Patents

Literature

51 results about "Ethanol synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

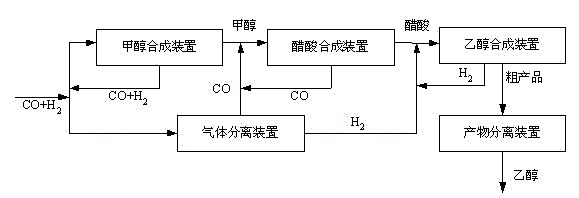

Process for preparing ethanol from synthesis gas via methyl alcohol

ActiveCN102690171AHigh selectivityHigh yieldOrganic compound preparationHydroxy compound preparationEthanol synthesisAcetic acid

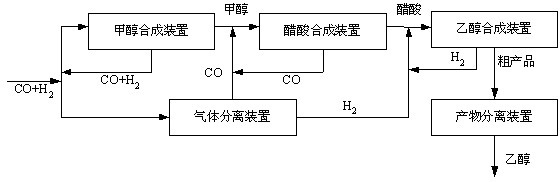

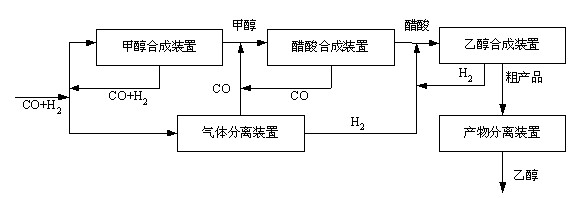

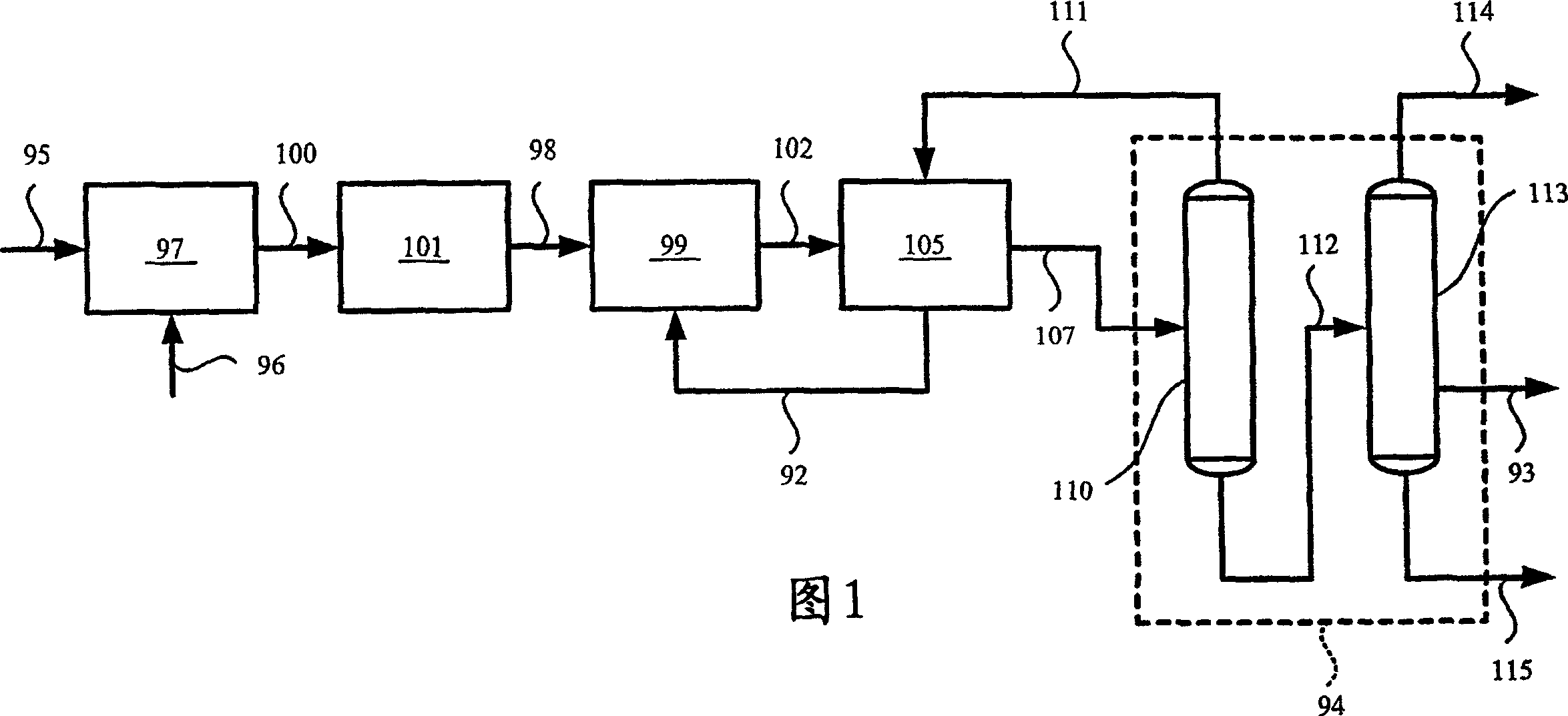

The invention relates to a process for preparing ethanol from synthesis gas via methyl alcohol. The synthesis gas is divided into two parts, one part of the synthesis gas is used for methanol synthesis, and the other part is separated as CO (carbon monoxide) and H2 (hydrogen); the synthesis gas and methanol synthesis circulating tail gas are mixed into methanol synthesis material gas; the methanol synthesis material gas is subjected to methanol synthesis reaction under the action of a methanol synthesis catalyst to obtain the methyl alcohol and methanol synthesis circulating tail gas; the CO separated from the synthesis gas and acetic acid synthesis circulating tail gas are mixed and then subjected to carbonylation together with methyl alcohol; acetic acid synthesis reaction is carried out to obtain acetic acid and acetic acid synthesis circulating tail gas; the H2 separated from the synthesis gas is mixed with ethanol synthesis circulating tail gas to enter a reactor; the mixed gas and acetic acid contact the catalyst to carry out the ethanol synthesis reaction by hydrogenation so as to obtain ethanol and by-product and ethanol synthesis circulating tail gas, and a crude product at the outlet of the reactor is separated to obtain ethanol. The process disclosed by the invention has the advantages of high ethanol yield, high energy utilization rate of overall process, low cost and feasibility in mass production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

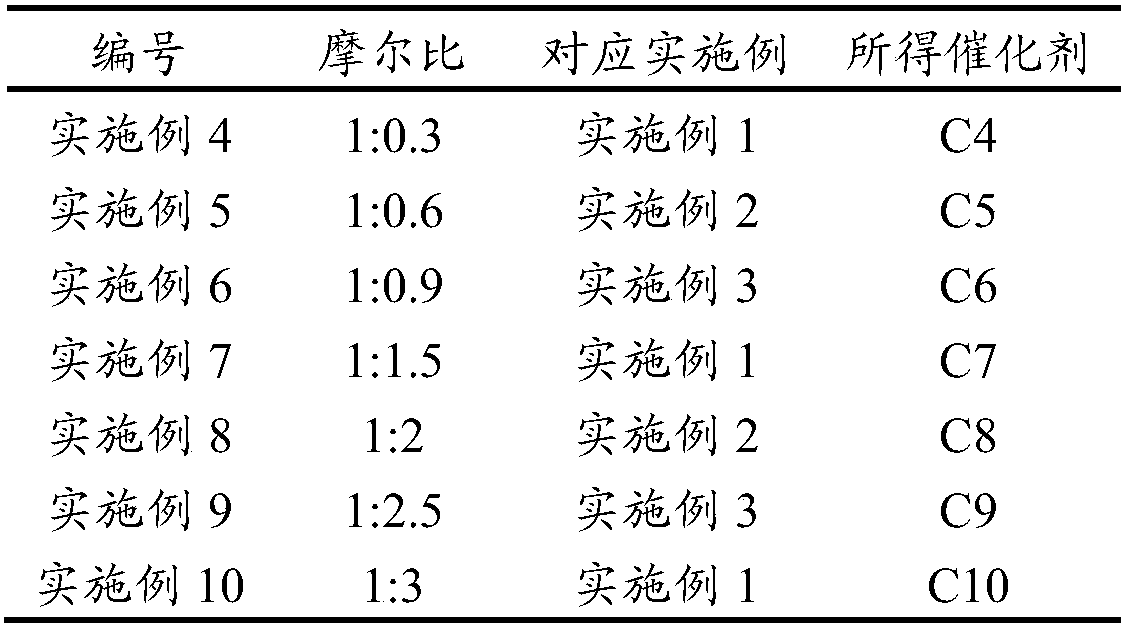

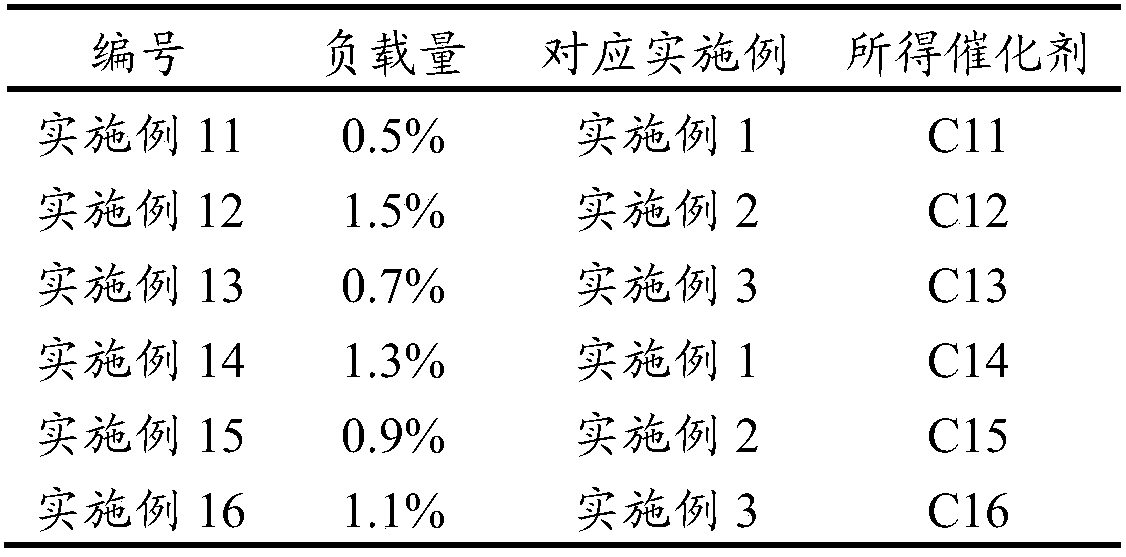

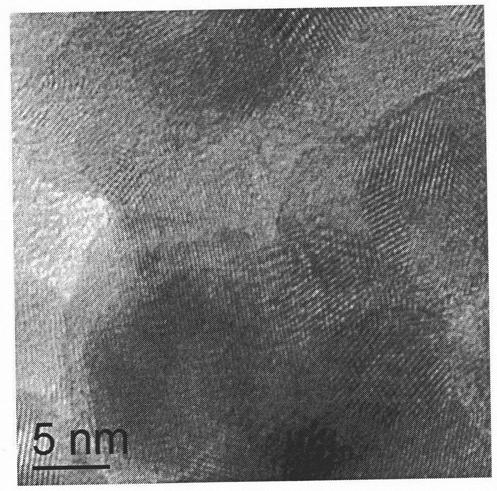

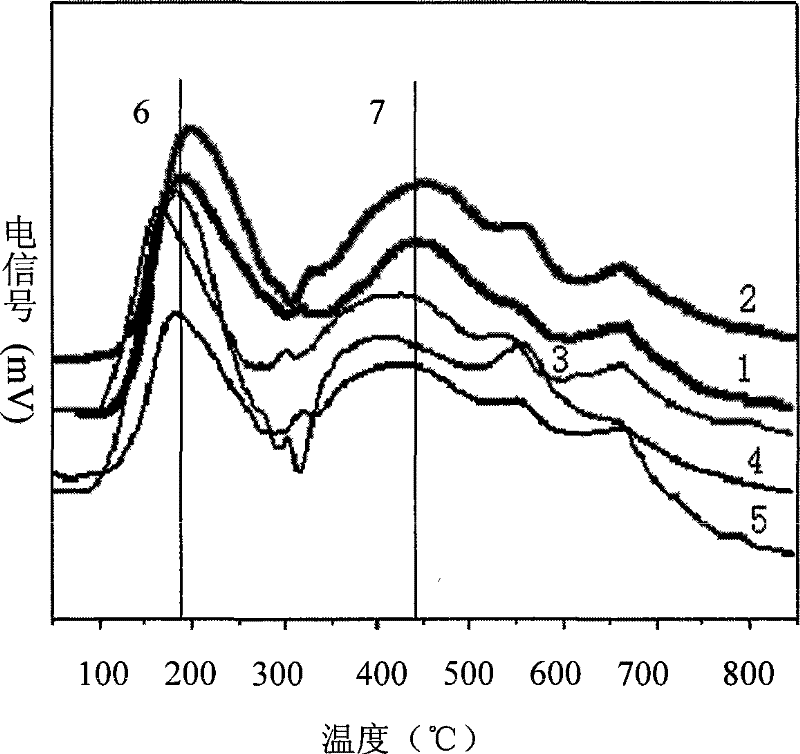

Copper-based catalyst for preparing ethanol by acetate hydrogenation and preparation method

InactiveCN104667925ASimple regenerationSimple preparation processOrganic compound preparationHydroxy compound preparationEthanol synthesisCopper

