Method for improving saponin yield by low-acid pretreatment of dioscorea composita

A technology of diosminum chrysanthemum and acid pretreatment, applied in the direction of fermentation, etc., can solve the problems of pollution, low hydrolysis yield, etc., achieve the effect of improving hydrolysis yield, avoiding long pretreatment period, and good promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The optimization of the acid hydrolysis condition of embodiment 1 diosgenin

[0051] One, the acid hydrolysis method of diosgenin

[0052] Take Dioscorea chrysanthemum freeze-dried powder and put it into a 50mL reaction kettle, add sulfuric acid solution according to the ratio of solid to liquid of 1:6, heat at 120°C, after the hydrolysis reaction is completed, cool to room temperature, then neutralize with NaOH, filter, and dry to obtain hydrolysis thing. The hydrolyzate was extracted with a Soxhlet extractor, petroleum ether (boiling range 60-90°C), and refluxed in a water bath at 90°C. After the solvent was recovered, the extract was dissolved in methanol to constant volume, and the content of diosgenin was determined by HPLC.

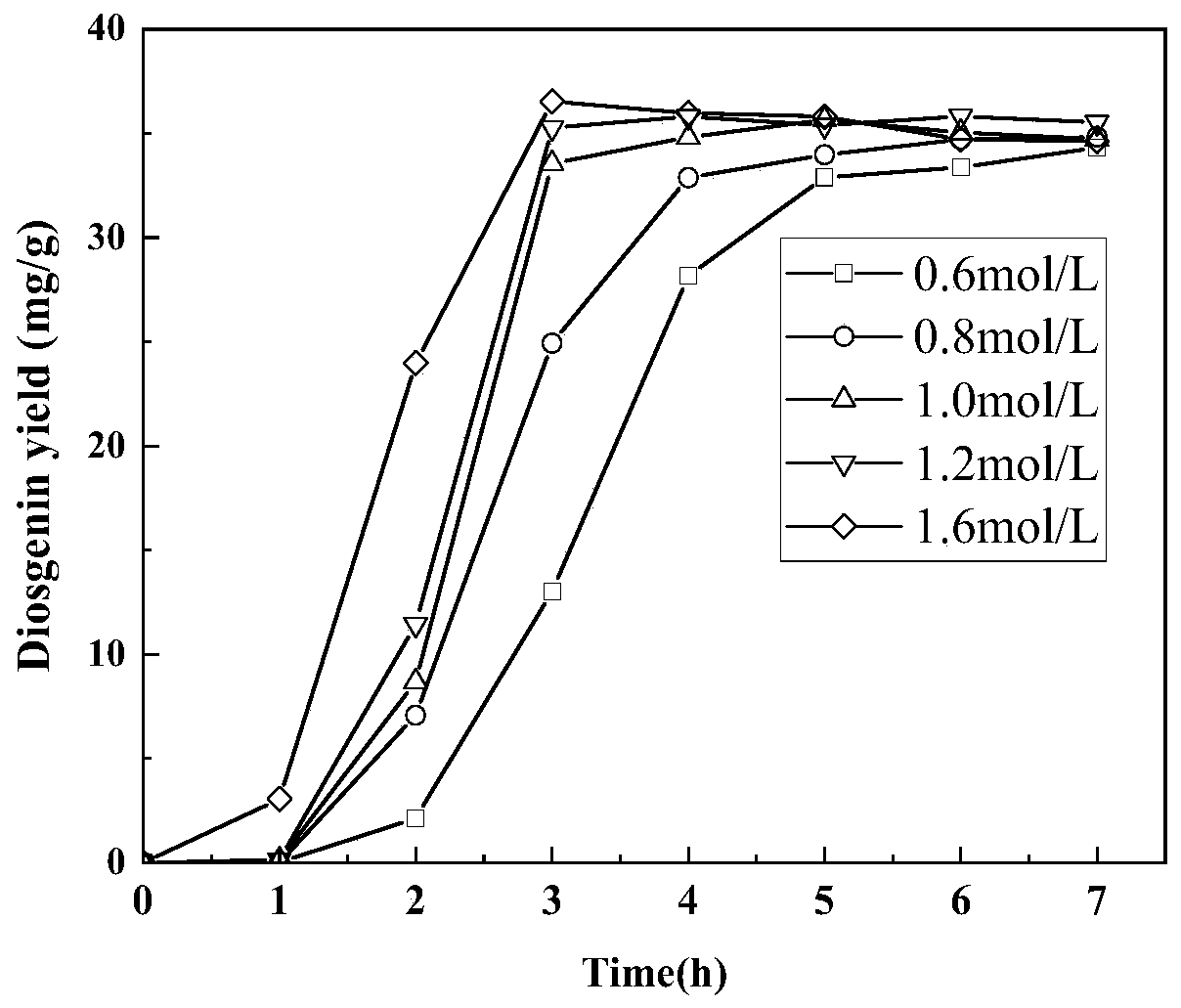

[0053] 2. Effect of sulfuric acid concentration on the acid hydrolysis of diosgenin

[0054] Select different concentrations of sulfuric acid (0.6mol / L, 0.8mol / L, 1.0mol / L, 1.2mol / L and 1.6mol / L) respectively, according to the solid-liquid ...

