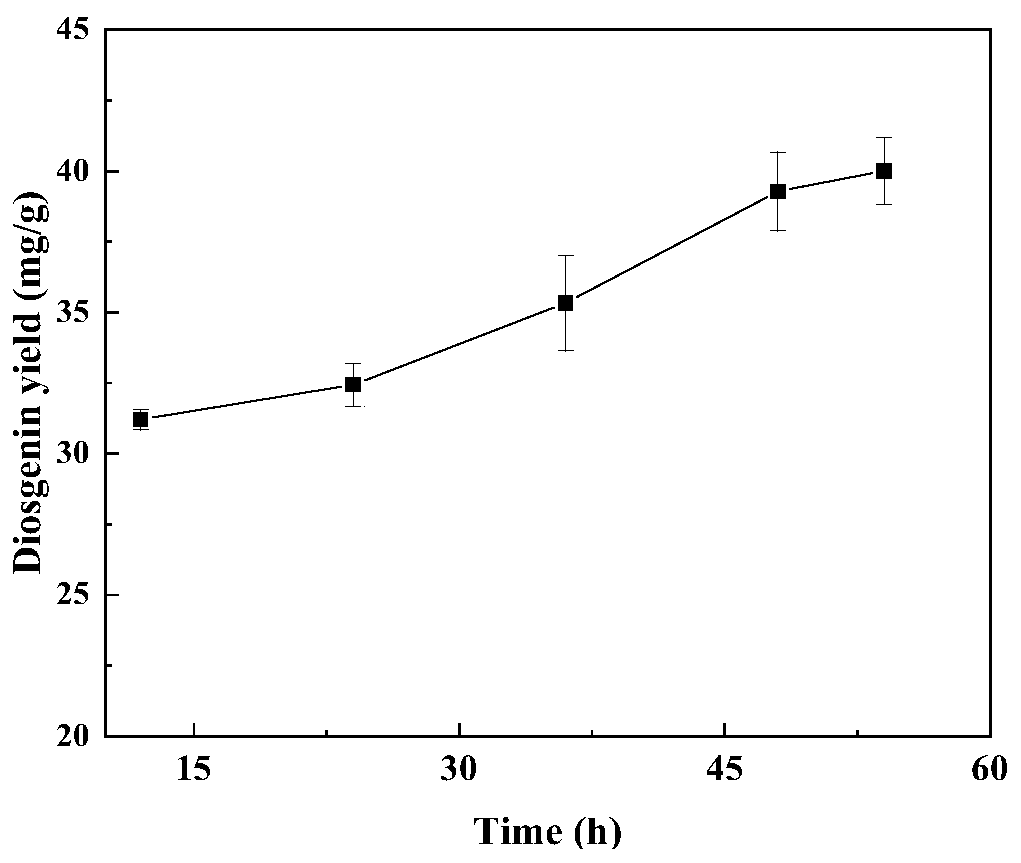

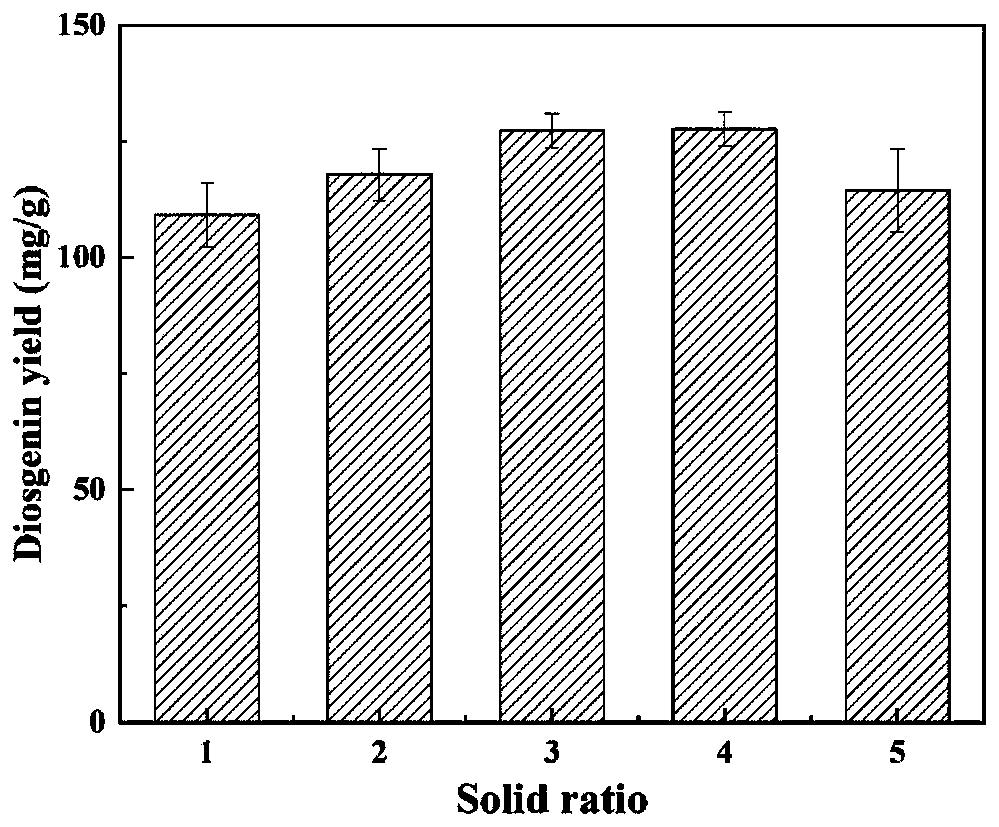

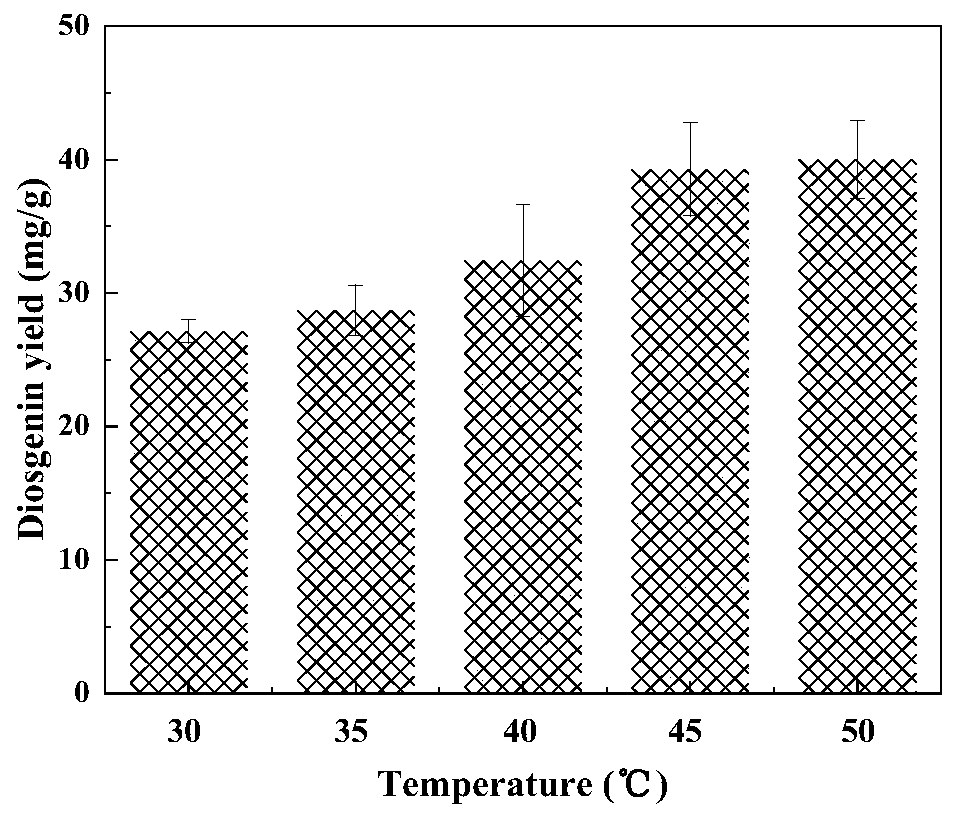

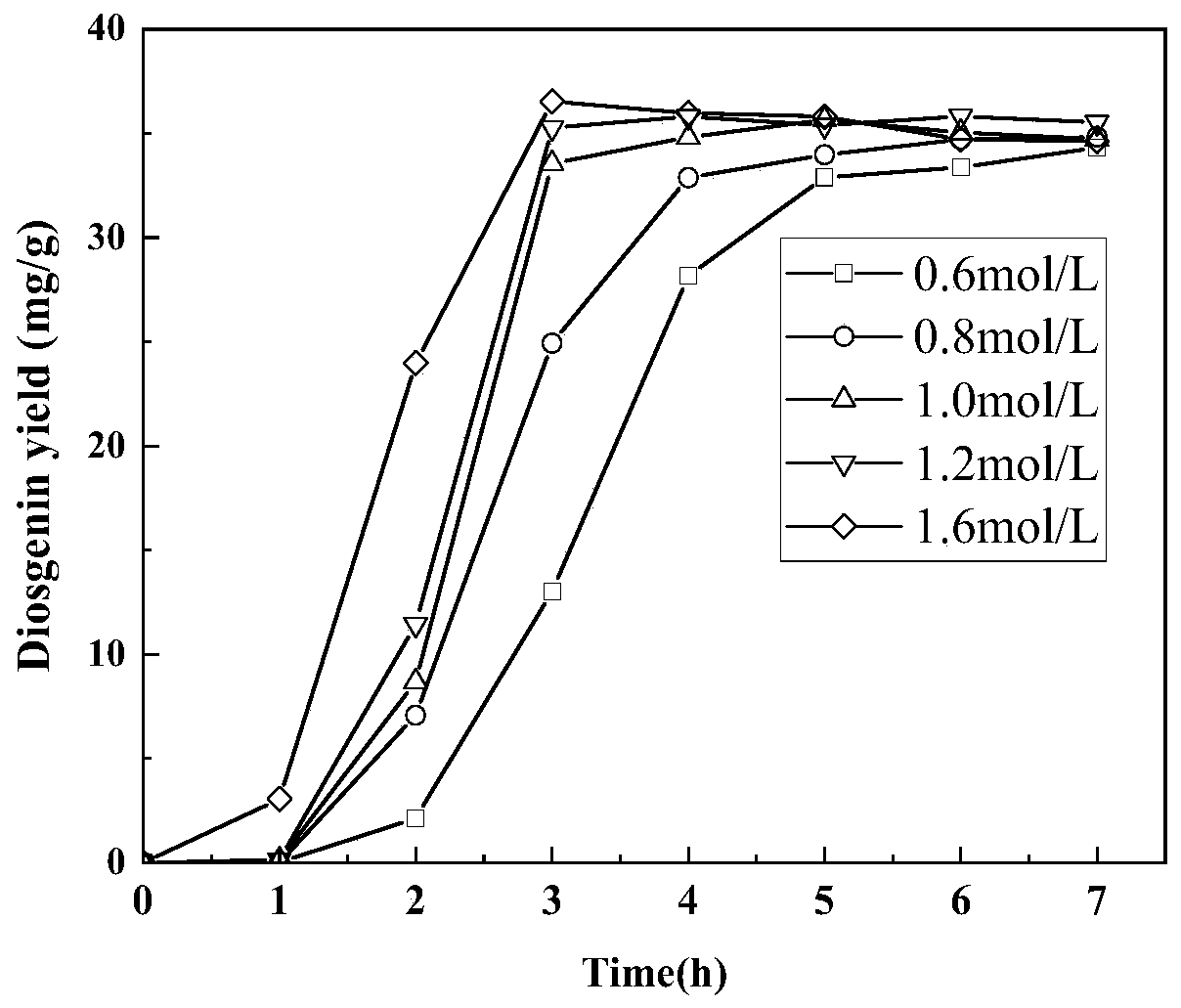

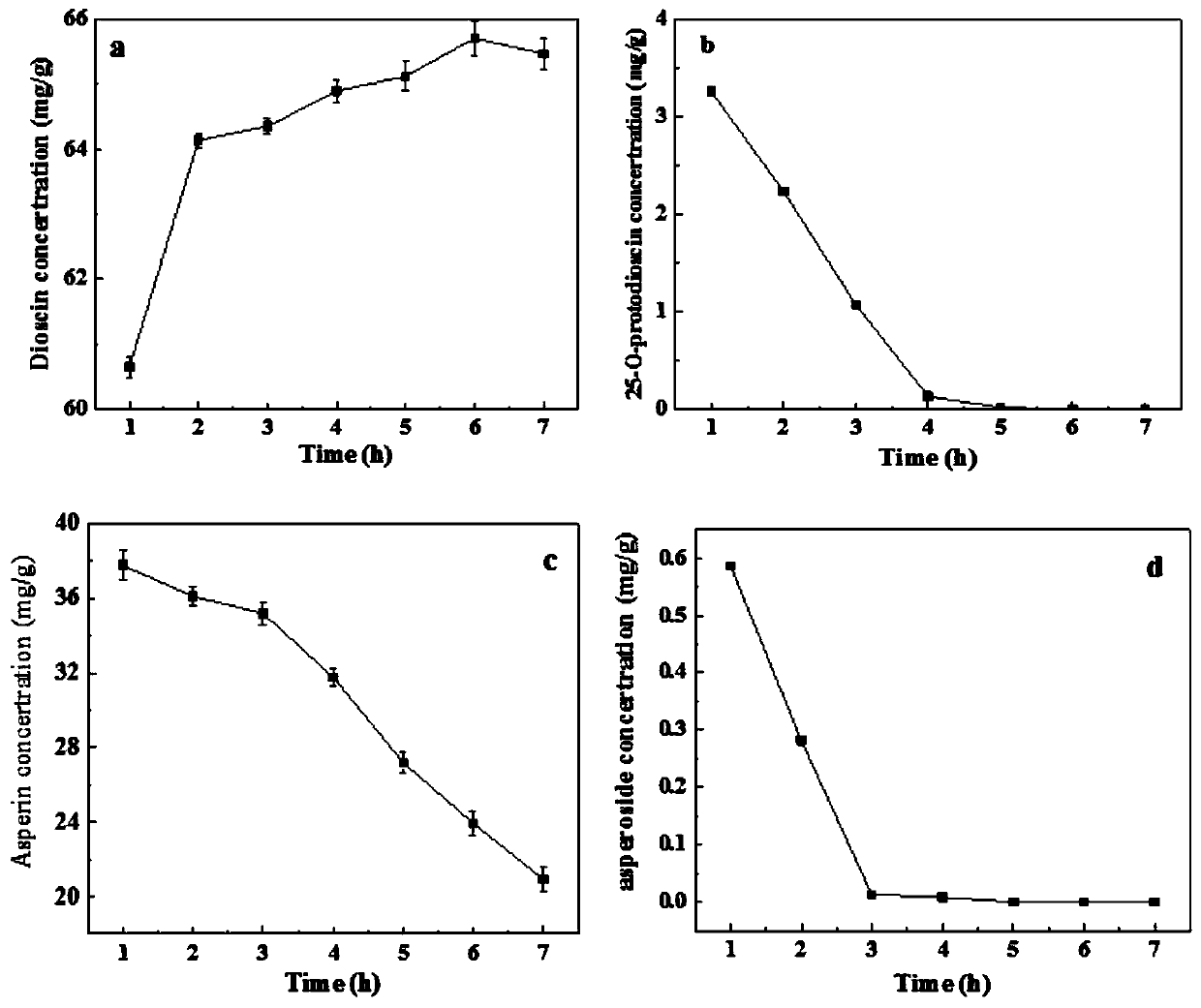

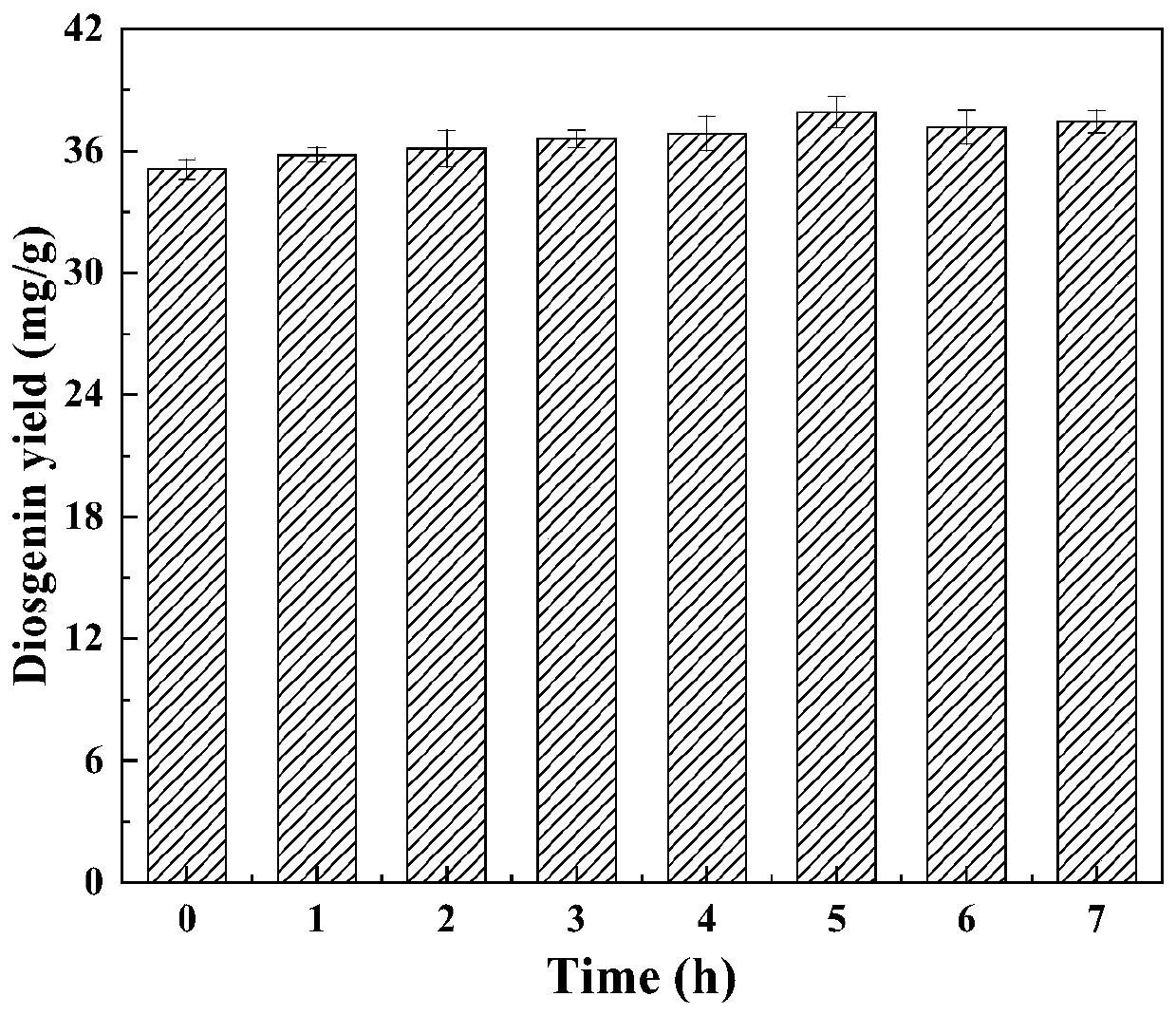

Method for increasing saponin yield of chrysanthemum leaf yams through natural fermentation

The invention discloses a method for increasing saponin yield of chrysanthemum leaf yams through natural fermentation. The method comprises the steps of performing natural fermentation on chrysanthemum leaf yams, and then performing acid hydrolysis; after an acid hydrolysis reaction is completed, performing cooling to room temperature, and then performing neutralization, filtration and drying so as to obtain hydrolysate; and performing extraction on the hydrolysate with petroleum ether to obtain diosgenin. According to the method disclosed by the invention, the chrysanthemum leaf yams are subjected to natural fermentation and acid hydrolysis, so that compared with the yield of the saponin obtained in a manner of directly performing hydrolysis