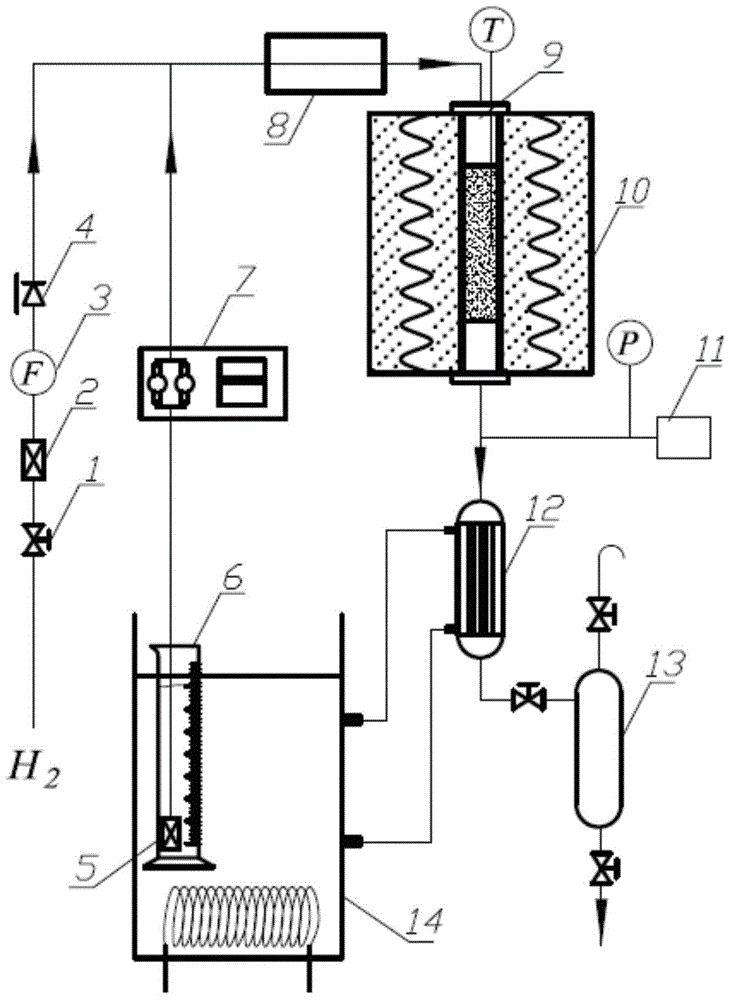

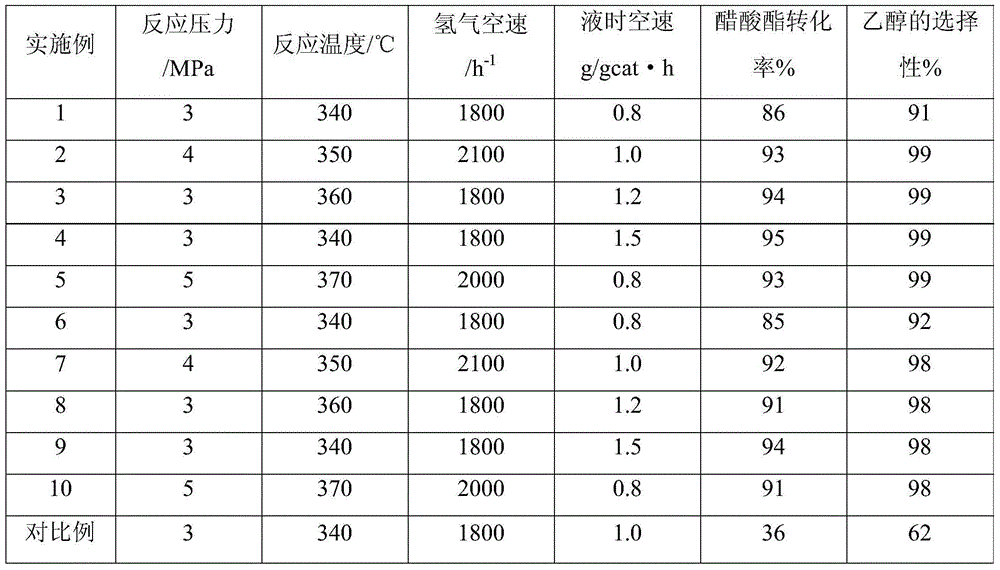

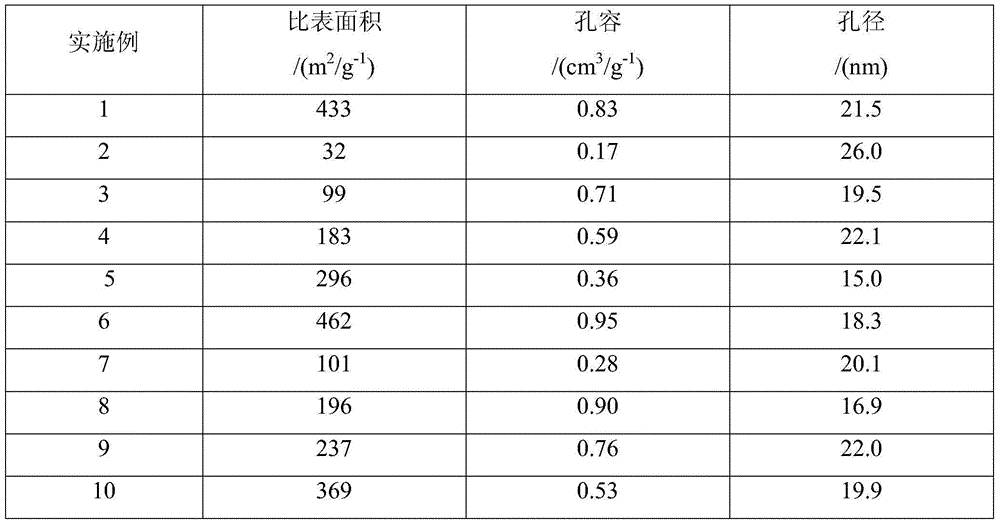

The invention discloses a copper-based catalyst for preparing ethanol by acetate hydrogenation and a preparation method. The catalyst is obtained by loading CuO and an auxiliary agent on a composite carrier, wherein the composite carrier is at least one of MgO-SiO2 and TiO2-SiO2; the mass ratio of MgO to SiO2 in the MgO-SiO2 ranges from (5:1) to (20:1), and the mass ratio of TiO2 to SiO2 in the TiO2-SiO2 ranges from (5:1) to (20:1); the mass of Cu in the CuO accounts for 5%-28% of the mass of the copper-based catalyst; and the mass of the auxiliary agent accounts for 1%-3% of the mass of the copper-based catalyst. The reaction activity of the catalyst is high when the catalyst is used for catalyzing acetate hydrogenation ethanol synthesis reaction; the conversion rate of acetate is more than 85%; the product selectivity is good and few byproducts are generated; the ethanol selectivity is up to 99%; and the catalyst can be simply regenerated after the reaction. The preparation method is simple and easy to operate, and has low cost.

Owner:TIANJIN UNIV

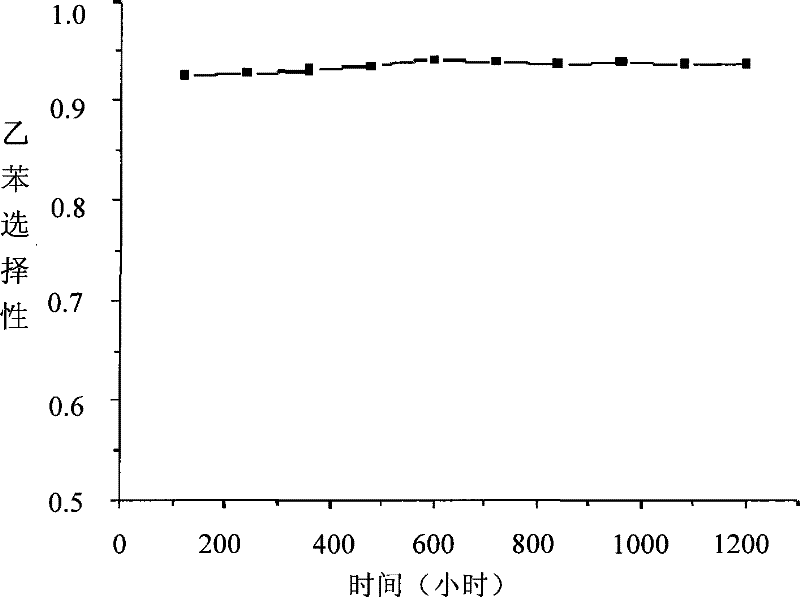

Catalyst for ethylbenzene and ethanol synthesis to realize shape-selectivity alkylation for diethylbenzene

InactiveCN102500410AHigh selectivityImprove conversion rateMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationIsomerizationReaction temperature

The invention relates to a catalyst for ethylbenzene and ethanol synthesis to realize shape-selectivity alkylation for diethylbenzene, which mainly resolves problems that existing ethylbenzene and ethanol synthesis is severe to secondary reaction such as ethylbenzene disproportionated reaction, isomerization reaction and the like in the technology of the diethylbenzene. Bioethanol can be used for replacing ethylene to resolve the problem that petrifaction raw materials are deficient. The technical scheme includes that the catalyst comprises, by weight, from 50 to 90 parts of hydrogen silicon-aluminum zeolite, from 1 to 10 parts of at least two metallic oxides of rare earth or alkaline metallic oxides and oxide binder, wherein SiO2 / Al2O3 mole ratio of the hydrogen silicon-aluminum zeolite is 20-200, the hydrogen silicon-aluminum zeolite is a 10-member ring pore structure, and the problems are resolved better. Reaction conditions of the synthesis to the diethylbenzene include that reaction temperature ranges from 350 DEG C to 450 DEG C; total pressure ranges from 0.2MPa to 2.0MPa; the ratio of ethylbenzene to ethanol ranges from 2.0 to 6.0; and space velocity ranges from 1-8h-1. The catalyst is applied to ethylbenzene alkylation process for the ethylbenzene and ethanol synthesis to the diethylbenzene, and has good catalytic reaction selectivity and yield.

Owner:TONGJI UNIV

Method for controlling the ratio of ethylene to propylene produced in an oxygenate to olefin conversion process

The present invention provides various processes for producing methanol and ethanol, preferably in a mixed alcohol stream. In one embodiment, the invention includes directing syngas to a synthesis zone wherein the syngas contacts a methanol synthesis catalyst and an ethanol synthesis catalyst under conditions effective to form methanol and ethanol. The methanol and ethanol, in a desired ratio, are directed to an oxygenate to olefin reaction system for conversion thereof to ethylene and propylene in a desired ratio. The invention also relates to processes for varying the weight ratio of ethylene to propylene formed in an oxygenate to olefin reaction system.

Owner:EXXONMOBIL CHEM PAT INC

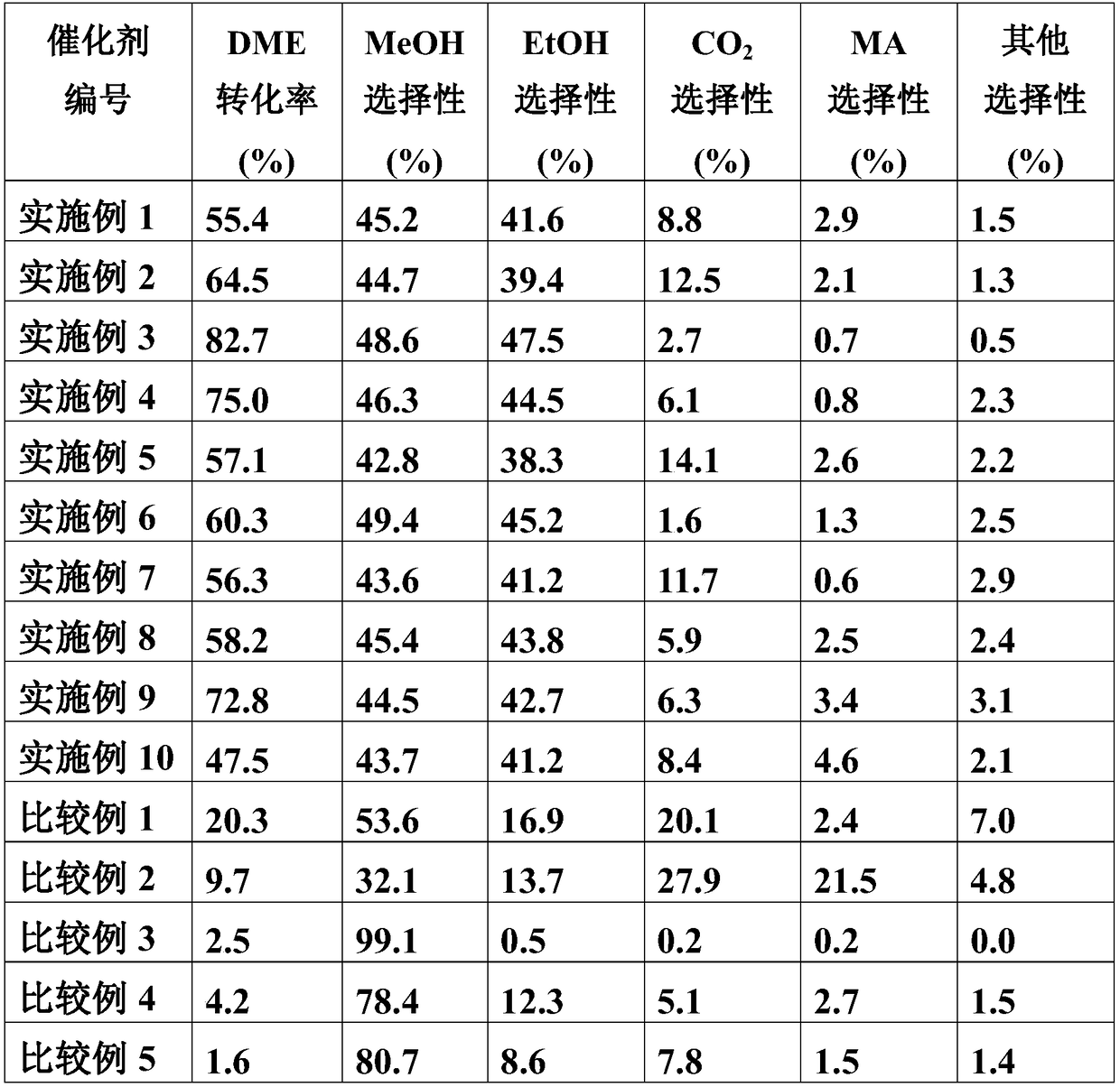

Preparation method of catalyst for ethanol synthesis and catalyst obtained thereby and application of catalyst

ActiveCN108238846AEasy to understandMolecular sieve catalystsOrganic compound preparationMolecular sieveEthanol synthesis

The invention relates to a preparation method of a core / shell catalyst which comprises (A) 40-80wt% of a copper-based catalyst core comprising CuMaOx as shown in a formula (I), wherein variables are defined in the description; and (B) a molecular sieve catalyst shell. The preparation method comprises the following steps: immersing copper-based catalyst particles with a silica sol and then coatingthe molecular sieve catalyst; or (b2) carrying out hydro-thermal treatment on a silane coupling agent solution and the copper-based catalyst particles, then carrying out hydro-thermal treatment with apure silicon molecular sieve, and finally, carrying out hydro-thermal treatment on the molecular sieve catalyst for a calcined product. The method can prepare the core / shell catalyst simply and successfully, and increased dimethyl ether conversion ratio and ethanol selectivity can be obtained when the catalyst is used for preparing ethanol by dimethyl ether and synthesized gas in a one-step method. The invention also provides the core / shell catalyst prepared by the method and an application of the core / shell catalyst in preparing ethanol by dimethyl ether and synthesized gas in the one-step method as the catalyst.

