Preparation method of 1, 4-succinic acid adenosine methionine

A technology of adenosylmethionine succinate and adenosylmethionine, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problem of inability to ensure that the product meets the relevant raw material drug standards, unstable product quality, Complicated preparation methods and other issues, to achieve the effects of high product yield, white color, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

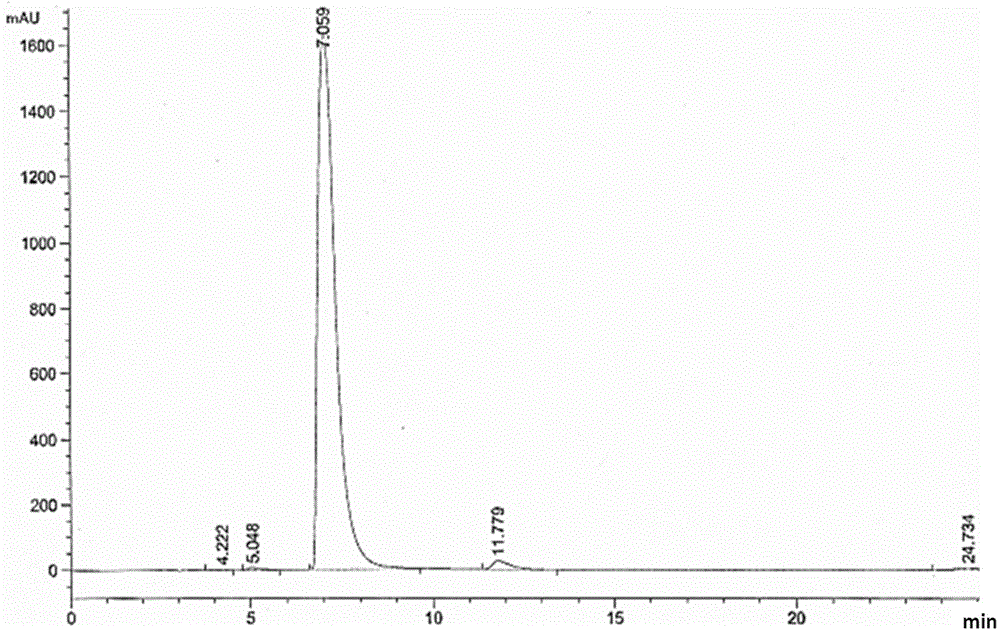

Image

Examples

Embodiment 1

[0045] A preparation method of 1,4-butanedisulfonic acid adenosylmethionine, which comprises the steps of:

[0046] (1) Fermentation and cultivation of adenosylmethionine-producing bacteria, the specific steps are as follows:

[0047] 1) Saccharomyces cerevisiae CPCC340488 was inoculated on the slant medium for slant culture, cultured at 30°C for 3 days, and then refrigerated at 4°C for 5 days to obtain a well-grown slant; the slant medium contained: soybean peptone 2.0wt% , yeast extract 0.5wt%, glucose 2.0wt% and agar strip 2.0wt%, the pH value of the slant medium is 6.0;

[0048] 2) Add 20mL of sterile water to the growing slope, scrape it off with a sterile inoculation stick, place it in a shaker and vibrate evenly, then insert the seed medium with an inoculation amount of 0.5mL / 250mL bottle, and carry out seed cultivation. Cultivate on a shaking table at 250 rpm for 24 hours at 28°C; wherein, the seed medium contains: 2.0wt% glucose, 1.0wt% yeast extract and 2.0wt% soybe...

Embodiment 2

[0058] A preparation method of 1,4-butanedisulfonic acid adenosylmethionine, which comprises the steps of:

[0059] (1) Fermentation and cultivation of adenosylmethionine-producing bacteria, the specific steps are as follows:

[0060] 1) Saccharomyces cerevisiae CPCC340488 was inoculated on the slant medium for slant culture, cultured at 30°C for 3 days, and then refrigerated at 4°C for 5 days to obtain a well-grown slant; the slant medium contained: soybean peptone 2.0wt% , yeast extract 0.5wt%, glucose 2.0wt% and agar strip 2.0wt%, the pH value of the slant medium is 6.0;

[0061] 2) Add 20mL sterile water to the well-grown slope, scrape it off with a sterile inoculation stick, place it in a shaker and oscillate evenly, then insert the inoculation amount of 1.5mL / 750mL bottle into the seed medium, and carry out seed cultivation. Cultivate on a shaking table at 250 rpm for 24 hours at 28°C; wherein, the seed medium contains: 2.0wt% glucose, 1.0wt% yeast extract and 2.0wt% so...

Embodiment 3

[0071] A preparation method of 1,4-butanedisulfonic acid adenosylmethionine, which comprises the steps of:

[0072] (1) Fermenting and culturing the adenosylmethionine-producing bacteria, the specific operation steps are the same as in Example 2;

[0073] Use oxalic acid to adjust the pH value of the fermented liquid to 3.0, and obtain 15L of wet cells after plate and frame filtration. After the wet cells are dried by cold wind until the water content is 10wt%, freeze-thaw treatment is carried out twice. The method of freeze-thaw treatment is as follows: Freeze the wet cells at -80°C for 24 hours, then thaw at 20-25°C for 4 hours; mix 75L of sulfuric acid aqueous solution with a pH value of 4 and the wet cells after freezing and thawing, and place them at 0-10°C for 3 hours. Obtain the acid solution containing the wall-broken bacteria;

[0074] (2) At 0-10°C, filter the acid solution containing broken-wall bacteria in a ceramic membrane, and add an aqueous solution of oxalic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com