Method for producing ethanol by glucose fed-batch fermentation based on online ethanol concentration response value monitoring

An ethanol concentration, fed-feed fermentation technology, applied in the field of microbial fermentation, can solve the problems of inability to realize key index parameters, expensive near-infrared instruments, long detection time, etc., to improve ethanol production efficiency and sugar alcohol conversion rate, and alleviate high bottom The inhibitory effect of the concentration of the substance, the effect of reducing the initial glucose concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This embodiment provides a method for producing ethanol by glucose-fed fermentation, the steps of the method comprising:

[0079] ①Seed culture: Pick a single colony from the plate, put it in a 250mL shake flask with 100mL seed medium, and culture it in a shaker at 30°C and 220rpm for 14h to obtain a seed culture solution;

[0080] 2. fermentation culture produces ethanol: with 20% inoculum size, described seed culture solution is inserted in the 5L sealed fermenter that fermentation medium is housed (working volume is 3L), and initial glucose concentration is 100g / L in the fermentation solution, The culture temperature was 30° C., the stirring speed was 150 rpm, and the fermentation culture was carried out.

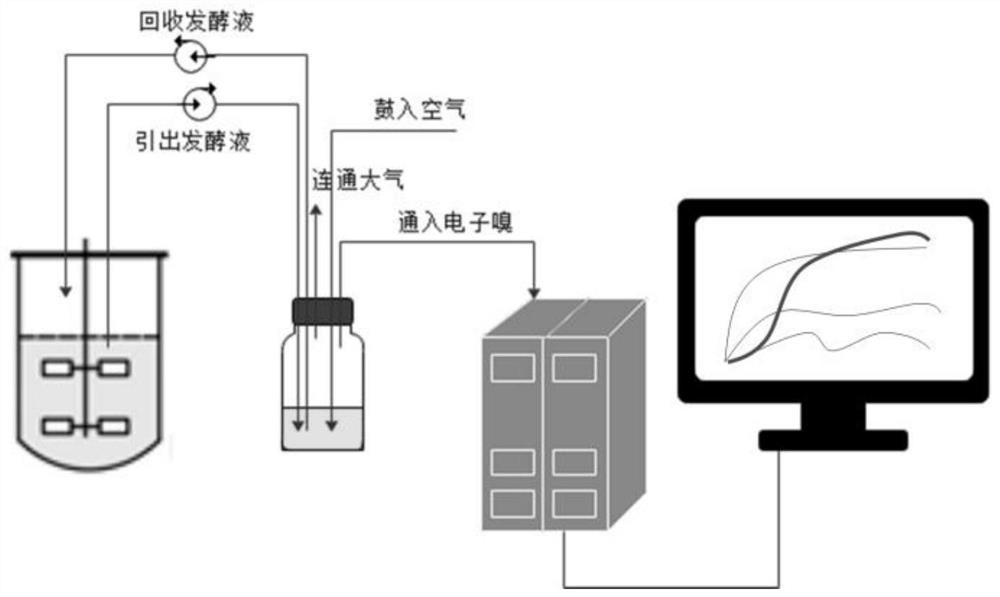

[0081] During the fermentation and cultivation process, the response value of ethanol concentration in the fermentation liquid is monitored online: the fermentation liquid is drawn from the fermenter to the external bottle through a peristaltic pump, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com