Embodiment 2

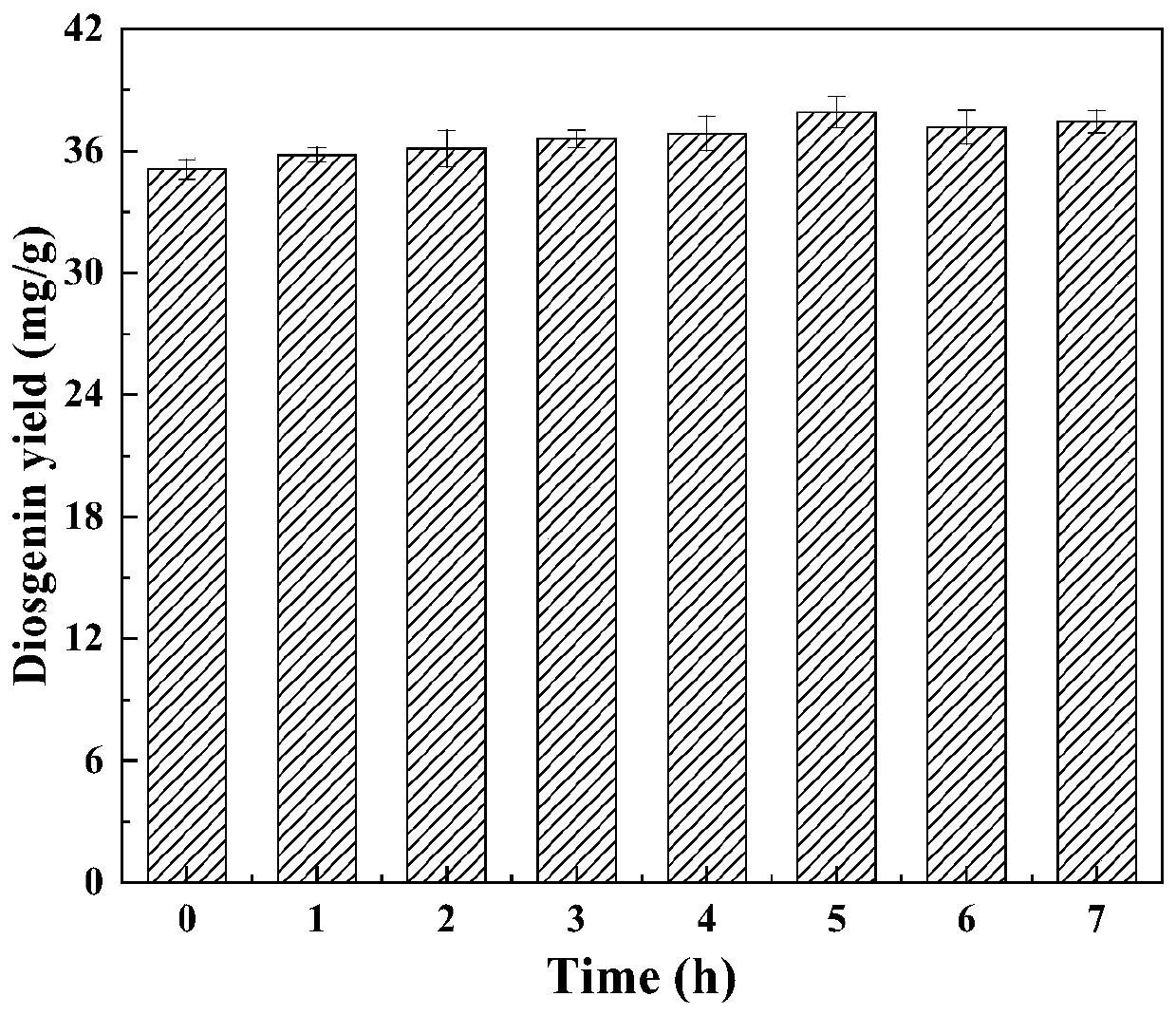

[0057] Example 2 Production of diosgenin by acid hydrolysis of Dioscorea chrysanthemum leaf after low-acid pretreatment

[0058] Select sulfuric acid with a concentration of 0.1mol / L, the temperature is 105°C, and the ratio of solid to liquid is 1:6. Pre-hydrolyze. g (water / raw material), centrifuge solid-liquid separation again, measure residual solids content, then, carry out the acid hydrolysis of diosgenin with the solid-to-liquid ratio of 1:6, pre-acidolysis is to the acid that diosgenin hydrolysis consumes and The COD in the waste acid water was analyzed,

[0059] Specifically, select sulfuric acid with a concentration of 0.1mol / L, the temperature is 105°C, the ratio of solid to liquid is 1:6, pre-hydrolyze for 6 hours, and directly centrifuge for solid-liquid separation, take the solid, and then make up to 6ml / g with deionized water (water / raw material), re-centrifuge solid-liquid separation, measure remaining solid content, then, carry out the acid hydrolysis of diosg...

