A method for improving the efficiency of cellulose enzymatic hydrolysis of rice straw by using lactic acid and guanidine hydrochloride

A technology of rice straw and cellulase, applied in the direction of fermentation, etc., can solve the problems of unfriendly environment and high cost, and achieve the effect of overcoming unfriendly environment, low cost, reducing equipment requirements and operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

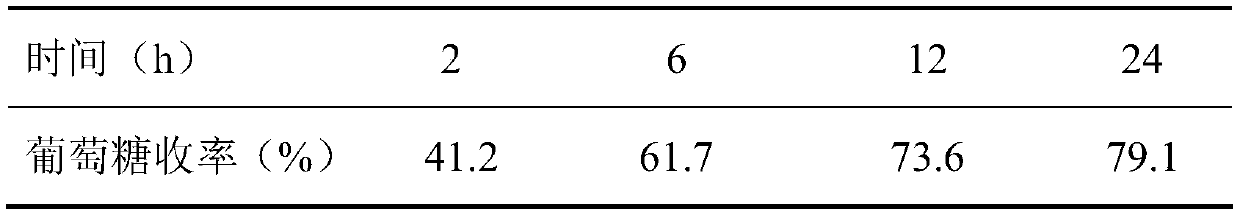

[0021] Lactic acid / guanidine hydrochloride (molar ratio 1:1) pretreatment improves rice straw enzymatic hydrolysis efficiency

[0022] a) Pretreatment: Accurately weigh 300mg of rice straw powder (the rice straw is dried and crushed into rice straw powder with an average particle size of 150-350μm) and 6g of lactic acid / guanidine hydrochloride deep eutectic solvent with a molar ratio of 1:1 , placed together in a 25mL Erlenmeyer flask, refluxed and stirred at 120°C for 6 hours; then cooled to room temperature, diluted with 6g of warm water, filtered, and then washed with 18g of deionized water for 4 times, and the filter residue was pretreated after drying After the rice straw.

[0023] b) Enzymolysis: Accurately weigh 20 mg of the above-mentioned pretreated rice straw, place it in a 50 mL Erlenmeyer flask, add 7 mL of citrate buffer solution (50 mmol / L, pH 4.8) and 160 U of the commercial product derived from Trichoderma reesei Cellulase was sealed and placed in a constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com