Owner:HIGHCHEM

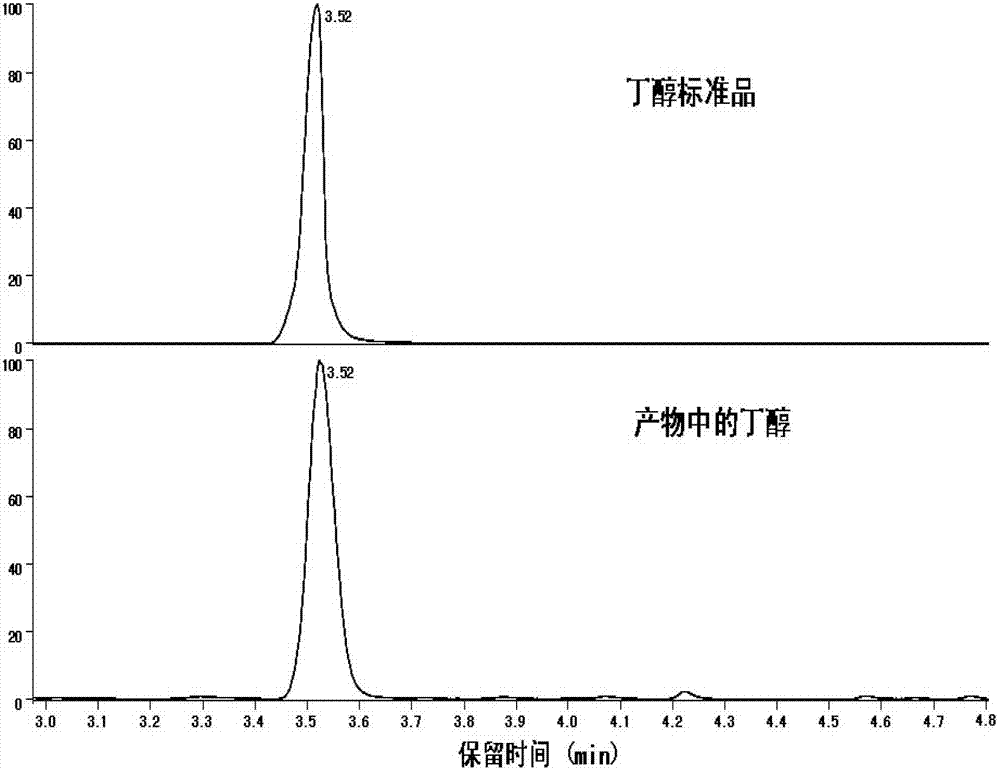

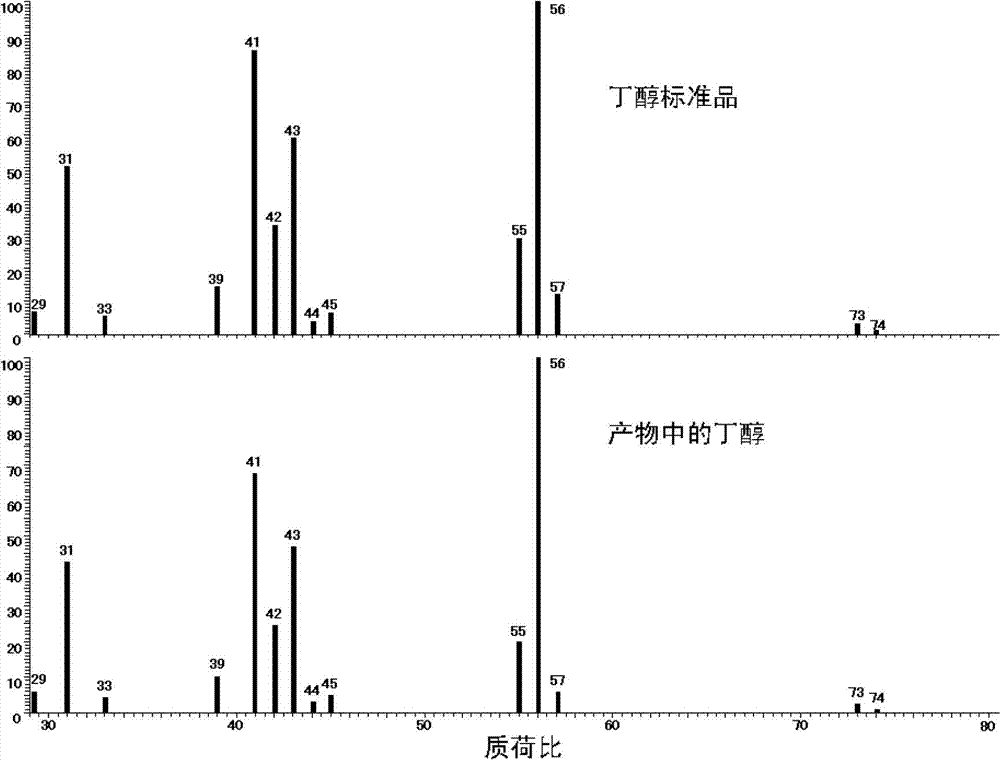

Method for preparing n-butanol from ethanol by using hydrothermal technique

InactiveCN103193593ARaw materials are easy to getLow costOrganic compound preparationHydroxy compound preparationSodium bicarbonateEthanol synthesis

The invention provides a method for preparing n-butanol from ethanol, and belongs to the technical field of hydrothermal chemistry. Ethanol and water are subjected to a hydrothermal reaction catalyzed by sodium bicarbonate and a metal cobalt powder in common. n-Butanol is prepared by reacting at 140-300 DEG C for 1-30 days. The present invention provides a novel mild reaction route for n-butanol synthesis from ethanol, simple catalysts are used, and n-butanol can be synthesized under mild conditions. The catalyst includes the metal cobalt powder and sodium bicarbonate, raw materials are readily available, and the cost is low. The catalyst is prepared by simply mixing without special treatment. The cobalt powder does not change after the reaction and can be reused. The method of the present invention is low in reaction temperature, has low requirement on equipments, only needs a sealed reactor, is easy to operate, and has selectivity for butanol up to 87%.

Owner:JILIN UNIV

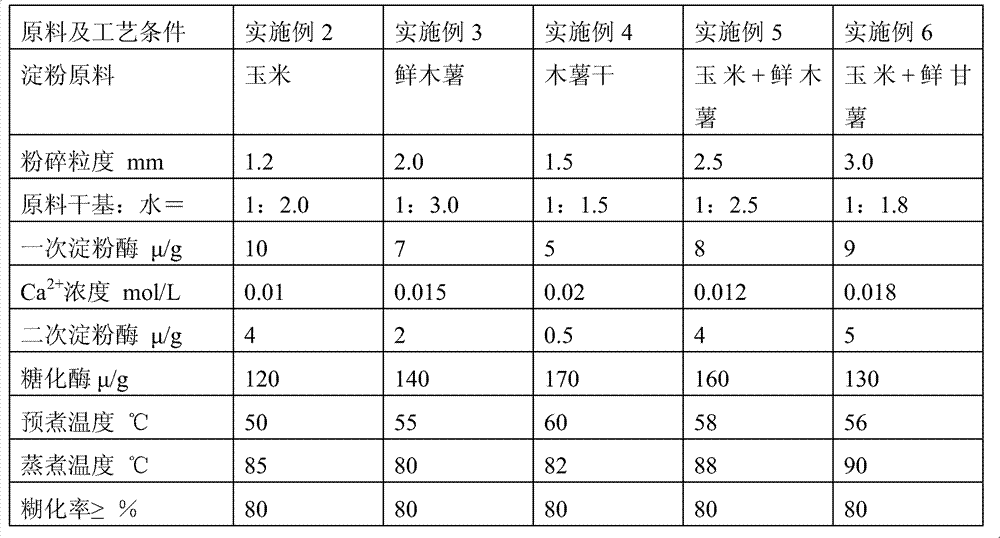

Method for preparing ethanol by low-temperature digestion and thick mash fermentation of starch as raw material

ActiveCN101948875AReduce moisture contentIncrease the sugar contentBiofuelsFermentationEthanol synthesisSlurry

The invention discloses a method for preparing ethanol by low-temperature digestion and thick mash fermentation of starch as a raw material, belonging to the field of ethanol synthesis with a fermentation method. The method adopts a process of low-temperature digestion for liquefying and thick mash fermentation and comprises the following operation steps of: a, cleaning and crushing raw materials, b, precooking to prepare powder slurry, c, digesting at low temperature for liquefying, and d, saccharifying, fermenting and distilling. The method for preparing the ethanol by low-temperature digestion and thick mash fermentation of starch as the raw material has the advantages of low water content and high sugar degree in a liquefied solution, low energy consumption, high yield, stable production and lower cost. The low-temperature digestion for liquefying ensures that total sugar content in the liquefied and pasted solution is not less than 25 percent, the thick mash fermentation ensures that ethanol content in fermented mature mash reaches 18 percent, the starch conversion rate is not less than 53 percent, and moreover, steam consumption amount is not larger than 0.7ton / ton of ethanol, and steam is saved by more than 40 percent.

Owner:江苏金茂源生物化工有限责任公司

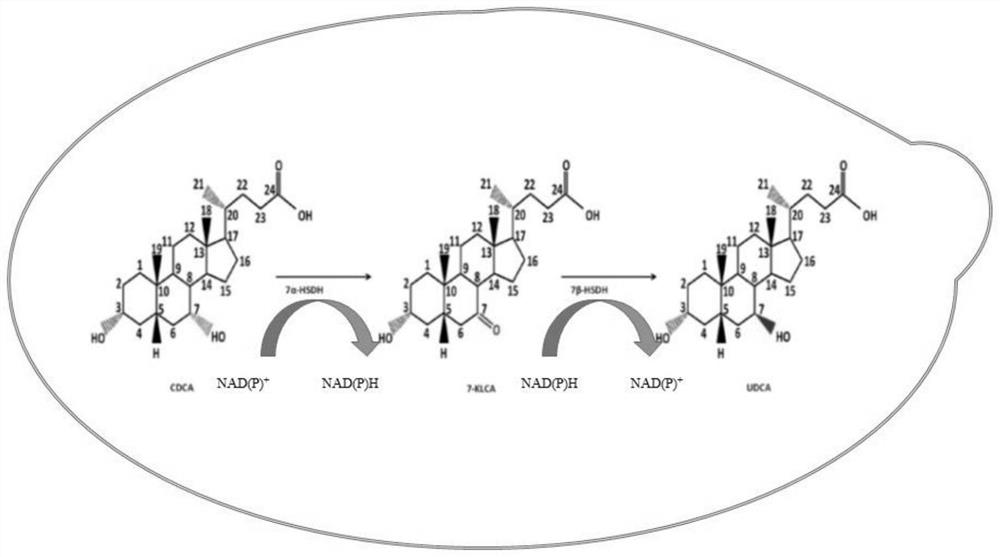

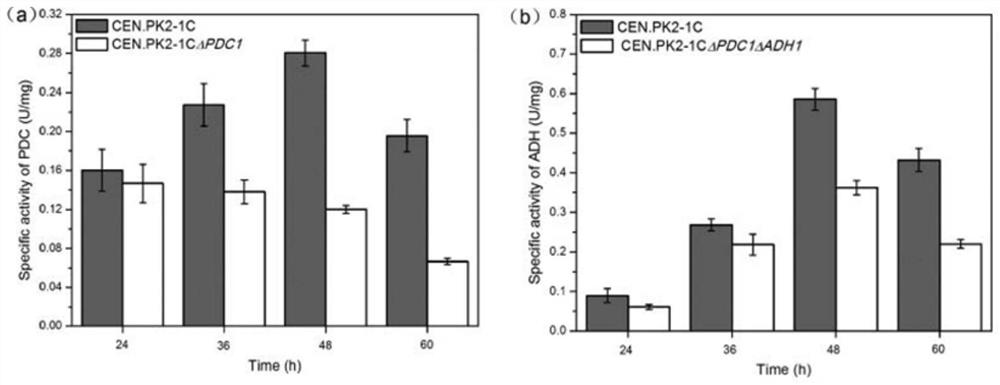

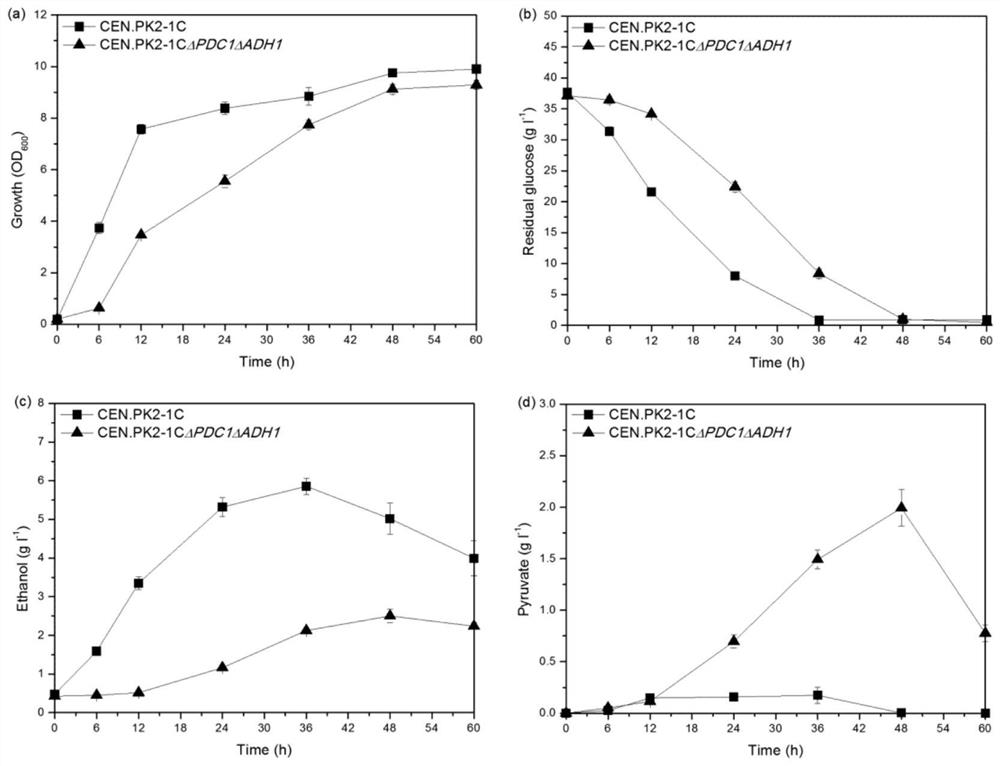

Recombinant yeast chassis cell transformation for efficiently converting chenodeoxycholic acid and construction and application of recombinant strain

The invention discloses recombinant yeast chassis cell transformation for efficiently converting chenodeoxycholic acid and recombinant strain construction and application, a saccharomyces cerevisiae strain S. Cerevisiae CEN.PK21C is used as a chassis cell of a recombinant yeast strain, a mutant yeast strain is obtained by knocking out target genes PDC1 and ADH1, and weakening of an ethanol synthesis path is realized. On the basis, 7 alpha HSDH and 7 beta HSDH coding genes from clostridium are heterologously expressed, and the purpose of biosynthesis of UDCA by taking CDCA as a substrate is achieved. At present, the conversion rate of the substrate CDCA reaches 90%.