on the diosgenin, the yield of the saponin obtained by the method is increased by 10%, and the hydrolysis yield and the production rate of the diosgenin are greatly increased. The preparation method disclosed by the invention has good applicationprospects and is worth wide popularization.

Owner:SOUTH CHINA AGRI UNIV

Method for improving enzymatic saccharification effect by xylose residue pretreatment

PendingCN110734942AImprove accessibilityHigh porosityClimate change adaptationBioloigcal waste fertilisersHydrolysateConcentrations glucose

The invention discloses a method for improving an enzymatic saccharification effect by xylose residue pretreatment. The method comprises the following steps: weighing xylose residues, adding deep eutectic solvent (DES) to carry out pretreatment, and carrying out solid-liquid separation on the pretreated xylose residues after the reaction is finished; adding KOH solution into the separated solid for pretreatment, carrying out solid-liquid separation after the reaction is finished, and separately collecting solid and liquid parts; and washing the solid part to be neutral, thereby obtaining pretreated xylose residues, carrying out enzymatic saccharification, and determining the glucose concentration in the enzymatic hydrolysate. According to the invention, the method for clean and highly-efficient pretreatment of the xylose residues can solve a problem of low cellulose hydrolysis efficiency, thereby reducing the use level of the cellulose and improving the conversion efficiency of reducing sugar, thus providing a certain theoretical basis for the comprehensive utilization of the xylose residues.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method capable of producing fermentable sugars from corncob residues by efficient enzymatic hydrolysis

InactiveCN108179159ABroaden the field of applicationExpand scopeFermentationFiberEnzymatic hydrolysis

The invention discloses a method capable of producing fermentable sugars from corncob residues by efficient enzymatic hydrolysis. The method comprises the following steps: (1) preparing raw materials;(2) performing pretreatment with a chemical method; (3) collecting reacted corncob residues, repeatedly washing the corncob residues multiple times until the corncob residues are neutral to obtain washed corncob residues; (4) performing enzymatic hydrolysis to obtain a hydrolysate for completion of production of the fermentable sugars from the corncob residues by efficient enzymatic hydrolysis. According to the method, the corncob residues are treated with a chemical pretreatment technique, hydrophilic performance of lignin in fiber raw materials is improved, the lignin is dissolved out easily, and accordingly, enzymatic hydrolysis yield of the corncob residues is increased; the corncob residues can be used in a higher-value manner with the method, investing cost for enzymatic hydrolysisis reduced, enzymatic hydrolysis efficiency is increased, raw material basis is provided for follow-up processing and utilization or production of products with high added value, so that application field and range of the corncob residues are expanded, and use quantity of wood fiber raw materials can be reduced effectively.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

