Patents

Literature

42 results about "Methionine preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methionine recovery processes

InactiveUS20050089975A1Promote recoveryReduce solubilityBiocideOrganic active ingredientsSolubilityMethionine recycling

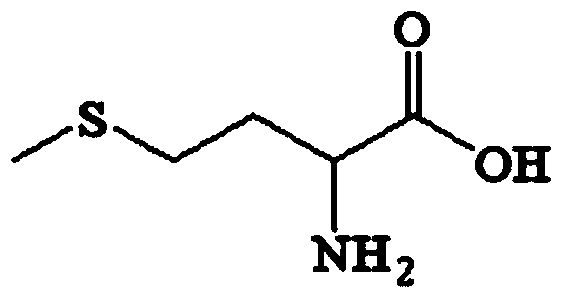

The present invention relates to a method of making a methionine preparation, for example for an animal feed additive. The invention also related to methods for increasing the solubility of a methionine preparation.

Owner:NOVUS INTERNATIONAL INC

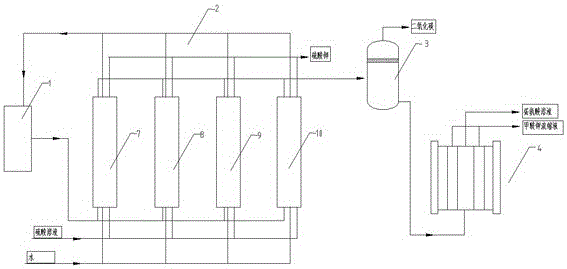

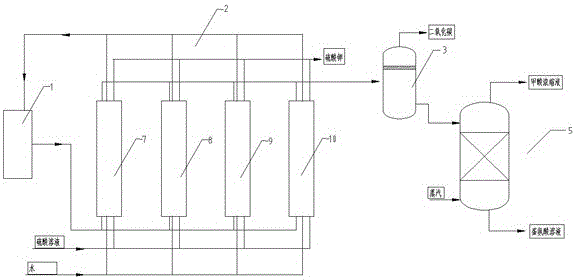

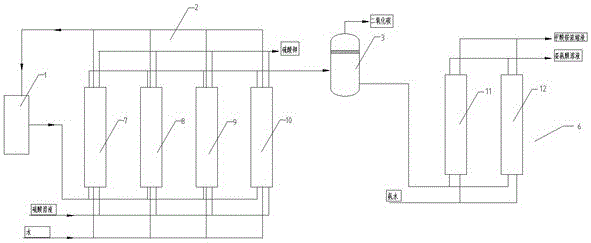

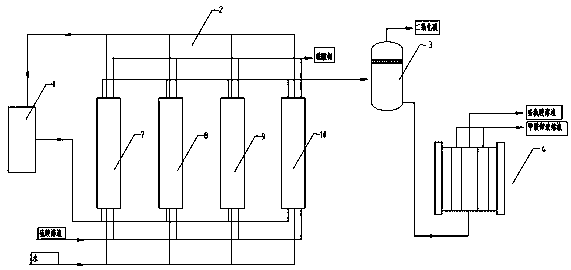

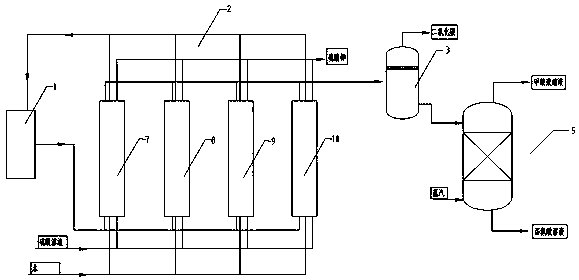

Post-treatment method and device for methionine preparation

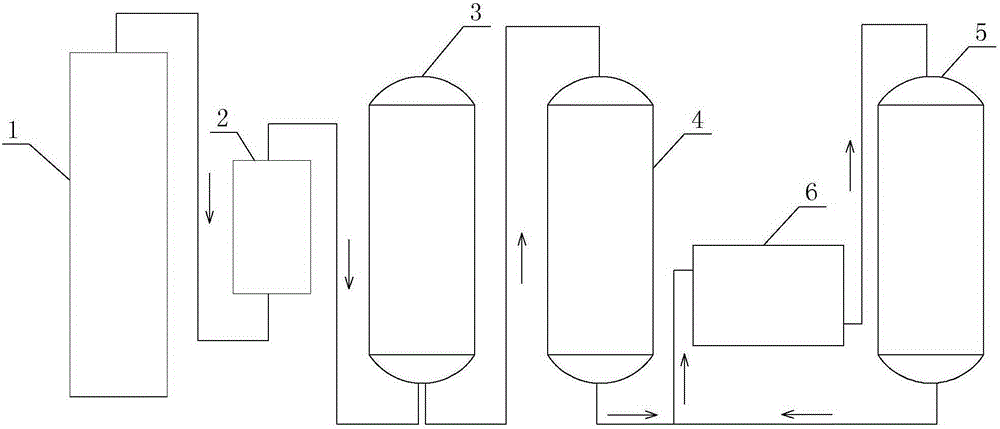

ActiveCN106748932AReduce energy consumptionReduce pressure on environmental protectionOrganic chemistryOrganic compound preparationElectricityFiltration

The invention provides a post-treatment method and device for methionine preparation. The post-treatment method comprises the treatment steps of filtration, acidification, gas-liquid separation, methionine separation and saturated-state acidification column regeneration. The methionine separation is performed by adopting an electrodialysis separation device or a stripping tower or alkaline resin acidification device. The hydrolysis step is that feed liquid is led to a material pipeline port at the bottom of the acidification columns and continuously passes through three serially connected acidification columns. The post-treatment device for methionine preparation comprises a filtering device, an acidic resin acidification device, a gas-liquid separation tank and a methionine separation device. For treatment of methionine production filtrate, new substances are not needed to be instructed. The energy consumption is reduced by 90%. Potassium formate can be taken out from the filtrate, and the filtrate can be beneficially circulated. A large amount of wastewater containing low-concentration formic acid is not produced, and environmental protection pressure is reduced.

Owner:SHANDONG XINHECHENG AMINO ACID

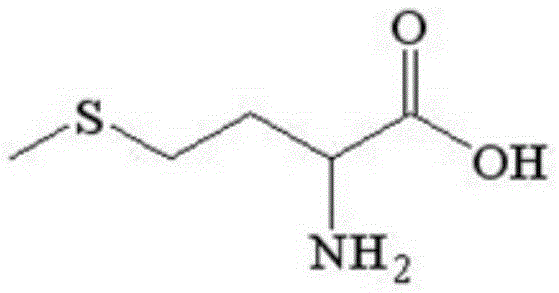

Cheap preparation method for high purity D,L-methionine

ActiveCN103641758AAvoid it happening againShorten production timeOrganic compound preparationSulfide preparationMethionine biosynthesisPressure reduction

The invention is directed at the field of chemical engineering and provides a cheap preparation method for high purity D,L-methionine. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; fully reacting the hydrocyanic acid gas mixture with methylthiopropionaldehyde under the catalysis of base so as to prepare a 2-hydroxy-4-methylthiobutyronityile system; reacting the 2-hydroxy-4-methylthiobutyronityile system with ammonia under the conditions of heating and pressurization and carrying out pressure reduction and deamination so as to obtain 2-amino-4-methylthiobutyronityile; and subjecting 2-amino-4-methylthiobutyronityile to acidolysis with inorganic acid so as to obtain D,L-methionine. According to the invention, raw materials used in the method are cheap and easily available, the intermediate 2-hydroxy-4-methylthiobutyronityile has stable properties, prepared 2-amino-4-methylthiobutyronityile has high yield and high purity, and D,L-methionine obtained after continued production has the advantages of high yield, high purity, great bulk density and low total production cost.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