Owner:JIANGNAN UNIV

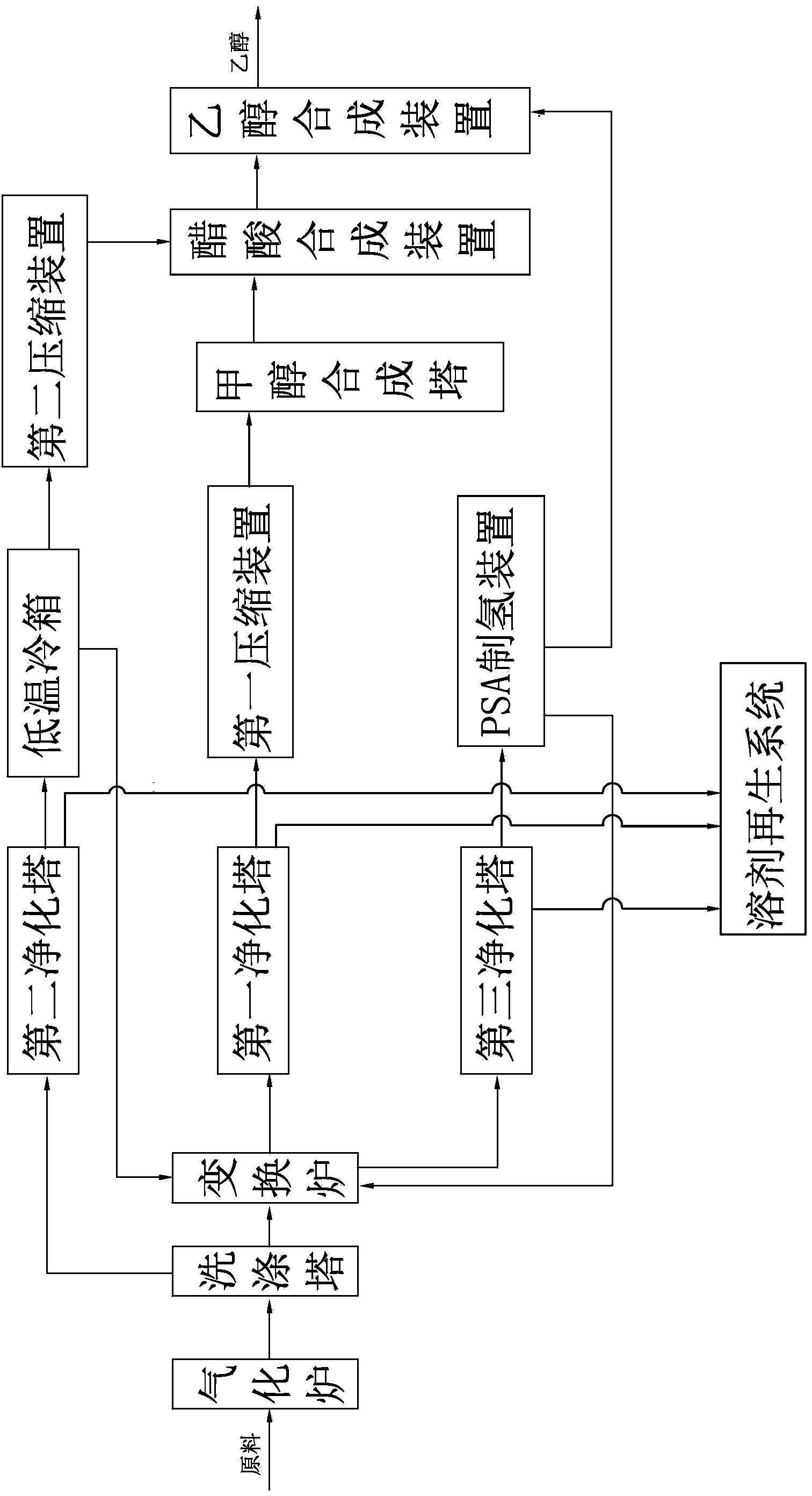

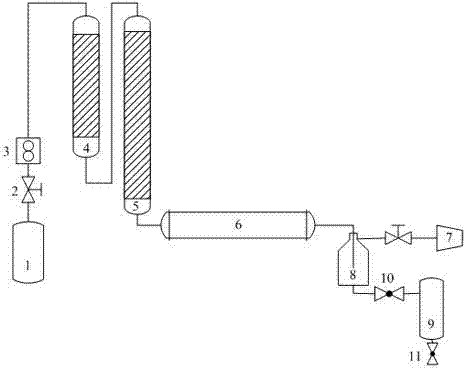

Co-production system for methanol and deeply processed ethanol gasoline and use method of co-production system

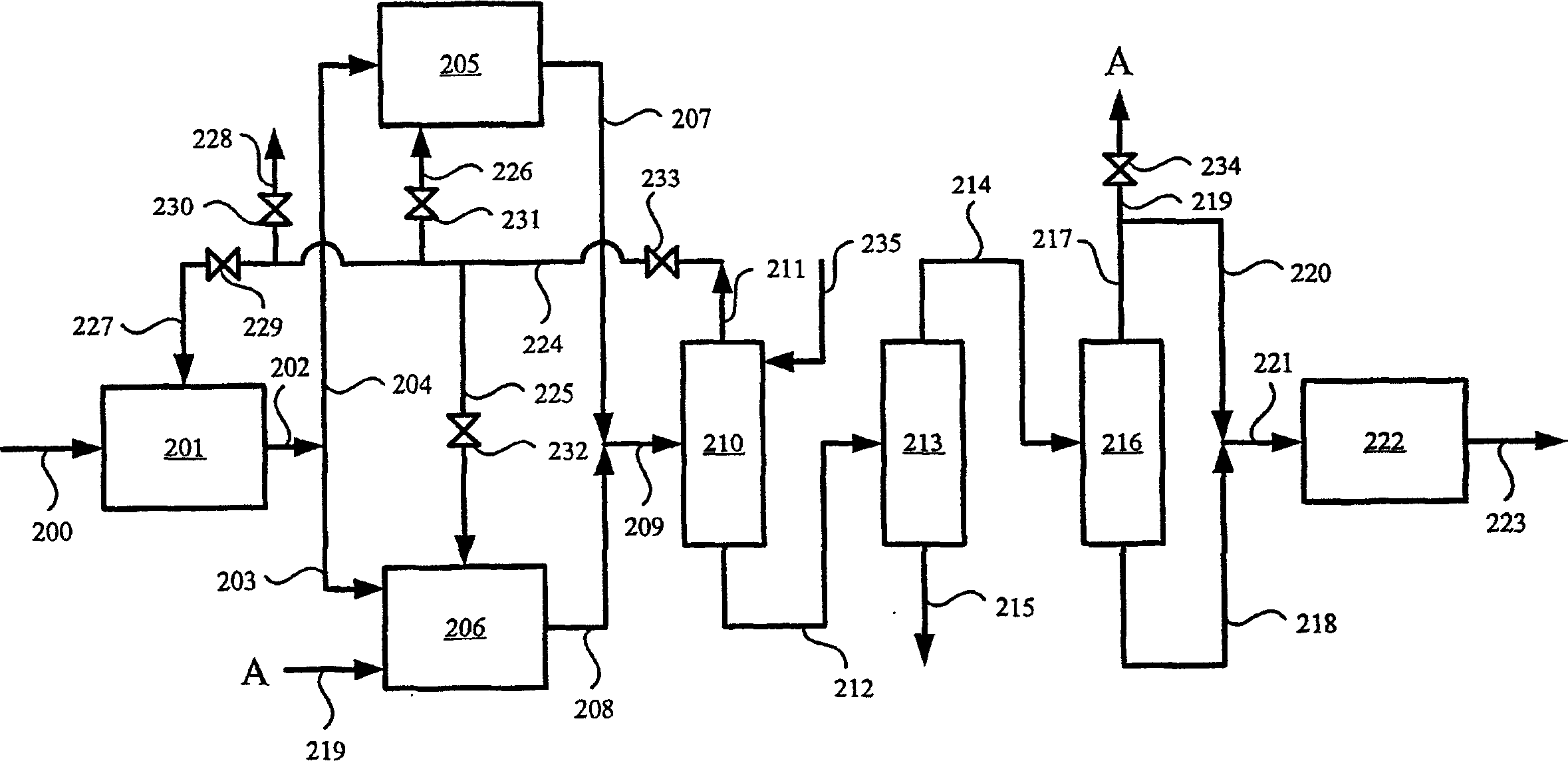

InactiveCN104263411ASpeed up the flowProcess technology managerOrganic compound preparationHydroxy compound preparationEthanol synthesisAcetic acid

The invention discloses a co-production system for methanol and deeply processed ethanol gasoline. The system comprises a gasification furnace, a washing tower, a conversion furnace, a first purification tower, a first compressing device, a methanol synthesis tower, an acetic acid synthesis device and an ethanol synthesis device which are connected in series sequentially, wherein the washing tower is further connected with a second purification tower, a low-temperature cooling box and a second compressing device in series sequentially, and the second compressing device is connected with the acetic acid synthesis device; and the conversion tower is further connected with a third purification device and a PSA (pressure swing adsorption) hydrogen production device in series sequentially, an outlet of the PSA hydrogen production device is connected with the ethanol synthesis device, and a tail gas outlet of the PSA hydrogen production device and a tail gas outlet of the low-temperature cooling box are connected with the conversion furnace respectively. The invention further provides a method for performing co-production by adopting the system. The method is simple, convenient, low in cost and capable of producing methanol and fuel ethanol, and the product structure can be completely adjusted according to market requirements.

Owner:ANHUI HUAIHUA

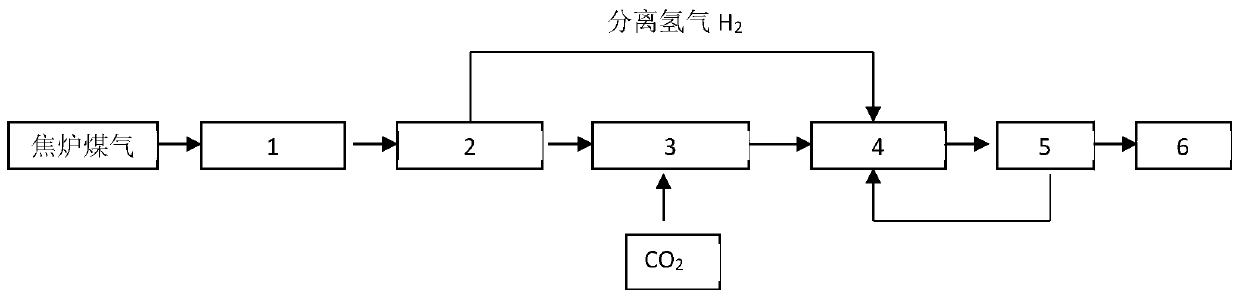

Method and system for directly preparing alcohol from coke oven gas

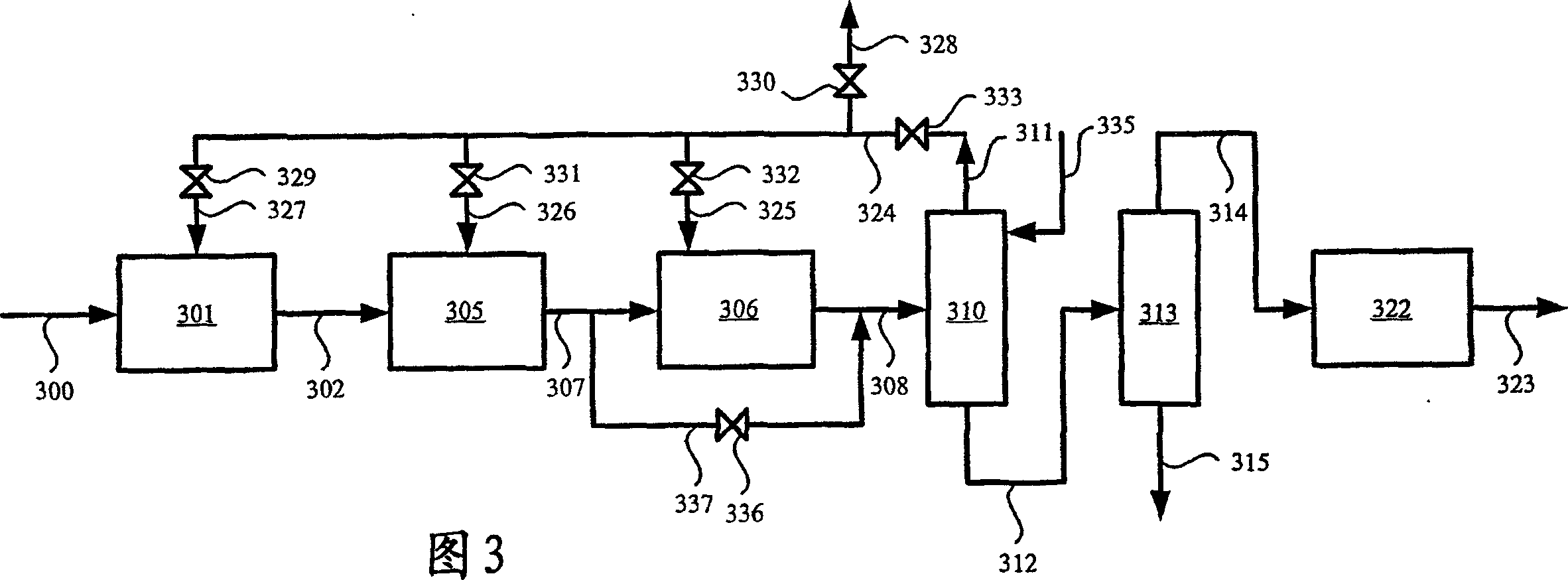

ActiveCN109776261ALow costReduce consumptionOrganic compound preparationHydroxy compound preparationEthanol synthesisHydrogen

The invention discloses a method and system for directly preparing alcohol from coke oven gas. The method comprises the steps of purifying coke oven gas to obtain refined coke oven gas, separating andextracting hydrogen in the coke oven gas through hydrogen extraction, reforming the hydrogen extracted coke oven gas and carbon dioxide in a dry reformer to obtain synthesis gas, mixing the synthesisgas with the separated and purified hydrogen, introducing the mixed gas into an ethanol synthesis device to obtain crude alcohol, and executing separation and refining to obtain a product. The methodis wide in adaptability, no additional hydrogen element is introduced, and methanol, ethanol or other alcohols are produced by adjusting the hydrogen-carbon ratio.

