A kind of preparation method of L-methionine

A technology of methionine and acetyl, which is applied in the field of L-methionine preparation, can solve the problems of L-methionine product optical rotation not meeting the requirements, enterprise loss, L-methionine impurity, etc., and achieve the effect of improving optical quality and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

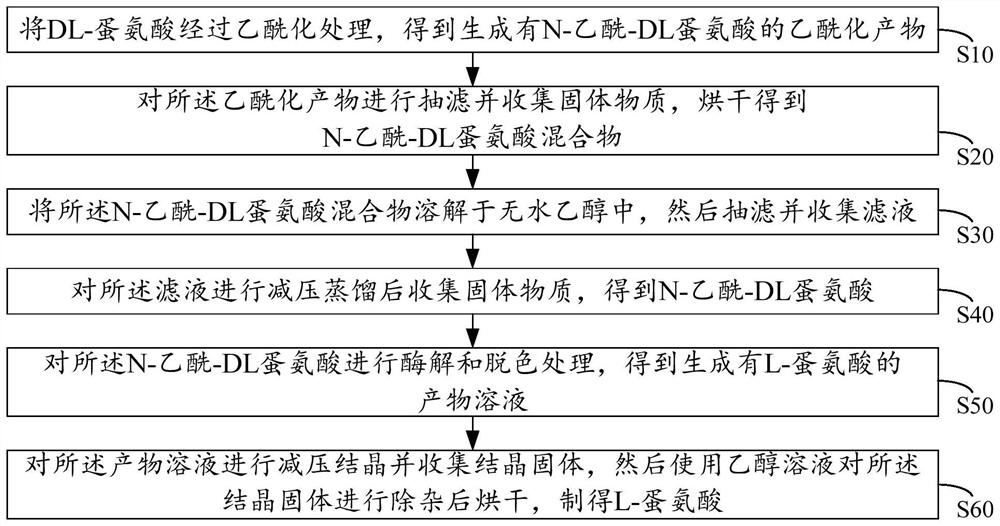

[0034] In view of this, the present invention proposes a preparation method of L-methionine, starting from the process of improving the enzymatic production of L-methionine, and realizing the purpose of the optical rotation of the finished product of L-methionine, figure 1 Shown is an example of the preparation method of L-methionine provided by the present invention. see figure 1 Shown, in this embodiment, the preparation method of described L-methionine comprises the following steps:

[0035] Step S10, acetylating DL-methionine to obtain an acetylated product containing N-acetyl-DL-methionine;

[0036] In this example, the method of acetylating DL-methionine to generate N-acetyl-DL-methionine is as follows: DL-methionine is mixed with NaOH and acetic anhydride, and the acetylation reaction is carried out at a temperature of 35-50°C to obtain the N-acetyl-DL-methionine. An acetylation product of N-acetyl-DL methionine; wherein, the mass ratio of DL-methionine, NaOH and acet...

Embodiment 1

[0059] (1) Mix commercially available DL-methionine with NaOH and acetic anhydride (the mass ratio of the three is 1:0.4:0.6), and carry out acetylation reaction at a temperature of 40°C to obtain N-acetyl-DL-methionine Acetylation products;

[0060] (2) Suction filter the acetylated product obtained in step (1) and collect the solid matter, and then dry it at a temperature of 55° C. to obtain a mixture of N-acetyl-DL methionine;

[0061] (3) Dissolving the N-acetyl-DL methionine mixture obtained in step (2) in absolute ethanol, then suction filtering and collecting the filtrate;

[0062] (4) under the vacuum of 0.03MPa, the filtrate obtained in step (3) is heated and distilled until the solvent is completely volatilized, and then the solid matter obtained by distillation is collected to obtain N-acetyl-DL methionine;

[0063] (5) Put the N-acetyl-DL methionine obtained in step (4) into the enzymolysis tank, then add aminoacylase and an appropriate amount of water to form the...

Embodiment 2

[0067] (1) Mix commercially available DL-methionine with NaOH and acetic anhydride (the mass ratio of the three is 1:0.2:0.3), and perform an acetylation reaction at a temperature of 35°C to obtain N-acetyl-DL-methionine. Acetylation products;

[0068](2) adding diameter to the acetylation product that step (1) obtains is the glass microsphere of 2.5mm (the mass ratio of glass microsphere and acetylation product is 1:10), then suction filtration and collect solid matter, solid The substance is dried at a temperature of 50° C. to obtain a mixture of N-acetyl-DL methionine;

[0069] (3) Dissolving the N-acetyl-DL methionine mixture obtained in step (2) in absolute ethanol, then suction filtering and collecting the filtrate;

[0070] (4) under the vacuum of 0.01MPa, the filtrate obtained in step (3) is heated and distilled until the solvent is completely volatilized, and then the solid matter obtained by distillation is collected to obtain N-acetyl-DL methionine;

[0071] (5) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com