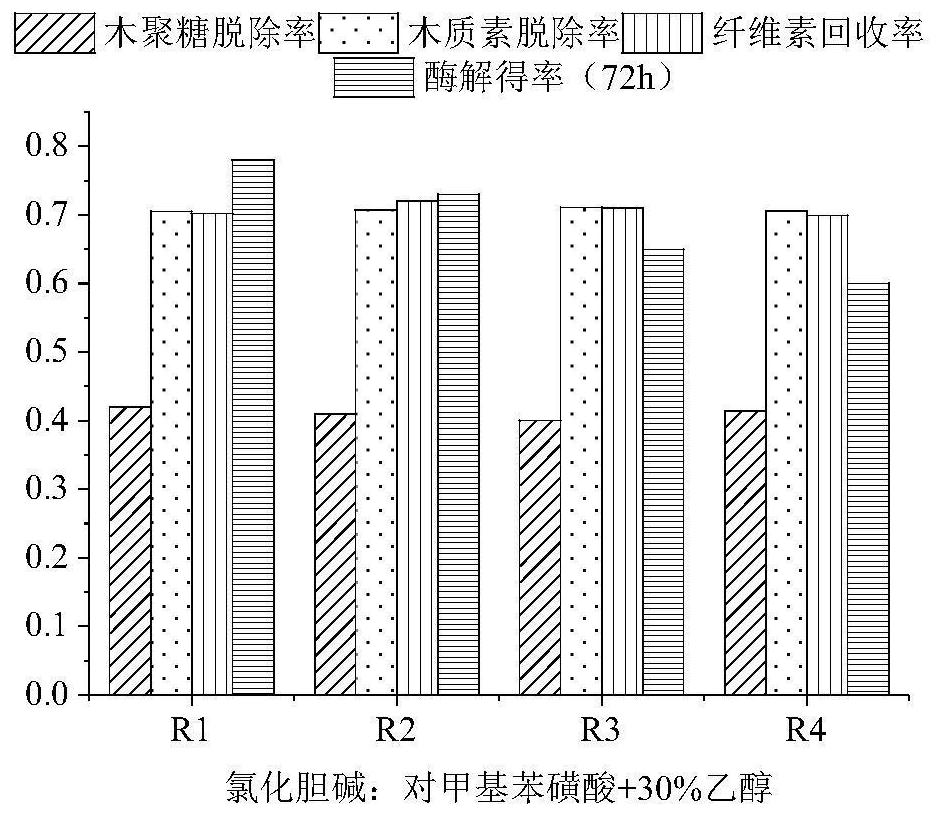

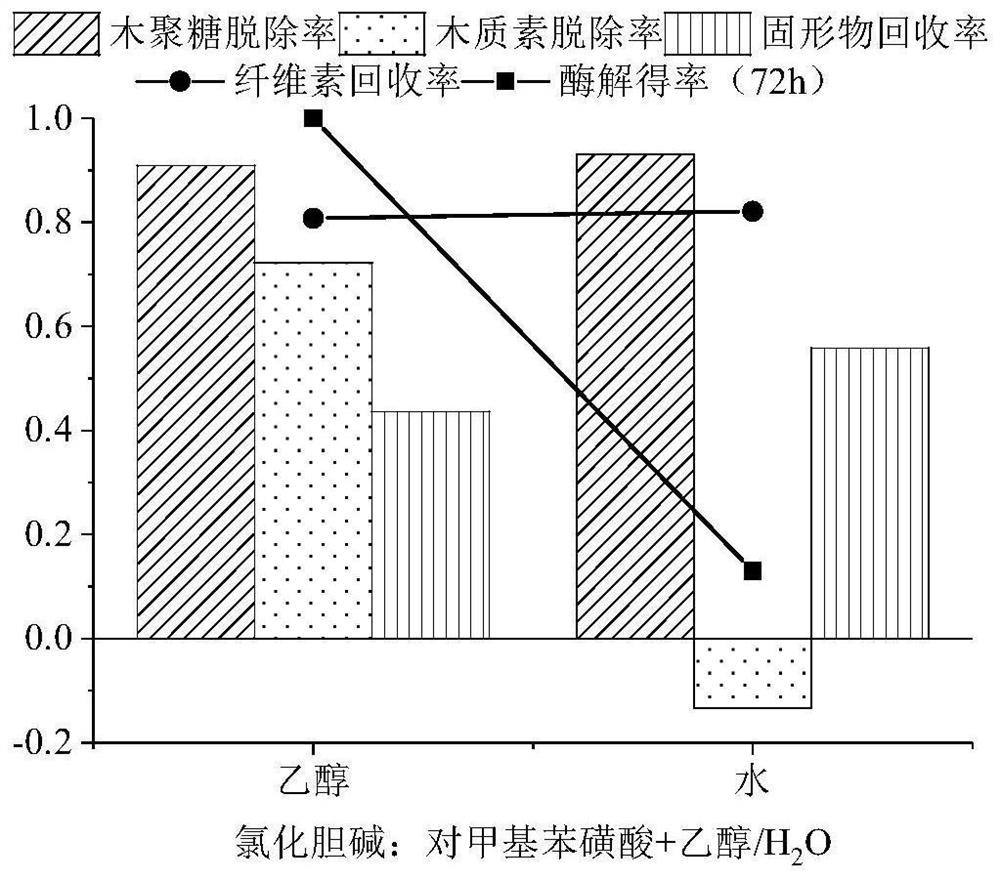

A kind of pretreatment method of lignocellulose raw material

Owner:NANJING FORESTRY UNIV

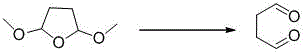

Hydrolyst, preparation method thereof and method for preparing butanedial

InactiveCN105457684AIncrease layer spacingIncrease the areaOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsButanedialO-Phosphoric Acid

The invention belongs to the technical field of catalysis, and discloses hydrolyst. According to the hydrolyst, a clay interlayer structure doped with polyvalent metal ions serves as the framework, the framework is loaded with SO42-, and the clay interlayer structure contains quaternary ammonium salt. The invention further discloses a preparation method of the hydrolyst, and a method for preparing butanedial through the hydrolyst. The hydrolyst is solid superacid with clay loaded with SO42-, is high in catalytic efficiency and can remarkably improve the hydrolytic yield of butanedial and shorten reaction time, the hydrolytic activity of 2,5-dimethoxy tetraoxyfuran is better than that of commonly-used hydrochloric acid, sulfuric acid and the like, the hydrolyst is quite easy to recycle, the hydrolytic reaction conditions are mild, production cost is low, and the hydrolyst is more green and environmentally friendly, can replace high-pollution and high-danger liquid acid catalysts such as commonly-used hydrochloric acid, sulfuric acid and phosphoric acid, and is quite wide in application prospects and potential.