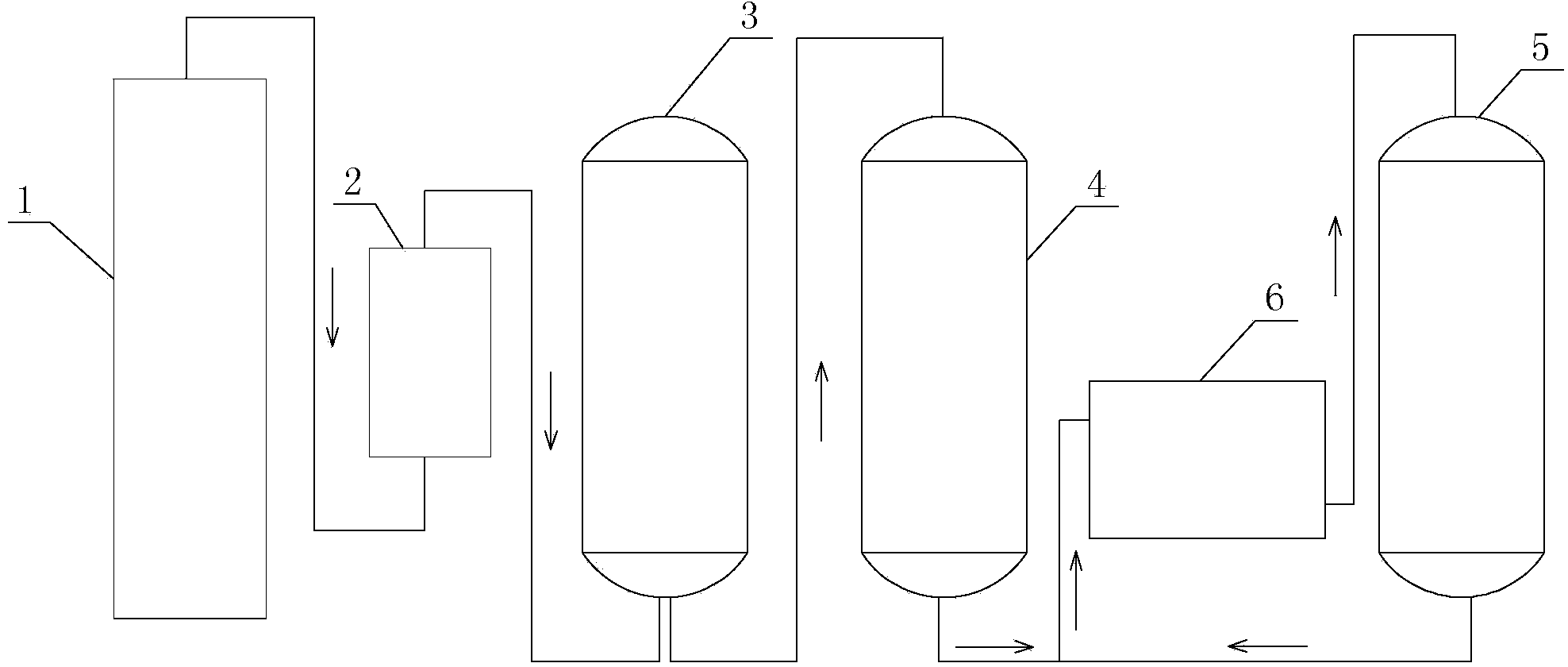

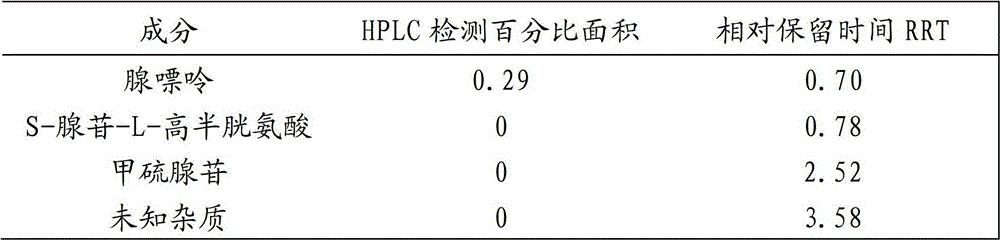

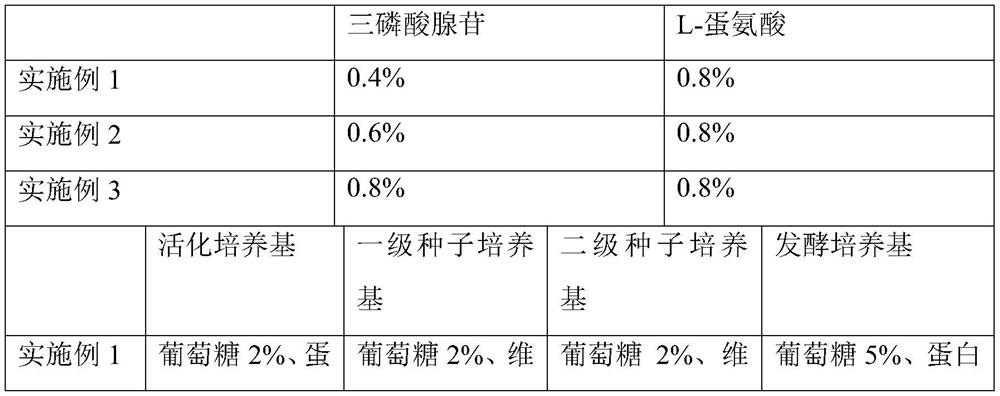

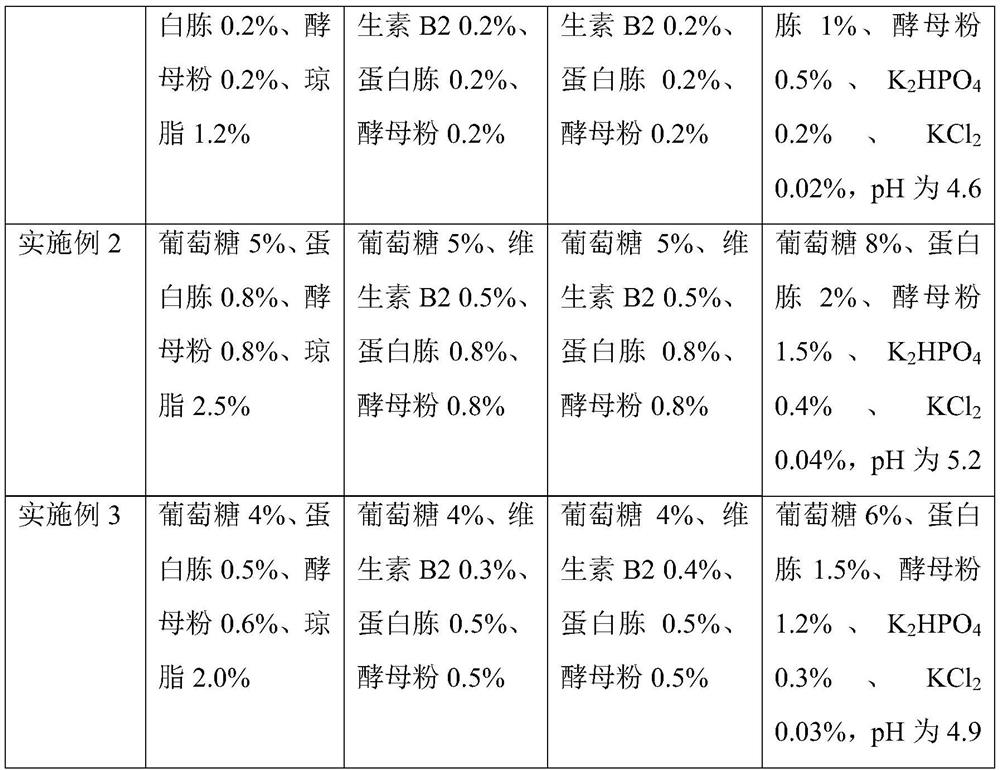

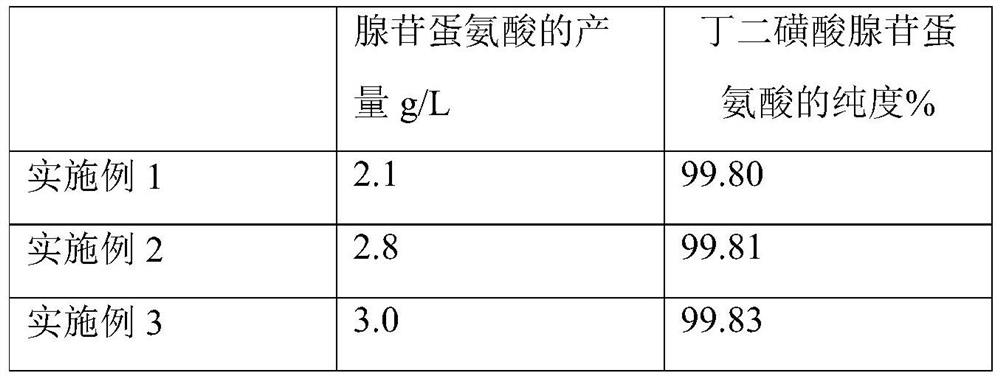

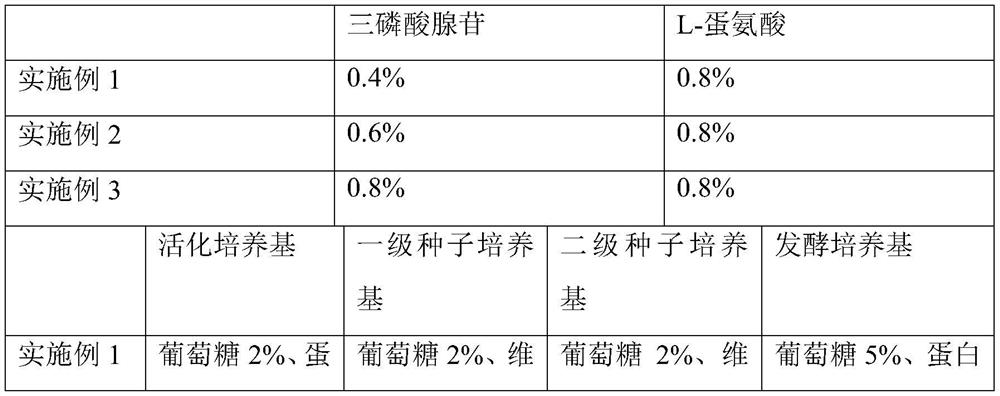

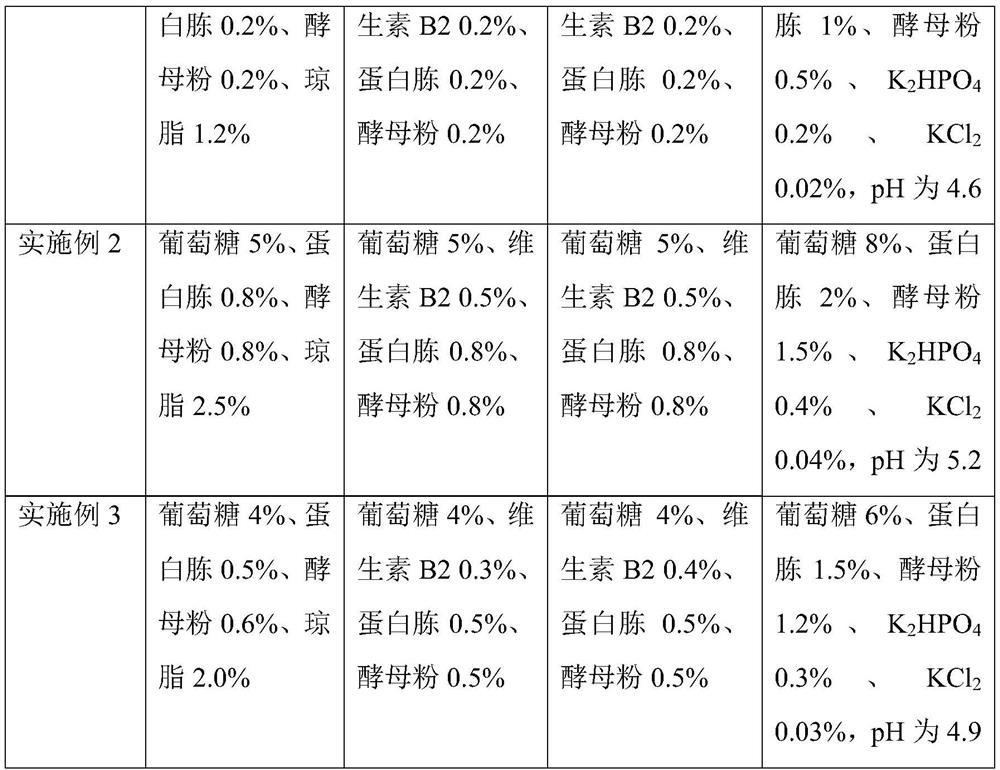

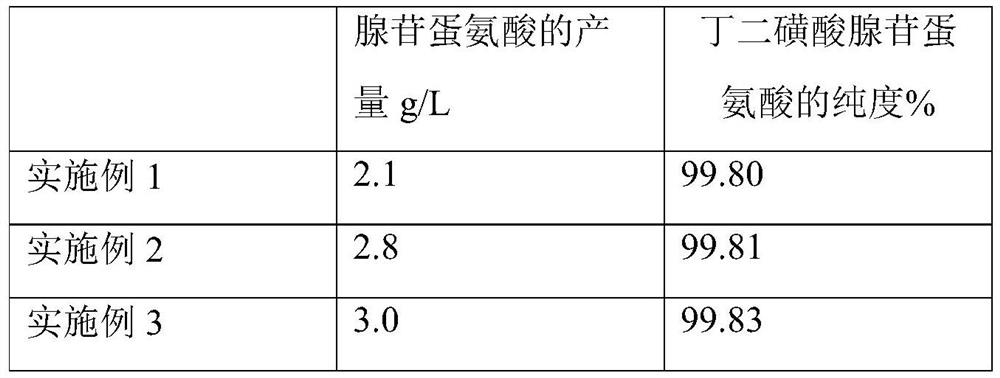

Process for preparing ademetionine butanedisulfonate

ActiveCN102747123AShort fermentation cycleEasy to separateSugar derivativesMicroorganism based processesPolymer scienceBacterial strain

The invention discloses a process for preparing ademetionine butanedisulfonate. The process comprises the steps of conducting seed culture, fermentation and refinement sequentially on bacterial strain saccharomyces cerevisiae and then obtaining finished products of the ademetionine butanedisulfonate. The process has the advantages of being short in fermentation period, good in separation effect and high in product purity.