Embodiment 3

[0060] The impact of embodiment 3 prehydrolysis on saponin

[0061] 1. Experimental method

[0062] Sulfuric acid with a concentration of 0.1mol / L is selected, the temperature is 105°C, and the ratio of solid to liquid is 1:6 for prehydrolysis treatment. Detect the content of steroidal saponin content after pretreatment.

[0063] 2. Experimental results

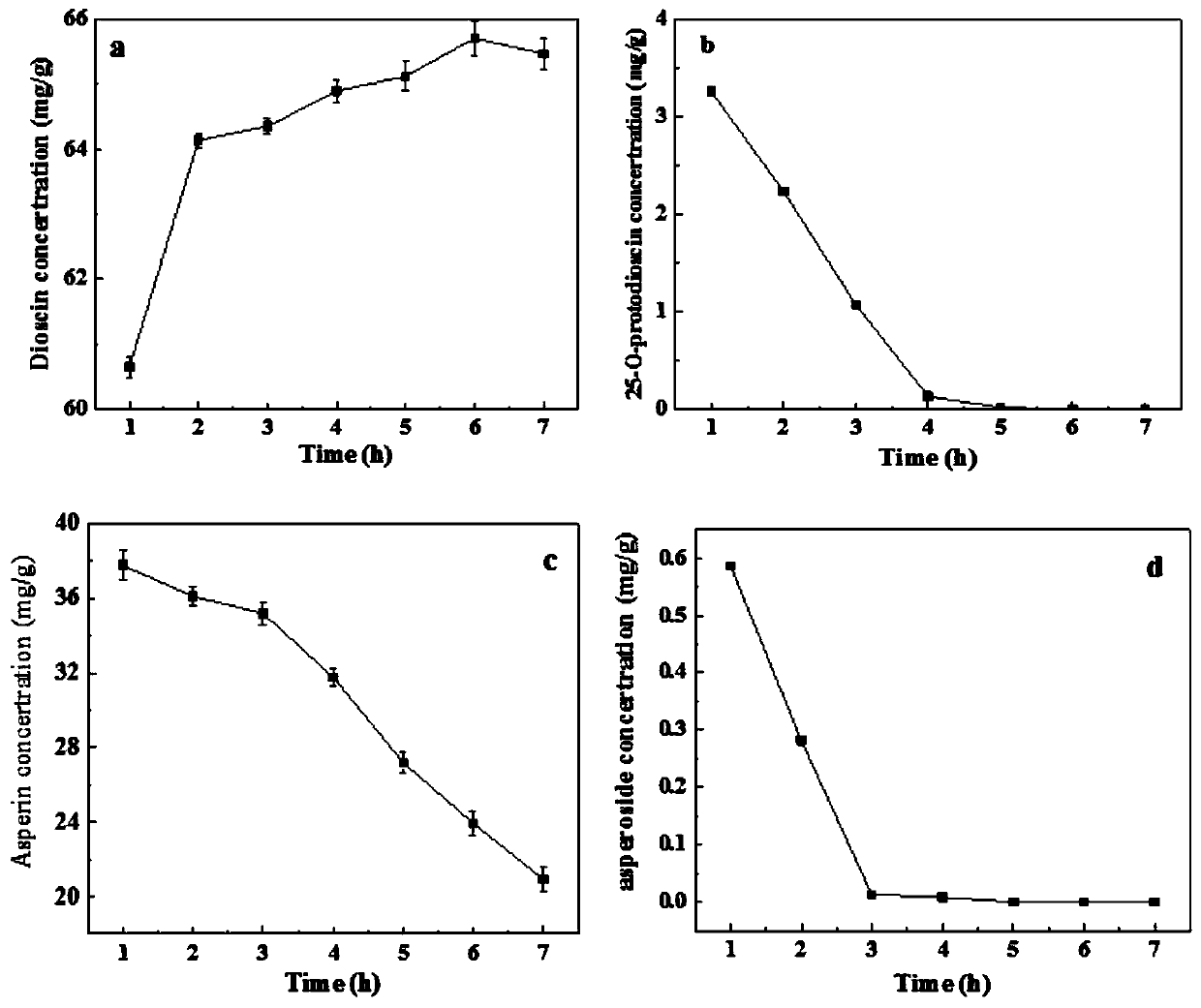

[0064] The change result of steroidal saponin content (1.0g Dioscorea chrysanthemi hydrolyzate system) after pretreatment is as follows image 3 .

[0065] The reduction of furostane saponin content and the increase of spirosterane saponin are the key to the improvement of diosgenin hydrolysis yield. In the process of low-acid hydrolysis, furostane saponin ( image 3 b and image 3 d) The content in the system is all reduced, wherein the content of 25-O-protodioscin is basically zero at 4 hours, and the furostane saponin asperoside with a lower content is also completely transformed after 3 hours; Alkanosides ( image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com