Owner:XINDI ENERGY ENG TECH

Method for preparing ethanol by low-temperature digestion and thick mash fermentation of starch as raw material

ActiveCN101948875BReduce moisture contentIncrease the sugar contentBiofuelsFermentationEthanol synthesisSlurry

The invention discloses a method for preparing ethanol by low-temperature digestion and thick mash fermentation of starch as a raw material, belonging to the field of ethanol synthesis with a fermentation method. The method adopts a process of low-temperature digestion for liquefying and thick mash fermentation and comprises the following operation steps of: a, cleaning and crushing raw materials, b, precooking to prepare powder slurry, c, digesting at low temperature for liquefying, and d, saccharifying, fermenting and distilling. The method for preparing the ethanol by low-temperature digestion and thick mash fermentation of starch as the raw material has the advantages of low water content and high sugar degree in a liquefied solution, low energy consumption, high yield, stable production and lower cost. The low-temperature digestion for liquefying ensures that total sugar content in the liquefied and pasted solution is not less than 25 percent, the thick mash fermentation ensures that ethanol content in fermented mature mash reaches 18 percent, the starch conversion rate is not less than 53 percent, and moreover, steam consumption amount is not larger than 0.7ton / ton of ethanol, and steam is saved by more than 40 percent.

Owner:江苏金茂源生物化工有限责任公司

Ethanol synthetic acetic acid catalyst and preparation method thereof, and preparation method of acetic acid

ActiveCN108126696AImprove performanceImprove catalytic performanceOrganic compound preparationCatalyst activation/preparationAcetic acidCarbon nanotube

The invention relates to a preparation method of an ethanol synthetic acetic acid catalyst. The preparation method of the ethanol synthetic acetic acid catalyst comprises the following steps: S1, performing pretreatment on a carbon nanotube to obtain a pretreated carbon nanotube; S2, treating the pretreated carbon nanotube by a hydrogen peroxide aqueous solution to obtain a hydrogen peroxide treated carbon nanotube; S3, preparing a mixed aqueous solution of H2PtCl6*6H2O and PdCl2, adding the hydrogen peroxide treated carbon nanotube into the mixture aqueous solution, performing ultrasonic treatment and completely drying to obtain a catalyst precursor; and S4, performing step-type two-stage process heating calcining treatment on the catalyst precursor under reducing atmosphere and inert atmosphere to obtain the catalyst. According to the preparation method and through various unique preparation steps as well as selection and determination of various unique technical characteristics in various steps, so that the ethanol synthetic acetic acid catalyst with excellent performance can be obtained, and a brand new catalyst with high properties is provided for preparation of the acetic acid by the ethanol.

Owner:NORTHEAST GASOLINEEUM UNIV

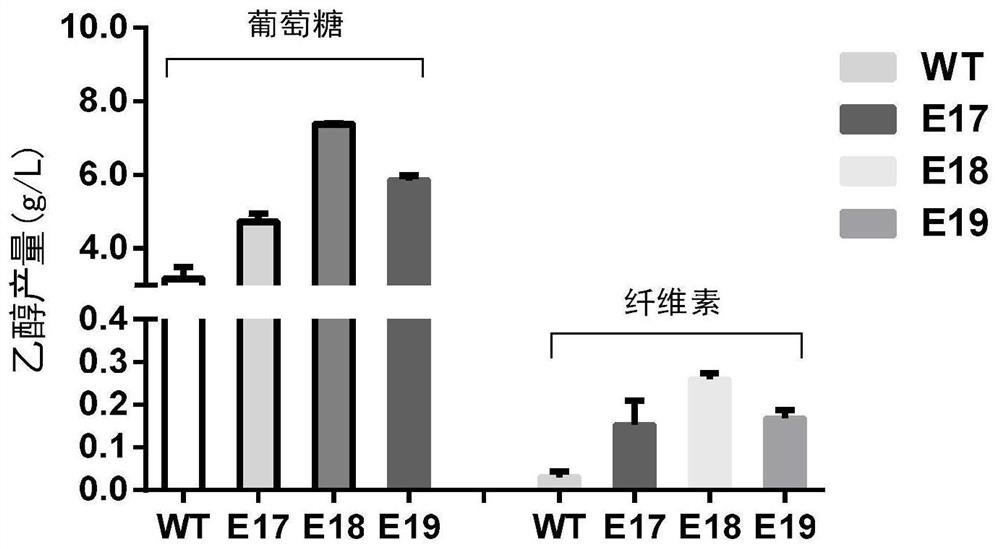

Recombinant filamentous fungus for producing ethanol as well as construction and application of recombinant filamentous fungus

ActiveCN113025506AEnhance ethanol production capacityReduce manufacturing costFungiHydrolasesEthanol synthesisEngineered genetic

The invention discloses a construction method of genetically engineered bacteria of filamentous fungi, which is characterized in that the filamentous fungi overexpresses ethanol synthesis positive regulatory genes and / or down-regulates endogenous ethanol synthesis negative regulatory genes through a genetic engineering method to obtain the genetically engineered bacteria. Compared with an original strain, the obtained genetically engineered bacteria has the advantage that the ethanol synthesis capability is improved.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

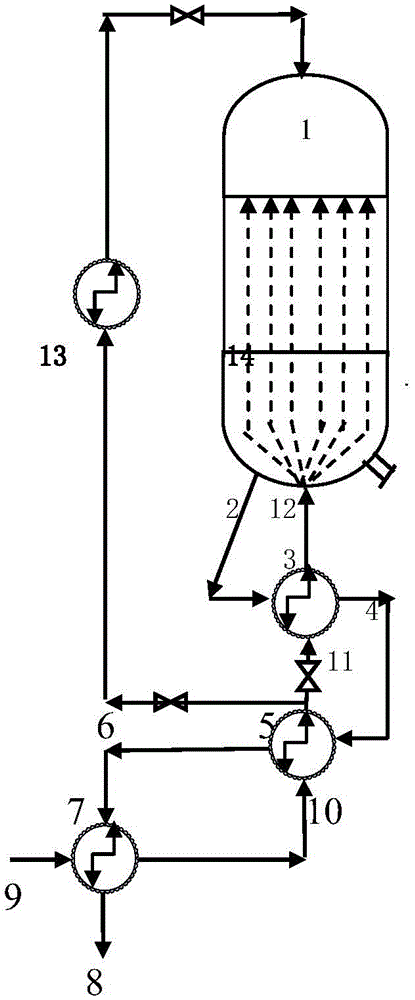

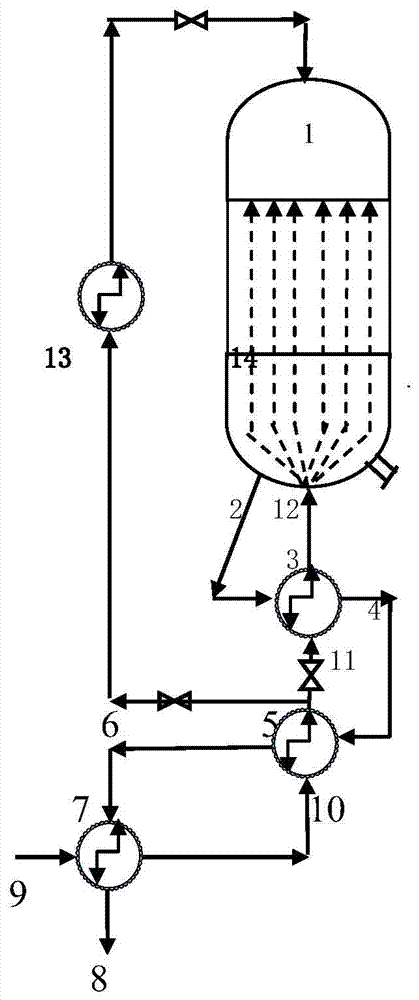

Ethanol synthesis reactor with heat exchange unit

ActiveCN104857894AEfficient recyclingEfficient use ofOrganic compound preparationChemical industryAcetic acidEthanol synthesis

The invention relates to an ethanol synthesis reactor with a heat exchange unit. The ethanol synthesis reactor comprises a reactor body and the heat exchange unit, wherein the reactor body is connected with a gas mixture reactor inlet pipe and a crude ethanol reactor heat outlet pipe. The ethanol synthesis reactor is characterized in that the heat exchange unit is formed by a first heat exchanger, a second heat exchanger and a third heat exchanger which are connected in series through a pipeline in turn; the gas mixture reactor inlet pipe is connected with a cold source channel of the first heat exchanger; the crude ethanol reactor heat outlet pipe is connected with a heat source channel of the first heat exchanger; a raw material hydrogen third heat exchanger inlet pipe is a cold source inlet pipe of the third heat exchanger; an acetic acid and hydrogen mixture second heat exchanger inlet pipe is connected with a cold source inlet pipe of the second heat exchanger. According to the ethanol synthesis reactor with the heat exchange unit, the heat recovery utilization rate is high, the pipes and the devices are connected with each other in a direct welding mode, and accordingly the problems of the pipe thermal stress and the system flange sealing are solved so as to solve the problems of the process for preparing ethanol through acetic acid and hydrogenation.

Owner:河南顺达新能源科技有限公司

Preparation method of catalyst for synthesis of ethyl acetate and co-production of normal butanol by ethanol one-step method

InactiveCN106622283AHigh catalytic efficiencyMetal/metal-oxides/metal-hydroxide catalystsEthyl acetateN-Butyl Alcohol

The invention relates to the field of preparation of catalysts, and particularly discloses a preparation method of a catalyst for synthesis of ethyl acetate and co-production of normal butanol by an ethanol one-step method. The preparation method comprises the steps: (1) preparing a solution A and a solution B; (2) preparing carrier particles and drying the carrier particles; (3) dipping the carrier particles with the solution A and the solution B separately and roasting for many times; (4) reducing the sample in mixed gas consisting of hydrogen and inert gas to obtain the required catalyst. The catalyst provided by the invention is applied to synthesis of the ethyl acetate and co-production of the normal butanol through ethanol, the catalytic efficiency of the catalyst is high, the ethanol feeding airspeed is 15 liters of ethanol per liter of catalyst per hour, the conversion rate of the ethanol is more than 30 percent and the highest conversion rate of the ethanol is 70 percent; the ethyl acetate selectivity ranges between 10 percent and 80 percent, the corresponding normal butanol selectivity ranges between 80 percent and 100 percent, and a good technical effect is achieved.

Owner:SHANDONG YUHUANG CHEM CO LTD

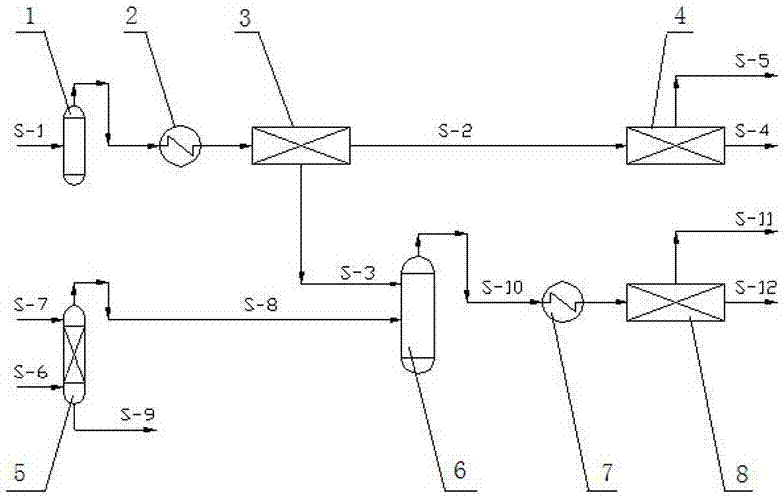

Method and device for preparing highly pure hydrogen and carbon monoxide

PendingCN106861376AGuaranteed uptimeDimethyl ether content decreasedGas treatmentHydrogen separation using solid contactHigh concentrationEthanol synthesis

The invention discloses a method and a device for preparing highly pure hydrogen and carbon monoxide from synthetic gas and carbon monoxide-rich tail gas obtained after ethanol synthesis through using a membrane separation-pressure swing adsorption integration technology. Liquid methanol is used to absorb dimethyl ether in the carbon monoxide-rich tail gas obtained after the ethanol synthesis in order to reduce the content of the dimethyl ether harmful to a membrane separation device to 0.5% or less, so the long-term stable running of the membrane separation device is ensured; and the carbon monoxide-rich tail gas obtained after the ethanol synthesis is effectively treated to make the carbon monoxide-rich tail gas recycled, so the energy saving and discharge reduction effects are effectively realized. The method and the device for preparing the highly pure hydrogen and high concentration carbon monoxide from the synthetic gas through the membrane separation-pressure swing adsorption integration technology have the advantages of energy consumption reduction, space saving and investment reduction.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

