Production method for continuous bubble tower absorption of polysorbate

A production method and sorbic acid technology, applied in the production field of sorbic acid polyester continuous bubbling tower absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

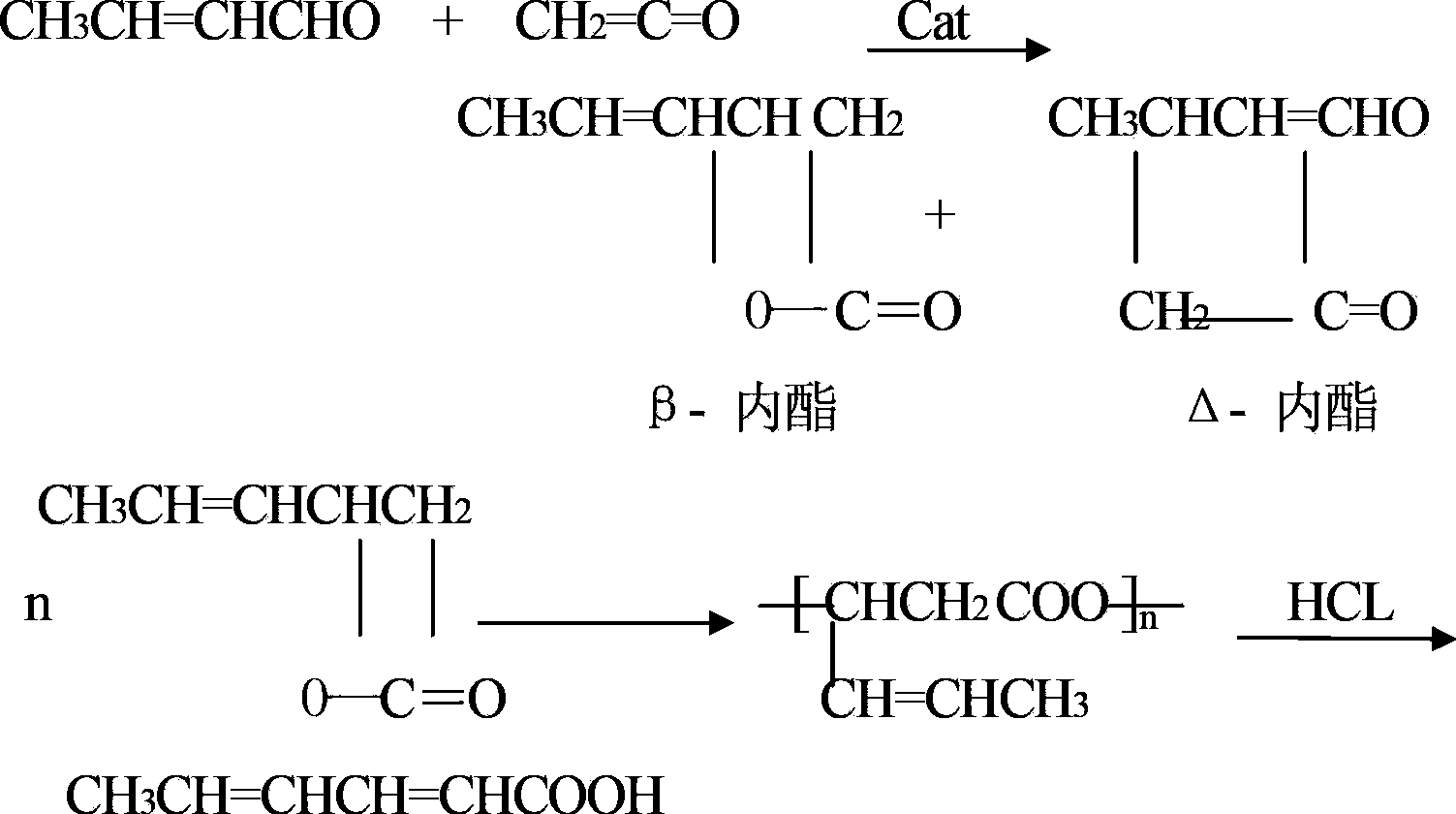

Method used

Image

Examples

Embodiment 1

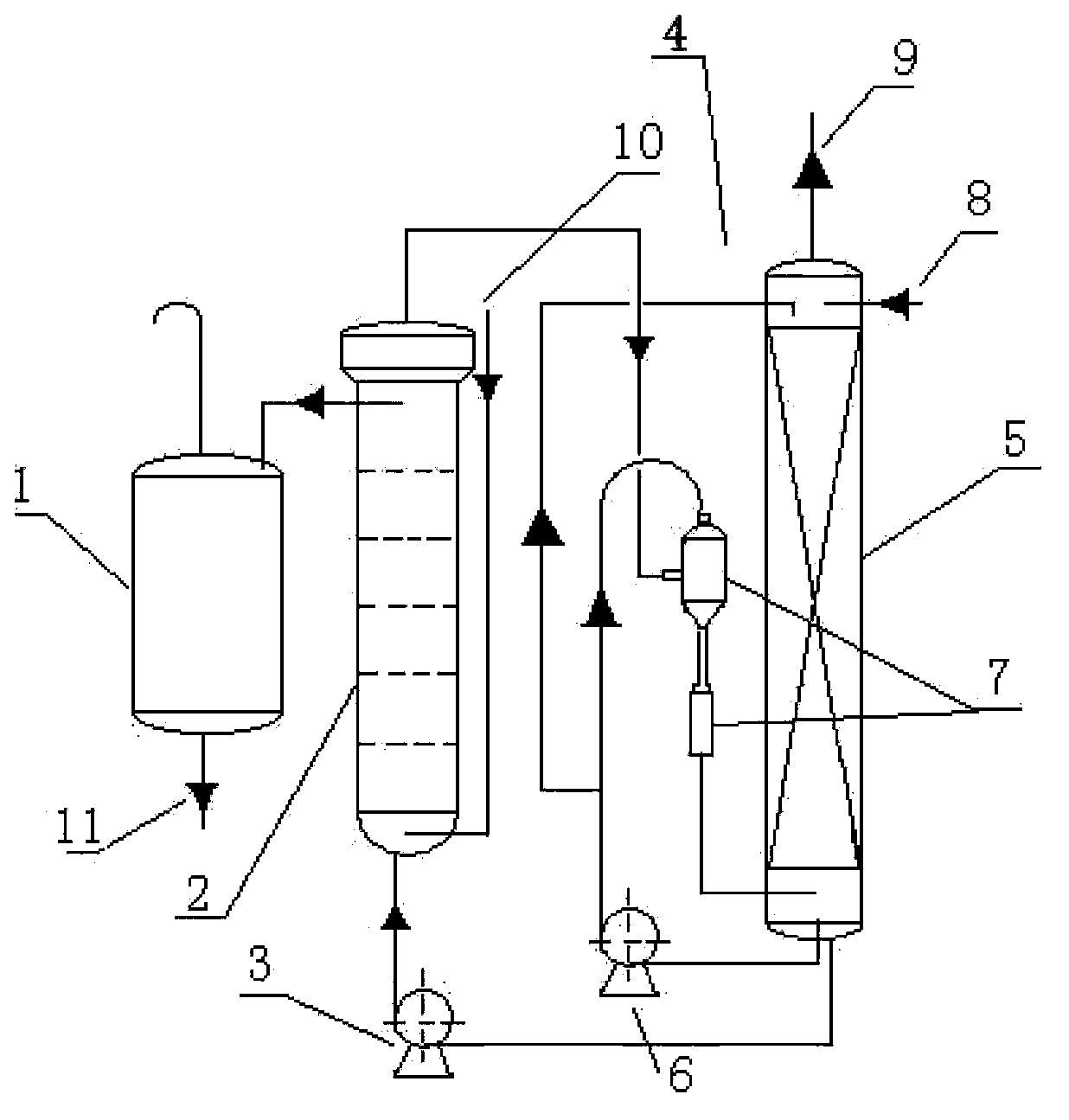

[0058] Schematic diagram of the reaction device for sorbic acid polyester continuous bubble column absorption as attached figure 1 shown.

[0059] Venturi jet pump 7 has a lift of 30m and a flow rate of 100m 3 / h, pumping capacity 150m 3 / h; the tower height of the secondary spray absorption tower 5 is 6m, and the tower diameter is 450mm; the tower height of the bubbling packed tower 2 is 3m, and the tower diameter is 400mm; the lift of the first circulation pump 3 is 30m; the lift of the second circulation pump 6 is 30m .

[0060] Content is that the material that 99% crotonaldehyde and polymerization catalyst mixes is sprayed in the tower by the top of spray absorption tower 5, and when the amount of liquid in the tower still is sufficient for system circulation, start the second circulation pump 6 outside the tower still. The crotonaldehyde material is circulated, and a part of the circulating material is sprayed into the top of the spray absorption tower 5, and returns...

Embodiment 2

[0063] Schematic diagram of the reaction device for sorbic acid polyester continuous bubble column absorption as attached figure 1 shown.