Owner:WUXI FORTUNE PHARMA

Preparation method of 1, 4-succinic acid adenosine methionine

ActiveCN104418928AEasy to operateHigh yieldSugar derivativesSugar derivatives preparationFiltration membraneAdenosine

The invention discloses a preparation method of 1, 4-succinic acid adenosine methionine. The preparation method comprises the following steps: acidifying and filtering a fermentation solution of adenosyl methionine-producing bacteria to obtain wet thalli, drying, performing freezing and thawing treatment, and uniformly mixing a water solution of inorganic strong acid with the wet thalli; filtering an acid solution containing wall-broken thalli in a ceramic membrane, adding the water solution of inorganic strong acid, and collecting filtrate; filtering the filtrate by a nano-filtration membrane to obtain a concentrated solution A; passing through a medium polar macroporous adsorption resin column, and washing with water, thereby obtaining effluent B; passing through an H+ type macroporous weakly acidic cation exchange resin column, performing elution on the H+ type macroporous acidic cation exchange resin column with 1, 4-succinic acid, performing distributed collection, and merging effluent C; sequentially filtering a collected solution by an ultra-filtration membrane and the nano-filtration membrane; and mixing a concentrated solution D with 1, 4-succinic acid, regulating the proportion of 1, 4-succinic acid to adenosyl methionine, and drying to obtain 1, 4-succinic acid adenosine methionine. The preparation method disclosed by the invention has the advantages of simplicity in operation, relatively high product yield, white color and luster and high purity.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

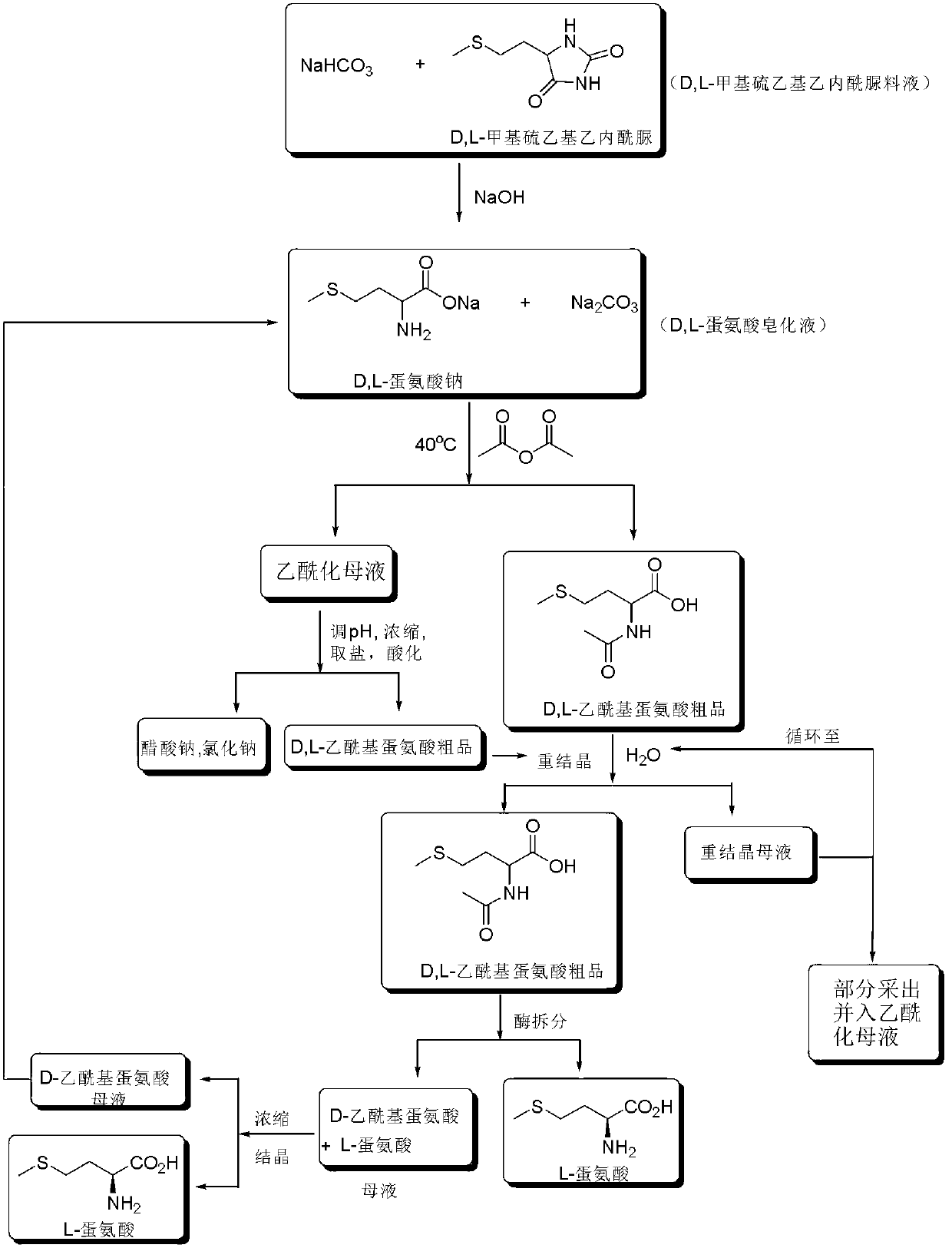

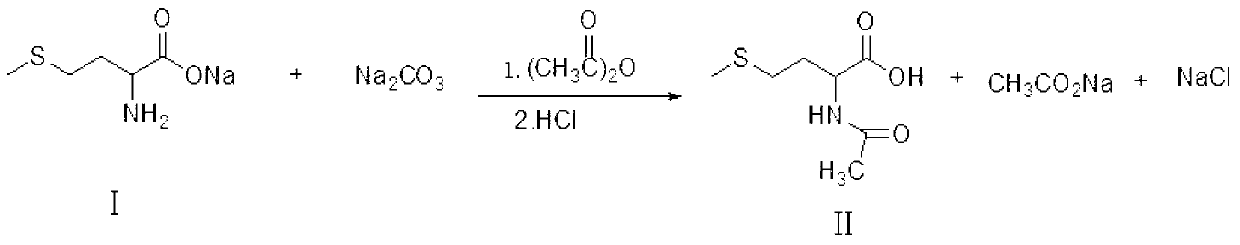

Method for preparing L-methionine by using acetylated saponification solution

ActiveCN103342671AReduce neutralizationEasy to separateSulfide preparationChemical industryAcetylation

The invention relates to a preparation method of L-methionine aiming at the field of the chemical industry. The preparation method comprises the following steps of: adding acid into an acetylated saponification solution which is used as a production raw material to adjust the pH, cooling and then performing crystallization to obtain D,L-acetylmethionine crystals; and adding the obtained D,L-acetylmethionine into amino invertase to perform resolution reaction so as to obtain L-methionine, and recycling remainders. According to the method, links for refining D,L-methionine are reduced, the saponification solution for producing the D,L-methionine is directly used for performing acetylation reaction, and the yield is up to 99%; and besides, neutralization and separation steps for production of the D,L-methionine are reduced, the L-methionine obtained by performing enzymolysis on recrystallized D,L-acetylmethionine at an enzymolysis speed which is higher than that of the conventional method is better in crystal form and whiteness, the purity is more than 99.5%, and the total yield of the L-methionine is improved to 70%. The preparation method is a comprehensive cycle process which is reasonable in design and reduces the production cost.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

L-methionine preparation method

InactiveCN102925530ASuitable for a wide range of productionHigh yieldFermentationChemical synthesisDL-methionine

The invention discloses an L-methionine preparation method, belongs to the chemical synthesis field, and solves the problems that a biological enzyme resolution method is low in economic indicator and large in pollution discharge, a traditional fermentation method is low in process yield and high in cost, and a chemical synthesis method is high in process and equipment requirements and large in investment. The preparation method includes the steps of obtaining acylated methionine due to acylation reaction of DL-methionine, adding common molds to ferment, generating mixture of L-methionine and the DL-methionine, adding hydrochloric acid for concentration by centrifuging, obtaining rough products after adding liquid caustic and invertase to concentrate and crystallize, and obtaining the L-methionine after decolourization and purification of the rough products. The L-methionine preparation method not only greatly improves product yield, but also shortens an operation cycle, improves original production environment, lowers production cost, and particularly suitable for wide production of the L-methionine.

Owner:NINGBO YUANFA BIOENG

Rumen bypass methionine preparation technology

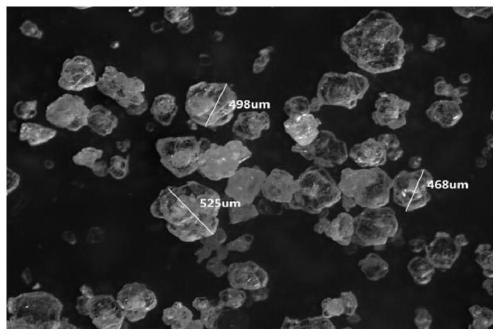

InactiveCN104705521AReduce manufacturing costEasy to operateAnimal feeding stuffRoom temperatureMethionine biosynthesis

The invention relates to a rumen bypass methionine preparation technology, methionine is dispersed in 80-90 DEG C grease for homogenizing for 2-3 hours, cooling room temperature is controlled at 8-10 DEG C for spraying, and after screening, a rumen bypass methionine product is prepared. Compared with the prior art, the rumen bypass methionine product is low in production cost, simple un process and easy to produce continuously, and is free of organic reagent, non-pollution to the environment, regular in shape, and narrow in particle size distribution, adding and premixing are easy, and the product qualification rate is high.

