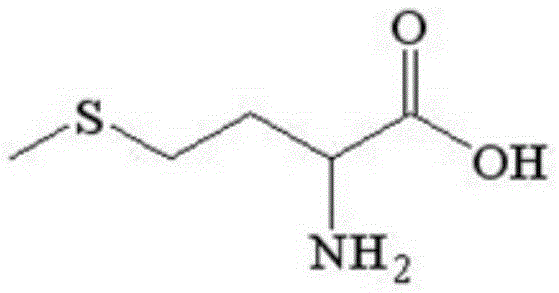

Preparation method of cheap and high-purity d,l-methionine

A technology of methionine and amino group, applied in the field of preparing D,L-methionine, can solve the problems of high production cost and influence, and achieve the effects of saving production time, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

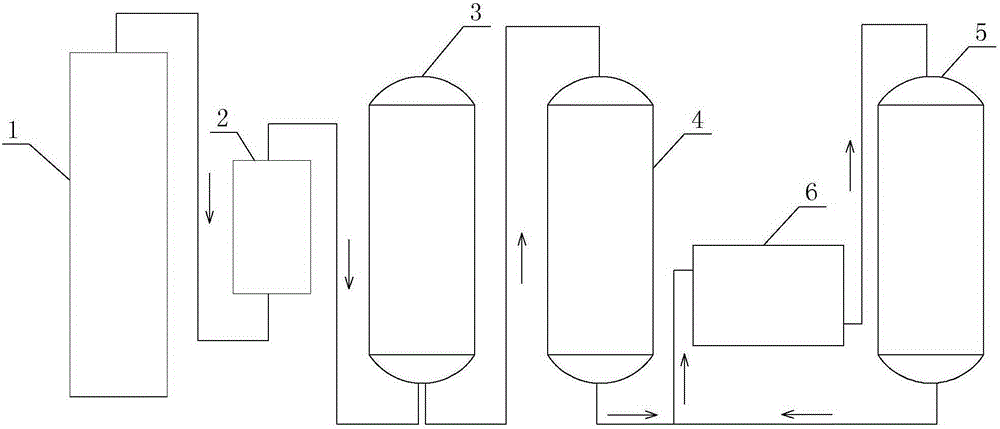

Method used

Image

Examples

Embodiment 1

[0045] The hydrocyanic acid mixed gas I from the hydrocyanic acid synthesis tower was detected. The composition of the hydrocyanic acid mixed gas I was: 8.87% hydrocyanic acid gas, 3.88% water vapor, 1.64% ammonia gas, 1.13% hydrogen gas, nitrogen gas 76.01%, oxygen 1.48%, carbon monoxide 5.67%, carbon dioxide 1.13%, methane 0.39%.

[0046] Hydrocyanic acid mixed gas I passes through a 75% sulfuric acid tower to absorb ammonia and water vapor in the mixed gas, and the composition of the obtained hydrocyanic acid mixed gas II is: 9.35% hydrocyanic acid gas, 1.57% hydrogen gas, and 79.44% nitrogen gas %, oxygen 1.71%, carbon monoxide 5.79%, carbon dioxide 1.50%, methane 0.64%.

Embodiment 2

[0048] Pass hydrogen cyanide mixed gas II into 223.3g of 94.5% methional with a mass fraction of 223.3g, which contains 3.3g of pyridine. React under normal pressure, control the reaction temperature to 45°C, the ventilation rate to 300L / min, absorb the tail gas with sodium hydroxide, and monitor the residual amount of methionaldehyde by HPLC. When the residual amount of methionaldehyde is less than 0.1%, you can stop feeding the crude hydrocyanic acid mixed gas II, and continue to stir for a period of time, and the conversion rate of 3-methylthiopropionaldehyde is 100%. A total of 270.64 g of light yellow liquid was obtained, the content of 2-hydroxy-4-methylthiobutyronitrile was 98%, and the residual hydrocyanic acid was 0.5%. The obtained 2-hydroxy-4-methylthiobutyronitrile together with its reaction solution (2-hydroxy-4-methylthiobutyronitrile system) was divided into two parts, one of which was stored at 3°C for 120 days, and no Decomposition; the other part was acidi...

Embodiment 3

[0050] Pass hydrogen cyanide mixed gas II into 223.3g of methional with a mass fraction of 94.5%, which contains 2.2g of pyridine and 10g of water. Under 0.15MPa, the reaction temperature is controlled to be 42°C, the ventilation rate is 280L / min, the tail gas is absorbed with sodium hydroxide, and the residual amount of methional is monitored by HPLC. When the residual amount of methionaldehyde is less than 0.1%, you can stop feeding the crude hydrocyanic acid mixed gas II, and continue to stir for a period of time, and the conversion rate of 3-methylthiopropionaldehyde is 100%. A total of 279.54 g of light yellow liquid was obtained, the content of 2-hydroxy-4-methylthiobutyronitrile was 98%, and the residual hydrocyanic acid was 0.07%.

[0051] At 45°C, 416.5g of ammonia water with a mass fraction of 60% was introduced into a stainless steel high-pressure reactor equipped with a stirrer, a thermometer, a pressure gauge, a feed pipe and a heat source. Then, within 2 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com