Preparation method of catalyst for ethanol synthesis and catalyst obtained thereby and application of catalyst

A catalyst, copper-based catalyst technology, applied in the preparation of organic compounds, chemical elements of heterogeneous catalysts, molecular sieve catalysts, etc., can solve problems such as low yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

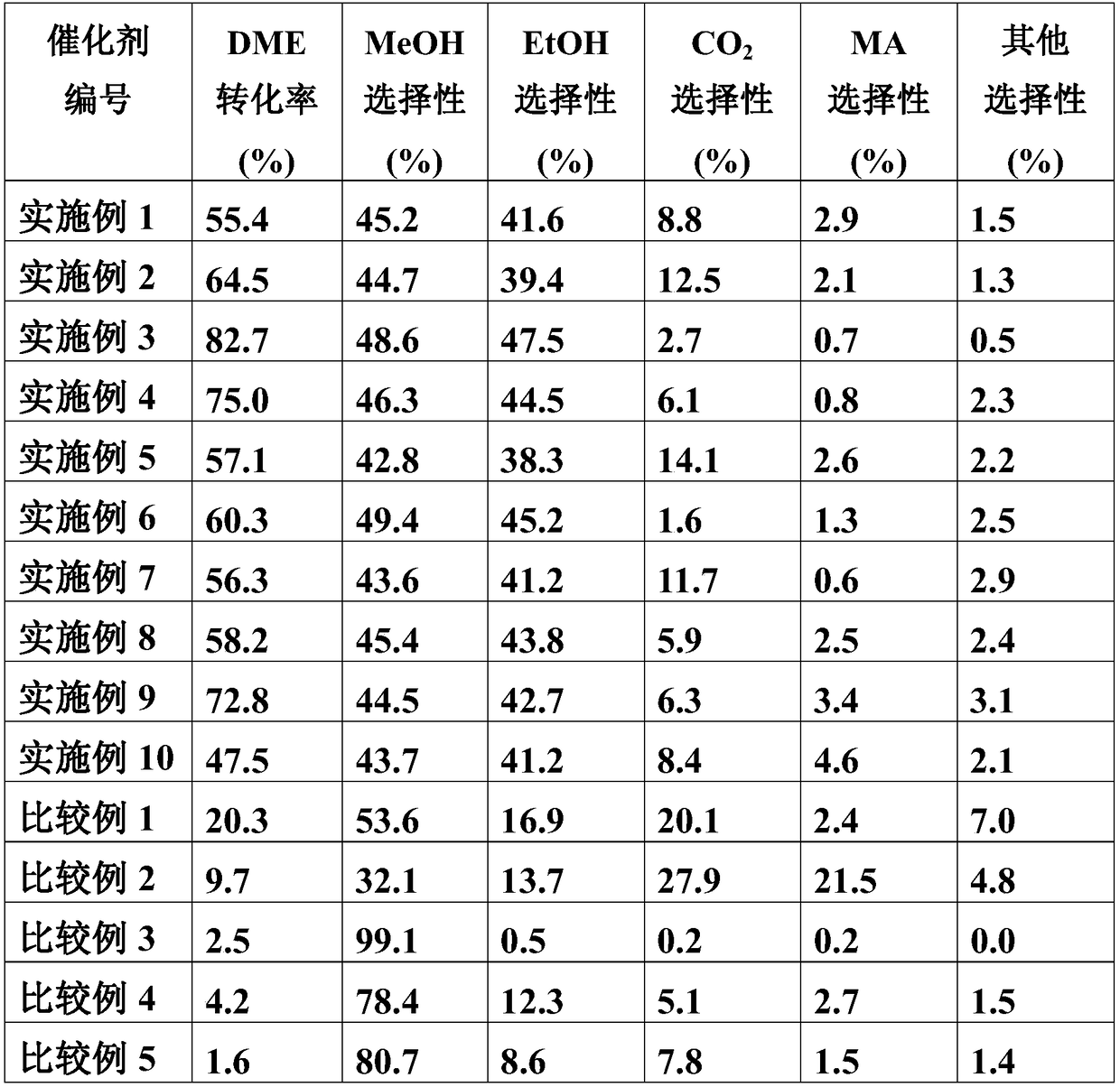

Examples

Embodiment 1

[0098] Catalyst preparation

[0099] Weigh 0.1 mol of copper nitrate and 0.1 mol of zinc nitrate, grind in an agate mortar for 0.5 h, add 0.2 mol of sodium carbonate, and continue grinding for 2 h. The obtained sample was washed with deionized water, dried at 100° C. for 10 h, calcined at 350° C. for 3 h, and pressed into 20-40 mesh granules. Put 0.5g of the obtained particles into 0.5g of 30wt% silica sol to fully infiltrate, then add commercial powder molecular sieve H-MOR (Tosoh Co., Ltd.), stir evenly, dry at 100°C for 6h, and roast at 500°C for 5h to obtain "CuZnO @S@H-MOR" core / shell catalyst, in which CuZnO is the core, H-MOR is the shell, S is the bonding layer (silica sol) connecting the core and the shell, and the core accounts for 80% of the total weight of the core / shell catalyst, The combined weight of core and shell accounts for 90% of the total weight of the core / shell catalyst.

[0100] Catalyst reduction and reaction

[0101] Weigh 0.5 g of the obtained cor...

Embodiment 2

[0103] Prepare 1M ammonia solution B with deionized water; weigh 0.1mol copper nitrate, 0.05mol zinc nitrate and 0.05mol aluminum nitrate, and prepare an aqueous solution A with deionized water. The prepared solution A and solution B were dripped into the same beaker respectively by the pulse liquid phase pump, and the drop rate of the two solutions was controlled to accurately control the pH value of the mixed solution obtained in real time to be 10, and the temperature of the mixed solution was kept at 50°C, keep stirring during the feeding process, and at the same time, precipitation occurs, stop adding solution B after the addition of solution A is complete. After the addition, the obtained precipitated mixture was aged for 12 hours, filtered, washed with deionized water, dried at 120°C for 10 hours, calcined at 350°C for 3 hours, and pressed into 20-40 mesh particles. Then put 0.5g of the obtained particles into 1g of 30wt% silica sol to fully infiltrate, then add commerc...

Embodiment 3

[0106] Weigh 0.1mol copper nitrate and 0.1mol zinc nitrate, configure 30mL aqueous solution with deionized water, and impregnate the aqueous solution in 0.5mol SiO 2 On the carrier, vacuum-dry at 50°C for 24 hours, bake at 350°C for 4 hours, and press to form 20-40 mesh particles. Then 0.5 g of the obtained particles were added to 0.3 wt% ethanol solution of 0.5 g of silane coupling agent APTMS (Aldrich), hydrothermally treated at 80 ° C for 12 h in a hydrothermal reactor, washed with deionized water, and dried at 100 ° C for 10 h , then add a 1wt% aqueous solution of commercial Silicalite-1 molecular sieve (Tosoh Co., Ltd.), hydrothermally treat at 100°C for 12h in a hydrothermal reactor, wash with deionized water, dry at 100°C for 10h, and then bake at 450°C for 5h. The resulting calcined product was added to the synthetic solution of H-ZSM-35 (1.85Na 2 O: 1Al 2 o 3 : 20SiO2 2 : 592H 2 (O: 19.7 pyrrolidine), hydrothermally treated at 200°C for 72h in a hydrothermal reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com