Application of ionic liquid to preparation of reducing sugar by cellulose hydrolysis

A technology of ionic liquid and acidic ionic liquid, which is applied in the field of hydrolyzing cellulose, can solve the problems of inconvenient operation, high viscosity, and increased cost, and achieve the effects of convenient operation, fast reaction speed, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

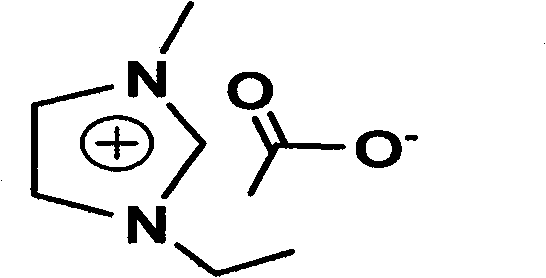

[0021] Add 15 grams of 1-ethyl-3-methylimidazole acetate into a round bottom flask, heat to 140°C, slowly add 0.6 grams of straw under vigorous stirring, stir until the straw is dissolved, and put 0.11 grams of Fe-containing 3+ aqueous solution (C (Fe3+) =0.025mol / L) and 0.6 gram of 1-methyl-3-(4-sulfonic acid butyl) imidazole bisulfate add reaction system, get a certain amount of reaction solution at regular intervals, quench the reaction with cold water, The pH of the reaction solution was adjusted to 7.0 with 0.5 mol / L NaOH, the supernatant was taken after centrifugation, and the total reducing sugar content was determined by DNS method. According to this method, the reaction time was 4h, and the yield of reducing sugar was 85%.

Embodiment 2~4

[0023] Other process conditions and experimental steps are the same as in Example 1, but using straws of different qualities and the mass of the catalyst being 150% of the mass of the corresponding straws, samples were taken at different times to measure reducing sugars, and the hydrolysis results are shown in Table 2. It proves that under the condition that the straw can be fully dissolved, its dissolved amount has basically no effect on the hydrolysis result.

[0024] Table 1 Effect of the amount of straw dissolved in ionic liquid on the hydrolysis results

[0025] project

Embodiment 5

[0027] Add 15 grams of 1-ethyl-3-methylimidazole acetate into a round bottom flask, heat to 140°C, slowly add 0.6 grams of straw under vigorous stirring, stir until the straw is dissolved, and put 0.11 grams of Fe-containing 3+ aqueous solution (C (Fe3+) =0.025mol / L) and 1.2 grams of 1-methyl-3-(4-sulfonic acid butyl) imidazolium bisulfate were added to the reaction system, and a certain amount of reaction solution was taken at regular intervals, and the reaction was quenched with cold water. The pH of the reaction solution was adjusted to 7.0 with 0.5 mol / L NaOH, the supernatant was taken after centrifugation, and the total reducing sugar content was determined by DNS method. According to this method, the reaction time was 3h, and the yield of reducing sugar was 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com