Owner:上海美农生物科技股份有限公司

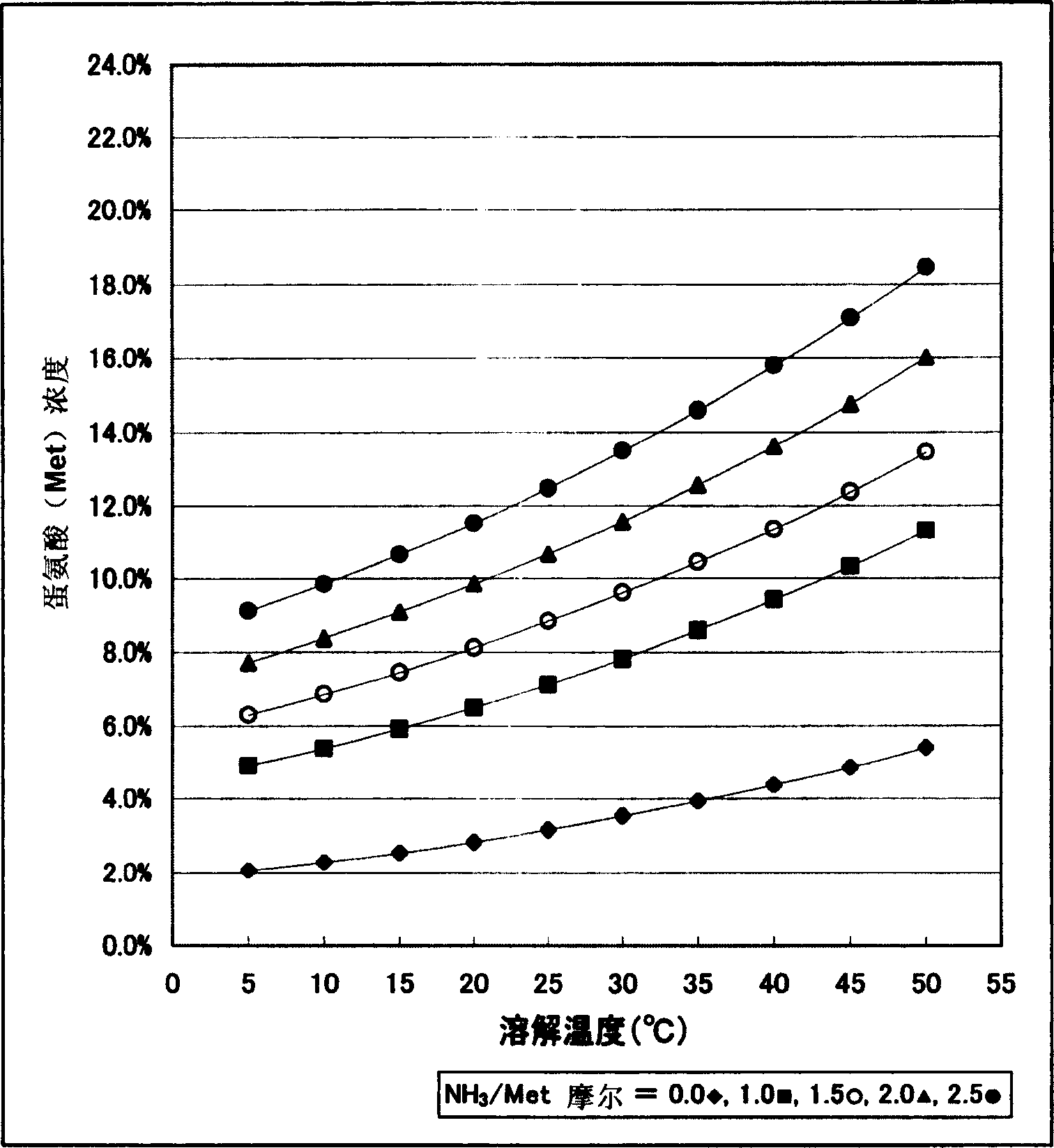

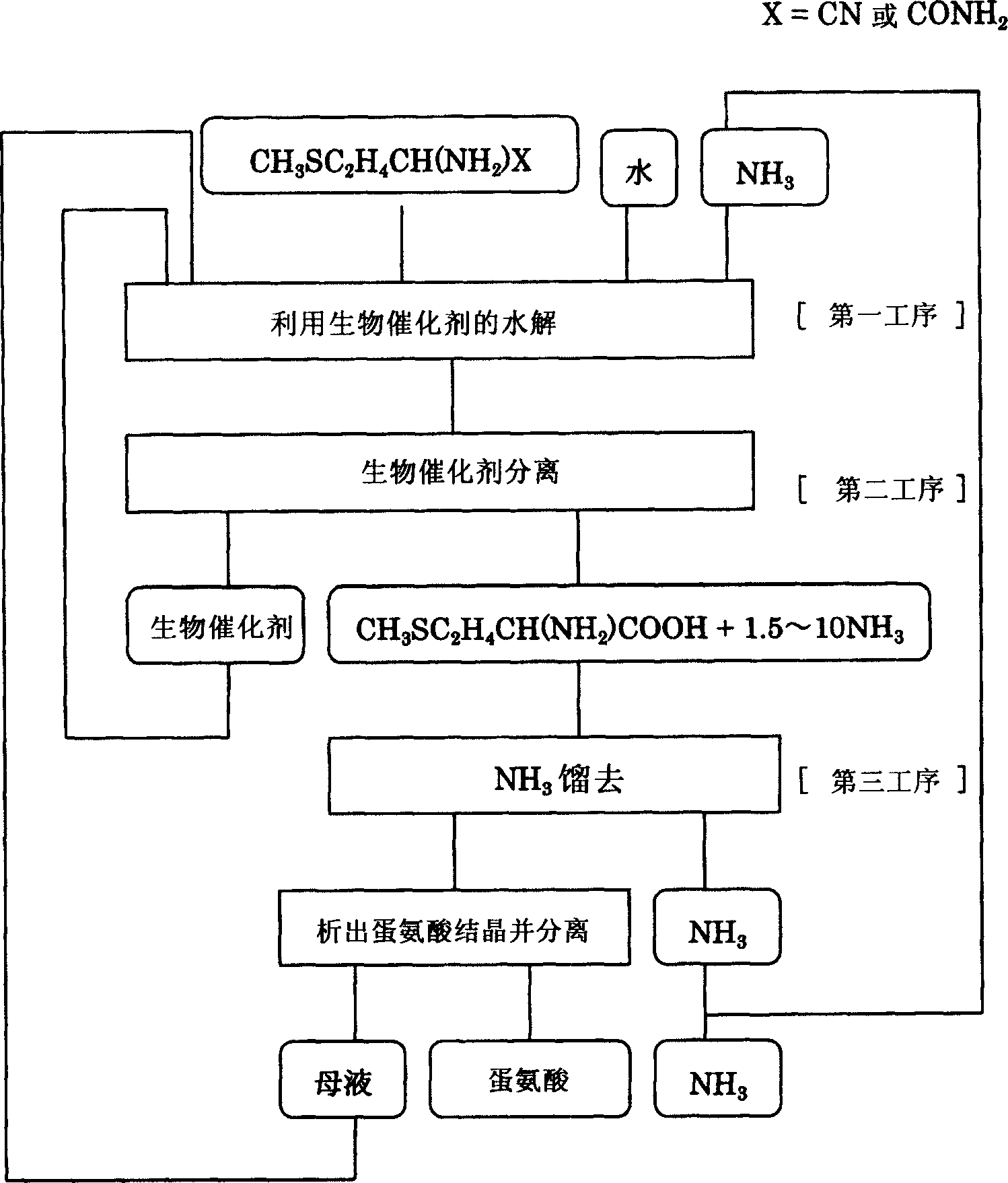

Process for the production of methionine

A practical method for producing methionine is presented. When a substance capable of producing methionine through hydrolysis is used as raw material and converted into methionine by using a biocatalyst, the biocatalyst is repeatedly usable and the accumulation amount of methionine dissolved in the reaction solution is increased, and methionine is obtained in a solid form from the reaction solution. Specifically, the present invention relates to a method for producing methionine comprising the following steps: a first step of converting raw material capable of producing methionine through hydrolysis of 2-amino-4-methylthiobutyronitrile, and 2-amino-4-methylthiobutanamide or the like in an aqueous ammonia solution, into methionine-containing aqueous ammonia solution, with a biocatalyst through hydrolysis, a second step of separating the biocatalyst from the methionine-containing aqueous ammonia solution obtained in the first step, and a third step of distilling ammonia out of the methionine-containing aqueous ammonia solution separated in the second step to deposit and separate crystals of methionine.

Owner:NIPPON SODA CO LTD

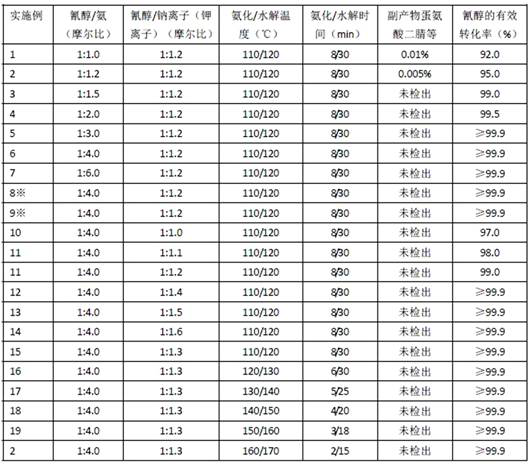

Economic and high-efficiency methionine preparation method

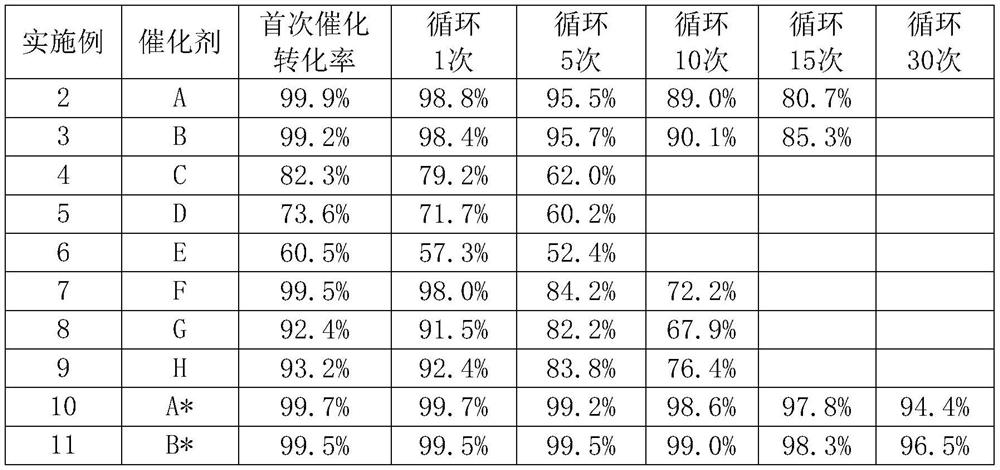

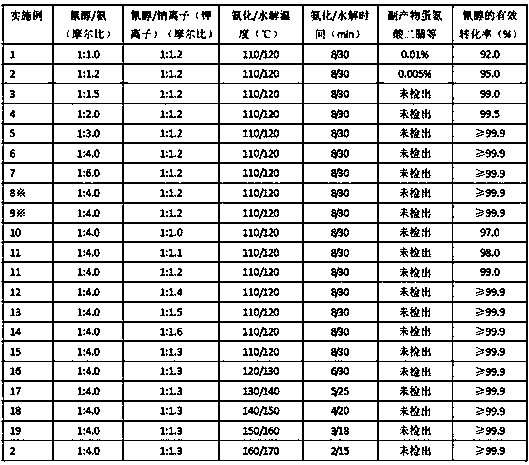

ActiveCN109232335AAverage hydrolysis alkali reductionShort reaction timeSulfide preparationSide effectConstant power

The invention provides an economic and high-efficiency methionine preparation method. The economic and high-efficiency methionine preparation method comprises the process of hydrolyzing of hydantoin intermediate, such as 5-(beta-methylthio-ethyl)hydantoin, and comprises the following specific steps of (1) mixing the hydantoin intermediate and a small amount of alkaline, sending into a reactor in phase I, and performing loop-open hydrolyzing reaction under the conditions of constant-power low-frequency ultrasonic wave and certain temperature; (2) continuously treating the liquid material in step (1) in a reactor in phase II, thoroughly hydrolyzing under the conditions of power same with the power in step (1) and higher-frequency ultrasonic wave and lower-temperature atmosphere, so as to obtain a saponification liquid of methionine; acidifying, so as to obtain the methionine. The economic and high-efficiency methionine preparation method has the advantages that the hydrolysis reaction efficiency of the hydantoin intermediate in the preparation process of the methionine is improved, and the reaction time is shortened by one time; the reaction temperature is greatly reduced, the hydrolysis yield rate is increased while the generation of side effect is reduced, and the requirement on the material of the reactor is lower.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Prepn. of methionine

InactiveCN1178909CGood crystal shapeThe volume ratio is largeOrganic compound preparationHydropoly/poly sulfide preparationHydrolysateMethionine biosynthesis

The present invention prepares easy to treat methionine with good crystal form and great bulk specific weight through the hydrolysis of 5-(beta-methylmercaptoethyl) hydantoin and the neutralization of hydrolysate with CO2 to separate methionine crystal. It features the continuous crystal separation in a crystal separating tank with casing. First, 15-40% of the hydrolysate and coagulant are filled in the tank and stirred while leading CO2 in so as to separate partial crystal, and then the rest hydrolysate, coagulant and CO2 is filled for continuous crystal separation.

Owner:SUMITOMO CHEM CO LTD

Manganese methionine preparation method

The invention discloses a manganese methionine preparation method, which comprises two steps of a salt forming reaction and a drying step. The preparation method comprises the following steps: a salt forming reaction is characterized in that methionine, basic manganese carbonate, benzoic acid and water in a reaction vessel, the materials are stirred, and heated at the temperature of 65 DEG C, carbon dioxide is overflowed, manganese methionine is generated, and mass ratio of methionine to basic manganese carbonate to benzoic acid to water is 7: 2: 3: 30; and the drying step is characterized in that the separated granular product is placed in a ventilating stainless steel drying screen, the product is placed in a drying box for drying, and the obtained product is sieved to obtain the manganese methionine, wherein the drying temperature is 110 DEG C. The method has the advantages that during production process, basic manganese carbonate and an initiator are used, the granular product is obtained, and is benefit for drying, crushing is not required, dust generation is avoided, and the method has the advantages of simple realization and convenient operation, saves the investment of production equipment and increases the production efficiency.