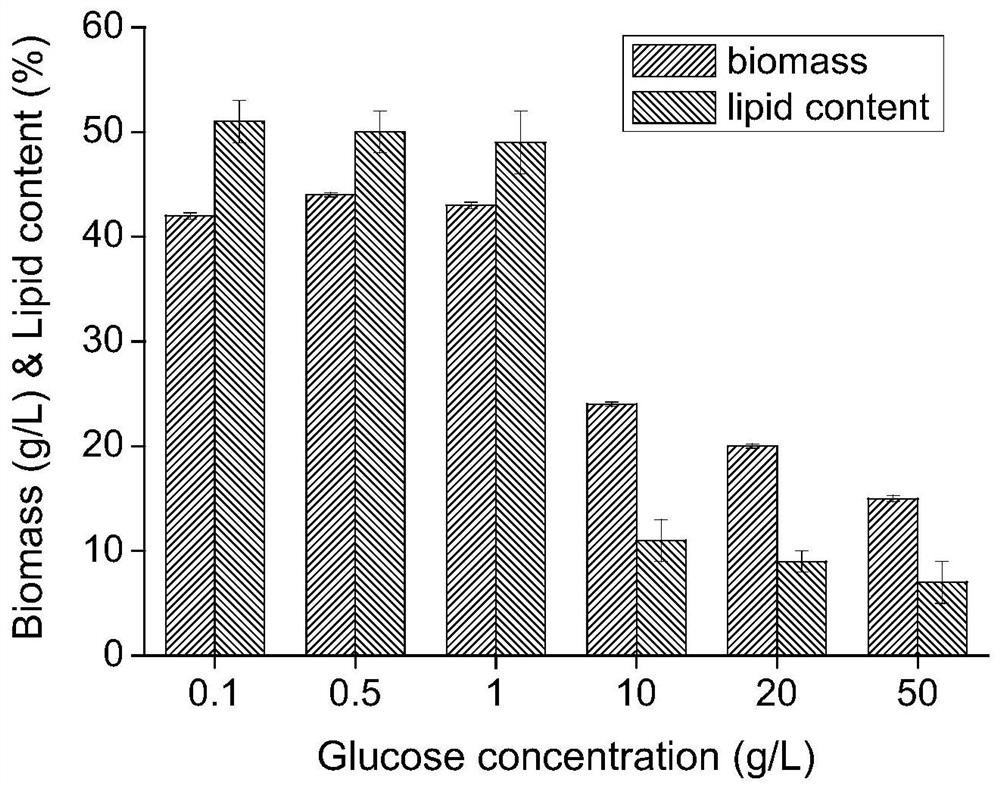

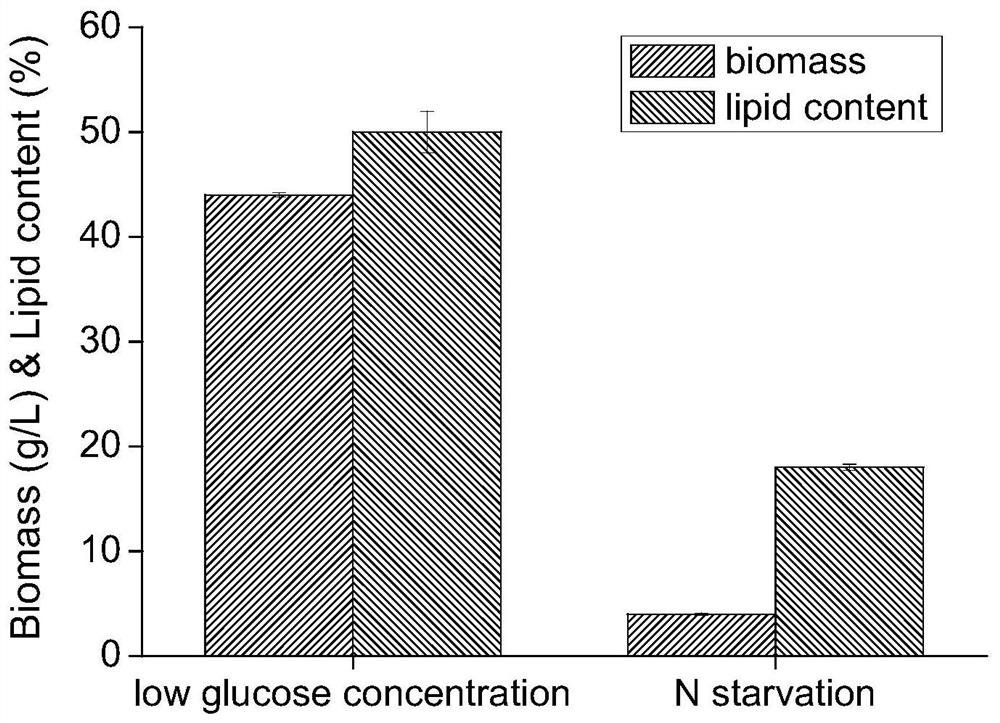

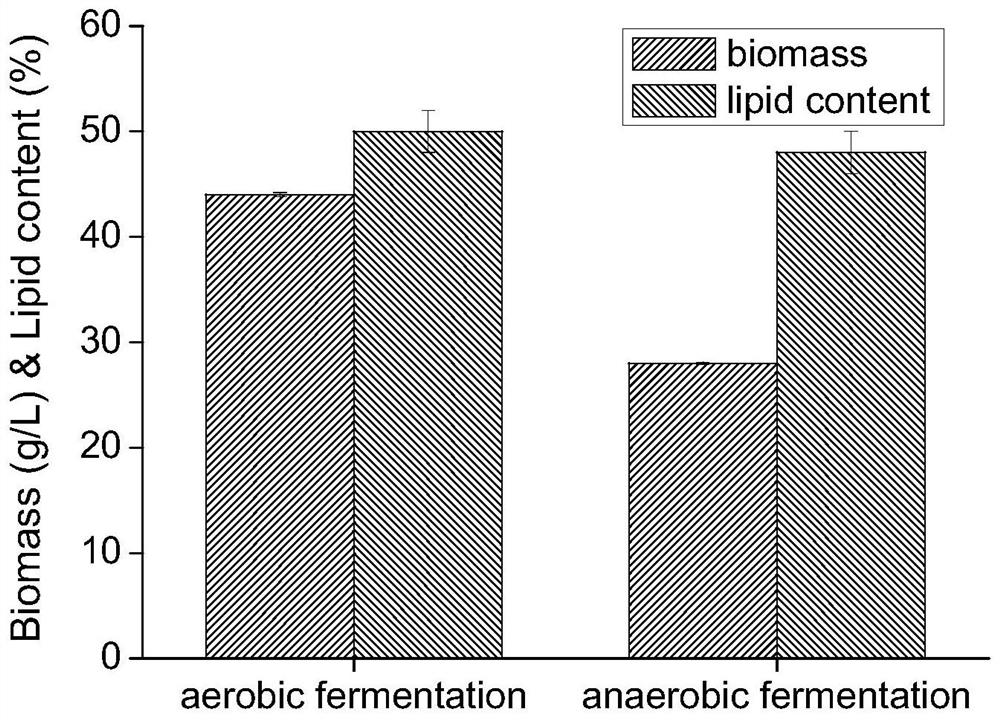

Culture method for improving grease content of saccharomyces cerevisiae by maintaining ultralow-concentration organic carbon source and application of culture method

The invention provides a culture method for increasing the grease content of saccharomyces cerevisiae by maintaining an ultralow-concentration organic carbon source and application of the culture method and belongs to the technical field of biology. Research finds that in the fermentation culture process of saccharomyces cerevisiae, the concentration of an organic carbon source in a fermentation culture solution is continuously maintained at an ultra-low level by controlling the supplementing amount of the organic carbon source, and in the state, activity of enzymes related to ethanol synthesis in saccharomyces cerevisiae cells is greatly reduced due to lack of an acting substrate, so activity of the enzymes related to ethanol synthesis in saccharomyces cerevisiae cells is improved. However, activity of enzymes related to fatty acid synthesis is not obviously influenced, so the flow direction of an organic carbon source deviates to fatty acid synthesis, and finally, a large amount of grease in saccharomyces cerevisiae cells is accumulated. The method is advantaged in that raw materials are low in cost, the culture method is simple and easy to implement, industrial production and application of the method are facilitated, and therefore the method has good actual production and application value.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Process for preparing ethanol from synthesis gas via methyl alcohol

ActiveCN102690171BHigh selectivityHigh yieldOrganic compound preparationHydroxy compound preparationAcetic acidEthanol synthesis

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for improving clostridium butyricum growth efficiency

ActiveCN105861410AHigh synthesis efficiencyImprove oxidation efficiencyBacteriaMicroorganism based processesBiotechnologyEthanol synthesis

The invention discloses a method for improving the clostridium butyricum growth efficiency, and belongs to the field of food fermentation. The invention provides the method for improving the clostridium butyricum growth efficiency by reducing generation of acidic products in the fermentation process and promoting ethanol synthesis, and the method particularly comprises the step that phenylalanine solution feeding is conducted in a sterile and anaerobic mode at constant speed when three stage fermentation of clostridium butyricum is conducted for 0.8 h till 4 h to 6 h before fermentation is completed, wherein the total concentration of acetaldehyde ranges from 1.5 mmol / L to 5.0 mmol / L. According to the method for improving the clostridium butyricum growth efficiency, acetaldehyde molecules serve as metabolic regulation molecules for use; by means of addition of the acetaldehyde molecules, the oxidation efficiency of NADH is promoted, the synthesis efficiency of ethanol is significantly enhanced, the generation efficiency of acetic acid and butyric acid is significantly reduced, the growth efficiency of the clostridium butyricum is further improved, and an excellent technical effect is produced. The method for improving the clostridium butyricum growth efficiency has the advantages that the materials are easy to purchase, the operation controllability is high, and the method is suitable for clostridium butyricum fermentation production.

Owner:HUBEI UNIV OF TECH

Formaldehyde scavenger and preparation method thereof

PendingCN111514942AShort reaction cycleImprove photocatalytic performanceMaterial nanotechnologyGas treatmentEthanol synthesisSilanes

The invention discloses a TiO2 / PVP / silane coupling agent formaldehyde scavenger and a preparation method thereof. The particle size of the TiO2 / PVP / silane coupling agent formaldehyde scavenger is 5-7nm, and the TiO2 / PVP / silane coupling agent formaldehyde scavenger has high dispersion crystallinity. According to the method, the formaldehyde scavenger with high catalytic performance is prepared by utilizing organic-inorganic hybrid composite modification measures of PVP and a silane coupling agent, and the formaldehyde scavenger prepared by the method is good in visible light photocatalytic performance; the preparation method does not need acid-base neutralization or ethanol synthesis and has the characteristics of simple process, low cost, short preparation period, environmental friendliness and the like. The formaldehyde scavenger can be used in the field of efficient formaldehyde removal under visible light and can also be used for other air purification, environmental protection andthe like and has a good application prospect.

Owner:尚国龙

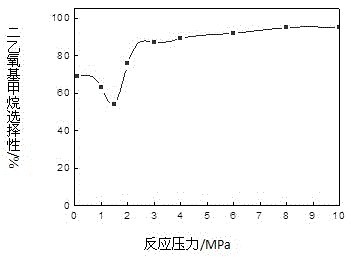

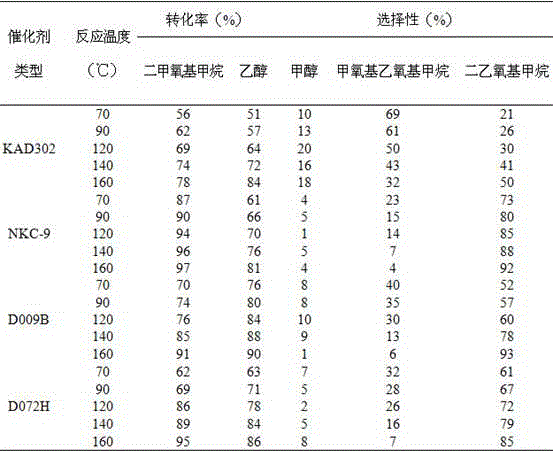

Method for synthesizing diethoxymethane from dimethoxymethane and ethanol

ActiveCN105669393AHigh selectivityEasy to operateOrganic chemistryOrganic compound preparationReaction temperatureAmberlyst-15

The invention provides a method for synthesizing diethoxymethane from dimethoxymethane and ethanol, relating to a method for preparing methane. The method comprises the following step: by using dimethoxymethane and ethanol as raw materials, reacting at 0-160 DEG C under the reaction pressure of 0.1-10.0 MPa by using a liquid acid and a supported liquid acid as catalysts to generate diethoxymethane at high selectivity. The resin catalyst is one or more of KAD302, KC107, NKC-9, DA-330, D009B, Amberlyst-15 and D072H containing sulfonic acid functional group. The reaction temperature is 0-160 DEG C, and the reaction pressure is 0.1-10.0 MPa. The filling gas is inert gas which is argon, helium, carbon dioxide or N2 mixture or a gas mixture thereof. The method has the advantages of single product and high selectivity, and has favorable application prospects. The required raw materials are cheap and accessible, and the whole process is simple to operate and can not generate any environment-polluting chemical substance. Thus, the method belongs to an environment-friendly technical route.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Catalyst used for synthesizing diethyl carbonate from urea and ethanol, preparation method and application thereof

ActiveCN104289215AEasy to makeGood repeatabilityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsEthanol synthesisAlkaline earth metal

The invention relates to a catalyst used for synthesizing diethyl carbonate from urea and ethanol. The catalyst is a solid alkaline catalyst and is prepared through a precipitation method or a coprecipitation method. A preparation method includes following steps: preparing an aqueous solution from soluble metal salt of alkaline-earth metals, transition metals and other metals; adding dropwisely a certain amount of a precipitating agent with a pH value being adjusted to between 8-12 to obtain a precursor; drying the precursor at 50-150 DEG C for 2-24 hours; and then calcining the precursor at 200-1000 DEG C for 2-10 hours. The catalyst is simple in preparation, is high in activity, is environmental-friendly, is easy to separate and recycle and is good in stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for synthesizing p-methoxystyrene from p-methoxyphenethyl alcohol

InactiveCN103922902ANo emissionsReduce pollutionOrganic chemistryOrganic compound preparationWater circulationVacuum pump

The present invention relates to a p-methoxystyrene synthesis process, specifically to production of p-methoxystyrene through gas-solid phase catalysis dehydration of p-methoxyphenethyl alcohol. The synthesis process is a continuous production process, and specifically comprises that: p-methoxyphenethyl alcohol is sucked through a water circulation vacuum pump, the feeding amount is adjusted through an adjustment valve, vaporization is performed with a vaporization device, the obtained material enters a reactor, a catalysis dehydration reaction is performed at a temperature of 275 DEG C, the obtained reaction gas is condensed into a liquid, and the liquid enters a product receiver. According to the present invention, the process has characteristics of simple process, mild process conditions, safe operation, single raw material and product, high selectivity, high yield, no by-product emission, low environmental pollution, simple structure of the required equipment, application of ordinary carbon steel, and no special requirement.

