Food-grade wheat protein hydrolase, wheat gluten hydrolysis treatment method and application

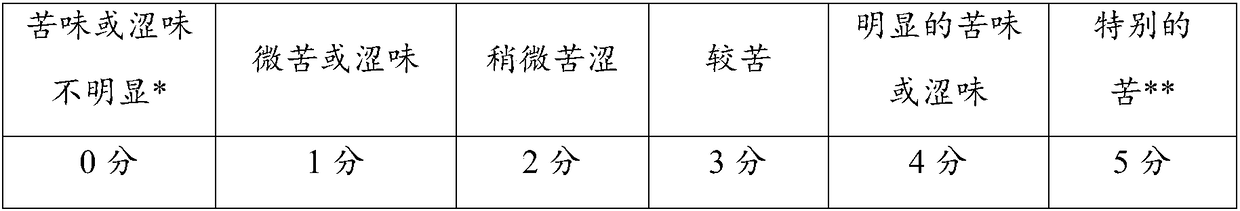

A wheat protein and hydrolytic enzyme technology, applied in the direction of hydrolytic enzymes, biochemical equipment and methods, enzymes, etc., can solve the problems of enzymolysis products with bitter taste, general taste, and low protein utilization rate, so as to improve the general taste and mild conditions , good flavor and mouthfeel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040]As a preferred embodiment of the present invention, the food-grade wheat proteolytic enzyme includes the following raw materials in parts by weight: 155-200 parts of alkaline protease, 125-160 parts of papain, 85-120 parts of acid protease, fiber 15-40 parts of prime enzyme and 500-640 parts of carrier.

[0041] Preferably, the food-grade wheat proteolytic enzyme includes the following raw materials in parts by weight: 160-195 parts of alkaline protease, 130-155 parts of papain, 85-115 parts of acid protease, 15-35 parts of cellulase and Carrier 500-620 parts.

[0042] By further limiting the amount of each raw material in the food-grade wheat proteolytic enzyme, the synergistic effect between the various enzymes is more significant, the ability to hydrolyze gluten is stronger, and the obtained enzymatic hydrolyzate has no bitterness and astringency Taste, and taste good.

[0043] The "comprising" in the present invention means that besides the stated components, other...

Embodiment 1

[0070] A food-grade wheat proteolytic enzyme provided in this example comprises the following raw materials in parts by weight: 150 parts of alkaline protease, 160 parts of papain, 90 parts of acid protease, 20 parts of cellulase and 580 parts of carrier.

Embodiment 2

[0072] A food-grade wheat proteolytic enzyme provided in this example comprises the following raw materials in parts by weight: 180 parts of alkaline protease, 140 parts of papain, 80 parts of acid protease, 10 parts of cellulase and 590 parts of carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com