[0064] Venturi jet pump 7 has a lift of 35m and a flow rate of 150m 3 / h, pumping capacity 180m 3 / h; the tower height of the secondary spray absorption tower 5 is 7m, and the tower diameter is 550mm; the tower height of the bubbling packed tower 2 is 4m, and the tower diameter is 500mm; the lift of the first circulation pump 3 is 50m; the lift of the second circulation pump 6 is 50m .

[0065] With reference to the operation of Example 1, 99% crotonaldehyde is changed into 60% crotonaldehyde solution taking toluene as solvent, and the reaction conversion rate of control crotonaldehyde is 80%, and the sorbic acid polyester solution obtained is equally pressed The depolymerization post-processing method operation of embodiment 1 obtains 815g of white finished product sorbic acid, and content is greater than 99.5%, and the depolymerizati...

Embodiment 3

[0067] Schematic diagram of the reaction device for sorbic acid polyester continuous bubble column absorption as attached figure 1 shown.

[0068] Venturi jet pump 7 has a lift of 40m and a flow rate of 250m 3 / h, pumping capacity 260m 3 / h; the tower height of the secondary spray absorption tower 5 is 10m, and the tower diameter is 650mm; the tower height of the bubbling packed tower 2 is 7m, and the tower diameter is 600mm; the lift of the first circulation pump 3 is 60m; the lift of the second circulation pump 6 is 50m .

[0069] With reference to the operation of Example 1, 99% crotonaldehyde is changed into 80% crotonaldehyde solution taking toluene as solvent, and the reaction conversion rate of control crotonaldehyde is 60%, and the sorbic acid polyester solution obtained is equally pressed The depolymerization post-processing method operation of embodiment 1 obtains 823g of white finished product sorbic acid, and content is greater than 99.5%, and the depolymerizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com