Owner:NANJING POLYTECHNIC INSITUTE

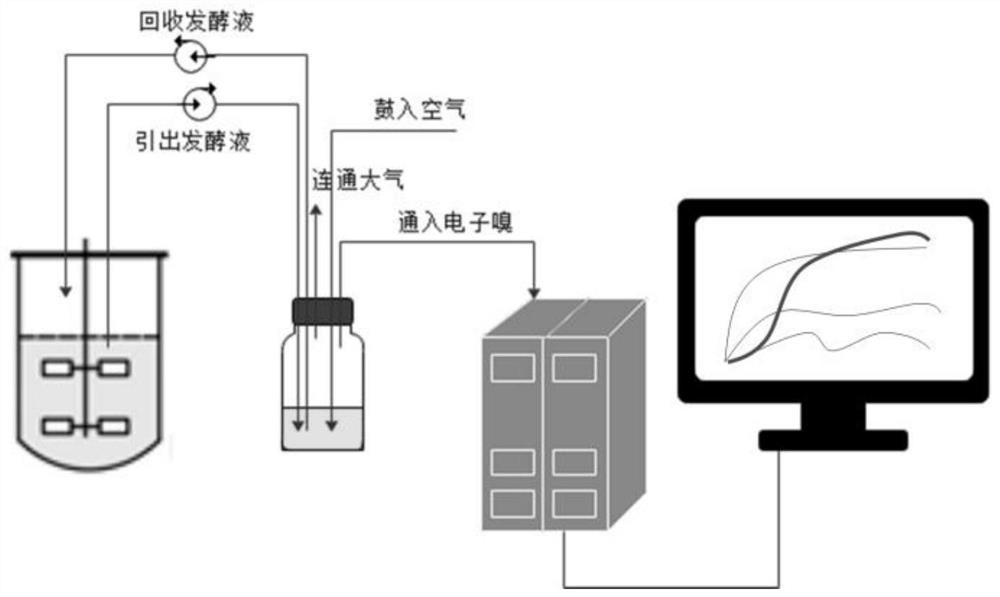

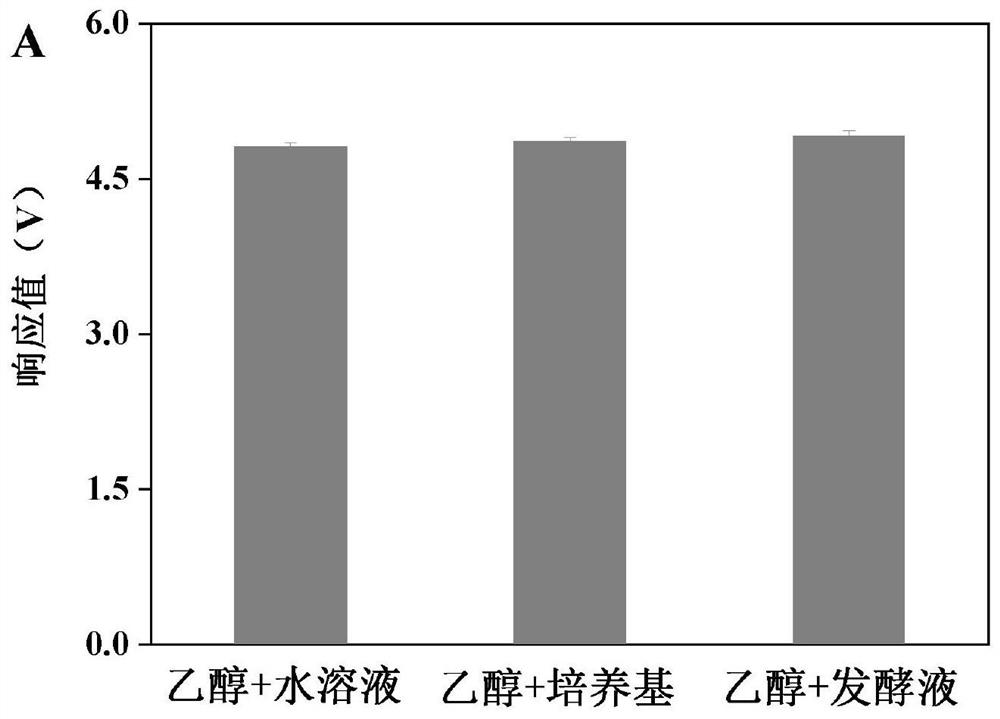

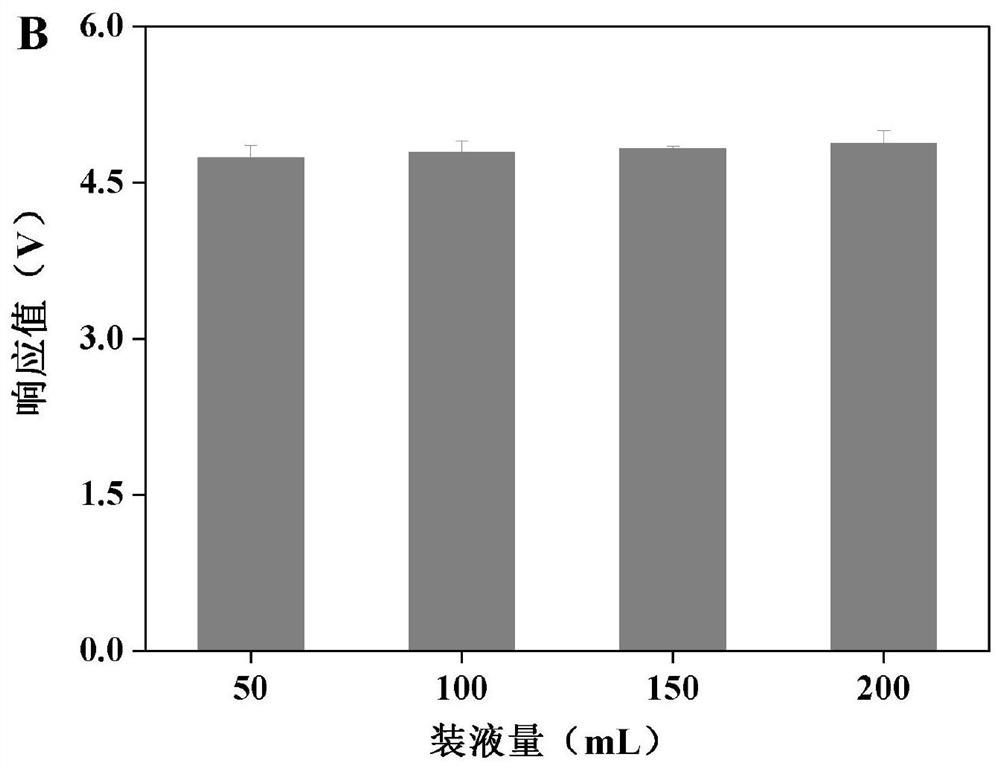

Method for producing ethanol by glucose fed-batch fermentation based on online ethanol concentration response value monitoring

PendingCN112553260AGood correlationTimely feedback generationWeighing by removing componentFungiBiotechnologyEthanol synthesis

The invention discloses a method for producing ethanol by glucose fed-batch fermentation based on online ethanol concentration response value monitoring. The method comprises the following steps: a step of conducting seed culture; and a step of producing ethanol by fermentation culture, wherein in the step of producing the ethanol by fermentation culture, the online ethanol concentration responsevalue monitoring is carried, and when the ethanol concentration response value is in a descending trend, glucose feeding is started to be carried out, and fermentation is continued. According to the method disclosed by the invention, the electronic olfactory is introduced into the ethanol fermentation process, and the relationship between the electronic olfactory and the ethanol concentration is established to prove that the electronic olfactory can realize the online monitoring of key indexes and parameters, especially the product ethanol concentration, in the fermentation process, so that glucose is added in stages in the ethanol fermentation process in an online guidance manner, and the inhibition effect on cell growth and ethanol synthesis in the fermentation process is relieved, thuseffectively improving the ethanol production efficiency and the sugar-ethanol conversion rate.

Owner:EAST CHINA UNIV OF SCI & TECH +1

A kind of zsm-5 catalyst and its preparation and application

ActiveCN101537369BHigh selectivityHigh activityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveEthanol synthesis

The invention provides a ZSM-5 molecular sieve catalyst and a preparation method thereof and the use thereof in reaction of preparing ethylbenzene by benzene and ethanol. The preparation method comprises: sulfate or nitrate solution of iron or titanium for the ZSM-5 catalyst with certain silica alumina ratio is adopted and modified by an immersion method or an ion exchange method, and the modified solution contains 1 to 10 percent of modified metals in percentage by weight; and then the modified metals are grinded and mixed evenly with binder pseudo-boehmite or gamma-Al2O3 molecular sieve according to the mass ratio of the molecular sieve to the binder of 85-65: 15-35, dilute nitric acid is added into the mixture, and the mixture is mixed, molded, dried and roasted and the modified ZSM-5 molecular sieve catalyst is obtained. The catalyst is applied to the reaction of synthesizing the ethylbenzene by the benzene and the ethanol, and the selectivity and conversion rate of the ethylbenzene are increased when the mol ratio of the benzene to the ethanol is 1 to 10.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Catalyst for synthesizing diethyl carbonate from urea and ethanol and its preparation method and application

ActiveCN104289215BEasy to makeGood repeatabilityOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsEthanol synthesisAlkaline earth metal

The invention relates to a catalyst for synthesizing diethyl carbonate from urea and ethanol. The catalyst is a solid base catalyst and is prepared by precipitation or co-precipitation. Make an aqueous solution of alkaline earth metals, transition metals and other metal soluble metal salts, drop a certain amount of precipitant, and adjust the pH value between 8‑12 to obtain a precursor, and then dry it at 50‑150 °C for 2‑ 24 hours, and finally calcined at 200-1000°C for 2-10 hours. The invention has the advantages of simple preparation of the catalyst, high activity, environmental friendliness, easy separation and recovery, and good stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