Owner:南通德益化工有限公司

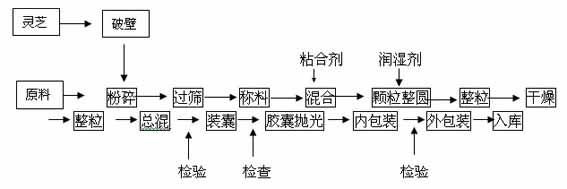

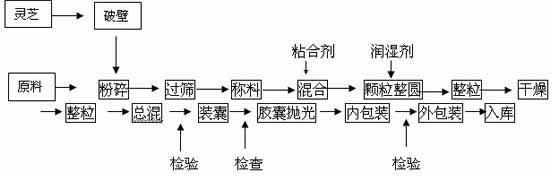

Ganoderma lucidum double vitamin methionine preparation and production method thereof

ActiveCN102379907AGood effectShorten the timeNervous disorderAntipyreticDiseaseCoronary heart disease

The invention discloses a Ganoderma lucidum double vitamin methionine preparation and a production method thereof. According to the invention, methionine, glossy Ganoderma lucidum spore powder, vitamin B1 and vitamin B2 are used as main composing raw materials; the production method for the preparation is to respectively sieve methionine and glossy Ganoderma lucidum spore powder, weigh and mix methionine and glossy Ganoderma lucidum spore powder, add the accessory of starch and a binder to prepare particles and prepare capsules and tablets from the powder. The preparation is applicable to diseases of frailty after sickness, inappetence, weight reduction, excessive use of the brain, neurasthenia and the like and can also be used for adjuvant treatment of chronic diseases of coronary heart disease, chronic hepatitis, bronchial asthma, anaemia, rheumatoid arthritis, gastric ulcer and the like.

Owner:广西两面针亿康药业股份有限公司

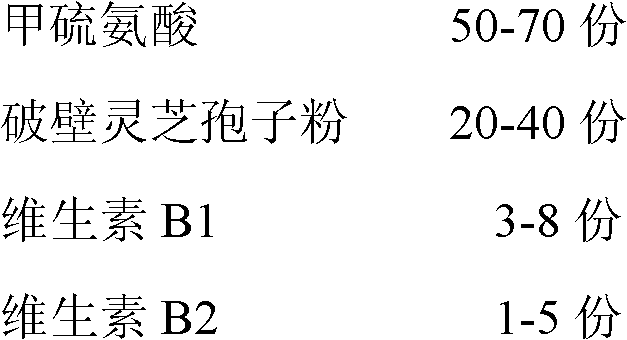

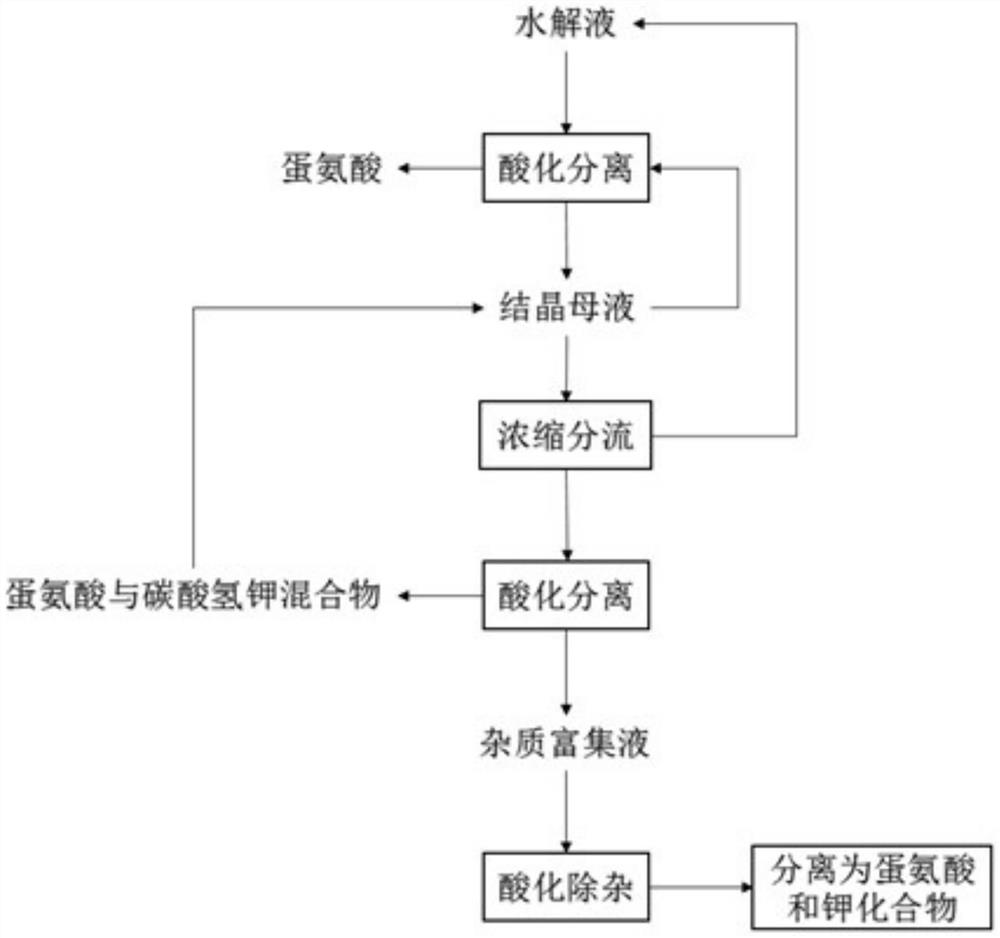

Optimized methionine preparation method based on carbon dioxide acidification method

PendingCN114044748AAffect qualityEfficient removalOrganic compound preparationSulfide preparationOil phaseHydrolysis

The invention relates to the field of methionine production, in particular to an optimized methionine preparation method based on a carbon dioxide acidification method. Compared with the prior art, the optimized methionine preparation method based on the carbon dioxide acidification method is more environment-friendly, economical and safe, the single yield is increased by extracting methionine in crystallization mother liquor, the single hydrolysis hydantoin amount in the follow-up circulation is increased by extracting alkaline potassium, formic acid and oil phase impurities are enriched and then extracted respectively, the hydrolysis circulation can be carried out for more times, impurities in the saponification liquid in the DL-methionine production process are effectively removed, and a large amount of impurities cannot be accumulated in the continuous methionine production process to affect the quality of methionine.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