Owner:ZHONGSHAN POLYTECHNIC

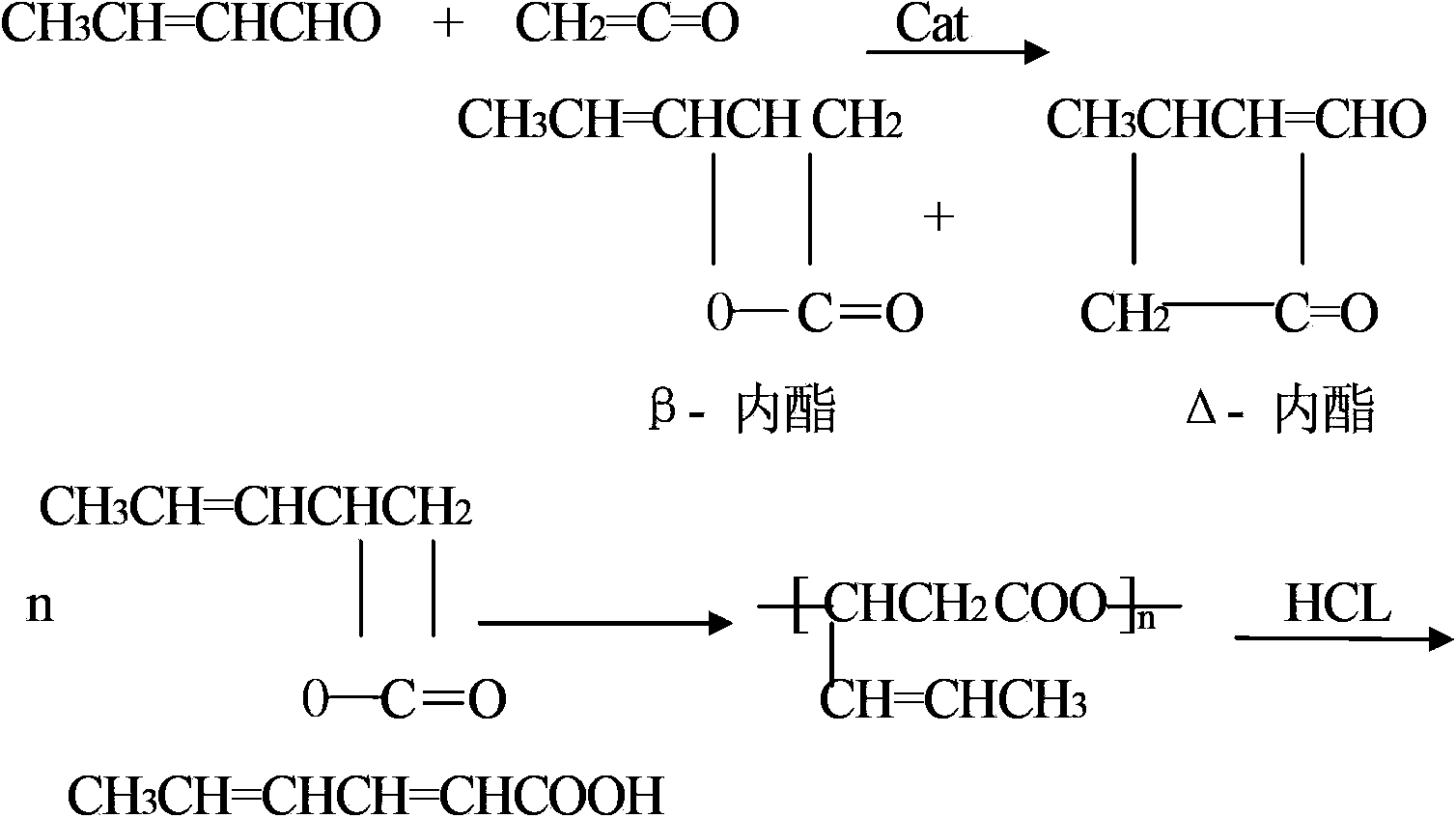

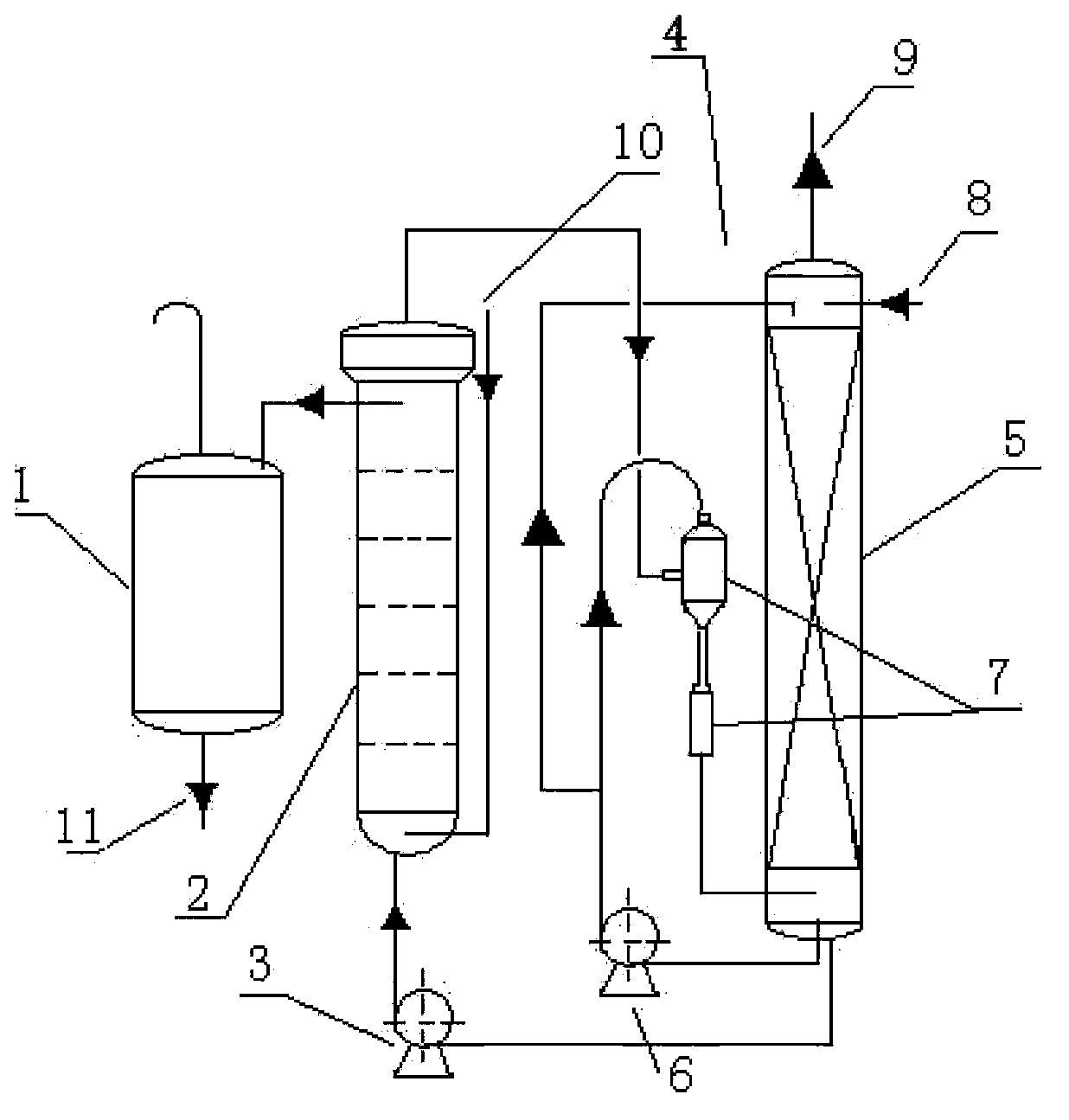

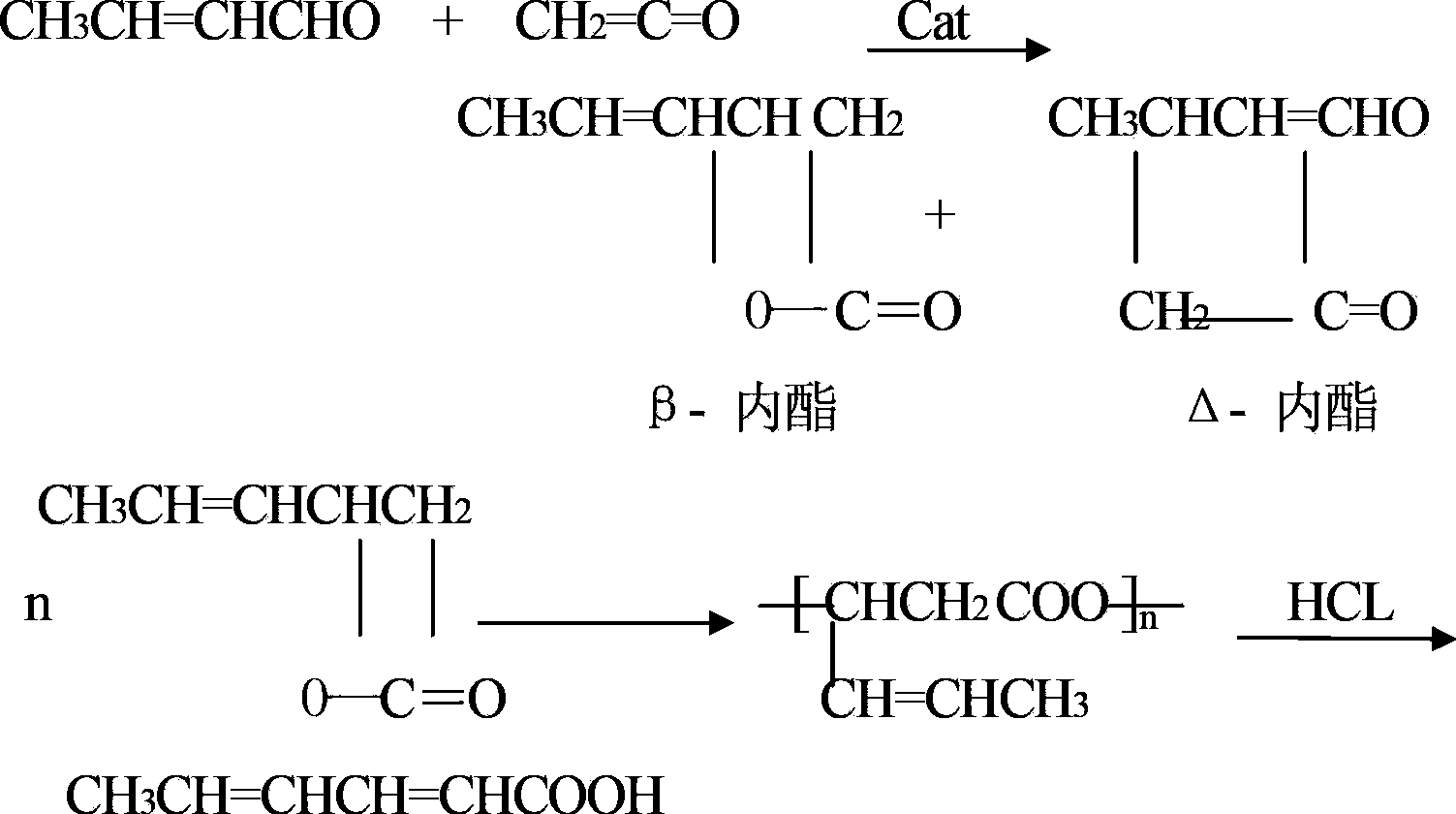

Reaction device for continuous bubble tower absorption of polysorbate

ActiveCN103446967BImprove hydrolysis yieldAvoid generatingDispersed particle separationPreparation from carboxylic acid esters/lactonesHigh concentrationPolyester

The invention provides a reaction device for continuous bubble tower absorption of polysorbate. The device comprises a polyester groove (1) for receiving qualified polysorbate, a bubble packed tower (2) for a downstream absorption reaction, and a first circulating pump (3) which is connected to the bottom of the bubble packed tower (2); the reaction device is characterized by further comprising a secondary spray absorbing packed tower combination device (4) for keeping the bubble packed tower (2) under negative pressure. Through the reaction device, a polymerization reaction between butenal and ketene is continuously performed and finished in the downstream bubble packed tower (2) under micro-negative pressure, to realize continuous reaction between high-concentration butenal and high-concentration ketene within relatively short time, so as to avoid generation of more tar, guarantee safe and stable production, improve polymerization efficiency, polyester quality and polyester hydrolysis yield, and reduce production cost; the reaction device has good reaction prospect.