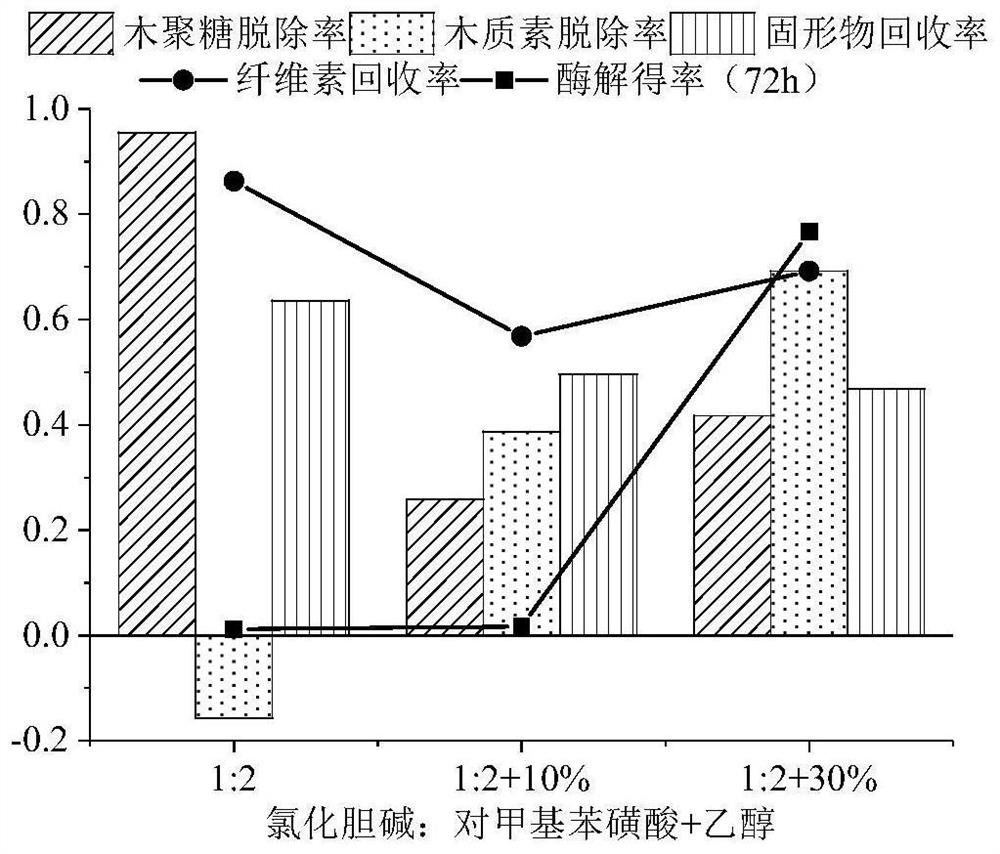

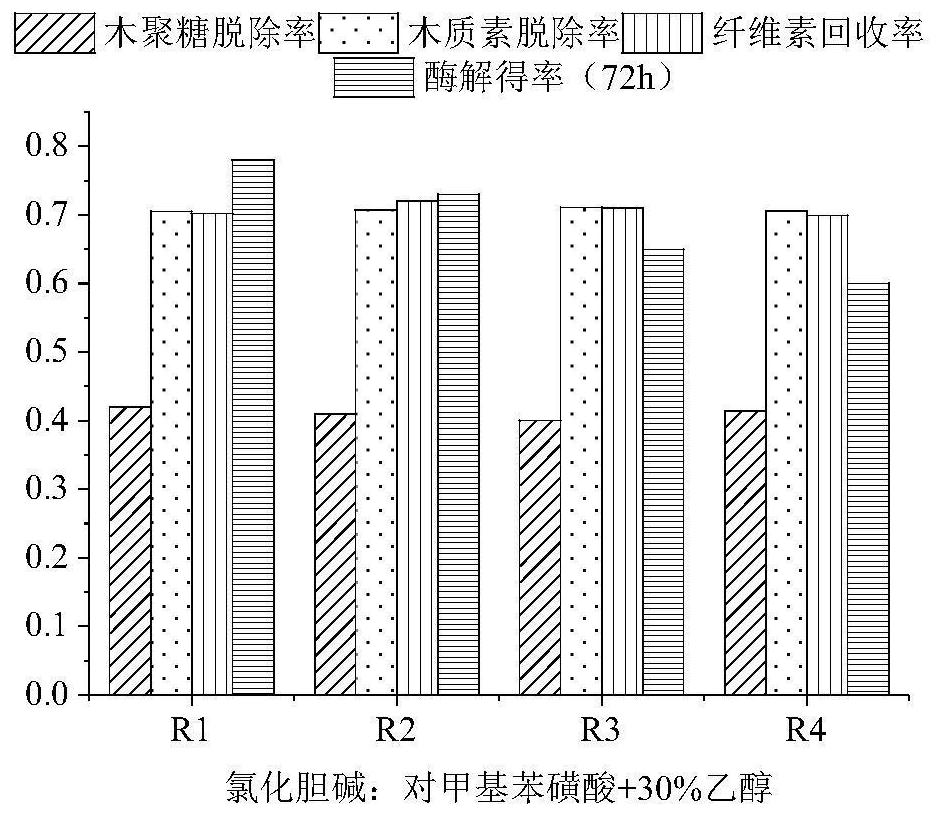

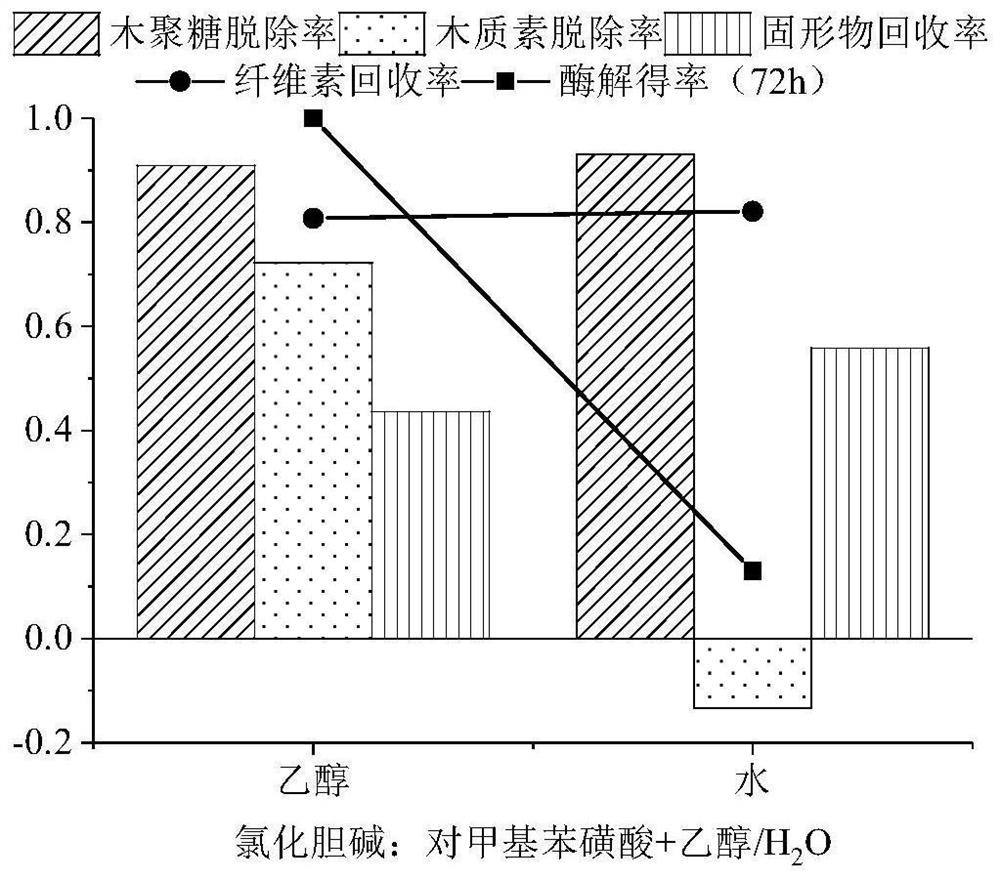

A kind of pretreatment method of lignocellulose raw material

Owner:NANJING FORESTRY UNIV

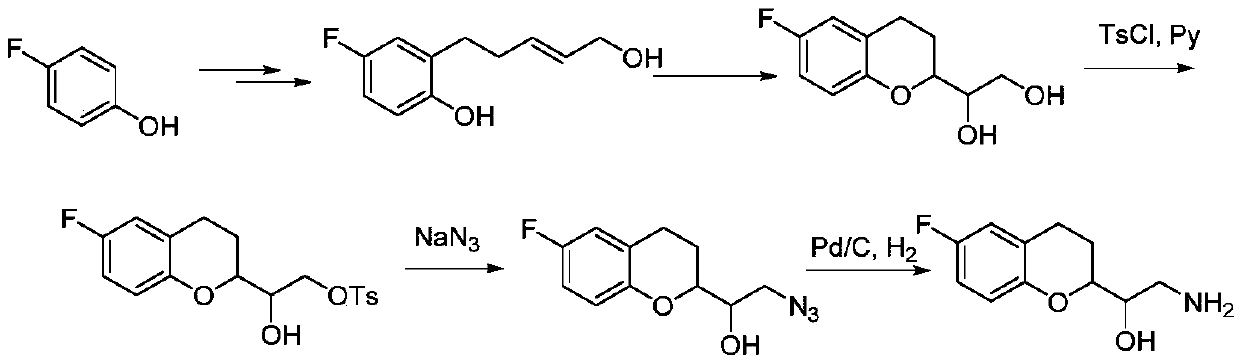

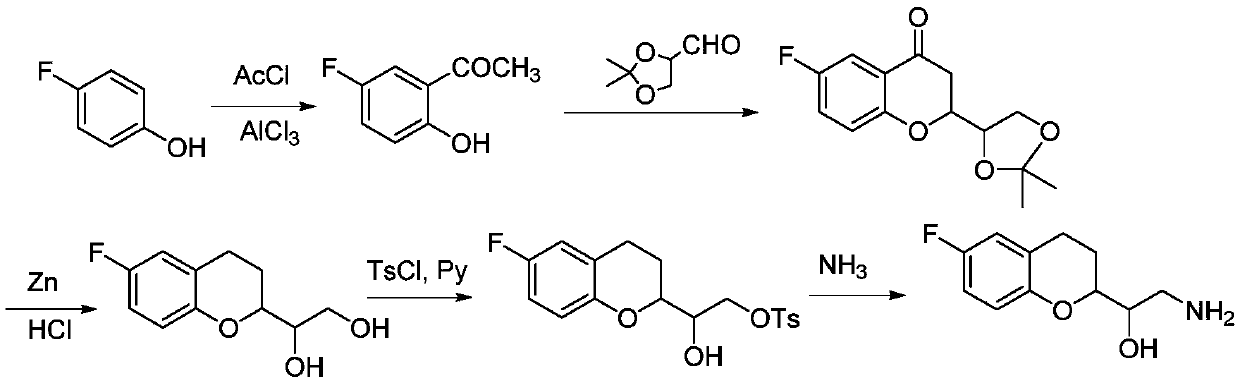

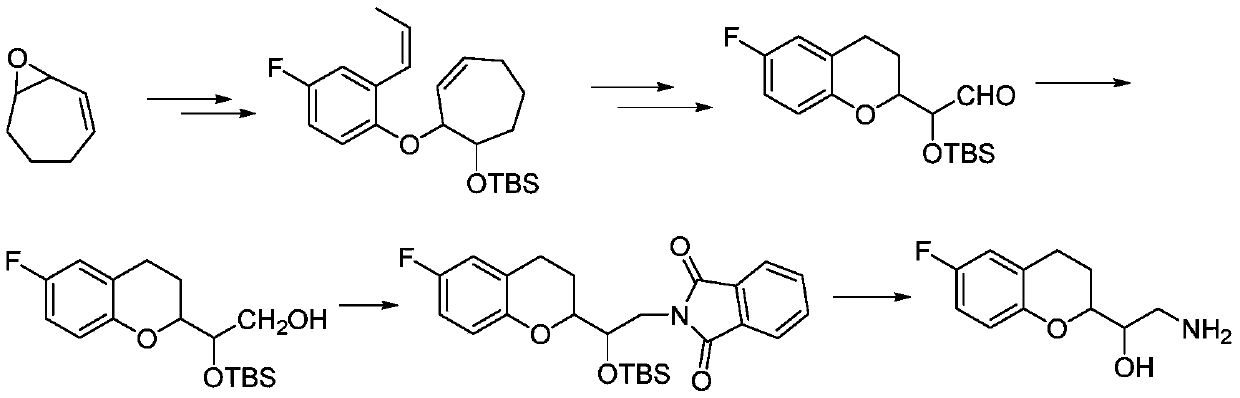

Synthetic method of 2-amino-1-(-6-fluoro-2-chromanyl)ethanol

ActiveCN103524470BMild conditionsSimple and fast operationOrganic chemistryEthanol synthesisSynthesis methods

The invention provides a synthesis method of 2-amino-1-(-6-fluoro-2-chromanyl)ethanol, which comprises the following steps: synthesizing 6-fluorochromanyl-2-carboxylic acid (I) used as an initial raw material into 6-fluorochromanyl-2-formacylimidazole (II); synthesizing the obtained 6-fluorochromanyl-2-formacylimidazole (II) into 1-(6-fluoro-2-chromanyl)-2-nitro-1-ethyl ketone (III); and finally, reducing the obtained 1-(6-fluoro-2-chromanyl)-2-nitro-1-ethyl ketone (III) into 2-amino-1-(-6-fluoro-2-chromanyl)ethanol (IV). The method provided by the invention has the advantages of accessible raw materials and mild reaction conditions, and is simple to operate and more suitable for industrial production.

Owner:BEIJING NORMAL UNIVERSITY +1

A kind of ethanol synthesis reactor with heat exchange unit

ActiveCN104857894BImprove recycling ratesEliminate sealing problemsOrganic compound preparationChemical industryEthanol synthesisAcetic acid

The invention relates to an ethanol synthesis reactor with a heat exchange unit. The ethanol synthesis reactor comprises a reactor body and the heat exchange unit, wherein the reactor body is connected with a gas mixture reactor inlet pipe and a crude ethanol reactor heat outlet pipe. The ethanol synthesis reactor is characterized in that the heat exchange unit is formed by a first heat exchanger, a second heat exchanger and a third heat exchanger which are connected in series through a pipeline in turn; the gas mixture reactor inlet pipe is connected with a cold source channel of the first heat exchanger; the crude ethanol reactor heat outlet pipe is connected with a heat source channel of the first heat exchanger; a raw material hydrogen third heat exchanger inlet pipe is a cold source inlet pipe of the third heat exchanger; an acetic acid and hydrogen mixture second heat exchanger inlet pipe is connected with a cold source inlet pipe of the second heat exchanger. According to the ethanol synthesis reactor with the heat exchange unit, the heat recovery utilization rate is high, the pipes and the devices are connected with each other in a direct welding mode, and accordingly the problems of the pipe thermal stress and the system flange sealing are solved so as to solve the problems of the process for preparing ethanol through acetic acid and hydrogenation.

Owner:河南顺达新能源科技有限公司

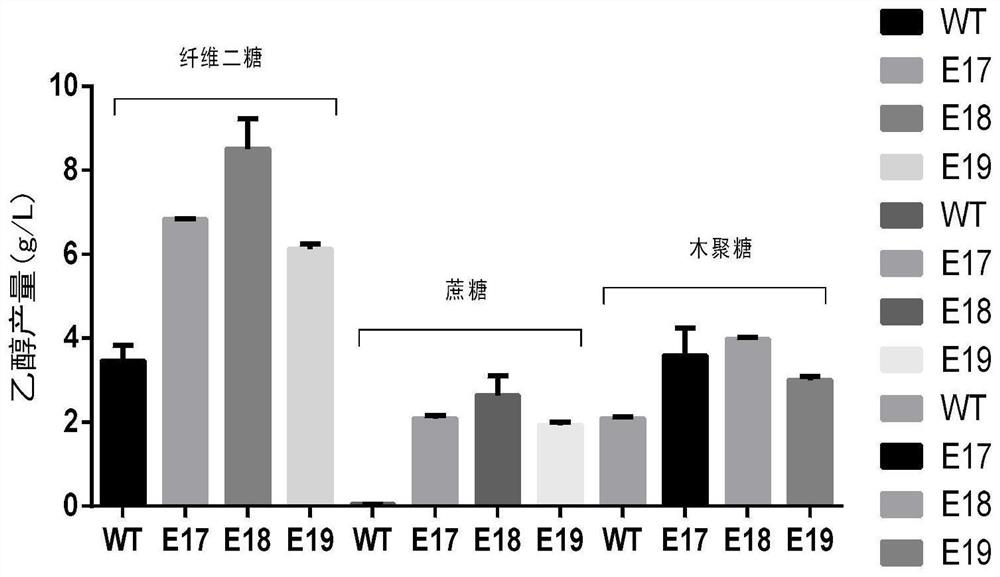

Recombinant filamentous fungus for producing ethanol from phosphofructokinase 2 mutant, construction of recombinant filamentous fungus and application of recombinant filamentous fungus in ethanol production

PendingCN114107357AEnhance ethanol production capacityImprove glucose metabolismTransferasesBiofuelsEthanol synthesisKinase activity

The invention discloses a phosphofructokinase 2 mutation and / or knockout recombinant filamentous fungus for ethanol production and construction and ethanol production application thereof, which is characterized in that an endogenous phosphofructokinase 2 gene is knocked out and / or a mutated phosphofructokinase 2 gene is expressed in the filamentous fungus; wherein the mutated phosphofructokinase 2 means that only kinase activity is retained and phosphatase activity is lost or reduced after mutation. Compared with the original strain, the obtained genetic engineering strain has the advantages that the ethanol synthesis capability is improved, and the glucose metabolism rate is accelerated.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com