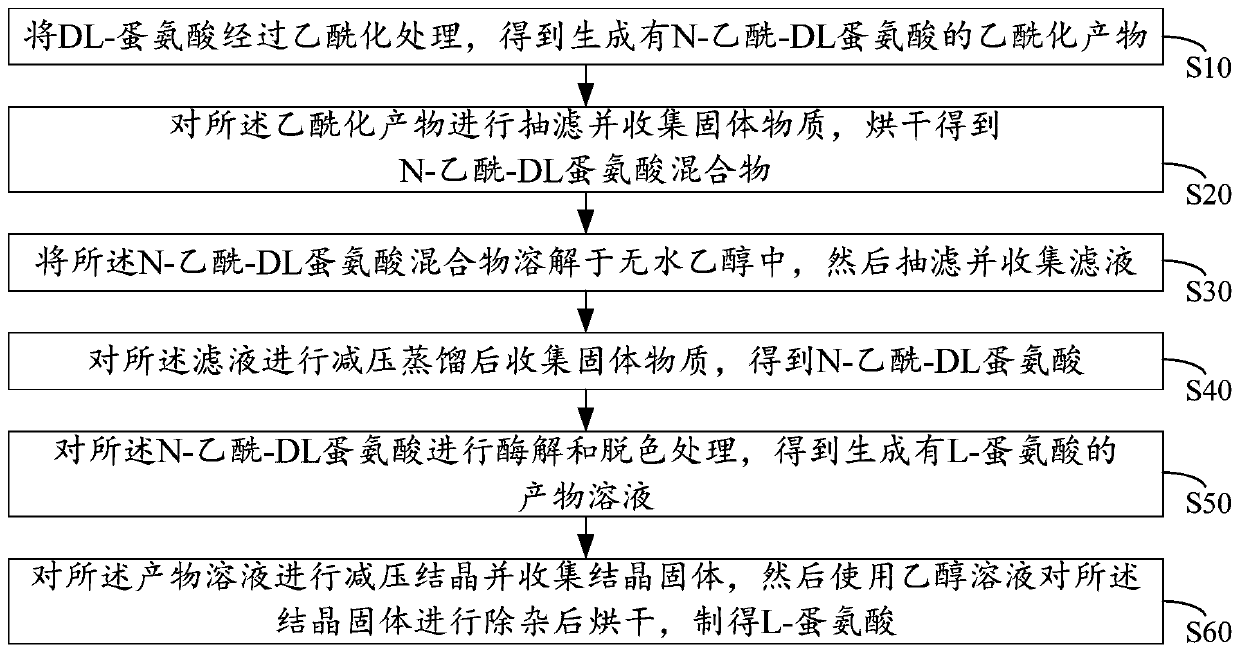

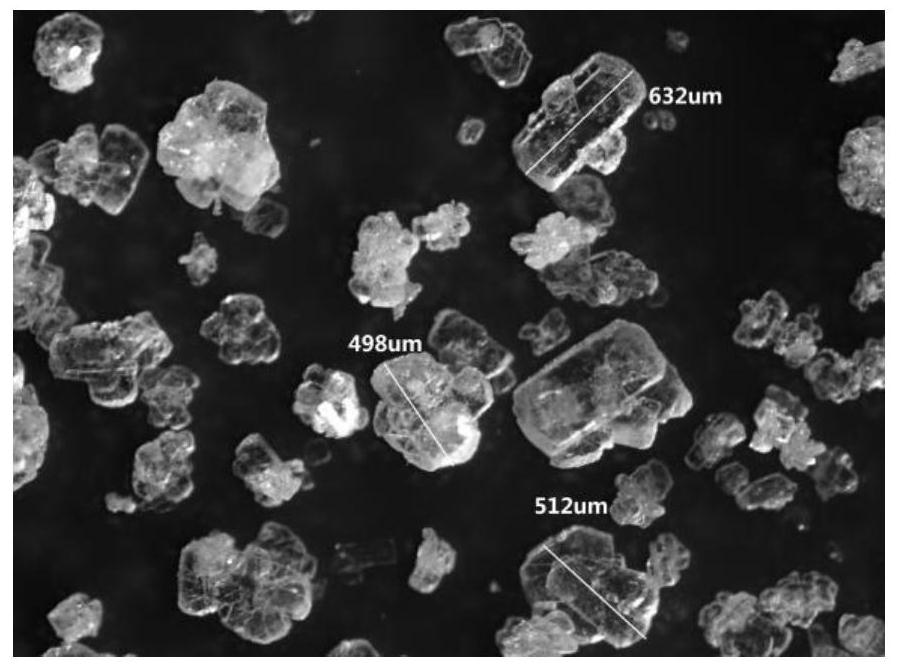

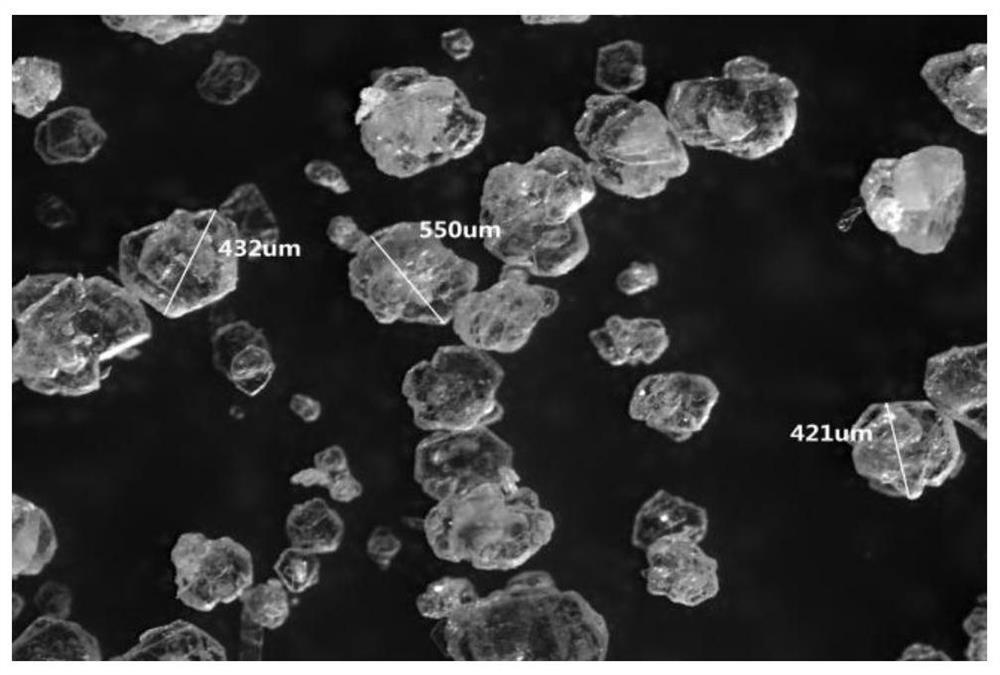

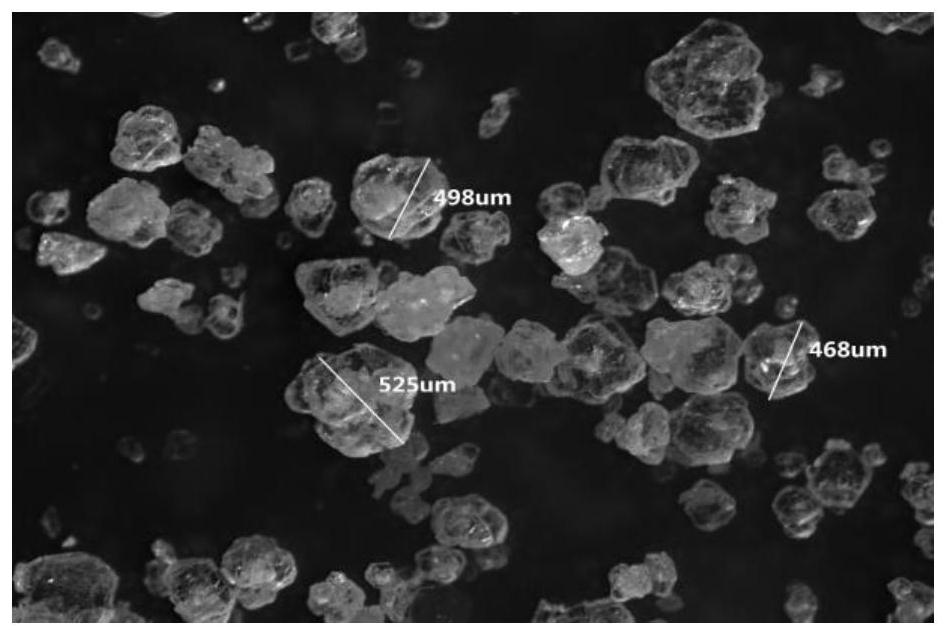

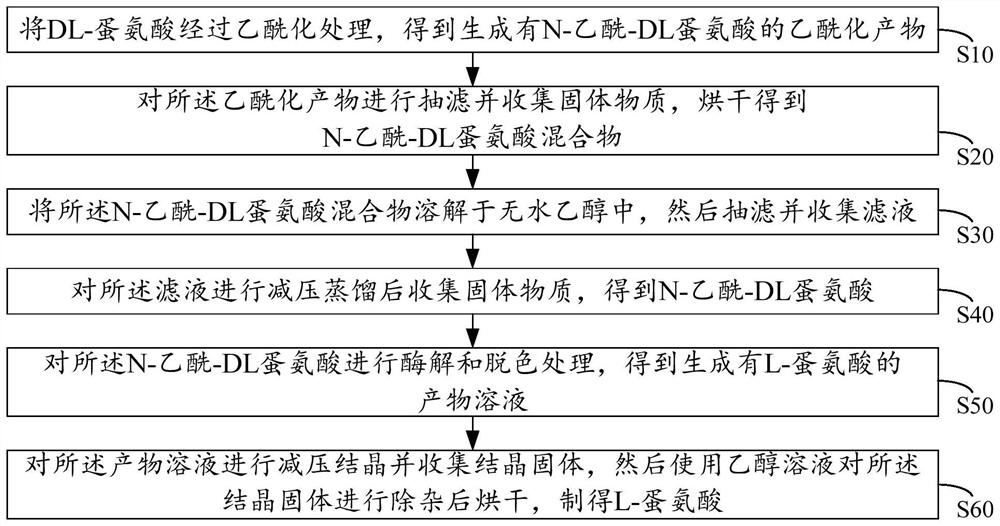

Preparation method of L-methionine

ActiveCN111269952AHigh purityImprove optical qualityOrganic compound preparationOrganic chemistry methodsAlcoholDL-methionine

The invention discloses a preparation method of L-methionine. The method comprises the following steps: carrying out acetylation treatment on DL-methionine to obtain an acetylation product with N-acetyl-DL methionine; carrying out suction filtration on the acetylation product, collecting a solid substance, and drying to obtain an N-acetyl-DL methionine mixture; dissolving the N-acetyl-DL methionine mixture into absolute ethyl alcohol, then carrying out suction filtration, and collecting a filtrate; carrying out reduced pressure distillation on the filtrate, and then collecting solid substancesto obtain N-acetyl-DL methionine; carrying out enzymolysis and decoloration treatment on the N-acetyl-DL methionine so as to obtain a product solution with L-methionine; and carrying out reduced pressure crystallization on the product solution, collecting a crystallized solid, removing impurities from the crystallized solid by using an ethanol solution, and drying to obtain L-methionine. According to the preparation method of the L-methionine, purity of the L-methionine is improved, and optical rotation quality of the L-methionine is increased.

Owner:湖北省八峰药化股份有限公司

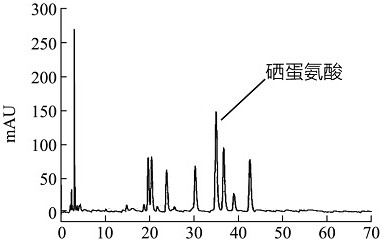

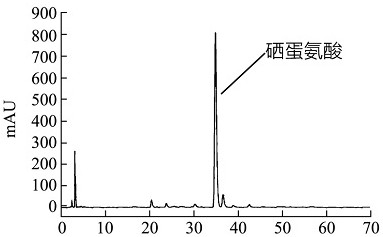

Preparation method for extracting, separating and purifying selenomethionine from cardamine hupingshanesis

InactiveCN112481323AImprove antioxidant capacityReduced purification stepsPeptide preparation methodsFermentationBiotechnologyCardamine hupingshanensis

The invention discloses a preparation method for extracting, separating and purifying selenomethionine from cardamine hupingshanesis. The preparation method comprises the following steps: (1) preparing a cardamine hupingshanesis extract; (2) decolorizing the cardamine hupingshanesis extract; (3) grading and purifying cardamine hupingshanesis crude protein;(4) hydrolyzing the cardamine hupingshanesis crude protein; and (5) purifying and freeze-drying the hydrolyzed protein. the preparation method for extracting, separating and purifying selenomethionine from cardamine hupingshanesis can obviously improve the color and purity of the cardamine hupingshanesis extract, is advanced, scientific and convenient to operate, the selenomethionine in cardamine hupingshanesis has good antioxidant activity, the selenomethionine can be applied to preparation of health-care products with antioxidant and anti-aging effects, and the method provides favorable technical means and use value for market application of cardamine hupingshanensis, and has huge economic and social benefits.

Owner:哈尔滨优妮珂科技发展有限公司

Preparation method of adenosylmethionine butanedisulfonate with health-care functions

ActiveCN112375797AImprove expression levelHigh catalytic activityFungiSugar derivativesPharmacyS-Adenosylmethionine Synthetase

The invention provides a preparation method of adenosylmethionine butanedisulfonate with health-care functions, and belongs to the technical field of pharmacy. According to the preparation method of the adenosylmethionine butanedisulfonate with the health-care functions, proline, fumaric acid and Na(2)HPO(4)-12H(2)O are added into afermentation medium at a content ratio of 2-4 to 1-2 to 1-2 duringthe implementation process so as to have expression level of s-adenosylmethionine synthetase improved with catalytic activity of the s-adenosylmethionine synthetase in a living body increased; and thus, improvement of L-methionine conversion rate can be guaranteed with addition of adenosine triphosphate at a relatively low content in a fermentation system. Reaction efficiency of the obtained adenosylmethionine with butanedisulfonic acid is high, so that the finally prepared adenosylmethionine butanedisulfonate product has obviously improved purity.

Owner:内蒙古拜克生物有限公司

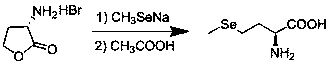

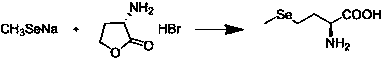

Method for preparing L-selenomethionine

The invention discloses a method for preparing L-selenomethionine and belongs to the field of additives. The method comprises the following steps: A. subjecting L-methionine and iodomethane to a reaction in water, so as to obtain an intermediate; and B. subjecting the intermediate and selenium sodium methoxide to a reaction in an alcoholic solvent, carrying out quenching with glacial acetic acid after the reaction ends up, adjusting a pH value of a reaction system to 5 to 6, and carrying out filtering and baking, thereby obtaining the L-selenomethionine. The method has the beneficial technicaleffects that the intermediate is simpler in preparation and lower in cost; the preparation operation of the intermediate is simpler; and employed raw materials and reagents are commercially available, a reaction process is free of production of fetid and hypertoxic byproduct, and thus, the method is more beneficial to labor protection and environments.

