A kind of zsm-5 catalyst and its preparation and application

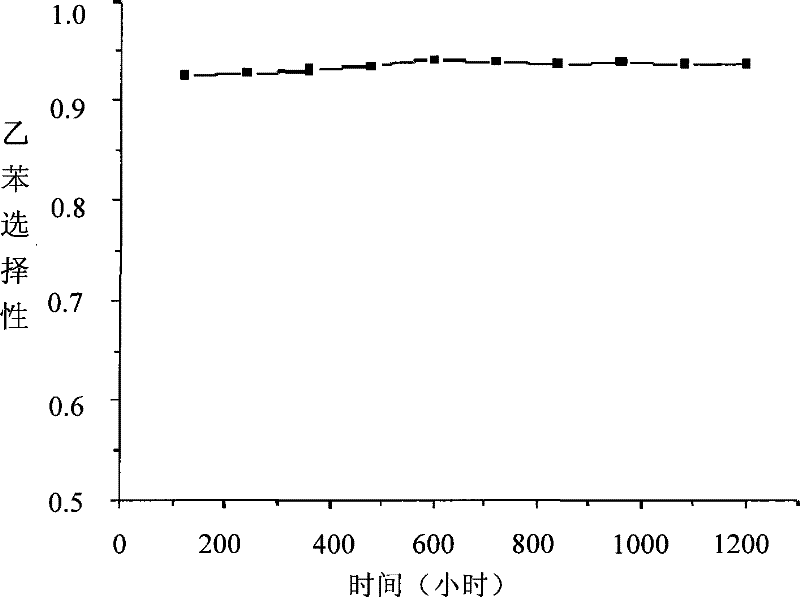

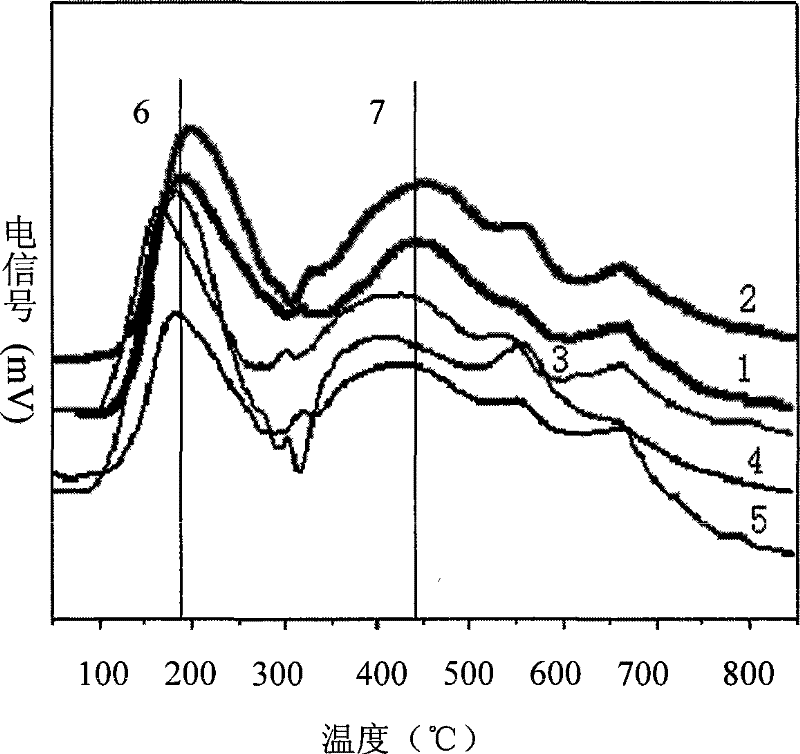

The technology of ZSM-5 and catalyst is applied in the field of ZSM-5 molecular sieve catalyst and its preparation and application, which can solve the problems of low ethylbenzene selectivity, short catalyst life, low pure benzene conversion rate, etc. The effect of long activity period and high ethylbenzene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The hydrogen-type ZSM-5 molecular sieve with a silicon-aluminum ratio of 60 was treated at 500° C. for 6 hours. Weigh 26 grams of the roasted hydrogen ZSM-5 molecular sieve powder, add it to 200 ml of 0.1mol / L titanium sulfate solution, stir at room temperature for 30 hours, then stir and evaporate to dryness at 80°C, and dry at 110°C After 12 hours, roast at 500° C. for 7 hours to obtain a molecular sieve with a titanium content of 3%, then add 14 grams of pseudo-boehmite, grind and mix evenly. Add 3wt% dilute nitric acid and knead evenly, extrude, dry at 120°C for 10 hours, and bake at 540°C for 6 hours to obtain the catalyst. The prepared catalyst was heated at a temperature of 380°C, a molar ratio of benzyl to alcohol of 4:1, and a weight hourly space velocity of 4h -1 Reaction evaluation under the conditions. The evaluation results show that the selectivity of ethylbenzene is 92.78%, and the conversion rate of benzene is 24.76%.

Embodiment 2

[0048] The hydrogen type ZSM-5 molecular sieve with a silicon-aluminum ratio of 90 was calcined at 600°C for 3 hours in advance. Measure 200 mL of titanium sulfate solution with a molar concentration of 0.02 mol / L, add 18 g of roasted hydrogen-type ZSM-5 molecular sieve powder, stir at room temperature for 10 hours, then stir and evaporate to dryness at 65°C, and bake at 100°C Dry for 24 hours and bake at 600°C for 10 hours. To obtain a molecular sieve with a titanium content of 1%, weigh 15 grams of the modified molecular sieve, add 5 grams of pseudoboehmite, add 5 wt% of dilute nitric acid, mix evenly, extrude, dry at 100°C for 20 hours, and roast at 600°C 4 hours to obtain the desired catalyst. At a temperature of 400°C, the molar ratio of benzene to ethanol is 5:1, and the weight hourly space velocity is 4h -1 Under the conditions of evaluation, the selectivity of ethylbenzene was evaluated to be 93.75%, and the conversion rate of benzene was 18.65%.

Embodiment 3

[0050] Treat the hydrogen-type ZSM-5 molecular sieve with a silicon-aluminum ratio of 96 at 500°C for 8 hours in advance, weigh 20 grams of the roasted hydrogen-type ZSM-5 molecular sieve powder, and add it to 250 ml of 0.2mol / L titanium sulfate solution , exchanged at 90°C for 3 hours, washed with 2500 ml of deionized water, dried at 110°C for 12 hours, and roasted at 500°C for 7 hours to obtain titanium ion-exchange modified molecular sieves, weighed 14 grams of modified molecular sieves and added 6 g γ-Al 2 o 3 , adding 5wt% dilute nitric acid, kneading evenly, extruding, drying at 110°C for 9 hours, and roasting at 540°C for 10 hours. Crush into 20-40 mesh at a temperature of 380°C, the molar ratio of benzene to ethanol is 2:1, and the weight hourly space velocity is 3h -1 Under the conditions of evaluation, the selectivity of ethylbenzene was evaluated to be 88.54%, and the conversion rate of benzene was 46.29%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com