Optimized methionine preparation method based on carbon dioxide acidification method

A carbon dioxide and methionine technology, applied in the field of methionine production, can solve the problems of membrane blockage, increased solution resistance, low electrodialysis efficiency, etc., and achieve the effect of increasing single yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

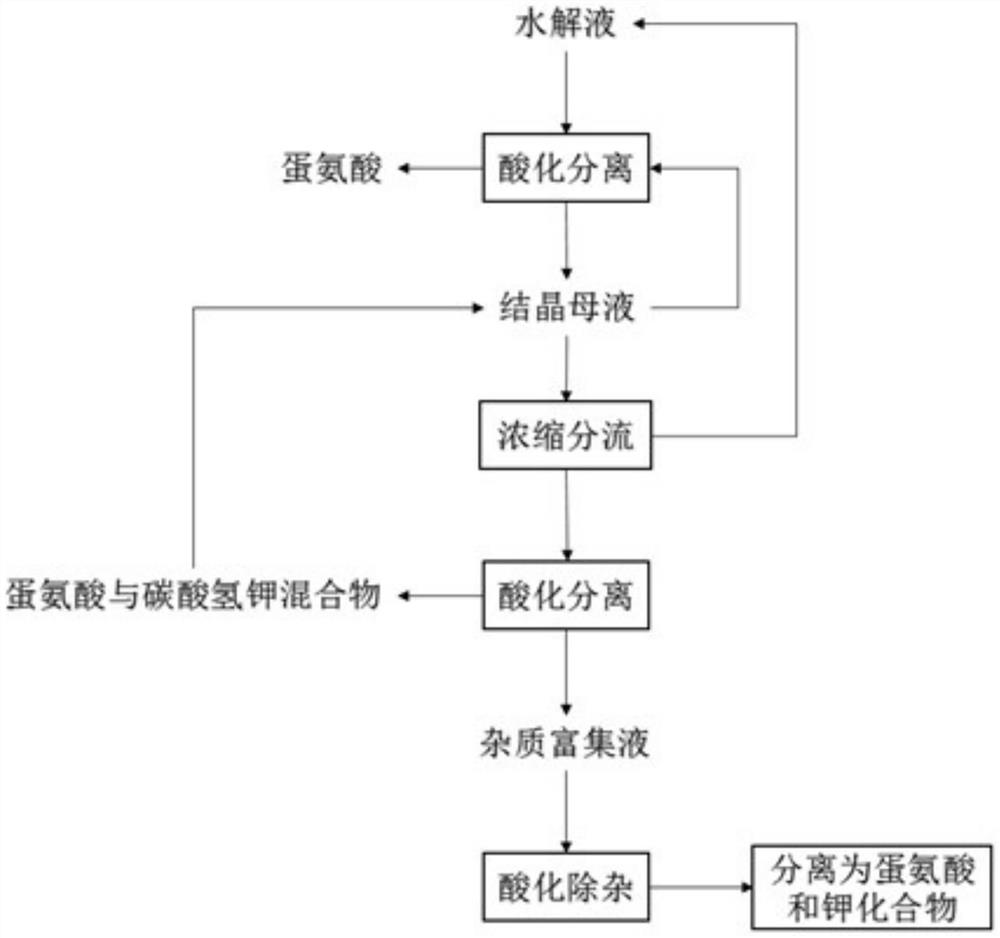

[0041] Example 1 The optimized preparation method of methionine based on carbon dioxide acidification method

[0042] S1.5-(2-Methylthioethyl)-hydantoin hydrolyzed by alkaline potassium hydrolysis, at a pressure of 3 to 10bar and a temperature of 10 to 40°C, pass through carbon dioxide and keep it warm for 10 to 100 minutes. During operation, the pressure can be selected from 3bar, 4bar, 5bar, 6bar, 7bar, 8bar, 9bar, 10bar, the temperature can be selected from 10℃, 20℃, 30℃, 40℃, and the holding time can be selected from 10min, 20min, 30min, 40min, 50min , 60min, 70min, 80min, 90min, 100min, centrifuged into methionine and crystallization mother liquor;

[0043] S2. Methionine is beaten with water and then separated and dried, and the beating water is incorporated into the crystallization mother liquor; the potassium bicarbonate embedded in the depth of methionine is washed out by means of beating, separated and dried again to obtain methionine with a content greater than 99% ...

Embodiment 2-1

[0053] Get 5-(β-methylthioethyl) hydantoin hydrolyzate 100kg through alkaline potassium hydrolysis, wherein the methionine content is 16.2wt%, and the alkaline potassium ion content is 11.5wt%. 11.1kg of methionine and 93kg of crystallization mother liquor were centrifuged at 25°C after feeding carbon dioxide for 80min; 11.1kg of methionine was separated and dried with 20kg of water and stirred at 25°C to obtain white methionine with a content of 99.7wt%; 93kg of crystallization mother liquor was obtained at 140 Concentrate at ℃ to 45kg concentrated solution, split 15kg split concentrated solution, and regenerate the remaining 30kg concentrated solution for the hydrolysis of 5-(2-methylthioethyl)-hydantoin, 15kg split concentrated solution at 20°C, 3bar 4.5 kg of crude methionine and 11 kg of impurity-enriched liquid were centrifuged after being acidified with carbon dioxide for 60 minutes; the pH of 11 kg of impurity-enriched liquid was adjusted to 2.3 with 98 wt % sulfuric ac...

Embodiment 2-2

[0055] Get 5-(β-methylthioethyl) hydantoin hydrolyzate 100kg through alkaline potassium hydrolysis, wherein the methionine content is 16.2wt%, and the alkaline potassium ion content is 11.5wt%. After feeding carbon dioxide at 25°C for 80 minutes, it was separated into 12.3kg of methionine and 90kg of crystallization mother liquor; 90kg of crystallization mother liquor was mixed with 19.8kg of beating water in Example 2-1, and then 4.5kg of crude methionine in Example 2-1 was added and stirred until Potassium bicarbonate in the mixture is completely dissolved to obtain the secondary mother liquor, and the extracted 105kg secondary mother liquor (the other 9kg secondary mother liquor is incorporated into the next hydrolyzate acidification system) is concentrated at 140°C to 44kg concentrate, and 15kg of the split concentrate Split, the remaining 29kg of the concentrated solution was regenerated and used for the hydrolysis of 5-(2-methylthioethyl)-hydantoin, and the 15kg of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com