Owner:河北凡博医药科技有限公司

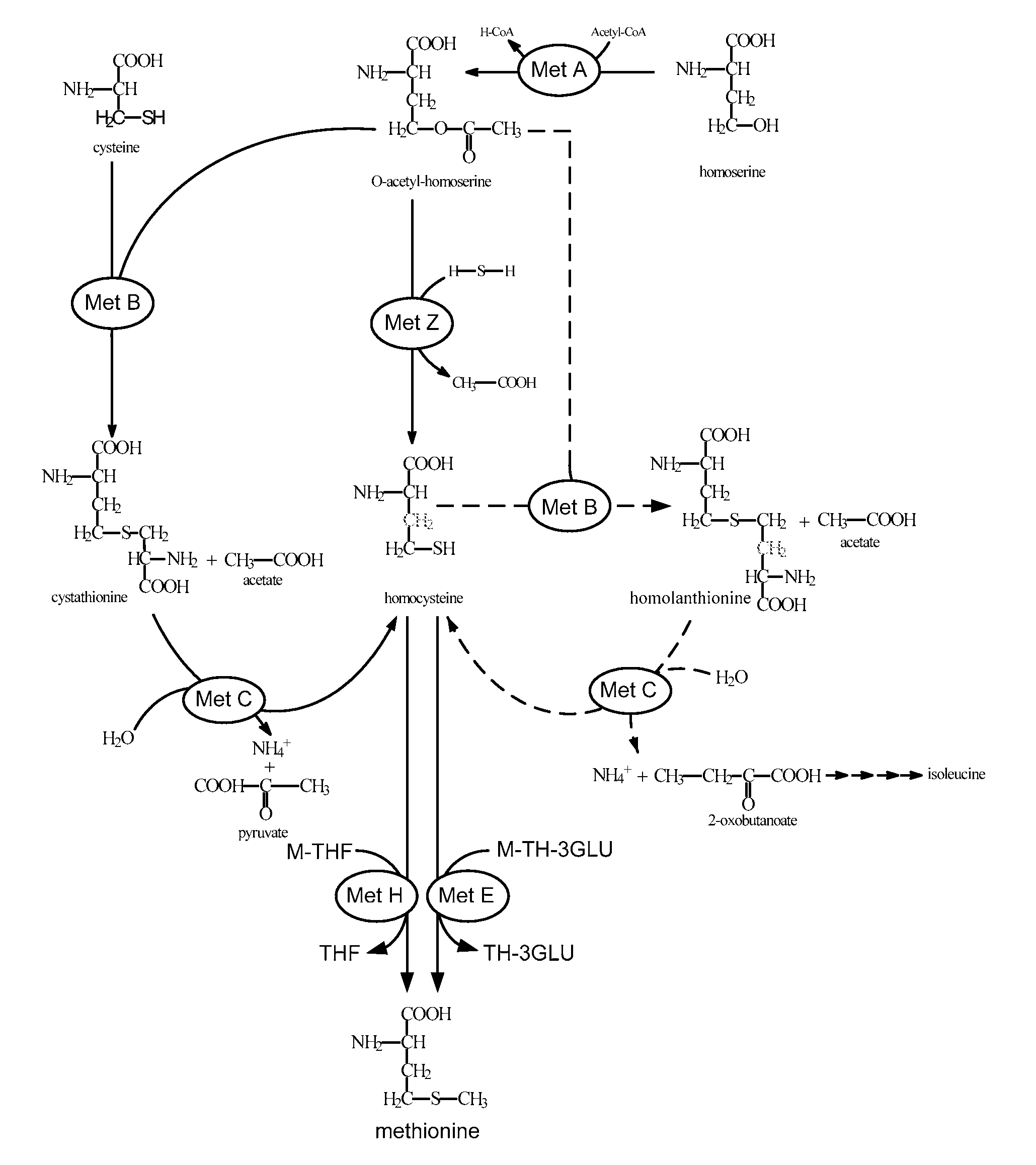

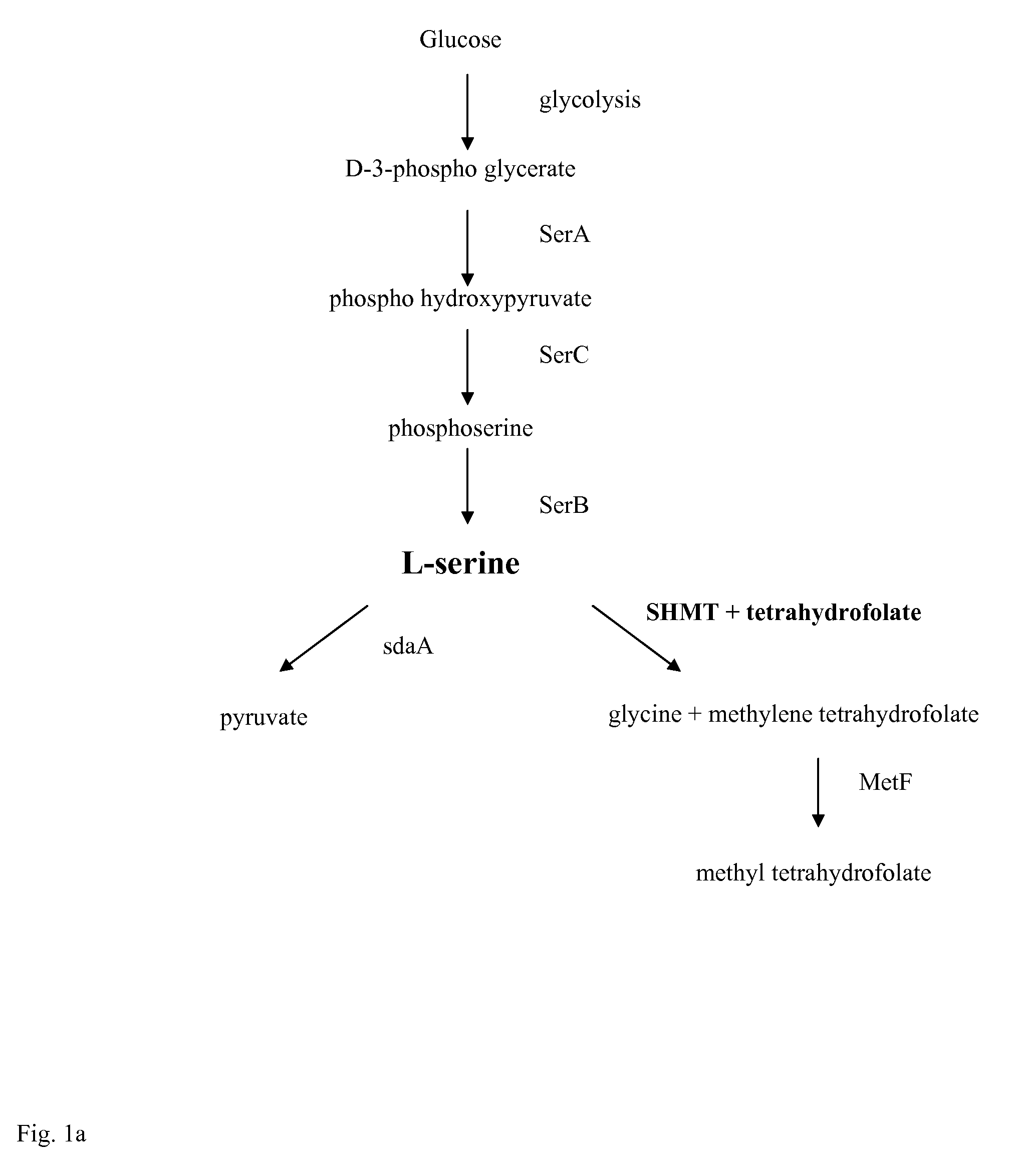

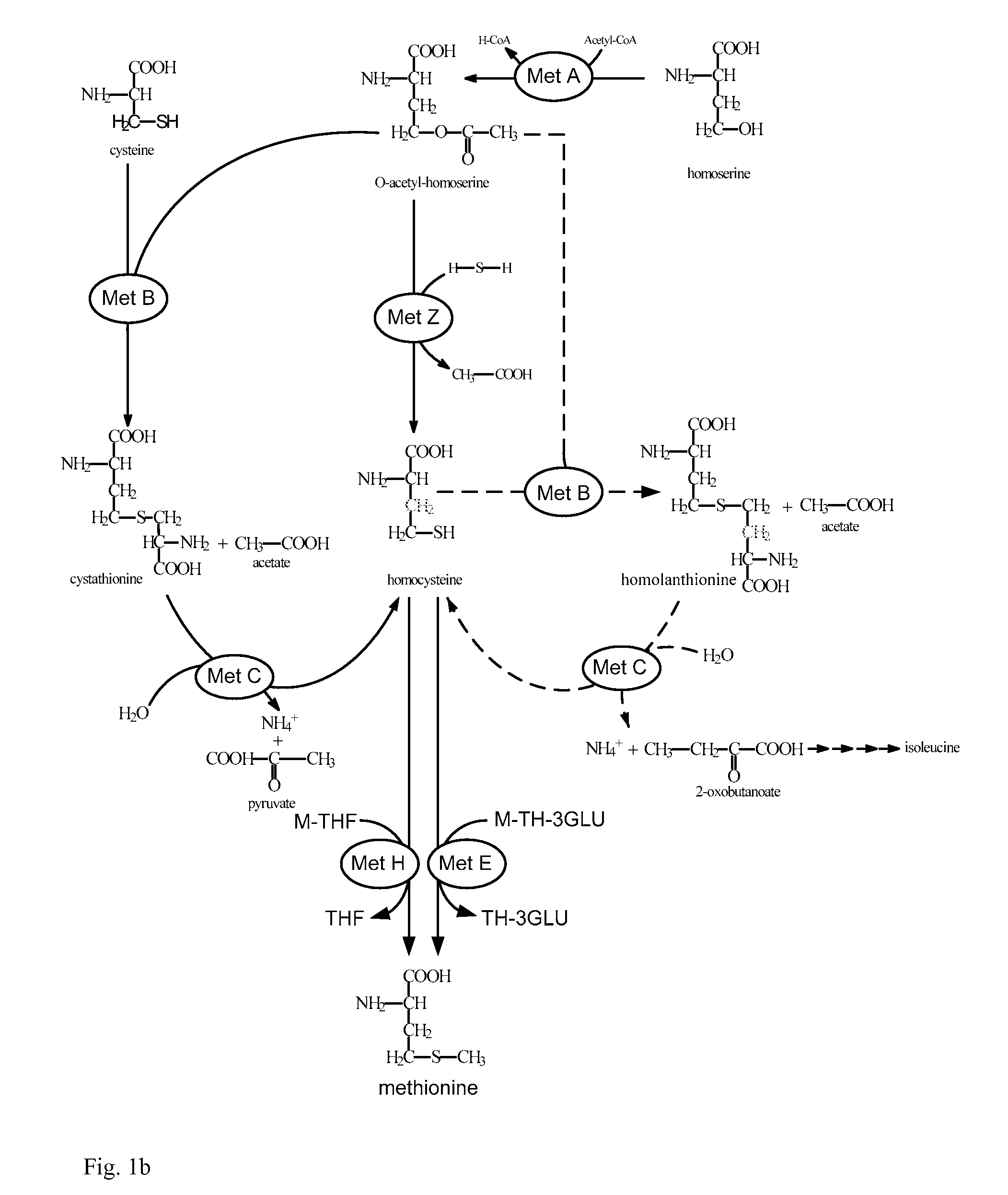

Process for the Preparation of L-Methionine

InactiveUS20100009416A1Efficient production of L-methionineEfficient productionBacteriaFermentationMicroorganismMethionine biosynthesis

The present invention relates to microorganisms and processes for the efficient preparation of L-methionine. In particular, the present invention relates to processes in which the amount of serine available for the metabolism of the microorganism is increased.

Owner:EVONIK DEGUSSA GMBH

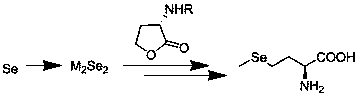

Preparation method of L-selenomethionine

The invention discloses a preparation method of L-selenomethionine, and belongs to the field of additives. The preparation method comprises the following steps of A. reacting a compound 1 with a compound 2 in a solvent, and filtering after reaction to obtain a green solid compound 3; B. firstly, reacting the compound 3 with sodium borohydride in a protic solvent for 1-10 hours, dripping dimethyl sulfate after the reaction time is reached, continuing to react for 1-5 hours, quenching by using acetic acid, filtering and drying to obtain the L-selenomethionine. The preparation method disclosed bythe invention has the beneficial effects that: 1. the compound 1 has mild condition and high yield; 2. the reaction condition of the compound 3 is mild, virulent and malodorous selenium sodium methoxide cannot be generated, and the labor protection and the environmental protection are facilitated; 3. the compound 3 is simple to separate and only needs to be centrifugally subjected to spin filtration, and the obtained product has high purity; and 4. the raw materials and reagents are commercially available, and the intermediate does not need to be separated in the preparation process of the L-selenomethionine, so that the operation is simple.