Owner:NANTONG ACETIC ACID CHEM

Method for improving saponin yield by low-acid pretreatment of dioscorea composita

The invention discloses a method for improving saponin yield by low-acid pretreatment of dioscorea composita. The method comprises the steps of pretreating dioscorea composita with low-concentration sulfuric acid, carrying out solid-liquid separation, and hydrolyzing diosgenin in a solid phase part. The problems of long pretreatment period of natural fermentation and potential risk of generating impurities are avoided; meanwhile, in a process of direct hydrolysis of the diosgenin, because starch and lignocellulose are hydrolyzed and further dehydrated, the content of organic matters in the hydrolyzed waste acid water is sharply increased, and serious environmental pollution problems are caused; and in addition, the hydrolysis yield of the diosgenin is obviously improved. The method has obvious advantages and good popularization and application values.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing fermentable sugar and lignosulfonate from furfural residues

The invention provides a method for preparing fermentable sugar and lignosulfonate from furfural residues. The method comprises the following steps of 1, ethanol and sulfite-based pretreatment comprising that furfural residues reacts with sulfite in an ethanol solution and reaction products are subjected to solid-liquid separation, 2, countercurrent washing comprising that the solids obtained by the step 1 are subjected to multistage countercurrent washing by an ethanol washing liquid, 3, enzyme hydrolysis comprising that the solids subjected to the multistage countercurrent washing are subjected to cellulase hydrolysis, and 4, ethanol recovery comprising that the liquid obtained by the solid-liquid separation in the step 1 is mixed with the washing liquid recovered after the countercurrent washing in the step 2 and the mixed solution is subjected to pressure reduction condensation to form ethanol and lignosulfonate. The method utilizes combination of an organic solvent method and a sulfite method. Through the sulfite method, furfural residues are pretreated so that furfural residue sample hydrophily is improved and lignin removal and hydrolysis rate increasing are realized. Through the organic solvent method, the raw materials are pre-treated so that pretreatment liquid recovery and recycle are realized and a production cost is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

Foaming agent of waterproof foam concrete, and preparation method

InactiveCN101698581BFormula refiningImprove stabilityBuild-up roofsBuilding insulationsFoam concreteDodecane

Owner:廖传海

A kind of application method of modified collagen polypeptide leather filler

ActiveCN109852742BModerate molecular weightHigh molecular weightTanning treatmentLeather impregnationEconomic benefitsPulp and paper industry

Owner:宏兴汽车皮革(福建)发展有限公司

A method for immobilizing cellulase and hydrolyzing cellulose

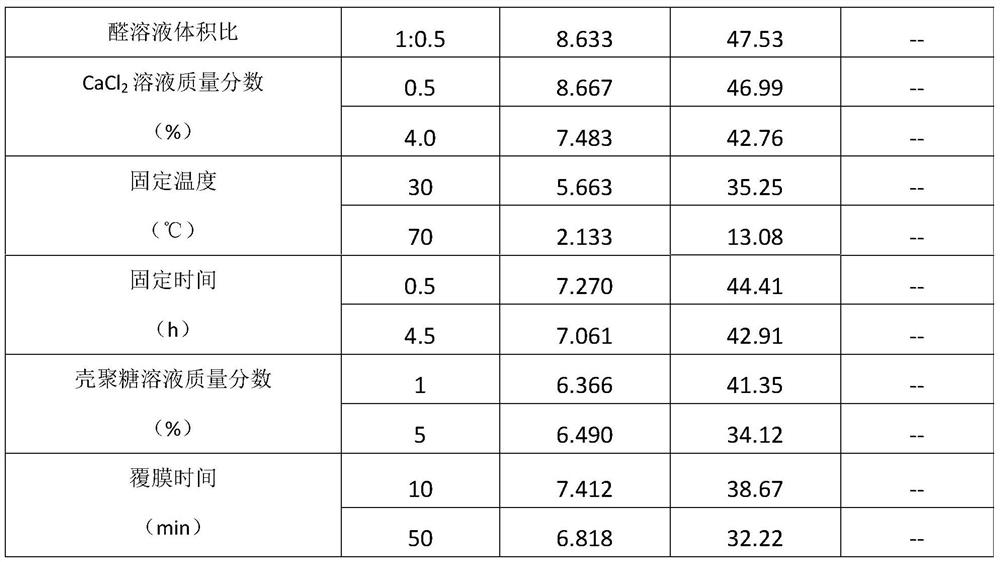

ActiveCN107893062BHigh activityEasy to fixNucleic acid reductionOn/in organic carrierPolyelectrolyteEnzymatic hydrolysis

The invention provides a method for immobilizing cellulase and hydrolyzing cellulose. The method for preparing immobilized cellulase uses sodium alginate as a carrier, and utilizes OH in sodium alginate ‑ and COOH ‑ Oxygen atom and Ca 2+ The principle of ion exchange reaction forms a gel, polyethylene glycol is used as a porogen and a hydrophilic agent, glutaraldehyde is used as a crosslinking agent, and the gel is formed between chitosan and sodium alginate-polyethylene glycol immobilized enzyme The polyelectrolyte membrane improves the stability of the immobilized enzyme. Using immobilized cellulase to hydrolyze cellulose can realize the repeated utilization of cellulase. Adding polyethylene glycol and chitosan can improve the enzyme fixation rate and enzyme activity of immobilized cellulase, reduce the Michaelis constant, increase the pore density of the carrier surface, increase the reducing sugar content of the enzymatic hydrolysis reaction, the enzymatic hydrolysis yield and TS degradation rate. The preparation and application method of the invention is simple and convenient to operate, mild in fixing conditions, low in investment and friendly to the environment.

Owner:BEIJING UNIV OF CHEM TECH

Production method for continuous bubble tower absorption of polysorbate

ActiveCN103446968AAchieve serializationAvoid generatingPressurized chemical processChemical/physical/physico-chemical processesPolyesterPtru catalyst

Owner:NANTONG ACETIC ACID CHEM

A method for improving the efficiency of cellulose enzymatic hydrolysis of rice straw by using lactic acid and guanidine hydrochloride

InactiveCN106480128BImprove enzymatic hydrolysis efficiencyHigh yieldFermentationBiotechnologyEnzymatic hydrolysis

The invention belongs to the fields of lignocellulose utilization and energy and chemical application, and discloses a green method for increasing a cellulose enzymolysis efficiency in rice straws by utilizing lactic acid / guanidine hydrochloride to extract hemicellulose. The green method includes: taking the lactic acid / the guanidine hydrochloride as a solvent to preprocessing the rice straws, filtering and separating to obtain residues, and drying to obtain preprocessed rice straws; taking the rice straw residues as a base material, and subjecting the base material to enzymolysis by cellulose so as to obtain a liquid sugar which mainly comprises glucose. The green method has the advantages that the enzymolysis efficiency of the rice straws can be increased effectively, a yield rate of fermentable reducing sugar is increased, and the defects of high cost and environmental unfriendliness of an ionic liquid preprocessing process are overcome.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com