Technology for continuously and rapidly synthesizing methionine by cyanohydrins method

A methionine, fast technology, applied in the chemical industry, can solve problems such as lack of economy and economy, incomplete hydrolysis, insufficient reaction, etc., to achieve the effect of saving material input and energy, fast reaction time, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

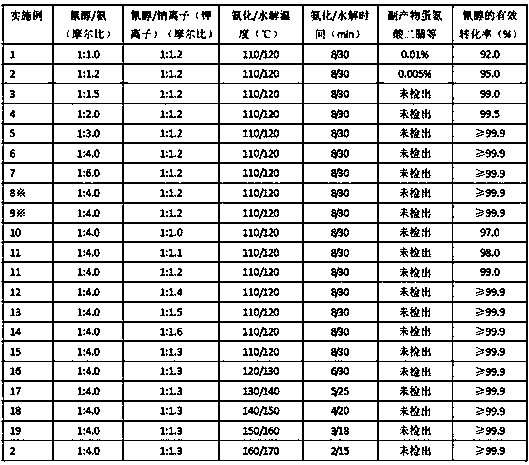

Examples

Embodiment

[0025] (1) Amination reaction: Preheat 2-hydroxy-4-methylthiobutyronitrile (cyanohydrin) aqueous solution (0.5 mole) to 60°C, and then pump it into the microchannel device through a metering pump at the same time as ammonia water, 2- The molar ratio of hydroxy-4-methylthiobutyronitrile (cyanohydrin) to ammonia is 1:1.5~6.0, the temperature is controlled at 90~170°C, the pressure of the ammoniated reaction is controlled at 0.8~1.5MPa, and the ammoniated reactant The residence time in the microchannel is 2 to 8min (that is, the time for the reaction solution to flow through the microchannel), and the outflowing liquid is a clear, colorless and transparent ammonia solution of 2-amino-4-methylthiobutyronitrile. After analysis, Methionine dinitrile was not detected;

[0026] (2) Hydrolysis reaction: pump the above-mentioned ammonia solution of 2-amino-4-methylthiobutyronitrile and sodium hydroxide solution (or potassium hydroxide, potassium carbonate solution) into the microchannel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com