Owner:河北凡博医药科技有限公司

Preparation method of methionine

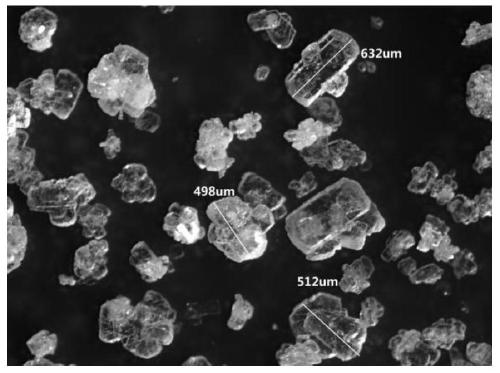

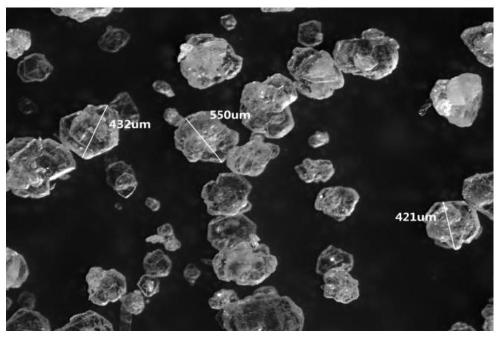

PendingCN114213293ALarge particlesAccelerated settlementOrganic compound preparationChemical recyclingPtru catalystHydrolysate

The invention belongs to the field of chemical engineering, and discloses a methionine preparation method, the method comprises a process of contacting a CeO2 solid catalyst with 2-amino-4-methylthio butyronitrile water-containing liquid flow, the CeO2 solid catalyst is in a rod-like crystal form, the crystal diameter is 10-80 nm, and the crystal length is 100-500 nm. Furthermore, according to the process disclosed by the invention, the step of catalyzing CeO2 is only put into an amidation reaction process of hydrolyzing 2-amino-4-methylthio butyronitrile into methionine amide, then the methionine amide hydrolysate is hydrolyzed by using solid acid to prepare the methionine hydrolysate, and finally the methionine is taken out by using a carbon dioxide acidification crystallization mode. The rod-like cerium dioxide catalyst used in the method has higher catalyst activity and better anti-pollution capacity, the production process does not generate low-value byproduct salt, the cerium dioxide catalyst has longer recycling period, the methionine is high in one-time crystal extraction rate and stable in yield, industrial adaptability is achieved, and the method is suitable for industrial production. The industrial popularization and application of methionine can be realized.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Technology for continuously and rapidly synthesizing methionine by cyanohydrins method

The invention provides a technology for continuously and rapidly synthesizing methionine by a cyanohydrins method. The technology for continuously and rapidly synthesizing the methionine by the cyanohydrins method comprises the steps that (1) ammonolysis reaction is carried out, specifically, ammonia and 2-hydroxy-4-methyl sulfide butyronitrile are pumped into a micro channel reactor for ammonolysis reaction, the reaction temperature is controlled at 60-200 DEG C, the standing time of a reactant is 0.5-8.0 min, and a 2-hydroxy-4-methyl sulfide butyronitrile water solution is obtained; and (2)alkaline hydrolysis reaction is carried out, specifically, the 2-hydroxy-4-methyl sulfide butyronitrile water solution in the step (1) and alkali are simultaneously added into the micro channel reactor for reaction, the reaction temperature is controlled at 80-200 DEG C, pressure is 1.0-2.5MPa, the reaction standing time is for 10-60 min, and DL-methionine is obtained through aftertreatment. According to the technology for continuously and rapidly synthesizing the methionine by the cyanohydrins method, the methionine is prepared by adopting an ammoniation and without catalysis alkaline hydrolysis technology, and the preparation technology of the methionine is simplified; and ammoniation and alkaline hydrolysis reaction is carried out by adopting the micro channel reactor under the condition of without a catalyst, the reaction time is quick, the yield is high, raw material pyrolytic polymer and secondary reaction products affecting the product yield and quality are greatly reduced, andreduction of the cost of the methionine in industrialization and improvement of the quality of the methionine in the industrialization are facilitated.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Additive used in methionine preparation process and preparation method of methionine

ActiveCN111100051AEasy to useImprove stabilityOrganic compound preparationFood processingMethionine biosynthesisStructural formula

The invention relates to an additive used in a methionine preparation process and a preparation method of methionine. The additive provided by the invention is a mixture containing a component A, a component B and a component C, wherein the component A has a structural formula represented by the following general formula (1), the component B has a structural formula represented by the following general formula (2), the component C is silicone oil, the general formula (1) is RCON(CH3)CH2CH2SO3Na (1), and the general formula (2) is shown in the specification. The preparation method of methionineprovided by the invention comprises the step of carrying out crystallization and / or recrystallization of methionine in the presence of the additive provided by the invention. The additive provided bythe invention is uniform in emulsification, good in stability, capable of being stably used for a long time and suitable for a continuous crystallization process. The prepared methionine is good in crystallization crystal form, high in bulk density and good in flowability. Besides, according to the preparation method of methionine, a crystallization system can continuously and stably operate fora long time, no obvious foaming phenomenon exists, and the crystallization process of the methionine product is stably carried out.

Owner:SHANDONG XINHECHENG AMINO ACID +2

Preparation method of cheap and high-purity d,l-methionine

ActiveCN103641758BStable in natureLong storage timeOrganic compound preparationSulfide preparationCombinatorial chemistrySulfuryl

The invention is directed at the field of chemical engineering and provides a cheap preparation method for high purity D,L-methionine. The preparation method comprises the following steps: preparing a hydrocyanic acid gas mixture by using an Andrussow process; fully reacting the hydrocyanic acid gas mixture with methylthiopropionaldehyde under the catalysis of base so as to prepare a 2-hydroxy-4-methylthiobutyronityile system; reacting the 2-hydroxy-4-methylthiobutyronityile system with ammonia under the conditions of heating and pressurization and carrying out pressure reduction and deamination so as to obtain 2-amino-4-methylthiobutyronityile; and subjecting 2-amino-4-methylthiobutyronityile to acidolysis with inorganic acid so as to obtain D,L-methionine. According to the invention, raw materials used in the method are cheap and easily available, the intermediate 2-hydroxy-4-methylthiobutyronityile has stable properties, prepared 2-amino-4-methylthiobutyronityile has high yield and high purity, and D,L-methionine obtained after continued production has the advantages of high yield, high purity, great bulk density and low total production cost.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

A kind of technology of continuous rapid synthesis of methionine by cyanohydrin method

The invention provides a process for continuously and rapidly synthesizing methionine by the cyanohydrin method, which includes: (1) ammoniation reaction: passing ammonia and 2-hydroxy-4-methylthiobutyronitrile into a microchannel reactor for ammoniation reaction, and controlling The reaction temperature is 60-200°C, the residence time of the reactants is 0.5-8.0min, and an aqueous solution of 2-amino-4-methylthiobutyronitrile is obtained; (2) Alkaline hydrolysis reaction: the step (1) 2-amino-4-methanol The thiobutyronitrile aqueous solution and the alkali are simultaneously added into the microchannel reactor for reaction, the reaction temperature is 80-200°C, the pressure is 1.0-2.5MPa, the reaction residence time is 10-60min, and DL-methionine is obtained after post-treatment. The invention adopts ammoniation and non-catalyzed alkaline hydrolysis process to prepare methionine, which simplifies the preparation process of methionine; selects microchannel reactor to carry out ammoniation and alkaline hydrolysis reaction under catalyst-free conditions, has fast reaction time and high yield, which affects product yield The quality and quality of raw material pyrolysis polymers and side reaction products are greatly reduced, which is beneficial to the cost reduction and quality improvement of methionine in industrialization.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Methionine recovery processes

InactiveUS8338141B2Promote recoveryReduce solubilityBiocideOrganic active ingredientsSolubilityMethionine recycling

The present invention relates to a method of making a methionine preparation, for example for an animal feed additive. The invention also related to methods for increasing the solubility of a methionine preparation.

Owner:NOVUS INTERNATIONAL INC

A post-treatment method and device for preparing methionine

ActiveCN106748932BReduce energy consumptionReduce pressure on environmental protectionOrganic chemistryOrganic compound preparationFiltrationWastewater

The invention provides a post-treatment method and device for methionine preparation. The post-treatment method comprises the treatment steps of filtration, acidification, gas-liquid separation, methionine separation and saturated-state acidification column regeneration. The methionine separation is performed by adopting an electrodialysis separation device or a stripping tower or alkaline resin acidification device. The hydrolysis step is that feed liquid is led to a material pipeline port at the bottom of the acidification columns and continuously passes through three serially connected acidification columns. The post-treatment device for methionine preparation comprises a filtering device, an acidic resin acidification device, a gas-liquid separation tank and a methionine separation device. For treatment of methionine production filtrate, new substances are not needed to be instructed. The energy consumption is reduced by 90%. Potassium formate can be taken out from the filtrate, and the filtrate can be beneficially circulated. A large amount of wastewater containing low-concentration formic acid is not produced, and environmental protection pressure is reduced.

Owner:SHANDONG XINHECHENG AMINO ACID

Additive used in the preparation process of methionine and the preparation method of methionine

ActiveCN111100051BEasy to useImprove stabilityOrganic compound preparationFood processingPolymer scienceMethionine biosynthesis

The invention relates to an additive used in the preparation process of methionine and a preparation method of methionine. The additive provided by the present invention is the mixture that comprises A, B and C component, and A component has the structural formula represented by following general formula (1); B component has the structural formula represented by following general formula (2): C component is Silicone oil; RCON(CH 3 )CH 2 CH 2 SO 3 Na(1) The preparation method of methionine provided by the present invention comprises crystallization and / or recrystallization of methionine in the presence of the additive provided by the present invention. The additive provided by the invention has uniform emulsification, good stability, can be used stably for a long time, and is suitable for continuous crystallization process. The prepared methionine has good crystal form, high bulk density and good fluidity. In addition, according to the preparation method of methionine of the present invention, the crystallization system can run continuously and stably for a long time without obvious foaming phenomenon, and the crystallization process of the methionine product proceeds smoothly.

Owner:SHANDONG XINHECHENG AMINO ACID +2

A kind of preparation method of L-methionine

ActiveCN111269952BHigh purityImprove optical qualityOrganic compound preparationOrganic chemistry methodsAlcoholDL-methionine

The invention discloses a preparation method of L-methionine, which comprises the following steps: acetylating DL-methionine to obtain an acetylated product containing N-acetyl-DL-methionine; suction-filtering and collecting the acetylated product The solid matter is dried to obtain the N-acetyl-DL methionine mixture; the N-acetyl-DL methionine mixture is dissolved in absolute ethanol, then suction filtered and the filtrate is collected; the filtrate is subjected to vacuum distillation and the solid matter is collected , to obtain N-acetyl-DL methionine; the N-acetyl-DL methionine is subjected to enzymatic hydrolysis and decolorization treatment to obtain a product solution that generates L-methionine; the product solution is crystallized under reduced pressure and the crystalline solid is collected, and then Using ethanol solution to remove impurities and then dry the crystalline solid to obtain L-methionine. The preparation method of L-methionine provided by the invention improves the purity of L-methionine and improves the optical quality of L-methionine.

Owner:湖北省八峰药化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com